|

Chemical-mechanical Polishing

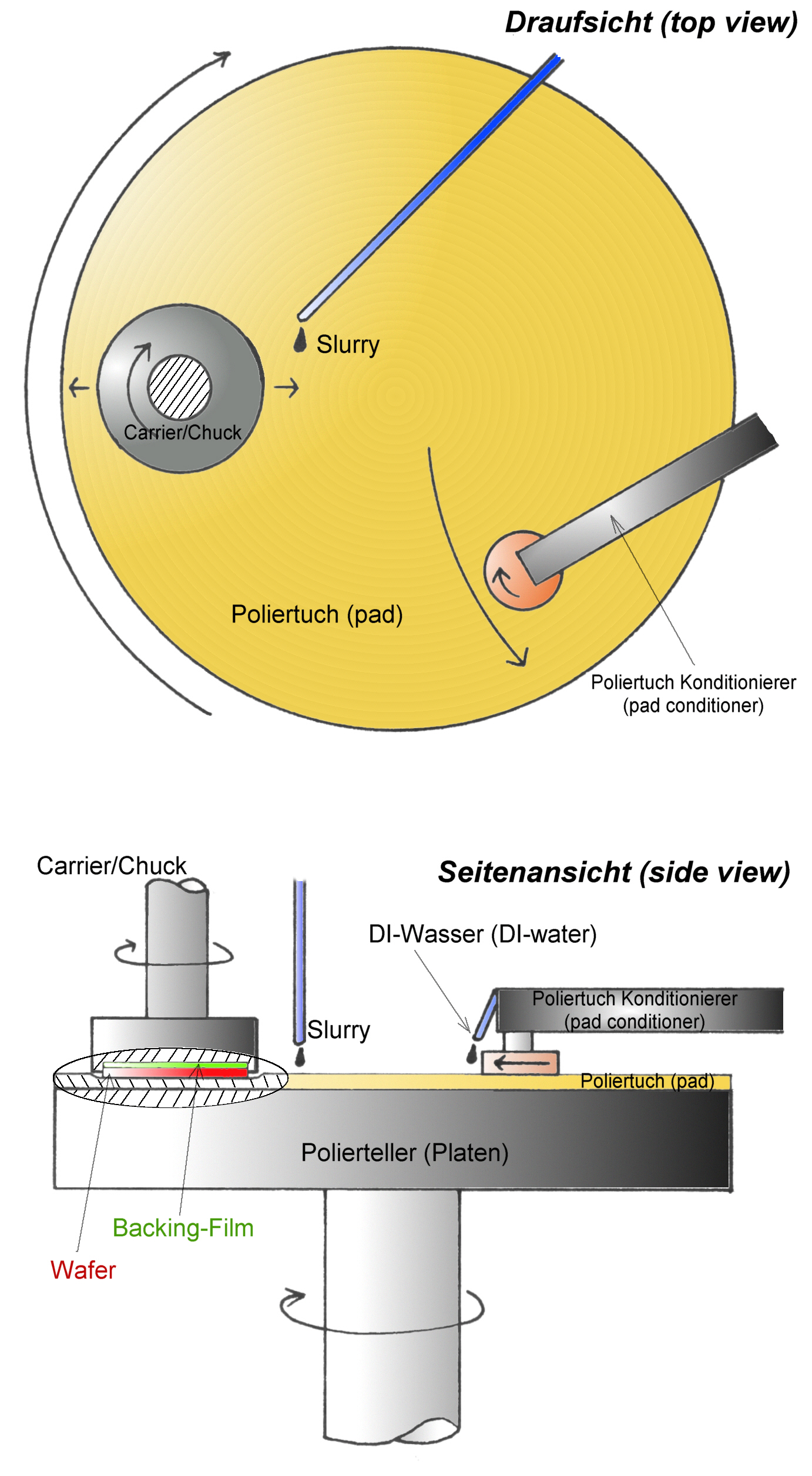

Chemical mechanical polishing (CMP) (also called chemical mechanical planarization) is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a wikt:hybrid, hybrid of chemical etching and free abrasive polishing. It is used in the semiconductor industry to polish semiconductor wafers as part of the integrated circuit manufacturing process. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not wiktionary:concentric, concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hybrid

Hybrid may refer to: Science * Hybrid (biology), an offspring resulting from cross-breeding ** Hybrid grape, grape varieties produced by cross-breeding two ''Vitis'' species ** Hybridity, the property of a hybrid plant which is a union of two different genetic parent strains * Hybrid (particle physics), a valence quark-antiquark pair and one or more gluons * Hybrid solar eclipse, a rare solar eclipse type * Hybrid star (other), with properties normally found in different types of stars Technology Transportation * Hybrid vehicle (other), various types of vehicles referred to as hybrids * Hybrid rail, an urban rail service for passengers using lightweight trains * Hybrid rocket, a rocket motor using propellants from two different states of matter * Hybrid shipping container, a container using phase change material in combination with the ability to recharge itself * Hybrid train, a locomotive, railcar, or train that uses an onboard rechargeable energy storage ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angstrom

The angstrom (; ) is a unit of length equal to m; that is, one ten-billionth of a metre, a hundred-millionth of a centimetre, 0.1 nanometre, or 100 picometres. The unit is named after the Swedish physicist Anders Jonas Ångström (1814–1874). It was originally spelled with Swedish letters, as Ångström and later as ångström (). The latter spelling is still listed in some dictionaries, but is now rare in English texts. Some popular US dictionaries list only the spelling ''angstrom''. The unit's symbol is Å, which is a letter of the Swedish alphabet, regardless of how the unit is spelled. However, "A" or "A.U." may be used in less formal contexts or typographically limited media. The angstrom is often used in the natural sciences and technology to express sizes of atoms, molecules, microscopic biological structures, and lengths of chemical bonds, arrangement of atoms in crystals, wavelengths of electromagnetic radiation, and dimensions of integrated circuit part ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etching (microfabrication)

Etching is used in microfabrication to chemically remove layers from the surface of a wafer (electronics), wafer during manufacturing. Etching is a critically important process module in fabrication, and every wafer undergoes many etching steps before it is complete. For many etch steps, part of the wafer is protected from the etchant by a "masking" material which resists etching. In some cases, the masking material is a photoresist which has been patterned using photolithography. Other situations require a more durable mask, such as silicon nitride. Etching media and technology The two fundamental types of etchants are liquid-phase ("wet") and plasma (physics), plasma-phase ("dry"). Each of these exists in several varieties. Wet etching The first etching processes used liquid-phase ("wet") etchants. This process is now largely outdated but was used up until the late 1980s when it was superseded by dry plasma etching. The wafer can be immersed in a bath of etchant, wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Nitride

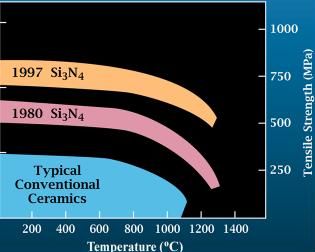

Silicon nitride is a chemical compound of the elements silicon and nitrogen. (''Trisilicon tetranitride'') is the most thermodynamically stable and commercially important of the silicon nitrides, and the term ″''Silicon nitride''″ commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot . It is very hard (8.5 on the mohs scale). It has a high thermal stability with strong optical nonlinearities for all-optical applications. Production Silicon nitride is prepared by heating powdered silicon between 1300 °C and 1400 °C in a nitrogen atmosphere: :3 Si + 2 → The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen. Without an iron catalyst, the reaction is complete after several hours (~7), when no further weight increase due to nitrogen absorption (per gram of silicon) is detected. In addition to , several other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shallow Trench Isolation

Shallow trench isolation (STI), also known as box isolation technique, is an integrated circuit feature which prevents electric current leakage between adjacent semiconductor device components. STI is generally used on CMOS process technology nodes of 250 nanometers and smaller. Older CMOS technologies and non-MOS technologies commonly use isolation based on LOCOS. STI is created early during the semiconductor device fabrication process, before transistors are formed. The key steps of the STI process involve etching a pattern of trenches in the silicon, depositing one or more dielectric materials (such as silicon dioxide) to fill the trenches, and removing the excess dielectric using a technique such as chemical-mechanical planarization. Certain semiconductor fabrication technologies also include deep trench isolation, a related feature often found in analog integrated circuits. The effect of the trench edge has given rise to what has recently been termed the "reverse narrow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress (mechanics), stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band, or dislocation. #Brittle, Brittle fractures occur without any apparent deformation before fracture. #Ductile, Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen structural integrity and failure, fails via fra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Interconnects

Copper interconnects are used in integrated circuits to reduce propagation delays and power consumption. Since copper is a better conductor than aluminium, ICs using copper for their Interconnect (integrated circuit), interconnects can have interconnects with narrower dimensions, and use less energy to pass electricity through them. Together, these effects lead to ICs with better performance. They were first introduced by IBM, with assistance from Motorola, in 1997. The transition from aluminium to copper required significant developments in fabrication (semiconductor), fabrication techniques, including radically different methods for patterning the metal as well as the introduction of barrier metal layers to isolate the silicon from potentially damaging copper atoms. Although the methods of superconformal copper electrodepostion were known since late 1960, their application at the (sub)micron via scale (e.g. in microchips) started only in 1988-1995 (see figure). By year 2002 it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has a great affinity towards oxygen, passivation (chemistry), forming a protective layer of aluminium oxide, oxide on the surface when exposed to air. It visually resembles silver, both in its color and in its great ability to reflect light. It is soft, magnetism, nonmagnetic, and ductility, ductile. It has one stable isotope, 27Al, which is highly abundant, making aluminium the abundance of the chemical elements, 12th-most abundant element in the universe. The radioactive decay, radioactivity of aluminium-26, 26Al leads to it being used in radiometric dating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components are etched onto a small, flat piece ("chip") of semiconductor material, usually silicon. Integrated circuits are used in a wide range of electronic devices, including computers, smartphones, and televisions, to perform various functions such as processing and storing information. They have greatly impacted the field of electronics by enabling device miniaturization and enhanced functionality. Integrated circuits are orders of magnitude smaller, faster, and less expensive than those constructed of discrete components, allowing a large transistor count. The IC's mass production capability, reliability, and building-block approach to integrated circuit design have ensured the rapid adoption of standardized ICs in place of designs using discre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photolithography

Photolithography (also known as optical lithography) is a process used in the manufacturing of integrated circuits. It involves using light to transfer a pattern onto a substrate, typically a silicon wafer. The process begins with a photosensitive material, called a photoresist, being applied to the substrate. A photomask that contains the desired pattern is then placed over the photoresist. Light is shone through the photomask, exposing the photoresist in certain areas. The exposed areas undergo a chemical change, making them either soluble or insoluble in a developer solution. After development, the pattern is transferred onto the substrate through etching, chemical vapor deposition, or ion implantation processes. Ultraviolet, Ultraviolet (UV) light is typically used. Photolithography processes can be classified according to the type of light used, including ultraviolet lithography, deep ultraviolet lithography, extreme ultraviolet lithography, extreme ultraviolet lithography ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives. Abrasives are extremely commonplace and are used very extensively in a wide variety of industrial, domestic, and technological applications. This gives rise to a large variation in the physical and chemical composition of abrasives as well as the shape of the abrasive. Some common uses for abrasives include grinding, polishing, buffing, honing, cutting, drilling, sharpening, lapping, and sanding (see abrasive machining). (For simplicity, "mineral" in this article will be used loosely to refer to both minerals and mineral-like substances ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |