|

Thermoplastic Vulcanizates

Thermoplastic vulcanizates (TPVs) are a type of thermoplastic elastomers (TPE) that undergo vulcanization processes during manufacturing, giving elastomeric properties to the final product. Vulcanization involves the cross-linking of polymer chains, leading to increased strength, durability, and flexibility. Their thermoplastic nature allows TPVs, unlike traditional vulcanized rubbers, to be melted and reprocessed multiple times. Across the automotive, household appliance, electrical, construction, and healthcare sectors, nearly 100 TPV grades are used globally. Monsanto trademarked the name ''Santoprene'' for these materials in 1977. The trademark is now owned by the Celanese Corporation. Similar material is available from Elastron, and others. Overview Thermoplastic vulcanizates were first reported in 1962 by A.M. Gessler and W.H. Haslett. In 1973, W.K. Fisher reported the dynamic vulcanization process through his prior work on polypropylene and EPDM rubber-based TPVs with perox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic Elastomer

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers (TPR), are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastic elastomers are not, in contrast making them relatively easy to use in manufacturing, for example, by injection moulding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties. Types There are six g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atomic Force Microscopy

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the optical diffraction limit. Overview Atomic force microscopy (AFM) gathers information by "feeling" or "touching" the surface with a mechanical probe. Piezoelectric elements that facilitate tiny but accurate and precise movements on (electronic) command enable precise scanning. Despite the name, the Atomic Force Microscope does not use the nuclear force. Abilities and spatial resolution The AFM has three major abilities: force measurement, topographic imaging, and manipulation. In force measurement, AFMs can be used to measure the forces between the probe and the sample as a function of their mutual separation. This can be applied to perform force spectroscopy, to measure the mechanical properties of the sample, such as the sample's Youn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is vacuum forming. In its simplest form, a small tabletop or lab size machine can be used to heat small cut sections of plastic sheet and stretch it over a mold using vacuum. This method is often used for sample and prototype parts. In complex and high-volume applications, very large production machines are utilized to heat and form the plastic sheet and trim the formed parts from the sheet in a continuous high-speed process and can produce many thousands of finished parts per hour depending on the machine and mold size and the size of the parts being formed. Therm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-shot Injection Molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Insert Molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a Molding (process), mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, Confectionery, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from 3D Metal Moulding, metal, usually either steel or aluminium, and Machining, precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Injection Molding Of Liquid Silicone Rubber

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume. Liquid silicone rubber is a high purity platinum cured silicone with low compression set, good stability and ability to resist extreme temperatures of heat and cold ideally suitable for production of parts, where high quality is required. Due to the thermosetting nature of the material, liquid silicone injection molding requires special treatment, such as intensive distributive mixing, while maintaining the material at a low temperature before it is pushed into the heated cavity and vulcanized. Chemically, silicone rubber is a family of thermoset elastomers that have a backbone of alternating silicon and oxygen atoms and methyl or vinyl side groups. Silicone rubbers constitute about 30% of the silicone family, making them the largest group of that family. Silicone rubbers maintain their mechanical properties over a wide range of temperatures and the presence of me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

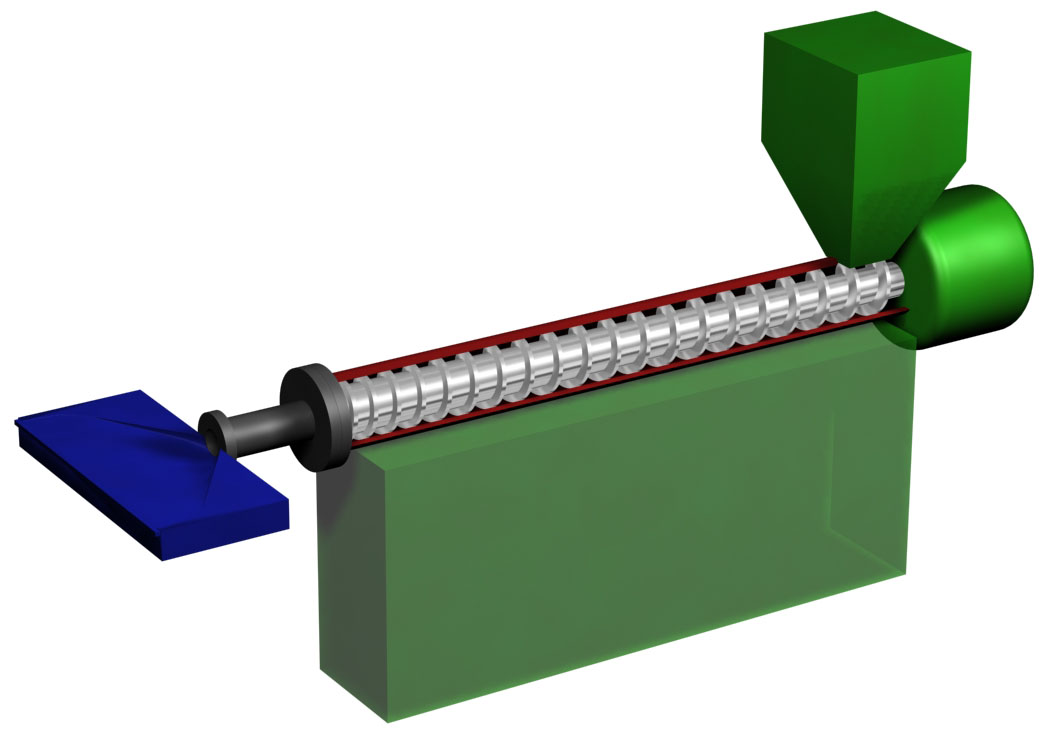

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coextrusion

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic ext ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Wiley & Sons

John Wiley & Sons, Inc., commonly known as Wiley (), is an American Multinational corporation, multinational Publishing, publishing company that focuses on academic publishing and instructional materials. The company was founded in 1807 and produces books, Academic journal, journals, and encyclopedias, in print and electronically, as well as online products and services, training materials, and educational materials for undergraduate, graduate, and continuing education students. History The company was established in 1807 when Charles Wiley opened a print shop in Manhattan. The company was the publisher of 19th century American literary figures like James Fenimore Cooper, Washington Irving, Herman Melville, and Edgar Allan Poe, as well as of legal, religious, and other non-fiction titles. The firm took its current name in 1865. Wiley later shifted its focus to scientific, Technology, technical, and engineering subject areas, abandoning its literary interests. Wiley's son Joh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scanning Electron Microscope

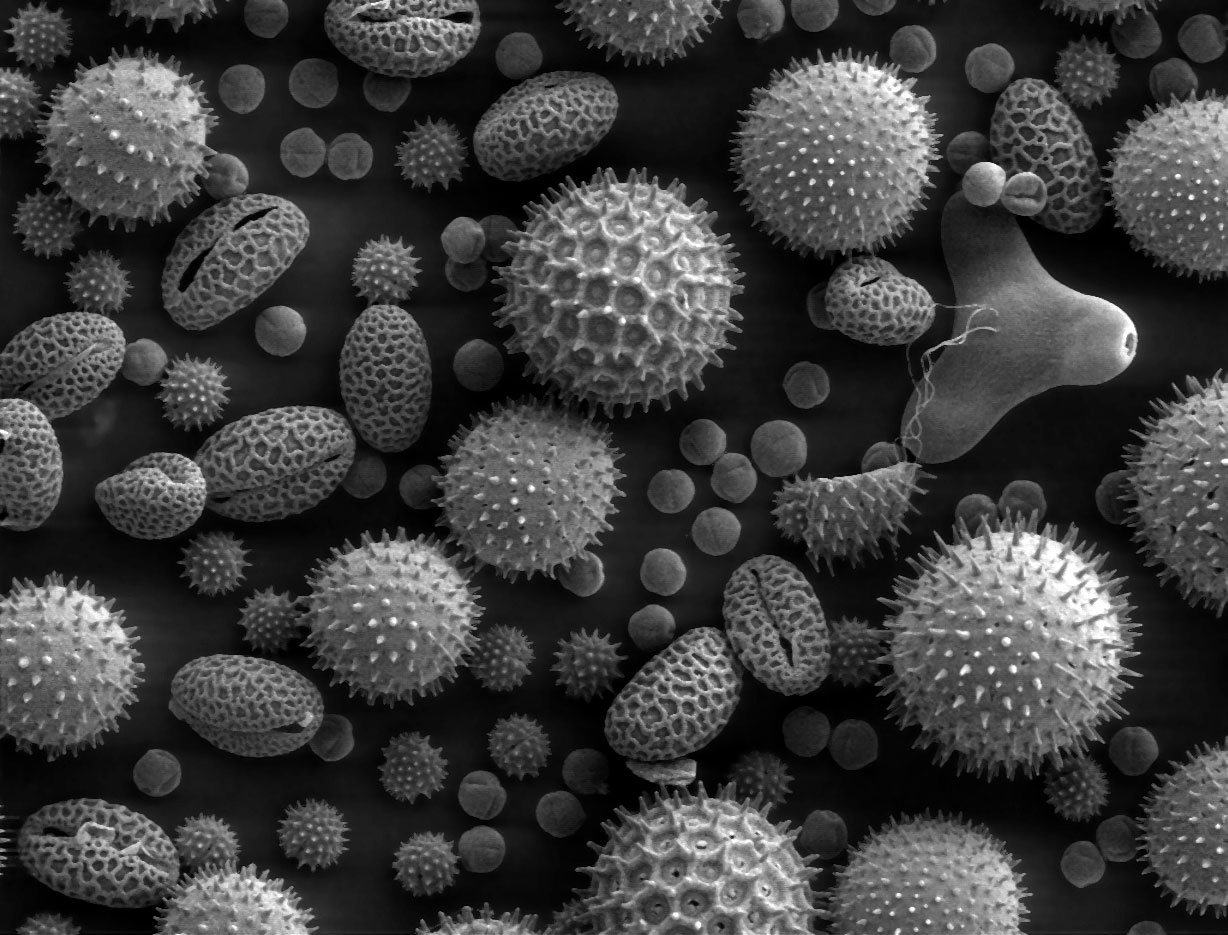

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition. The electron beam is scanned in a raster scan pattern, and the position of the beam is combined with the intensity of the detected signal to produce an image. In the most common SEM mode, secondary electrons emitted by atoms excited by the electron beam are detected using a secondary electron detector ( Everhart–Thornley detector). The number of secondary electrons that can be detected, and thus the signal intensity, depends, among other things, on specimen topography. Some SEMs can achieve resolutions better than 1 nanometer. Specimens are observed in high vacuum in a conventional SEM, or in low vacuum or wet conditions in a variable pressure or environmental SEM, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |