Stereolithography on:

[Wikipedia]

[Google]

[Amazon]

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of

(“Apparatus for Production of Three-Dimensional Objects by Stereolithography”) Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive.

Rapid Prototyping and Stereolithography animation

– Animation demonstrates stereolithography and the actions of an SL machine {{3d printing Japanese inventions Laser applications 3D printing processes Computer-assisted surgery Health informatics 1986 introductions

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

technology used for creating model

A model is an informative representation of an object, person, or system. The term originally denoted the plans of a building in late 16th-century English, and derived via French and Italian ultimately from Latin , .

Models can be divided in ...

s, prototype

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and Software prototyping, software programming. A prototype ...

s, pattern

A pattern is a regularity in the world, in human-made design, or in abstract ideas. As such, the elements of a pattern repeat in a predictable manner. A geometric pattern is a kind of pattern formed of geometric shapes and typically repeated l ...

s, and production parts in a layer by layer fashion using photochemical

Photochemistry is the branch of chemistry concerned with the chemical effects of light. Generally, this term is used to describe a chemical reaction caused by absorption of ultraviolet (wavelength from 100 to 400 nm), visible (400–750&nb ...

processes by which light causes chemical monomer

A monomer ( ; ''mono-'', "one" + '' -mer'', "part") is a molecule that can react together with other monomer molecules to form a larger polymer chain or two- or three-dimensional network in a process called polymerization.

Classification

Chemis ...

s and oligomer

In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relativ ...

s to cross-link

In chemistry and biology, a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural ...

together to form polymers

A polymer () is a substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeating subunits derived from one or more species of monomers. Due to their broad spectrum of properties, b ...

. U.S. Patentbr>4,575,330(“Apparatus for Production of Three-Dimensional Objects by Stereolithography”) Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive.

History

Stereolithography or "SLA" printing is an early and widely used 3D printing technology. In the early 1980s, Japanese researcher Hideo Kodama first invented the modern layered approach to stereolithography by using ultraviolet light to cure photosensitive polymers. In 1984, just before Chuck Hull filed his own patent, Alain Le Mehaute, Olivier de Witte and Jean Claude André filed a patent for the stereolithography process. The French inventors' patent application was abandoned by the French General Electric Company (now Alcatel-Alsthom) and CILAS (The Laser Consortium). Le Mehaute believes that the abandonment reflects a problem with innovation in France. The term “stereolithography” (Greek: stereo-solid andlithography

Lithography () is a planographic method of printing originally based on the miscibility, immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by ...

) was coined in 1984 by Chuck Hull when he filed his patent for the process. Hull patented stereolithography as a method of creating 3D objects by successively "printing" thin layers of an object using a medium curable by ultraviolet light

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of th ...

, starting from the bottom layer to the top layer. Hull's patent described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with a liquid photopolymer

A photopolymer or light-activated resin is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example harde ...

. The beam is focused onto the surface of the liquid photopolymer, creating each layer of the desired 3D object by means of crosslinking (generation of intermolecular bonds in polymers). It was invented with the intent of allowing engineers to create prototypes of their designs in a more time effective manner.Gibson, Ian, and Jorge Bártolo, Paulo. “History of Stereolithography.” Stereolithography: Materials, Processes, and Applications. (2011): 41-43. Print. 7 October 2015. After the patent was granted in 1986, Hull co-founded the world's first 3D printing company, 3D Systems, to commercialize it.

Stereolithography's success in the automotive industry allowed 3D printing to achieve industry status and the technology continues to find innovative uses in many fields of study. Attempts have been made to construct mathematical models of stereolithography processes and to design algorithms to determine whether a proposed object may be constructed using 3D printing.

Technology

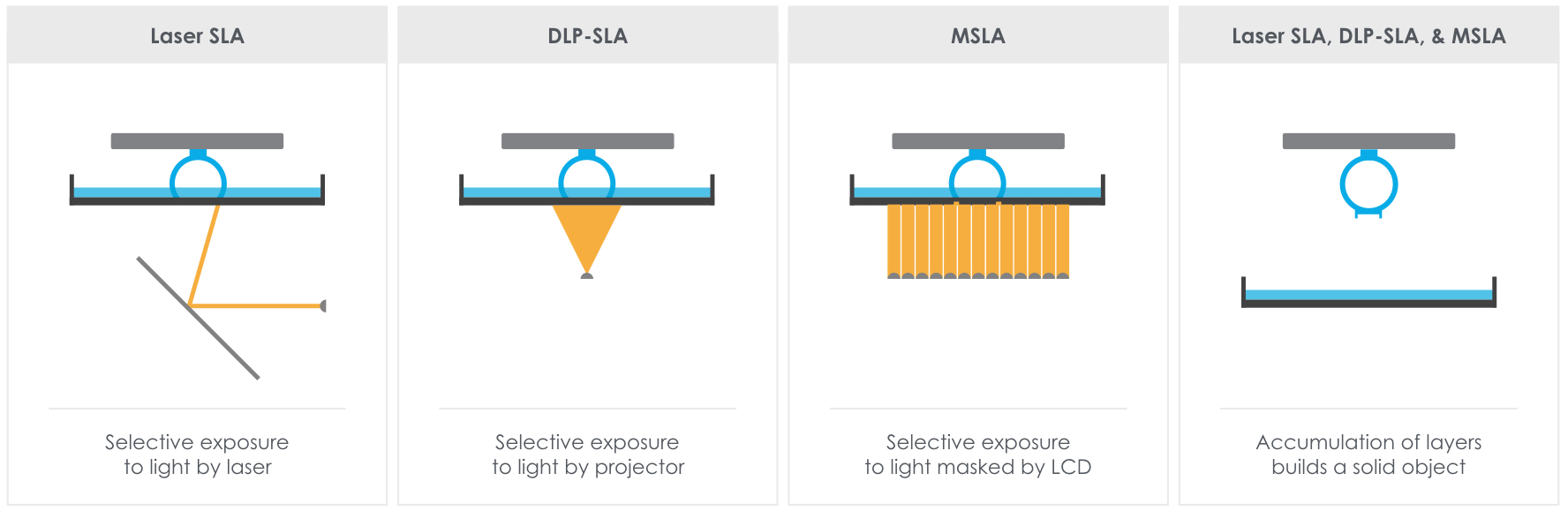

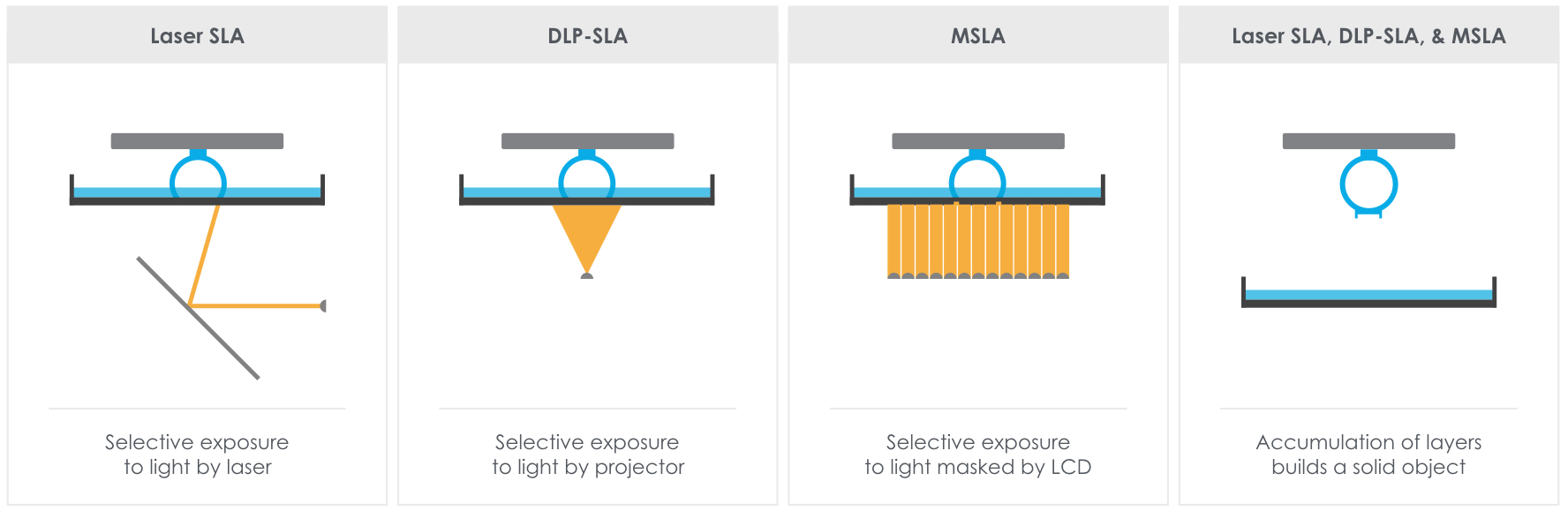

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat ofphotopolymer

A photopolymer or light-activated resin is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example harde ...

resin. With the help of computer aided manufacturing or computer-aided design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve c ...

(CAM/CAD) software,Lipson, Hod, Francis C. Moon, Jimmy Hai, and Carlo Paventi. "3-D Printing the History of Mechanisms." Journal of Mechanical Design J. Mech. Des. (2004): 1029-033. Print. the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object. Then, the build platform lowers one layer and a blade recoats the top of the tank with resin. This process is repeated for each layer of the design until the 3D object is complete. Completed parts must be washed with a solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

to clean wet resin from their surfaces.

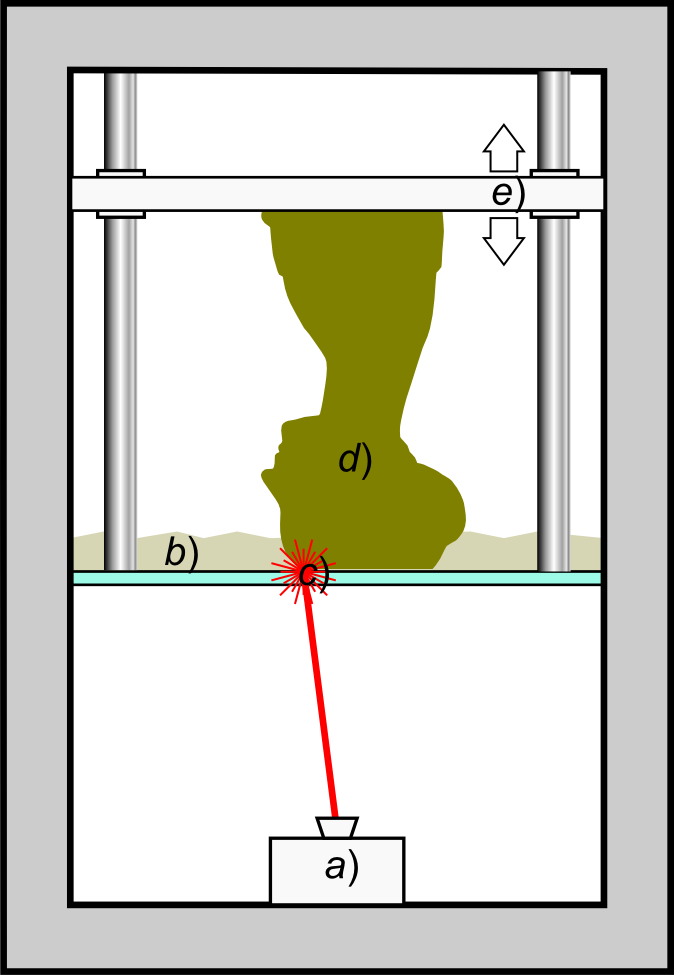

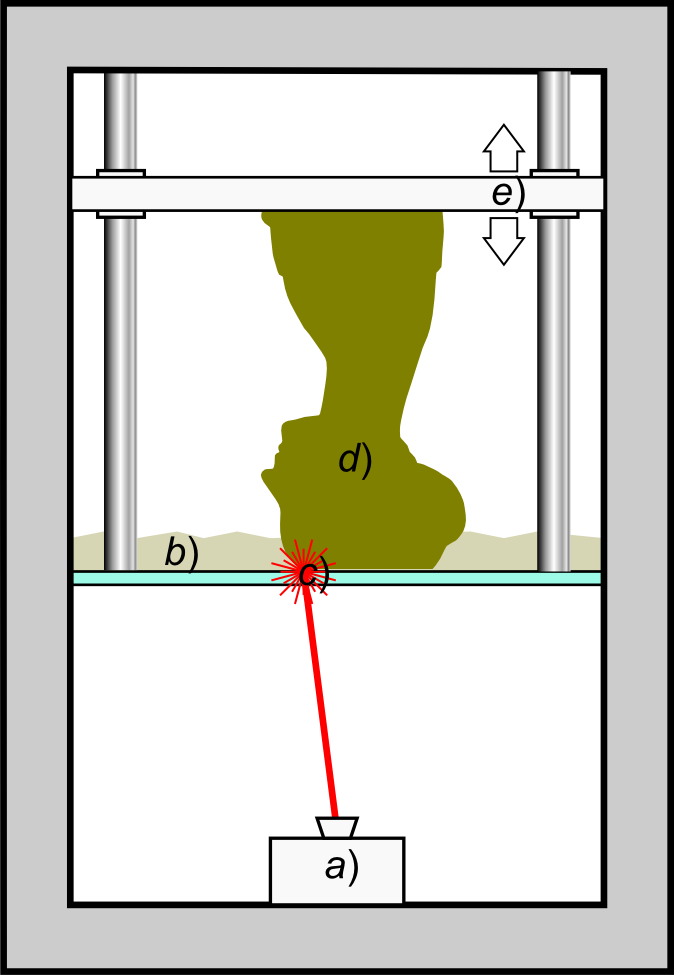

It is also possible to print objects "bottom up" by using a vat with a transparent bottom and focusing the UV or deep-blue polymerization laser upward through the bottom of the vat. An inverted stereolithography machine starts a print by lowering the build platform to touch the bottom of the resin-filled vat, then moving upward the height of one layer. The UV laser then writes the bottom-most layer of the desired part through the transparent vat bottom. Then the vat is "rocked", flexing and peeling the bottom of the vat away from the hardened photopolymer; the hardened material detaches from the bottom of the vat and stays attached to the rising build platform, and new liquid photopolymer flows in from the edges of the partially built part. The UV laser then writes the second-from-bottom layer and repeats the process. An advantage of this bottom-up mode is that the build volume can be much bigger than the vat itself, and only enough photopolymer is needed to keep the bottom of the build vat continuously full of photopolymer. This approach is typical of desktop SLA printers, while the right-side-up approach is more common in industrial systems.

Stereolithography requires the use of supporting structures which attach to the elevator platform to prevent deflection

Deflection or deflexion may refer to:

Board games

* Deflection (chess), a tactic that forces an opposing chess piece to leave a square

* Khet (game), formerly ''Deflexion'', an Egyptian-themed chess-like game using lasers

Mechanics

* Deflection ...

due to gravity, resist lateral pressure from the resin-filled blade, or retain newly created sections during the "vat rocking" of bottom up printing. Supports are typically created automatically during the preparation of CAD models and can also be made manually. In either situation, the supports must be removed manually after printing.

Other forms of stereolithography build each layer by LCD masking, or using a DLP projector.

Materials

The liquid materials used for SLA printing are commonly referred to as "resins" and are thermoset polymers. A wide variety of resins are commercially available and it is also possible to use homemade resins to test different compositions for example. Material properties vary according to formulation configurations: "materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance". Recently, some studies have tested the possibility to green or reusable materials to produce "sustainable" resins. It is possible to classify the resins in the following categories: * Standard resins, for general prototyping * Engineering resins, for specific mechanical and thermal properties * Dental and medical resins, for biocompatibility certifications * Castable resins, for zero ash-content after burnout * Biomaterial resins, formulated as aqueous solutions of syntheticpolymers

A polymer () is a substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeating subunits derived from one or more species of monomers. Due to their broad spectrum of properties, b ...

like polyethylene glycol

Polyethylene glycol (PEG; ) is a polyether compound derived from petroleum with many applications, from industrial manufacturing to medicine. PEG is also known as polyethylene oxide (PEO) or polyoxyethylene (POE), depending on its molecular wei ...

, or biological polymers such as gelatin

Gelatin or gelatine () is a translucent, colorless, flavorless food ingredient, commonly derived from collagen taken from animal body parts. It is brittle when dry and rubbery when moist. It may also be referred to as hydrolyzed collagen, coll ...

, dextran

Dextran is a complex branched glucan (polysaccharide derived from the condensation of glucose), originally derived from wine. IUPAC defines dextrans as "Branched poly-α-d-glucosides of microbial origin having glycosidic bonds predominantly C-1 ...

, or hyaluronic acid

Hyaluronic acid (; abbreviated HA; conjugate base hyaluronate), also called hyaluronan, is an anionic, nonsulfated glycosaminoglycan distributed widely throughout connective, epithelial, and neural tissues. It is unique among glycosaminog ...

.

Uses

Medical modeling

Stereolithographic models have been used in medicine since the 1990s, for creating accurate 3D models of various anatomical regions of a patient, based ondata

Data ( , ) are a collection of discrete or continuous values that convey information, describing the quantity, quality, fact, statistics, other basic units of meaning, or simply sequences of symbols that may be further interpreted for ...

from computer scans. Medical modelling involves first acquiring a CT, MRI

Magnetic resonance imaging (MRI) is a medical imaging technique used in radiology to generate pictures of the anatomy and the physiological processes inside the body. MRI scanners use strong magnetic fields, magnetic field gradients, and rad ...

, or other scan. This data consists of a series of cross sectional images of the human anatomy. In these images different tissues show up as different levels of grey. Selecting a range of grey values enables specific tissues to be isolated. A region of interest is then selected and all the pixels connected to the target point within that grey value range are selected. This enables a specific organ to be selected. This process is referred to as segmentation. The segmented data may then be translated into a format suitable for stereolithography. While stereolithography is normally accurate, the accuracy of a medical model depends on many factors, especially the operator performing the segmentation correctly. There are potential errors possible when making medical models using stereolithography but these can be avoided with practice and well trained operators.

Stereolithographic models are used as an aid to diagnosis, preoperative planning and implant design and manufacture. This might involve planning and rehearsing osteotomies, for example. Surgeons use models to help plan surgeries but prosthetists and technologists also use models as an aid to the design and manufacture of custom-fitting implants. For instance, medical models created through stereolithography can be used to help in the construction of Cranioplasty plates.

In 2019, scientists at Rice University

William Marsh Rice University, commonly referred to as Rice University, is a Private university, private research university in Houston, Houston, Texas, United States. Established in 1912, the university spans 300 acres.

Rice University comp ...

published an article in the journal ''Science'', presenting soft hydrogel

A hydrogel is a Phase (matter), biphasic material, a mixture of Porosity, porous and Permeation, permeable solids and at least 10% of water or other interstitial fluid. The solid phase is a water Solubility, insoluble three dimensional network ...

materials for stereolithography used in biological research applications.

Prototyping

Stereolithography is often used for prototyping parts. For a relatively low price, stereolithography can produce accurate prototypes, even of irregular shapes. Businesses can use those prototypes to assess the design of their product or as publicity for the final product.Advantages and disadvantages

Advantages

One of the advantages of stereolithography is its speed; functional parts can be manufactured within a day. The length of time it takes to produce a single part depends upon the complexity of the design and the size. Printing time can last anywhere from hours to more than a day. SLA printed parts, unlike those obtained from FFF/FDM, do not exhibit significantanisotropy

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit ve ...

(structural non-uniformity) and there's no visible layering pattern. The surface quality is, in general, superior. Prototypes and designs made with stereolithography are strong enough to be machined

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

and can also be used to make master patterns for injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

or various metal casting

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is ...

processes.

Disadvantages

Although stereolithography can be used to produce virtually any synthetic design, it is often costly (due to costlier machines compared to FFF, costlier resin and costly post-processing steps such as washing and curing), though the price is coming down. Since 2012, however, public interest in 3D printing has inspired the design of several consumer SLA machines which can cost considerably less. Beginning in 2016, substitution of the SLA and DLP methods using a high resolution, high contrast LCD panel has brought prices down to below 200. The layers are created in their entirety since the entire layer is displayed on the LCD screen and is exposed using UV LEDs that lie below. Resolutions of .01mm are attainable. Another disadvantage is that the photopolymers are sticky, messy, and need to be handled with care. Newly made parts need to be washed, further cured, and dried. The environmental impact of all these processes requires more study to be understood, but in general SLA technologies have not created any biodegradable or compostable forms of resin, while other 3-D printing methods offer some compostable PLA options. The choice of materials is limited compared to FFF, which can process virtually any thermoplastic.See also

*Fused filament fabrication

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is ...

(FFF or FDM)

* Selective laser sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined ...

(SLS)

* Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and cert ...

* laminated object manufacturing (LOM)

* .stl - file format

References

Sources

* Kalpakjian, Serope, and Steven R. Schmid (2006). ''Manufacturing Engineering and Technology'', 5th edition. Ch. 20. Upper Saddle River, NJ: Pearson Prentice Hall. pp. 586–587.External links

Rapid Prototyping and Stereolithography animation

– Animation demonstrates stereolithography and the actions of an SL machine {{3d printing Japanese inventions Laser applications 3D printing processes Computer-assisted surgery Health informatics 1986 introductions