Surface Topography on:

[Wikipedia]

[Google]

[Amazon]

Surface finish, also known as surface texture or surface topography, is the nature of a

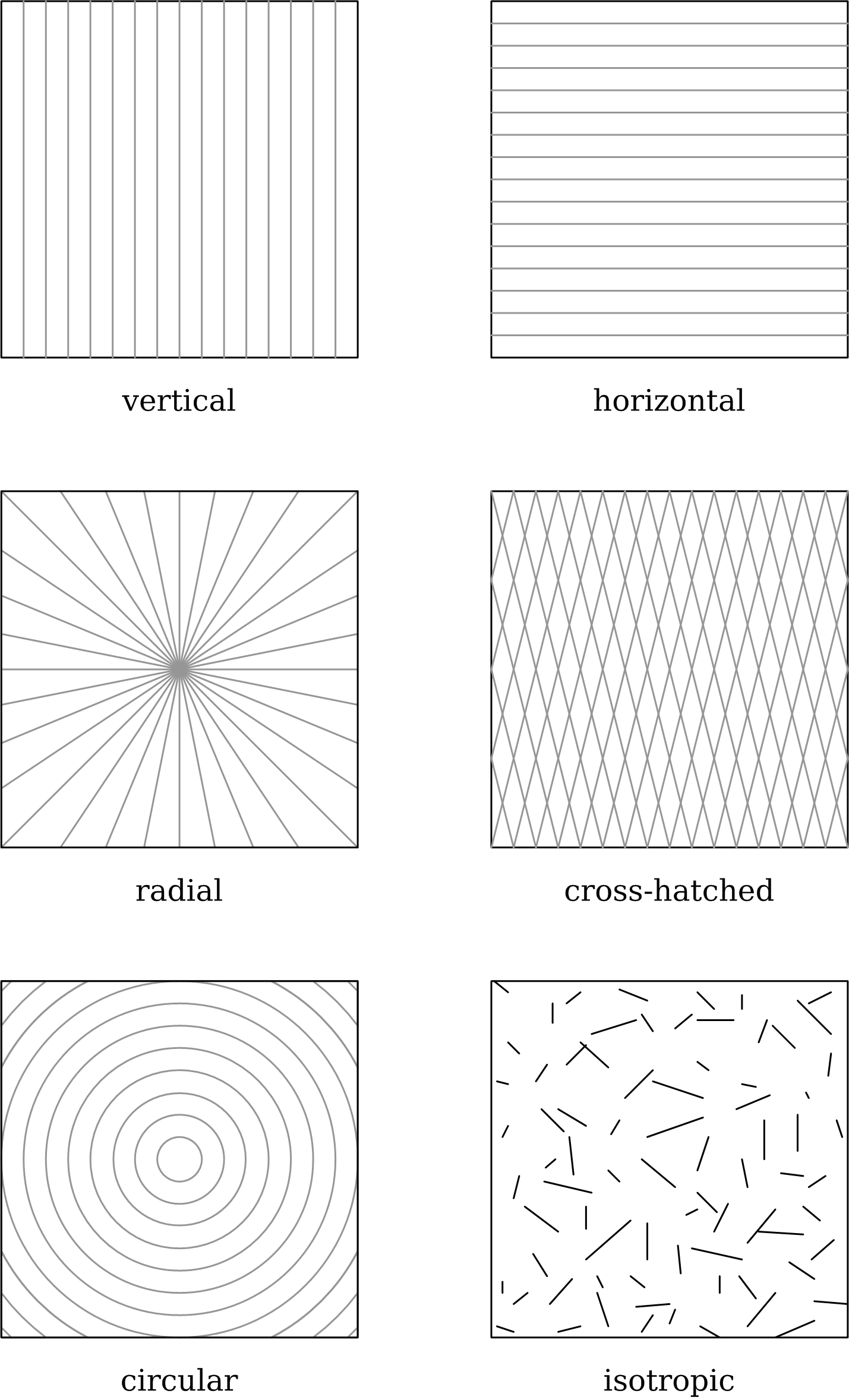

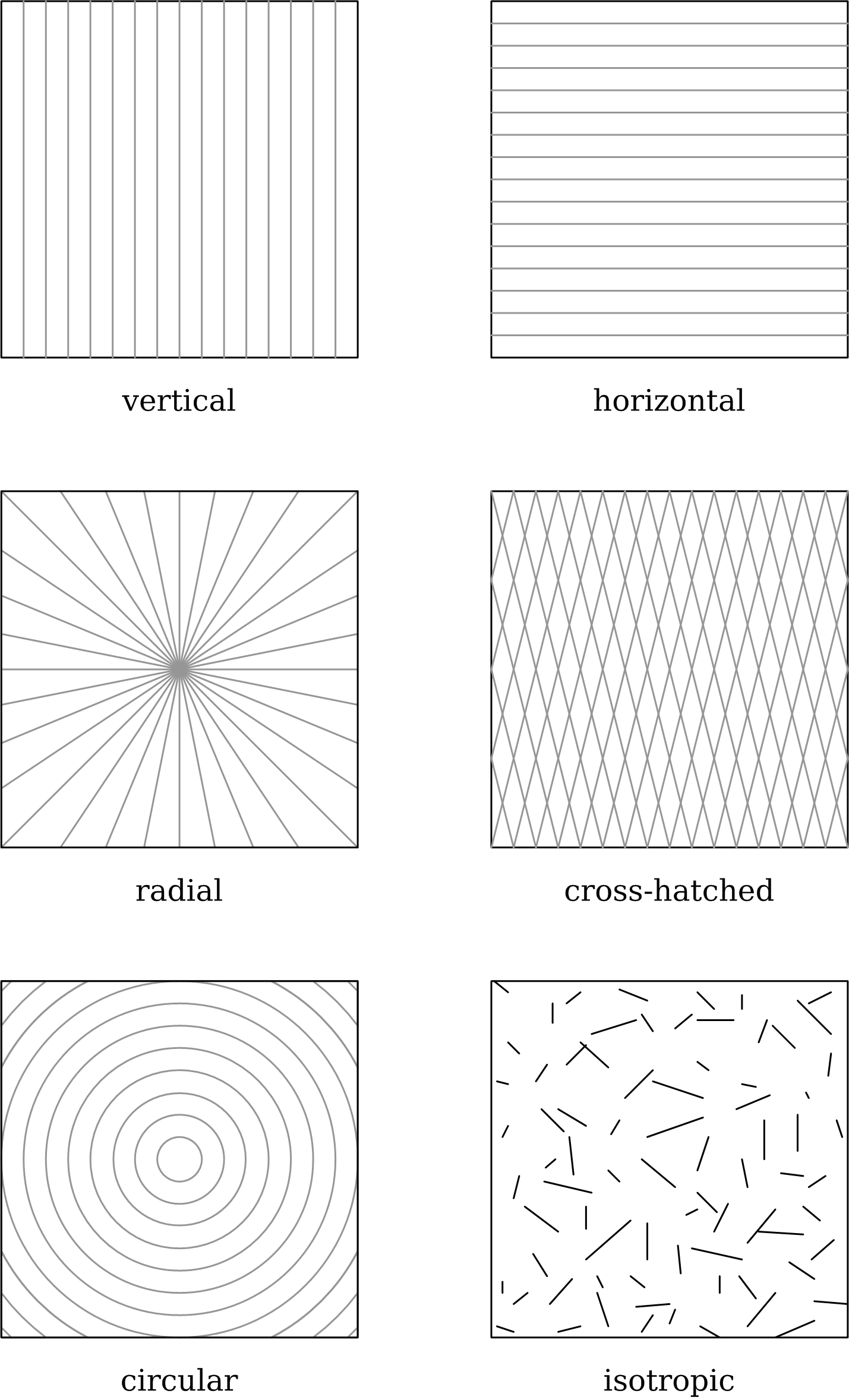

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Surface finish may be measured in two ways: ''contact'' and ''non-contact'' methods. Contact methods involve dragging a measurement

Surface finish may be measured in two ways: ''contact'' and ''non-contact'' methods. Contact methods involve dragging a measurement

surface

A surface, as the term is most generally used, is the outermost or uppermost layer of a physical object or space. It is the portion or region of the object that can first be perceived by an observer using the senses of sight and touch, and is t ...

as defined by the three characteristics of lay, surface roughness, and waviness

Waviness is the measurement of the more widely spaced component of surface texture. It is a broader view of roughness because it is more strictly defined as "the irregularities whose spacing is greater than the roughness sampling length". It can ...

.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane).

Surface texture is one of the important factors that control friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding (motion), sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative la ...

and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's phys ...

. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture.

Each manufacturing process

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a ...

(such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool.

A wide variety of machines are used for grinding, best classified as portable or stationary:

* Portable power tools such as angle grinders, die grin ...

, polishing, lapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first ste ...

, abrasive blasting

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove su ...

, honing, electrical discharge machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal

fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material i ...

(EDM), milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using rota ...

, lithography

Lithography () is a planographic method of printing originally based on the immiscibility of oil and water. The printing is from a stone ( lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by the German ...

, industrial etching

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching incl ...

/chemical milling

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching incl ...

, laser texturing, or other processes.

Lay

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a rope

A rope is a group of yarns, plies, fibres, or strands that are twisted or braided together into a larger and stronger form. Ropes have tensile strength and so can be used for dragging and lifting. Rope is thicker and stronger than similarly ...

.

Surface roughness

Surface roughness, commonly shortened to ''roughness,'' is a measure of the total spaced surface irregularities. In engineering, this is what is usually meant by "surface finish." A Lower number constitutes finer irregularities, i.e., a smoother surface.Waviness

Waviness is the measure of surface irregularities with a spacing greater than that of surface roughness. These irregularities usually occur due towarping

Warp, warped or warping may refer to:

Arts and entertainment Books and comics

* WaRP Graphics, an alternative comics publisher

* ''Warp'' (First Comics), comic book series published by First Comics based on the play ''Warp!''

* Warp (comics), a ...

, vibrations

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic, such as the motion of a pendulum—or random, suc ...

, or deflection during machining.

Measurement

stylus

A stylus (plural styli or styluses) is a writing utensil or a small tool for some other form of marking or shaping, for example, in pottery. It can also be a computer accessory that is used to assist in navigating or providing more precision ...

across the surface; these instruments are called profilometer

A profilometer is a measuring instrument used to measure a surface's profile, in order to quantify its roughness. Critical dimensions as step, curvature, flatness are computed from the surface topography.

While the historical notion of a pro ...

s. Non-contact methods include: interferometry

Interferometry is a technique which uses the '' interference'' of superimposed waves to extract information. Interferometry typically uses electromagnetic waves and is an important investigative technique in the fields of astronomy, fiber o ...

, confocal microscopy

Confocal microscopy, most frequently confocal laser scanning microscopy (CLSM) or laser confocal scanning microscopy (LCSM), is an optical imaging technique for increasing optical resolution and contrast of a micrograph by means of using a s ...

, focus variation Focus variation is a method used to sharpen images and to measure surface irregularities by means of optics with limited depth of field.

Algorithm

The algorithm work as follows:

# at first images with difference focus are captured. This is done by ...

, structured light

A structured light pattern designed for surface inspection

An Automatix Seamtracker arc welding robot equipped with a camera and structured laser light source, enabling the robot to follow a welding seam automatically

Structured light is the p ...

, electrical capacitance

Capacitance is the capability of a material object or device to store electric charge. It is measured by the change in charge in response to a difference in electric potential, expressed as the ratio of those quantities. Commonly recognized a ...

, electron microscopy

An electron microscope is a microscope that uses a beam of accelerated electrons as a source of illumination. As the wavelength of an electron can be up to 100,000 times shorter than that of visible light photons, electron microscopes have a ...

, atomic force microscopy

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the opt ...

and photogrammetry

Photogrammetry is the science and technology of obtaining reliable information about physical objects and the environment through the process of recording, measuring and interpreting photographic images and patterns of electromagnetic radiant ima ...

.

Specification

In the United States, surface finish is usually specified using the ASME Y14.36M standard. The other common standard isInternational Organization for Standardization

The International Organization for Standardization (ISO ) is an international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Ar ...

(ISO) 1302:2002, although the same has been withdrawn in favour of ISO 21920-1:2021.

Many factors contribute to the surface finish in manufacturing. In forming processes, such as molding or metal forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the mater ...

, surface finish of the die determines the surface finish of the workpiece. In machining, the interaction of the cutting edges and the microstructure of the material being cut both contribute to the final surface finish.

In general, the cost of manufacturing a surface increases as the surface finish improves.. Any given manufacturing process is usually optimized enough to ensure that the resulting texture is usable for the part's intended application. If necessary, an additional process will be added to modify the initial texture. The expense of this additional process must be justified by adding value in some way—principally better function or longer lifespan. Parts that have sliding contact with others may work better or last longer if the roughness is lower. Aesthetic improvement may add value if it improves the saleability of the product.

A practical example is as follows. An aircraft maker contracts with a vendor

In a supply chain, a vendor, supplier, provider or a seller, is an enterprise that contributes goods or services. Generally, a supply chain vendor manufactures inventory/stock items and sells them to the next link in the chain. Today, these terms ...

to make parts. A certain grade of steel is specified for the part because it is strong enough and hard enough for the part's function. The steel is machinable although not free-machining. The vendor decides to mill

Mill may refer to:

Science and technology

*

* Mill (grinding)

* Milling (machining)

* Millwork

* Textile manufacturing, Textile mill

* Steel mill, a factory for the manufacture of steel

* List of types of mill

* Mill, the arithmetic unit of the A ...

the parts. The milling can achieve the specified roughness (for example, ≤ 3.2 μm) as long as the machinist uses premium-quality inserts in the end mill

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most mi ...

and replaces the inserts after every 20 parts (as opposed to cutting hundreds before changing the inserts). There is no need to add a second operation (such as grinding or polishing) after the milling as long as the milling is done well enough (correct inserts, frequent-enough insert changes, and clean coolant

A coolant is a substance, typically liquid, that is used to reduce or regulate the temperature of a system. An ideal coolant has high thermal capacity, low viscosity, is low-cost, non-toxic, chemically inert and neither causes nor promotes corros ...

). The inserts and coolant cost money, but the costs that grinding or polishing would incur (more time and additional materials) woul