Thermoplastic Elastomers on:

[Wikipedia]

[Google]

[Amazon]

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers (TPR), are a class of

There are six generic classes of commercial TPEs (designations according to ISO 18064) together with one unclassified category:

*Styrenic block copolymers, TPS (TPE-s)

* Thermoplastic polyolefinelastomers, TPO (TPE-o)

* Thermoplastic vulcanizates, TPV (TPE-v or TPV)

*

There are six generic classes of commercial TPEs (designations according to ISO 18064) together with one unclassified category:

*Styrenic block copolymers, TPS (TPE-s)

* Thermoplastic polyolefinelastomers, TPO (TPE-o)

* Thermoplastic vulcanizates, TPV (TPE-v or TPV)

*

TPE became a commercial reality when thermoplastic polyurethane polymers became available in the 1950s. During the 1960s styrene block copolymer became available, and in the 1970s a wide range of TPEs came on the scene. The worldwide usage of TPEs (680,000 tons/year in 1990) is growing at about nine percent per year.

TPE became a commercial reality when thermoplastic polyurethane polymers became available in the 1950s. During the 1960s styrene block copolymer became available, and in the 1970s a wide range of TPEs came on the scene. The worldwide usage of TPEs (680,000 tons/year in 1990) is growing at about nine percent per year.

Block copolymers can "microphase separate" to form periodic nanostructures, as in the styrene-butadiene-styrene (SBS) block copolymer (shown at right). The polymer is known as Kraton and is used for shoe soles and

Block copolymers can "microphase separate" to form periodic nanostructures, as in the styrene-butadiene-styrene (SBS) block copolymer (shown at right). The polymer is known as Kraton and is used for shoe soles and  Other TPEs have crystalline domains where one kind of block co-crystallizes with other block in adjacent chains, such as in copolyester rubbers, achieving the same effect as in the SBS block polymers. Depending on the block length, the domains are generally more stable than the latter owing to the higher crystal

Other TPEs have crystalline domains where one kind of block co-crystallizes with other block in adjacent chains, such as in copolyester rubbers, achieving the same effect as in the SBS block polymers. Depending on the block length, the domains are generally more stable than the latter owing to the higher crystal

Latest Material and Technological Developments for Activewear

(Joanne Yip, 2020, ''page 66-67)'' {{DEFAULTSORT:Thermoplastic Elastomer Biomaterials Polymers

copolymer

In polymer chemistry, a copolymer is a polymer derived from more than one species of monomer. The polymerization of monomers into copolymers is called copolymerization. Copolymers obtained from the copolymerization of two monomer species are som ...

s or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains as ...

and elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''ela ...

ic properties.

While most elastomers are thermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

s, thermoplastic elastomers are not, in contrast making them relatively easy to use in manufacturing, for example, by injection moulding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials.

The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-link

In chemistry and biology, a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural ...

ing bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties.

Types

There are six generic classes of commercial TPEs (designations according to ISO 18064) together with one unclassified category:

*Styrenic block copolymers, TPS (TPE-s)

* Thermoplastic polyolefinelastomers, TPO (TPE-o)

* Thermoplastic vulcanizates, TPV (TPE-v or TPV)

*

There are six generic classes of commercial TPEs (designations according to ISO 18064) together with one unclassified category:

*Styrenic block copolymers, TPS (TPE-s)

* Thermoplastic polyolefinelastomers, TPO (TPE-o)

* Thermoplastic vulcanizates, TPV (TPE-v or TPV)

*Thermoplastic polyurethane

Thermoplastic polyurethane (TPU) is any of the polyurethane polymers that are thermoplastic; that is, they become pliable when heated and harden when cooled. This is in contrast to most polyurethanes, which are thermosets, hardening irreversibly. ...

s, TPU (TPU)

*Thermoplastic copolyester, TPC (TPE-E)

*Thermoplastic polyamides, TPA (TPE-A)

*Unclassified thermoplastic elastomers, TPZExamples

*TPE materials that come from the block copolymers group include CAWITON†, MELIFLEX, THERMOLAST K†, THERMOLAST M†, Chemiton, Arnitel, Hytrel, Dryflex†, Mediprene, Kraton, Pibiflex, Sofprene†, Tuftec†and Laprene†. † indicates styrenic block copolymers (TPE-s). *Laripur, Desmopan, Estane, Texin and Elastollan are examples ofthermoplastic polyurethane

Thermoplastic polyurethane (TPU) is any of the polyurethane polymers that are thermoplastic; that is, they become pliable when heated and harden when cooled. This is in contrast to most polyurethanes, which are thermosets, hardening irreversibly. ...

s (TPU).

*Sarlink, Santoprene, Termoton, Solprene, THERMOLAST V, Vegaprene, and Forprene are examples of TPV materials.

*Examples of thermoplastic olefin

Thermoplastic olefin, thermoplastic polyolefin (TPO), or olefinic thermoplastic elastomers refer to polymer/filler blends usually consisting of some fraction of a thermoplastic, an elastomer or rubber, and usually a filler.

Outdoor applications ...

elastomers (TPO) compound are For-Tec E or Engage. Ninjaflex used for 3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

.

Criteria for thermoplastic elastomers

In order to qualify as a thermoplastic elastomer, a material must have these three essential characteristics: *The ability to be stretched to moderate elongations and, upon the removal of stress, return to something close to its original shape *Processable as a melt at elevated temperature *Absence of significant creepHistory

Microstructure

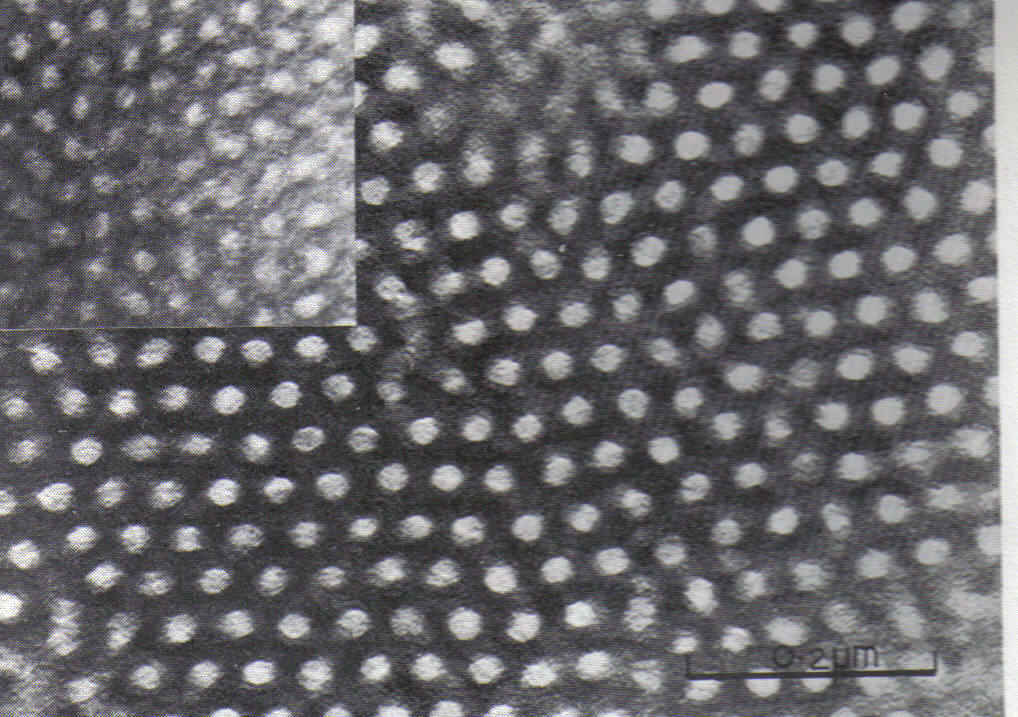

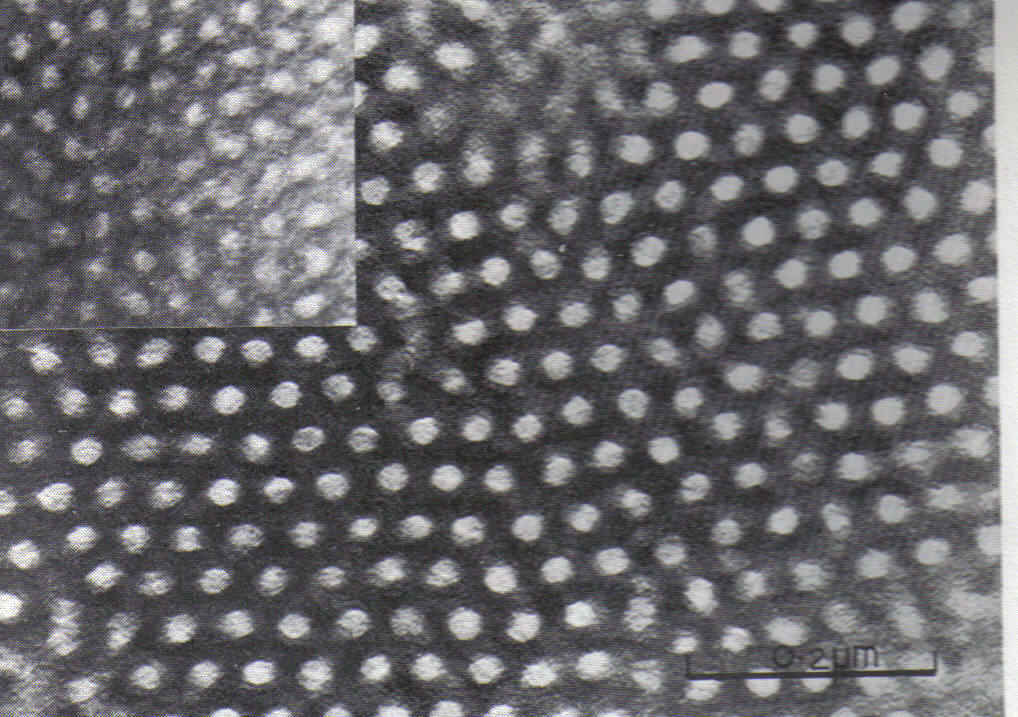

The styrene-butadiene materials possess a two-phase microstructure due to incompatibility between thepolystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It i ...

and polybutadiene

Polybutadiene utadiene rubber, BRis a synthetic rubber. It offers high elasticity, high resistance to wear, good strength even without fillers, and excellent abrasion resistance when filled and vulcanized. "Polybutadiene" is a collective name fo ...

blocks, the former separating into spheres or rods depending on the exact composition. With low polystyrene content, the material is elastomeric with the properties of the polybutadiene predominating. Generally they offer a much wider range of properties than conventional cross-linked rubbers because the composition can vary to suit final construction goals.

Block copolymers can "microphase separate" to form periodic nanostructures, as in the styrene-butadiene-styrene (SBS) block copolymer (shown at right). The polymer is known as Kraton and is used for shoe soles and

Block copolymers can "microphase separate" to form periodic nanostructures, as in the styrene-butadiene-styrene (SBS) block copolymer (shown at right). The polymer is known as Kraton and is used for shoe soles and adhesive

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

The use of adhesives offers certain advantage ...

s. Owing to the microfine structure, a transmission electron microscope

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a gr ...

(TEM) was needed to examine the structure. The butadiene matrix was stained with osmium tetroxide

Osmium tetroxide (also osmium(VIII) oxide) is the chemical compound with the formula OsO4. The compound is noteworthy for its many uses, despite its toxicity and the rarity of osmium. It also has a number of unusual properties, one being that the ...

to provide contrast in the image.

The material was made by living polymerization

In polymer chemistry, living polymerization is a form of chain growth polymerization where the ability of a growing polymer chain to terminate has been removed. This can be accomplished in a variety of ways. Chain termination and chain transf ...

so that the blocks are almost monodisperse, so helping to create a very regular microstructure. The molecular weight

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

of the polystyrene blocks in the main picture is 102,000; the inset picture has a molecular weight of 91,000, producing slightly smaller domains. The spacing between domains has been confirmed by small-angle X-ray scattering, a technique which gives information about microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymer ...

.

Since most polymers are incompatible with one another, forming a block polymer will usually result in phase separation, and the principle has been widely exploited since the introduction of the SBS block polymers, especially where one of the block is highly crystalline. One exception to the rule of incompatibility is the material Noryl, where polystyrene and polyphenylene oxide or PPO form a continuous blend with one another.

melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state of matter, state from solid to liquid. At the melting point the solid and liquid phase (matter), phase exist in Thermodynamic equilib ...

. That point determines the processing temperatures needed to shape the material, as well as the ultimate service use temperatures of the product. Such materials include Hytrel, a polyester-polyether copolymer and Pebax, a nylon or polyamide-polyether copolymer.

Advantages

Depending on the environment, TPEs have outstanding thermal properties and material stability when exposed to a broad range of temperatures and non-polar materials. TPEs consume less energy to produce, can be colored easily by most dyes, and allow economical quality control. TPE requires little or no compounding, with no need to add reinforcing agents, stabilizers or cure systems. Hence, batch-to-batch variations in weighting and metering components are absent, leading to improved consistency in both raw materials and fabricated articles. TPE materials have the potential to berecyclable

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the propert ...

since they can be molded, extruded and reused like plastics, but they have typical elastic properties of rubbers which are not recyclable owing to their thermosetting characteristics. They can also be ground up and turned into 3D printing filament with a recyclebot.

Processing

The two most important manufacturing methods with TPEs areextrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing pro ...

and injection molding. TPEs can now be 3D printed and have been shown to be economically advantageous to make products using distributed manufacturing. Compression molding

Compression molding is a method of molding (process), molding in which the molding material, generally preheated, is first placed in an open, heated Molding (process), mold cavity. The mold is closed with a top force or plug member, pressure ...

is seldom, if ever, used. Fabrication via injection molding is extremely rapid and highly economical. Both the equipment and methods normally used for the extrusion or injection molding of a conventional thermoplastic are generally suitable for TPEs. TPEs can also be processed by blow molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

In general, there are three main types of blow molding: extrusion blow molding, injection ...

, melt calendaring, thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and cert ...

, and heat welding.

Applications

TPEs are used where conventional elastomers cannot provide the range of physical properties needed in the product. These materials find large application in the automotive sector and in household appliances sector. For instance, copolyester TPEs are used insnowmobile

A snowmobile, also known as a snowmachine (chiefly Alaskan), motor sled (chiefly Canadian), motor sledge, skimobile, snow scooter, or simply a sled is a motorized vehicle designed for winter travel and recreation on snow.

Their engines normally ...

tracks where stiffness and abrasion resistance are at a premium. Thermoplastic olefins (TPO) are increasingly used as a roofing material. TPEs are also widely used for catheter

In medicine, a catheter ( ) is a thin tubing (material), tube made from medical grade materials serving a broad range of functions. Catheters are medical devices that can be inserted in the body to treat diseases or perform a surgical procedure. ...

s where nylon block copolymers offer a range of softness ideal for patients. Thermoplastic silicone and olefin blends are used for extrusion of glass run and dynamic weatherstripping car profiles. Styrene block copolymers are used in shoe soles for their ease of processing, and widely as adhesives.

Owing to their unrivaled abilities in two-component injection molding to various thermoplastic substrates, engineered TPS materials also cover a broad range of technical applications ranging from automotive market to consumer and medical products. Examples of those are soft grip surfaces, design elements, back-lit switches and surfaces, as well as sealings, gaskets, or damping elements. TPE is commonly used to make suspension bushings for automotive performance applications because of its greater resistance to deformation when compared to regular rubber bushings. Thermoplastics have experienced growth in the heating, ventilation, and air conditioning (HVAC

Heating, ventilation, and air conditioning (HVAC ) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. ...

) industry due to the function, cost effectiveness and adaptability to modify plastic resins into a variety of covers, fans and housings.

References

Further reading

* PR Lewis and C Price, ''Polymer'', 13, 20 (1972) * Modern Plastic Mid-October Encyclopedia Issue, Introduction to TPEs, ''page:109-110''Latest Material and Technological Developments for Activewear

(Joanne Yip, 2020, ''page 66-67)'' {{DEFAULTSORT:Thermoplastic Elastomer Biomaterials Polymers