|

Bed Of Nails Tester

A bed of nails tester is a traditional electronic test fixture used for in-circuit testing. It has pins inserted into holes in an epoxy phenolic glass cloth laminated sheet (G-10) which are aligned using tooling pins to make contact with test points on a printed circuit board and are also connected to a measuring unit by wires. Named by analogy with a real-world bed of nails, these devices contain an array of small, spring-loaded pogo pins; each pogo pin makes contact with one node in the circuitry of the DUT (device under test). By pressing the DUT down against the bed of nails, reliable contact can be quickly and simultaneously made with hundreds or even thousands of individual test points within the circuitry of the DUT. The hold-down force may be provided manually or by means of a vacuum or a mechanical presser, thus pulling the DUT downwards onto the nails. Devices that have been tested on a bed of nails tester may show evidence of this after the process: small dimples (fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boundary Scan

Boundary scan is a method for testing interconnects (wire lines) on printed circuit boards or sub-blocks inside an integrated circuit (IC). Boundary scan is also widely used as a debugging method to watch integrated circuit pin states, measure voltage, or analyze sub-blocks inside an integrated circuit. The Joint Test Action Group (JTAG) developed a specification for boundary scan testing that was standardized in 1990 as the IEEE Std. 1149.1-1990. In 1994, a supplement that contains a description of the boundary scan description language (BSDL) was added which describes the boundary-scan logic content of IEEE Std 1149.1 compliant devices. Since then, this standard has been adopted by electronic device companies all over the world. Boundary scan is now mostly synonymous with JTAG.IEEE Std 1149.1 (JTAG) Testability ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

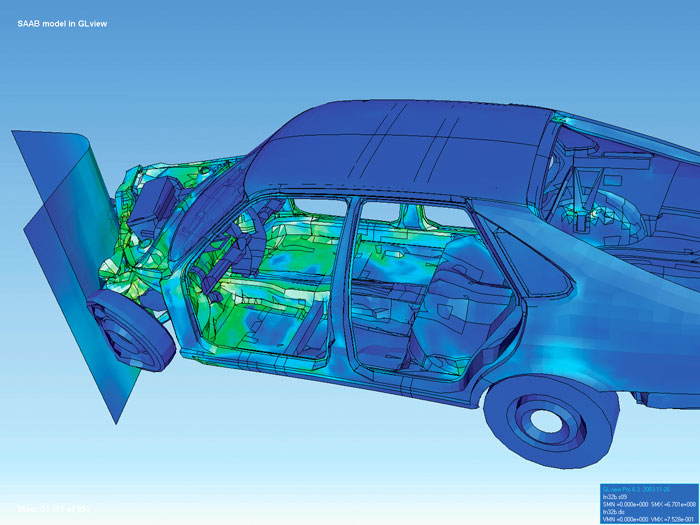

Finite Element Method

Finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. Computers are usually used to perform the calculations required. With high-speed supercomputers, better solutions can be achieved and are often required to solve the largest and most complex problems. FEM is a general numerical method for solving partial differential equations in two- or three-space variables (i.e., some boundary value problems). There are also studies about using FEM to solve high-dimensional problems. To solve a problem, FEM subdivides a large system into smaller, simpler parts called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure Deformation (mechanics)#Strain, strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an Electrical insulation, insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmons came up with an original way to measure the force introduced into the sample b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pad Cratering

Pad cratering is a mechanically induced fracture in the resin between copper foil and outermost layer of fiberglass of a printed circuit board (PCB). It may be within the resin or at the resin to fiberglass interface. The pad remains connected to the component (usually a Ball Grid Array, BGA) and leaves a "crater" on the surface of the printed circuit board. Overview Pad cratering most often occurs during dynamic mechanical events such as mechanical shock or board flexure due to In-circuit test (ICT), board depaneling, or connector insertion. However, pad cratering has also been known to occur during thermal shock or even thermal cycling. Susceptibility to pad cratering can be impacted by several factors such as: PCB thickness, PCB laminate material properties, component size and stiffness, component location, and solder alloy selection among other factors. Testing IPC-9708 provides three test methods to characterize the pad cratering of a component and PCBA: pin pull, ball pull, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

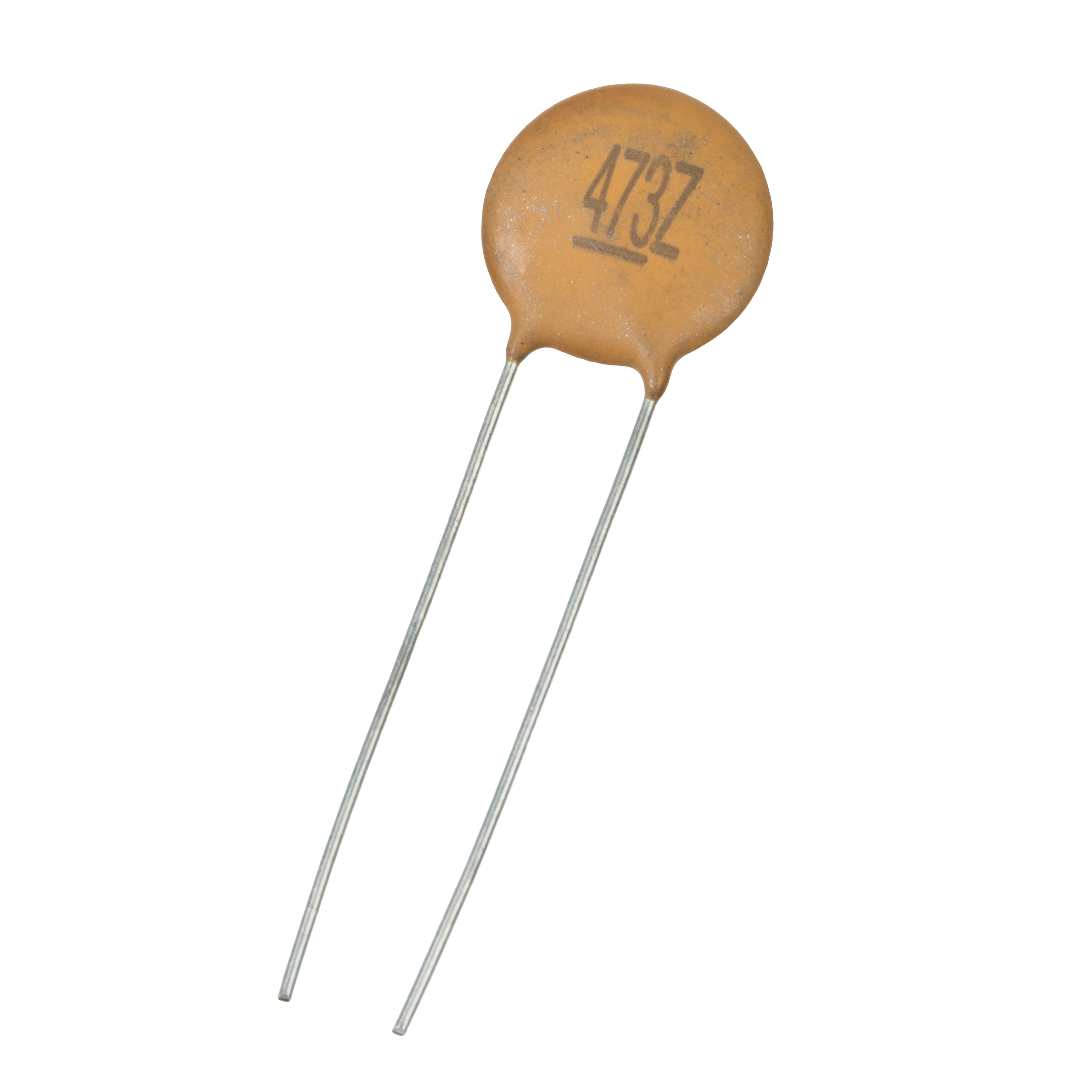

Capacitor Flex Cracking

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications. Ceramic capacitors are divided into two application classes: * Class 1 ceramic capacitors offer high stability and low losses for resonant circuit applications. * Class 2 ceramic capacitors offer high volumetric efficiency for buffer, by-pass, and coupling applications. Ceramic capacitors, especially multilayer ceramic capacitors (MLCCs), are the most produced and used capacitors in electronic equipment that incorporate approximately one trillion (1012) pieces per year.Download Ceramic capacitors of special shapes and styles are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Built-in Self-test

A built-in self-test (BIST) or built-in test (BIT) is a mechanism that permits a machine to test itself. Engineers design BISTs to meet requirements such as: *high reliability *lower repair cycle times or constraints such as: *limited technician accessibility *cost of testing during manufacture The main purpose of BIST is to reduce the complexity, and thereby decrease the cost and reduce reliance upon external (pattern-programmed) test equipment. BIST reduces cost in two ways: # reduces test-cycle duration # reduces the complexity of the test/probe setup, by reducing the number of I/O signals that must be driven/examined under tester control. Both lead to a reduction in hourly charges for automated test equipment (ATE) service. Applications BIST is commonly placed in weapons, avionics, medical devices, automotive electronics, complex machinery of all types, unattended machinery of all types, and integrated circuits. Automotive Automotive tests itself to enhance safety ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Optical Inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera machine vision, autonomously scans the device under test for both catastrophic failure (e.g. missing component) and Product defect, quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-re-flow as well as other stages. Historically, the primary place for AOI systems has been after solder re-flow or "post-production." Mainly because, post-re-flow AOI systems can inspect for most types of defects (component placement, solder shorts, missing solder, etc.) at one place in the line with one single system. In this way the faulty boards are reworked and the other boards are sent to the next process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

In-circuit Tester

in-circuit is an adjective that is used in following terms: * In-circuit debugging * In-circuit emulation * In-circuit emulator In-circuit emulation (ICE) is the use of a hardware device or in-circuit emulator used to debug the software of an embedded system. It operates by using a processor with the additional ability to support debugging operations, as well as to carr ... * In-circuit programming {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Test Fixture

A test fixture is a device used to consistently test some item, device, or piece of software. Test fixtures are used in the testing of electronics, software and physical devices. Electronics In testing electronic equipment such as circuit boards, electronic components, and chips, a test fixture is a device or setup designed to hold the device under test in place and allow it to be tested by being subjected to controlled electronic test signals. Examples are a bed of nails tester or smart fixture. Test fixtures can come in different shapes, sizes, and functions. There are several different types of test fixtures, including In-circuit testing, In-Circuit Test Fixtures, Functional testing (manufacturing), Functional Test Fixtures, and Wireless Test Fixtures. In Circuit Test (ICT) fixtures individually test each component on a Printed circuit board, PCB, while functional test fixtures assess the entire board's functionality. Functional test fixtures simulate real-world conditions ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often discuss ideal test results that would occur in a ''perfect'' vacuum, which they sometimes simply call "vacuum" or free space, and use the term partial vacuum to refer to an actual imperfect vacuum as one might have in a laboratory or in space. In engineering and applied physics on the other hand, vacuum refers to any space in which the pressure is considerably lower than atmospheric pressure. The Latin term ''in vacuo'' is used to describe an object that is surrounded by a vacuum. The ''quality'' of a partial vacuum refers to how closely it approaches a perfect vacuum. Other things equal, lower gas pressure means higher-quality vacuum. For example, a typical vacuum cleaner produces enough suction to reduce air pressur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Device Under Test

A device under test (DUT), also known as equipment under test (EUT) and unit under test (UUT), is a manufactured product undergoing testing, either at first manufacture or later during its life cycle as part of ongoing functional testing and calibration checks. This can include a test after repair to establish that the product is performing in accordance with the original product specification. Electronics testing In the electronics industry a DUT is any electronic assembly under test. For example, cell phones coming off of an assembly line may be given a final test in the same way as the individual chips were earlier tested. Each cell phone under test is, briefly, the DUT. For circuit boards, the DUT is often connected to the test equipment using a bed of nails tester of pogo pins. Semiconductor testing In semiconductor testing, the device under test is a die on a wafer or the resulting packaged part. A connection system is used, connecting the part to automatic or manual ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |