Separator (electricity) on:

[Wikipedia]

[Google]

[Amazon]

A separator is a permeable

A separator is a permeable

Initially,

Initially,

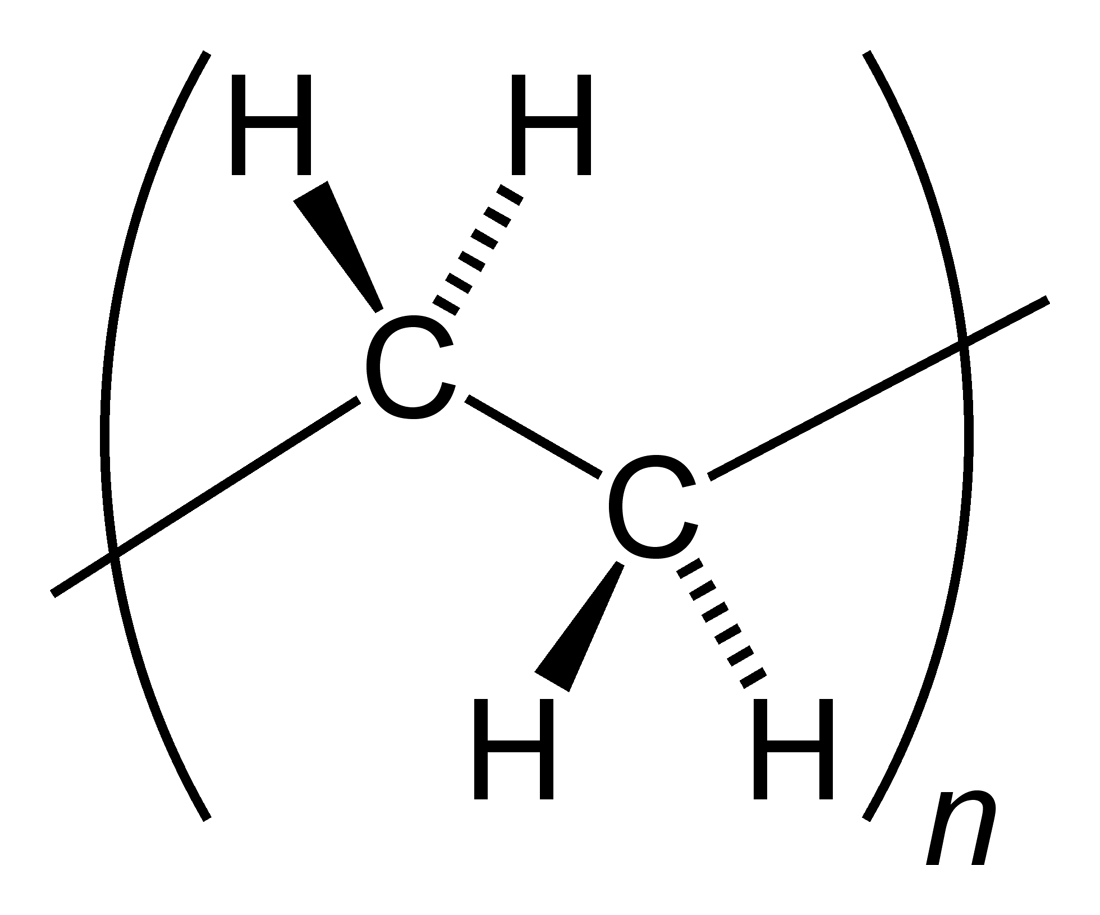

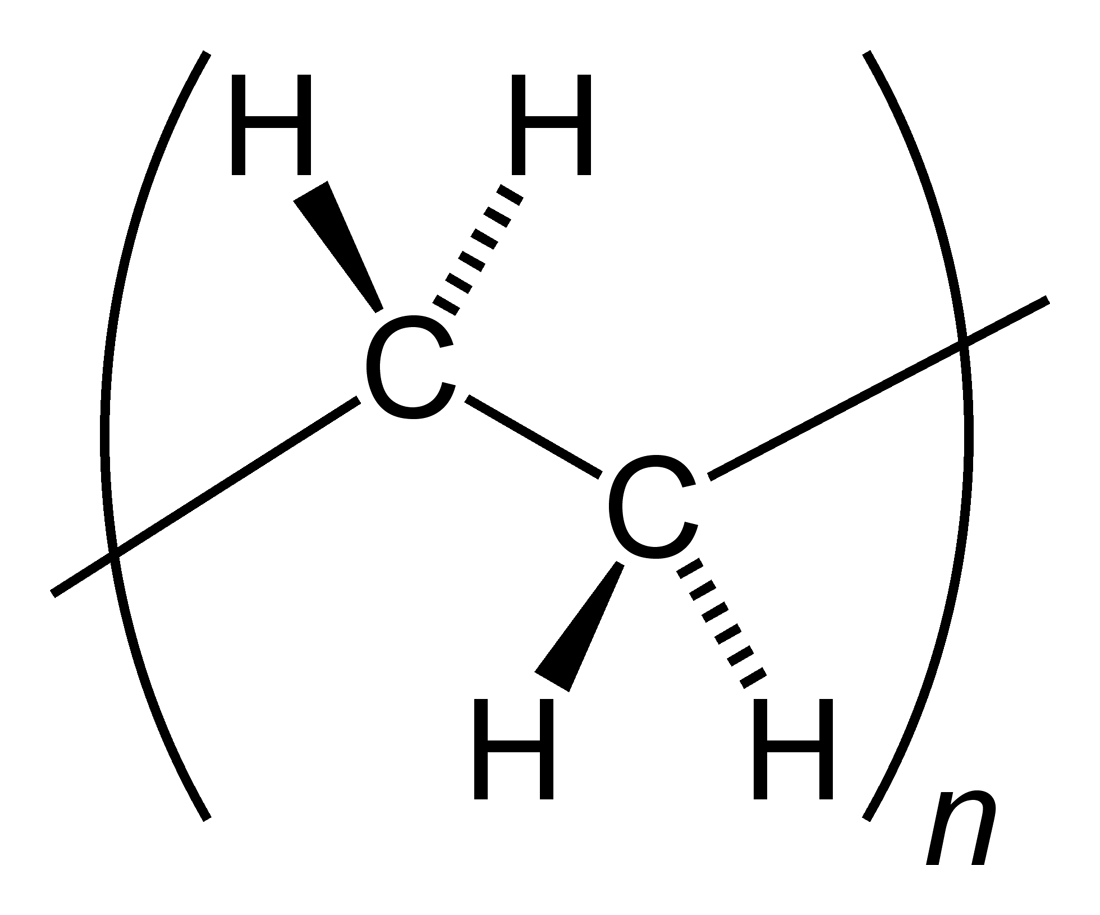

Specific types of polymers are ideal for the different types of synthesis. Most polymers currently used in battery separators are

Specific types of polymers are ideal for the different types of synthesis. Most polymers currently used in battery separators are

The separator is always placed between the anode and the cathode. The pores of the separator are filled with the electrolyte and packaged for use.

The separator is always placed between the anode and the cathode. The pores of the separator are filled with the electrolyte and packaged for use.

membrane

A membrane is a selective barrier; it allows some things to pass through but stops others. Such things may be molecules, ions, or other small particles. Membranes can be generally classified into synthetic membranes and biological membranes. Bi ...

placed between a battery's anode

An anode usually is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, which is usually an electrode of the device through which conventional current leaves the devic ...

and cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional curren ...

. The main function of a separator is to keep the two electrodes apart to prevent electrical short circuit

A short circuit (sometimes abbreviated to short or s/c) is an electrical circuit that allows a current to travel along an unintended path with no or very low electrical impedance. This results in an excessive current flowing through the circuit ...

s while also allowing the transport of ionic charge carrier

In solid state physics, a charge carrier is a particle or quasiparticle that is free to move, carrying an electric charge, especially the particles that carry electric charges in electrical conductors. Examples are electrons, ions and holes. ...

s that are needed to close the circuit during the passage of current

Currents, Current or The Current may refer to:

Science and technology

* Current (fluid), the flow of a liquid or a gas

** Air current, a flow of air

** Ocean current, a current in the ocean

*** Rip current, a kind of water current

** Current (hydr ...

in an electrochemical cell

An electrochemical cell is a device that either generates electrical energy from chemical reactions in a so called galvanic cell, galvanic or voltaic cell, or induces chemical reactions (electrolysis) by applying external electrical energy in an ...

.

Separators are critical components in liquid electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

batteries. A separator generally consists of a polymeric membrane

A polymer () is a substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeating subunits derived from one or more species of monomers. Due to their broad spectrum of properties, both ...

forming a microporous layer. It must be chemically and electrochemically stable with regard to the electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

and electrode materials and mechanically strong enough to withstand the high tension during battery construction. They are important to batteries because their structure and properties considerably affect the battery performance, including the batteries energy and power densities, cycle life, and safety.

History

Unlike many forms of technology, polymer separators were not developed specifically for batteries. They were instead spin-offs of existing technologies, which is why most are not optimized for the systems they are used in. Even though this may seem unfavorable, most polymer separators can be mass-produced at a low cost, because they are based on existing forms of technologies. Yoshino and co-workers atAsahi Kasei

is a multinational Japanese chemical company. Its main products are chemicals and materials.

It was founded in May 1931, using the paid-in capital of Nobeoka Ammonia Fiber Co., Ltd, a Nobeoka, Miyazaki-based producer of ammonia, nitric acid ...

first developed them for a prototype of secondary lithium-ion batteries

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li+ ions into electronically conducting solids to store energy. Li-ion batteries are characterized by higher specific energy, energy ...

(LIBs) in 1983.

Initially,

Initially, lithium cobalt oxide

Lithium cobalt oxide, sometimes called lithium cobaltateA. L. Emelina, M. A. Bykov, M. L. Kovba, B. M. Senyavin, E. V. Golubina (2011), "Thermochemical properties of lithium cobaltate". ''Russian Journal of Physical Chemistry'', volume 85, issue ...

was used as the cathode and polyacetylene

Polyacetylene (IUPAC name: polyethyne) usually refers to an organic polymer with the repeating unit . The name refers to its conceptual construction from polymerization of acetylene to give a chain with repeating olefin groups. This compound is ...

as the anode. Later in 1985, it was found that using lithium cobalt oxide

Lithium cobalt oxide, sometimes called lithium cobaltateA. L. Emelina, M. A. Bykov, M. L. Kovba, B. M. Senyavin, E. V. Golubina (2011), "Thermochemical properties of lithium cobaltate". ''Russian Journal of Physical Chemistry'', volume 85, issue ...

as the cathode and graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

as the anode produced an excellent secondary battery with enhanced stability, employing the frontier electron theory of Kenichi Fukui. This enabled the development of portable devices, such as cell phones and laptops. However, before lithium-ion batteries

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li+ ions into electronically conducting solids to store energy. Li-ion batteries are characterized by higher specific energy, energy ...

could be mass-produced, safety concerns needed to be addressed such as overheating and over potential. One key to ensuring safety was the separator between the cathode and anode. Yoshino developed a microporous polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bott ...

membrane separator with a “fuse” function. In the case of abnormal heat generation within the battery cell, the separator provides a shutdown mechanism. The micropores close by melting and the ionic flow terminates. In 2004, a novel electroactive polymer separator with the function of overcharge protection was first proposed by Denton and coauthors. This kind of separator reversibly switches between insulating and conducting states. Changes in charge potential drive the switch. More recently, separators primarily provide charge transport and electrode separation.

Materials

Materials include nonwoven fibers (cotton

Cotton (), first recorded in ancient India, is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure ...

, nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups.

Nylons are generally brownish in color and can possess a soft texture, with some varieti ...

, polyester

Polyester is a category of polymers that contain one or two ester linkages in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include some natura ...

s, glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

), polymer films (polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bott ...

, polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene.

Polypropylene belongs to the group of polyolefin ...

, poly (tetrafluoroethylene

Tetrafluoroethylene (TFE) is a fluorocarbon with the chemical formula . It is a colorless gas. Its structure is . It is used primarily in the industrial preparation of fluoropolymers. It is the simplest perfluorinated alkene.

It was first repor ...

), polyvinyl chloride

Polyvinyl chloride (alternatively: poly(vinyl chloride), colloquial: vinyl or polyvinyl; abbreviated: PVC) is the world's third-most widely produced synthetic polymer of plastic (after polyethylene and polypropylene). About 40 million tons of ...

), ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

and naturally occurring substances (rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds.

Types of polyisoprene ...

, asbestos

Asbestos ( ) is a group of naturally occurring, Toxicity, toxic, carcinogenic and fibrous silicate minerals. There are six types, all of which are composed of long and thin fibrous Crystal habit, crystals, each fibre (particulate with length su ...

, wood

Wood is a structural tissue/material found as xylem in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulosic fibers that are strong in tension and embedded in a matrix of lignin t ...

). Some separators employ polymeric materials with pores of less than 20 Å, generally too small for batteries. Both dry and wet processes are used for fabrication.

Nonwovens consist of a manufactured sheet, web or mat of directionally or randomly oriented fibers.

Supported liquid membranes consist of a solid and liquid phase contained within a microporous separator.

Some polymer electrolytes form complexes with alkali metal

The alkali metals consist of the chemical elements lithium (Li), sodium (Na), potassium (K),The symbols Na and K for sodium and potassium are derived from their Latin names, ''natrium'' and ''kalium''; these are still the origins of the names ...

salts, which produce ionic conductors that serve as solid electrolytes.

Solid ion conductors, can serve as both separator and the electrolyte.

Separators can use a single or multiple layers/sheets of material.

Production

Polymer separators generally are made from microporous polymer membranes. Such membranes are typically fabricated from a variety of inorganic, organic and naturally occurring materials. Pore sizes are typically larger than 50–100 Å. Dry and wet processes are the most common separation production methods for polymeric membranes. The extrusion and stretching portions of these processes induce porosity and can serve as a means of mechanical strengthening. Membranes synthesized by dry processes are more suitable for higher power density, given their open and uniform pore structure, while those made by wet processes are offer more charge/discharge cycles because of their tortuous and interconnected pore structure. This helps to suppress the conversion of charge carriers into crystals on anodes during fast or low temperature charging.Dry process

The dry process involves extruding, annealing and stretching steps. The final porosity depends on the morphology of the precursor film and the specifics of each step. The extruding step is generally carried out at a temperature higher than themelting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state of matter, state from solid to liquid. At the melting point the solid and liquid phase (matter), phase exist in Thermodynamic equilib ...

of the polymer resin. This is because the resins are melted to shape them into a uniaxially-oriented tubular film, called a precursor film. The structure and orientation of the precursor film depends on the processing conditions and the resin's characteristics. In the annealing process, the precursor is annealed at a temperature slightly lower than the polymer's melting point. The purpose of this step is to improve the crystalline structure. During stretching, the annealed film is deformed along the machine direction by a cold stretch followed by a hot stretch followed by relaxation. The cold stretch creates the pore structure

Pore structure is a common term employed to characterize the porosity, pore size, pore size distribution, and pore morphology (such as pore shape, surface roughness, and tortuosity of pore channels) of a porous medium. Pores are the openings in t ...

by stretching the film at a lower temperature with a faster strain rate. The hot stretch increases pore sizes using a higher temperature and a slower strain rate. The relaxation step reduces internal stress within the film.

The dry process is only suitable for polymers with high crystallinity

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a large influence on hardness, density, transparency and diffusi ...

. These include but are not limited to: semi-crystalline polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More speciali ...

s, polyoxymethylene

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. Short-chained POM (chain length ...

, and isotactic

Tacticity (from , "relating to arrangement or order") is the relative stereochemistry of adjacent chiral centers within a macromolecule. The practical significance of tacticity rests on the effects on the physical properties of the polymer. The ...

poly (4-methyl-1-pentene). One can also use blends of immiscible polymers, in which at least one polymer has a crystalline structure, such as polyethylene-polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene.

