|

Extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Bar Stock

Bar stock, also (colloquially) known as blank, slug or billet, is a common form of raw purified metal, used by industry to manufacture metal parts and products. Bar stock is available in a variety of extrusion shapes and lengths. The most common shapes are round (circular cross-section), rectangular, square and hexagonal. A bar is characterised by an "enclosed invariant convex cross-section", meaning that pipes, angle stock and objects with varying diameter are not considered bar stock. Bar stock is commonly processed by a sequence of sawing, turning, milling, drilling and grinding to produce a final product, often vastly different from the original stock. In some cases, the process is partially automated by specialized equipment which feeds the stock into the appropriate processing machine. Process and types Most metal produced by a steel mill or aluminium plant is formed (via rolling or extrusion) into long continuous strips of various size and shape. These strips are c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Roll Forming

Roll forming, also spelled roll-forming or rollforming, is a type of rolling (metalworking), rolling involving the continuous bending (metalworking), bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section (geometry), cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities. Overview A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a ''flower pattern'', which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, Finite element analysis, computer simulation is often used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

HDPE Pipe Being Extruded

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2008, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 MPa) than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and more opa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

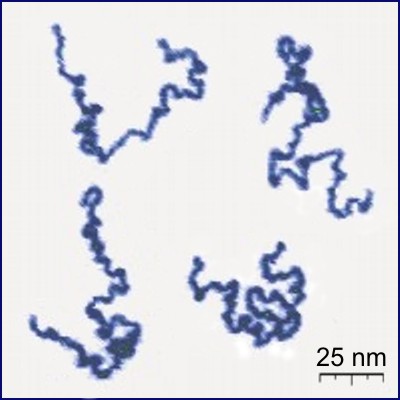

Polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compound (chemistry), compounds, produces unique physical property, physical properties including toughness, high rubber elasticity, elasticity, viscoelasticity, and a tendency to form Amorphous solid, amorphous and crystallization of polymers, semicrystalline structures rath ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has a great affinity towards oxygen, passivation (chemistry), forming a protective layer of aluminium oxide, oxide on the surface when exposed to air. It visually resembles silver, both in its color and in its great ability to reflect light. It is soft, magnetism, nonmagnetic, and ductility, ductile. It has one stable isotope, 27Al, which is highly abundant, making aluminium the abundance of the chemical elements, 12th-most abundant element in the universe. The radioactive decay, radioactivity of aluminium-26, 26Al leads to it being used in radiometric dating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Cold Working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature at or near room temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Hot Working

In metallurgy, hot working refers to processes where metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. This is important because recrystallization keeps the materials from strain hardening, which ultimately keeps the yield strength and hardness low and ductility high.Degarmo, p. 373. This contrasts with cold working. Many kinds of working, including rolling, forging, extrusion, and drawing, can be done with hot metal. Temperature The lower limit of the hot working temperature is determined by its recrystallization temperature. As a guideline, the lower limit of the hot working temperature of a material is 60% its melting temperature (on an absolute temperature scale). The upper limit for hot working is determined by various factors, such as: excessive oxidation, grain growth, or an undesirable phase transformation. In practice materials are usua ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Cold Work

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature at or near room temperature. Such processes are contrasted with hot working techniques like Rolling (metalworking)#Hot rolling, hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystallite, crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal hardness, harder, stiffness, stiffer, and strength of materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Joseph Bramah

Joseph Bramah (13 April 1748 – 9 December 1814) was an English inventor and locksmith. He is best known for having improved the flush toilet and inventing the hydraulic press. Along with William Armstrong, 1st Baron Armstrong, he can be considered one of the two fathers of hydraulic engineering. Early life Joseph Bramah was the second son in the family of Joseph Bramma (note the different spelling of the surname), a farmer, and his wife, Mary Denton. He was educated at the local school in Silkstone in South Yorkshire, and on leaving school he was apprenticed to a local carpenter. On completing his apprenticeship he moved to London, where he started work as a cabinet-maker. In 1783 he married Mary Lawton of Mapplewell, near Barnsley, and the couple set up home in London. They subsequently had a daughter and four sons. The couple lived first at 124 Piccadilly, but later moved to Eaton Street, Pimlico. Improved water closet In London, Bramah worked for a Mr Allen, installing w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Tube (fluid Conveyance)

A tube, or tubing, is a long hollow cylinder used for moving fluids (liquids or gases) or to protect electrical or optical cables and wires. The terms "Pipe (fluid conveyance), pipe" and "tube" are almost interchangeable, although minor distinctions exist — generally, a tube has tighter engineering requirements than a pipe. Both pipe and tube imply a level of rigidity and permanence, whereas a Hose (tubing), hose is usually portable and flexible. A tube and pipe may be specified by standard pipe size designations, ''e.g.'', nominal pipe size, or by nominal (value), nominal outside or inside diameter and/or wall thickness. The actual dimensions of pipe are usually not the nominal dimensions: A 1-inch pipe will not actually measure 1 inch in either outside or inside diameter, whereas many types of tubing are specified by actual inside diameter, outside diameter, or wall thickness. Manufacture There are three classes of manufactured tubing: seamless, as-welded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |