sputter on:

[Wikipedia]

[Google]

[Amazon]

In physics, sputtering is a phenomenon in which microscopic

In physics, sputtering is a phenomenon in which microscopic

In the case of multiple charged projectile ions a particular form of electronic sputtering can take place that has been termed ''potential sputtering''. In these cases the potential energy stored in multiply charged ions (i.e., the energy necessary to produce an ion of this charge state from its neutral atom) is liberated when the ions recombine during impact on a solid surface (formation of hollow atoms). This sputtering process is characterized by a strong dependence of the observed sputtering yields on the charge state of the impinging ion and can already take place at ion impact energies well below the physical sputtering threshold. Potential sputtering has only been observed for certain target species and requires a minimum potential energy.

In the case of multiple charged projectile ions a particular form of electronic sputtering can take place that has been termed ''potential sputtering''. In these cases the potential energy stored in multiply charged ions (i.e., the energy necessary to produce an ion of this charge state from its neutral atom) is liberated when the ions recombine during impact on a solid surface (formation of hollow atoms). This sputtering process is characterized by a strong dependence of the observed sputtering yields on the charge state of the impinging ion and can already take place at ion impact energies well below the physical sputtering threshold. Potential sputtering has only been observed for certain target species and requires a minimum potential energy.

Thin Film Evaporation Guide

- an introduction with animations

Sputtering Basics - animated film of a sputtering process

Free molecular dynamics simulation program (Kalypso) capable of modeling sputtering

American Vacuum Society short courses

on thin film deposition * (The original paper on Kaufman sputter sources.) * {{Authority control Coatings Physical vapor deposition techniques Materials science Thin film deposition Surface science

In physics, sputtering is a phenomenon in which microscopic

In physics, sputtering is a phenomenon in which microscopic particle

In the physical sciences, a particle (or corpuscle in older texts) is a small localized object which can be described by several physical or chemical properties, such as volume, density, or mass.

They vary greatly in size or quantity, from s ...

s of a solid material are ejected from its surface, after the material is itself bombarded by energetic particle

In the physical sciences, a particle (or corpuscle in older texts) is a small localized object which can be described by several physical or chemical properties, such as volume, density, or mass.

They vary greatly in size or quantity, from s ...

s of a plasma or gas. It occurs naturally in outer space, and can be an unwelcome source of wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

in precision components. However, the fact that it can be made to act on extremely fine layers of material is utilised in science and industry—there, it is used to perform precise etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

, carry out analytical techniques, and deposit thin film

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

layers in the manufacture of optical coating

An optical coating is one or more thin-film optics, thin layers of material deposited on an optical component such as a lens (optics), lens, prism (optics), prism or mirror, which alters the way in which the optic reflection (physics), reflects a ...

s, semiconductor device

A semiconductor device is an electronic component that relies on the electronic properties of a semiconductor material (primarily silicon, germanium, and gallium arsenide, as well as organic semiconductors) for its function. Its conductivit ...

s and nanotechnology

Nanotechnology is the manipulation of matter with at least one dimension sized from 1 to 100 nanometers (nm). At this scale, commonly known as the nanoscale, surface area and quantum mechanical effects become important in describing propertie ...

products. It is a physical vapor deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polym ...

technique.

Physics

When energetic ions collide with atoms of a target material, an exchange ofmomentum

In Newtonian mechanics, momentum (: momenta or momentums; more specifically linear momentum or translational momentum) is the product of the mass and velocity of an object. It is a vector quantity, possessing a magnitude and a direction. ...

takes place between them.

These ions, known as "incident ions", set off collision cascades in the target. Such cascades can take many paths; some recoil back toward the surface of the target. If a collision cascade reaches the surface of the target, and its remaining energy is greater than the target's surface binding energy

In physics and chemistry, binding energy is the smallest amount of energy required to remove a particle from a system of particles or to disassemble a system of particles into individual parts. In the former meaning the term is predominantly use ...

, an atom will be ejected. This process is known as "sputtering". If the target is thin (on an atomic scale), the collision cascade can reach through to its back side; the atoms ejected in this fashion are said to escape the surface binding energy "in transmission".

The average number of atoms ejected from the target per incident ion is called the "sputter yield". The sputter yield depends on several things: the angle at which ions collide with the surface of the material, how much energy they strike it with, their masses, the masses of the target atoms, and the target's surface binding energy. If the target possesses a crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macros ...

structure, the orientation of its axes with respect to the surface is an important factor.

The ions that cause sputtering come from a variety of sources—they can come from plasma, specially constructed ion sources, particle accelerator

A particle accelerator is a machine that uses electromagnetic fields to propel electric charge, charged particles to very high speeds and energies to contain them in well-defined particle beam, beams. Small accelerators are used for fundamental ...

s, outer space (e.g. solar wind

The solar wind is a stream of charged particles released from the Sun's outermost atmospheric layer, the Stellar corona, corona. This Plasma (physics), plasma mostly consists of electrons, protons and alpha particles with kinetic energy betwee ...

), or radioactive materials (e.g. alpha radiation).

A model for describing sputtering in the cascade regime for amorphous flat targets is Thompson's analytical model. An algorithm that simulates sputtering based on a quantum mechanical treatment including electrons stripping at high energy is implemented in the program TRIM.

Another mechanism of physical sputtering is called "heat spike sputtering". This can occur when the solid is dense enough, and the incoming ion heavy enough, that collisions occur very close to each other. In this case, the binary collision approximation is no longer valid, and the collisional process should be understood as a many-body process. The dense collisions induce a heat spike (also called thermal spike), which essentially melts a small portion of the crystal. If that portion is close enough to its surface, large numbers of atoms may be ejected, due to liquid flowing to the surface and/or microexplosions. Heat spike sputtering is most important for heavy ions (e.g. Xe or Au or cluster ions) with energies in the keV–MeV range bombarding dense but soft metals with a low melting point (Ag, Au, Pb, etc.). The heat spike sputtering often increases nonlinearly with energy, and can for small cluster ions lead to dramatic sputtering yields per cluster of the order of 10,000. For animations of such a process see "Re: Displacement Cascade 1" in the external links

An internal link is a type of hyperlink on a web page to another page or resource, such as an image or document, on the same website or domain. It is the opposite of an external link, a link that directs a user to content that is outside its d ...

section.

Physical sputtering has a well-defined minimum energy threshold, equal to or larger than the ion energy at which the maximum energy transfer from the ion to a target atom equals the binding energy of a surface atom. That is to say, it can only happen when an ion is capable of transferring more energy into the target than is required for an atom to break free from its surface.

This threshold is typically somewhere in the range of ten to a hundred eV.

''Preferential sputtering'' can occur at the start when a multicomponent solid target is bombarded and there is no solid state diffusion. If the energy transfer is more efficient to one of the target components, or it is less strongly bound to the solid, it will sputter more efficiently than the other. If in an AB alloy the component A is sputtered preferentially, the surface of the solid will, during prolonged bombardment, become enriched in the B component, thereby increasing the probability that B is sputtered such that the composition of the sputtered material will ultimately return to AB.

Electronic sputtering

The term ''electronic sputtering'' can mean either sputtering induced by energetic electrons (for example in a transmission electron microscope), or sputtering due to very high-energy or highly charged heavy ions that lose energy to the solid, mostly by electronicstopping power

Stopping power is the supposed ability of a weapon – typically a ranged weapon such as a firearm – to cause a target (human or animal) to be incapacitated or immobilized. Stopping power contrasts with lethality in that it pertains only to a ...

, where the electronic excitations cause sputtering. Electronic sputtering produces high sputtering yields from insulators, as the electronic excitations that cause sputtering are not immediately quenched, as they would be in a conductor. One example of this is Jupiter's ice-covered moon Europa, where a MeV sulfur ion from Jupiter's magnetosphere can eject up to 10,000 H2O molecules.

Potential sputtering

Etching and chemical sputtering

Removing atoms by sputtering with an inert gas is called '' ion milling'' or ''ion etching''. Sputtering can also play a role inreactive-ion etching

Reactive-ion etching (RIE) is an etching (microfabrication), etching technology used in microfabrication. RIE is a type of dry etching which has different characteristics than Isotropic etching, wet etching. RIE uses chemical reaction, chemically ...

(RIE), a plasma process carried out with chemically active ions and radicals, for which the sputtering yield may be enhanced significantly compared to pure physical sputtering. Reactive ions are frequently used in secondary ion mass spectrometry (SIMS) equipment to enhance the sputter rates. The mechanisms causing the sputtering enhancement are not always well understood, although the case of fluorine etching of Si has been modeled well theoretically.

Sputtering observed to occur below the threshold energy of physical sputtering is also often called chemical sputtering. The mechanisms behind such sputtering are not always well understood, and may be hard to distinguish from chemical etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

. At elevated temperatures, chemical sputtering of carbon can be understood to be due to the incoming ions weakening bonds in the sample, which then desorb by thermal activation. The hydrogen-induced sputtering of carbon-based materials observed at low temperatures has been explained by H ions entering between C-C bonds and thus breaking them, a mechanism dubbed ''swift chemical sputtering''.

Applications and phenomena

Sputtering only happens when the kinetic energy of the incoming particles is much higher than conventional thermal energies ( ≫ 1 eV). When done withdirect current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow throug ...

(DC sputtering), voltages of 3-5 kV are used. When done with alternating current

Alternating current (AC) is an electric current that periodically reverses direction and changes its magnitude continuously with time, in contrast to direct current (DC), which flows only in one direction. Alternating current is the form in w ...

( RF sputtering), frequencies are around the 14 MHz range.

Sputter cleaning

Surfaces of solids can be cleaned from contaminants by using physical sputtering in avacuum

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressur ...

. Sputter cleaning is often used in surface science

Surface science is the study of physical and chemical phenomena that occur at the interface of two phases, including solid–liquid interfaces, solid– gas interfaces, solid– vacuum interfaces, and liquid– gas interfaces. It includes the ...

, vacuum deposition and ion plating. In 1955 Farnsworth, Schlier, George, and Burger reported using sputter cleaning in an ultra-high-vacuum system to prepare ultra-clean surfaces for low-energy electron-diffraction (LEED) studies. Sputter cleaning became an integral part of the ion plating process. When the surfaces to be cleaned are large, a similar technique, plasma cleaning, can be used. Sputter cleaning has some potential problems such as overheating, gas incorporation in the surface region, bombardment (radiation) damage in the surface region, and the roughening of the surface, particularly if ''over done.'' It is important to have a ''clean'' plasma in order to not continually recontaminate the surface during sputter cleaning. Redeposition of sputtered material on the substrate can also give problems, especially at high sputtering pressures. Sputtering of the surface of a compound or alloy material can result in the surface composition being changed. Often the species with the least mass or the highest vapor pressure

Vapor pressure or equilibrium vapor pressure is the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. The equilibrium vapor pressure is an indicat ...

is the one preferentially sputtered from the surface.

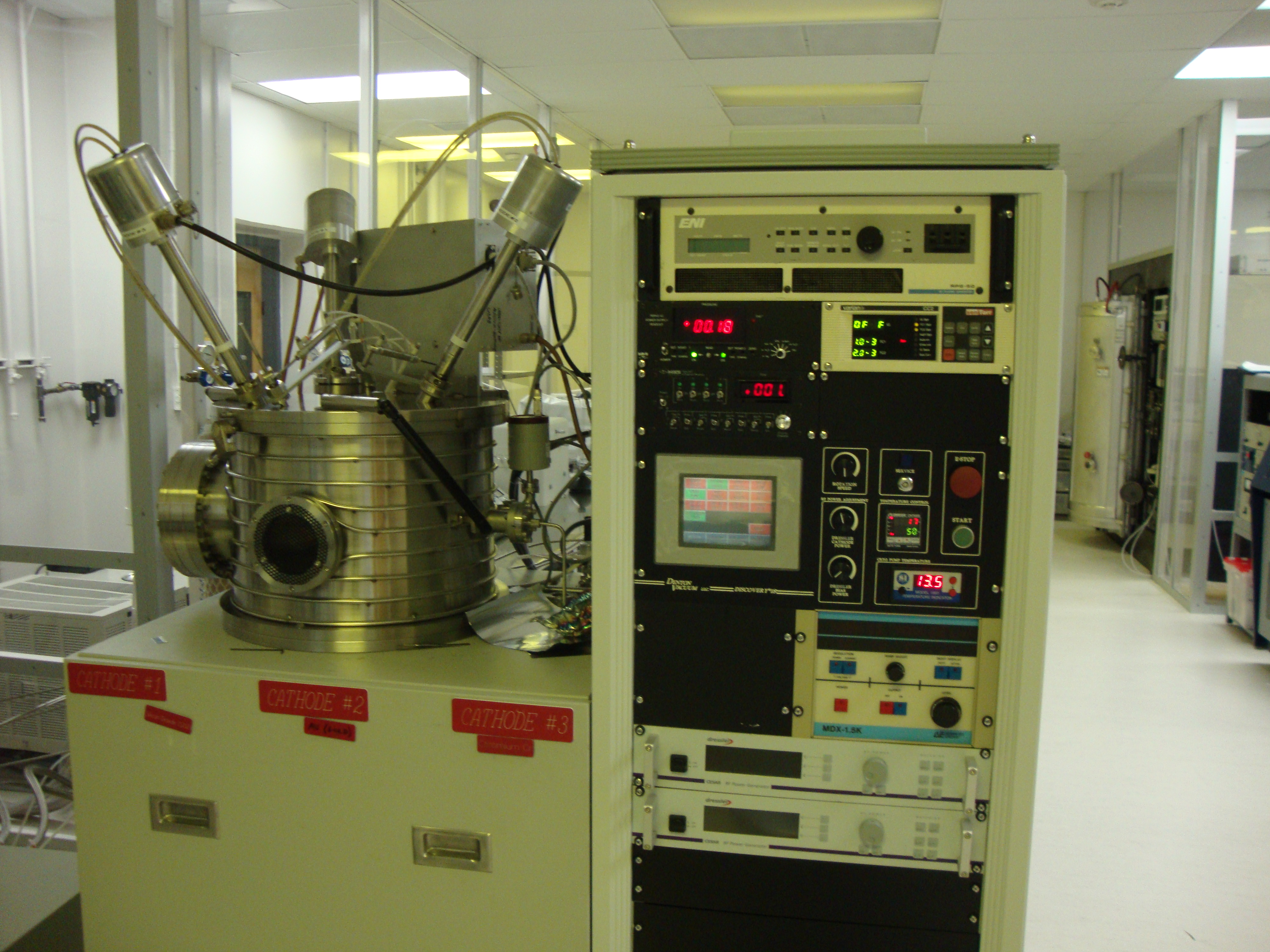

Film deposition

Sputter deposition is a method of depositingthin film

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

s by sputtering that involves eroding material from a "target" source onto a "substrate", e.g. a silicon wafer, solar cell, optical component, or many other possibilities. Resputtering, in contrast, involves re-emission of the deposited material, e.g. SiO2 during the deposition also by ion bombardment.

Sputtered atoms are ejected into the gas phase but are not in their thermodynamic equilibrium

Thermodynamic equilibrium is a notion of thermodynamics with axiomatic status referring to an internal state of a single thermodynamic system, or a relation between several thermodynamic systems connected by more or less permeable or impermeable ...

state, and tend to deposit on all surfaces in the vacuum chamber. A substrate (such as a wafer) placed in the chamber will be coated with a thin film. Sputtering deposition usually uses an argon

Argon is a chemical element; it has symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice as abu ...

plasma because argon, a noble gas, will not react with the target material.

Sputter damage

Sputter damage is usually defined during transparent electrode deposition on optoelectronic devices, which is usually originated from the substrate's bombardment by highly energetic species. The main species involved in the process and the representative energies can be listed as (values taken from): * Sputtered atoms (ions) from the target surface (~10 eV), the formation of which mainly depends on the binding energy of the target material; * Negative ions (originating from the carrier gas) formed in the plasma (~5–15 eV), the formation of which mainly depends on the plasma potential; * Negative ions formed at the target surface (up to 400 eV), the formation of which mainly depends on the target voltage; * Positive ions formed in the plasma (~15 eV), the formation of which mainly depends on the potential fall in front of a substrate at floating potential; * Reflected atoms and neutralized ions from the target surface (20–50 eV), the formation of which mainly depends on the background gas and the mass of the sputtered element. As seen in the list above, negative ions (e.g., O− and In− for ITO sputtering) formed at the target surface and accelerated toward the substrate acquire the largest energy, which is determined by the potential between target and plasma potentials. Although the flux of the energetic particles is an important parameter, high-energy negative O− ions are additionally the most abundant species in plasma in case of reactive deposition of oxides. However, energies of other ions/atoms (e.g., Ar+, Ar0, or In0) in the discharge may already be sufficient to dissociate surface bonds or etch soft layers in certain device technologies. In addition, the momentum transfer of high-energy particles from the plasma (Ar, oxygen ions) or sputtered from the target might impinge or even increase the substrate temperature sufficiently to trigger physical (e.g., etching) or thermal degradation of sensitive substrate layers (e.g. thin film metal halide perovskites). This can affect the functional properties of underlying charge transport and passivation layers and photoactive absorbers or emitters, eroding device performance. For instance, due to sputter damage, there may be inevitable interfacial consequences such as pinning of the Fermi level, caused by damage-related interface gap states, resulting in the formation of Schottky-barrier impeding carrier transport. Sputter damage can also impair the doping efficiency of materials and the lifetime of excess charge carriers in photoactive materials; in some cases, depending on its extent, such damage can even lead to a reduced shunt resistance.Etching

In the semiconductor industry sputtering is used to etch the target. Sputter etching is chosen in cases where a high degree of etchinganisotropy

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit ve ...

is needed and selectivity is not a concern. One major drawback of this technique is wafer damage and high voltage use.

For analysis

Another application of sputtering is to etch away the target material. One such example occurs in secondary ion mass spectrometry (SIMS), where the target sample is sputtered at a constant rate. As the target is sputtered, the concentration and identity of sputtered atoms are measured usingmass spectrometry

Mass spectrometry (MS) is an analytical technique that is used to measure the mass-to-charge ratio of ions. The results are presented as a ''mass spectrum'', a plot of intensity as a function of the mass-to-charge ratio. Mass spectrometry is used ...

. In this way the composition of the target material can be determined and even extremely low concentrations (20 μg/kg) of impurities detected. Furthermore, because the sputtering continually etches deeper into the sample, concentration profiles as a function of depth can be measured.

In space

Sputtering is one of the forms of space weathering, a process that changes the physical and chemical properties of airless bodies, such as asteroids and theMoon

The Moon is Earth's only natural satellite. It Orbit of the Moon, orbits around Earth at Lunar distance, an average distance of (; about 30 times Earth diameter, Earth's diameter). The Moon rotation, rotates, with a rotation period (lunar ...

. On icy moons, especially Europa, sputtering of photolyzed water from the surface leads to net loss of hydrogen and accumulation of oxygen-rich materials that may be important for life. Sputtering is also one of the possible ways that Mars

Mars is the fourth planet from the Sun. It is also known as the "Red Planet", because of its orange-red appearance. Mars is a desert-like rocky planet with a tenuous carbon dioxide () atmosphere. At the average surface level the atmosph ...

has lost most of its atmosphere

An atmosphere () is a layer of gases that envelop an astronomical object, held in place by the gravity of the object. A planet retains an atmosphere when the gravity is great and the temperature of the atmosphere is low. A stellar atmosph ...

and that Mercury continually replenishes its tenuous surface-bounded exosphere

The exosphere is a thin, atmosphere-like volume surrounding a planet or natural satellite where molecules are gravitationally bound to that body, but where the density is so low that the molecules are essentially collision-less. In the case of ...

.

Optics

Due to its adaptability with a wide range of materials, Sputtering is used to create various types of coatings that enhance the performance of optical components. Anti-reflective coatings are applied to lenses and optical instruments to minimize light reflection and increase light transmission, which improves clarity and reduces glare. Sputtering is also used to deposit reflective coatings on mirrors, ensuring high reflectivity and durability for applications such astelescopes

A telescope is a device used to observe distant objects by their emission, Absorption (electromagnetic radiation), absorption, or Reflection (physics), reflection of electromagnetic radiation. Originally, it was an optical instrument using len ...

, cameras, and laser systems.

See also

*Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plas ...

References

External links

Thin Film Evaporation Guide

- an introduction with animations

Sputtering Basics - animated film of a sputtering process

Free molecular dynamics simulation program (Kalypso) capable of modeling sputtering

American Vacuum Society short courses

on thin film deposition * (The original paper on Kaufman sputter sources.) * {{Authority control Coatings Physical vapor deposition techniques Materials science Thin film deposition Surface science