Polypropylene belongs to the group of polyolefin ...

, polystyrene-polypropylene, and poly (ethylene

Ethylene (IUPAC name: ethene) is a hydrocarbon which has the formula or . It is a colourless, flammable gas with a faint "sweet and musky" odour when pure. It is the simplest alkene (a hydrocarbon with carbon–carbon bond, carbon–carbon doub ...

terephthalate) - polypropylene blends.

Dry Microstructure

After processing, separators formed from the dry process possess a porous microstructure. While specific processing parameters (such as temperature and rolling speed) influence the final microstructure, generally, these separators have elongated, slit-like pores and thin fibrils that run parallel to the machine direction. These fibrils connect larger regions of semi-crystalline polymer, which run perpendicular to the machine direction.Wet process

The wet process consists of mixing, heating, extruding, stretching and additive removal steps. The polymer resins are first mixed with, paraffin oil,antioxidant

Antioxidants are Chemical compound, compounds that inhibit Redox, oxidation, a chemical reaction that can produce Radical (chemistry), free radicals. Autoxidation leads to degradation of organic compounds, including living matter. Antioxidants ...

and other additives. The mixture is heated to produce a homogenous solution. The heated solution is pushed through a sheet die to make a gel-like film. The additives are then removed with a volatile solvent to form the microporous result. This microporous result can then be stretched uniaxially (along the machine direction) or biaxially (along both the machine and transverse directions, providing further pore definition.

The wet process is suitable for both crystalline and amorphous polymers. Wet process separators often use ultrahigh-molecular-weight polyethylene. The use of these polymers enables the batteries with favorable mechanical properties, while shutting it down when it becomes too hot.

Wet Microstructure

When subjected to biaxial stretching, separators formed from the wet process have rounded pores. These pores are dispersed throughout an interconnected polymer matrix.Choice of polymer

Specific types of polymers are ideal for the different types of synthesis. Most polymers currently used in battery separators are

Specific types of polymers are ideal for the different types of synthesis. Most polymers currently used in battery separators are polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More speciali ...

based materials with semi-crystalline

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a large influence on hardness, density, transparency and diffusi ...

structure. Among them, polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bott ...

, polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene.

Polypropylene belongs to the group of polyolefin ...

, PVC, and their blends such as polyethylene-polypropylene are widely used. Recently, graft polymers have been studied in an attempt to improve battery performance, including micro-porous poly(methyl methacrylate

Methyl methacrylate (MMA) is an organic compound with the formula . This colorless liquid, the methyl ester of methacrylic acid (MAA), is a monomer produced on a large scale for the production of poly(methyl methacrylate) (PMMA).

History

MMA ...

)-grafted and siloxane

In organosilicon chemistry, a siloxane is an organic compound containing a functional group of two silicon atoms bound to an oxygen atom: . The parent siloxanes include the oligomeric and polymeric hydrides with the formulae and . Siloxanes ...

grafted polyethylene separators, which show favorable surface morphology and electrochemical properties compared to conventional polyethylene separators. In addition, polyvinylidene fluoride

Polyvinylidene fluoride or polyvinylidene difluoride (PVDF) is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride. Its chemical formula is (C2H2F2)''n''.

PVDF is a specialty plastic use ...

(PVDF) nanofiber webs can be synthesized as a separator to improve both ion conductivity and dimensional stability. Another type of polymer separator, polytriphenylamine (PTPAn)-modified separator, is an electroactive separator with reversible overcharge protection.

Placement

The separator is always placed between the anode and the cathode. The pores of the separator are filled with the electrolyte and packaged for use.

The separator is always placed between the anode and the cathode. The pores of the separator are filled with the electrolyte and packaged for use.

Essential properties

; Chemical stability: The separator material must be chemically stable against the electrolyte and electrode materials under the strongly reactive environments when the battery is fully charged. The separator should not degrade. Stability is assessed by use testing. ; Thickness: A battery separator must be thin to facilitate the battery'senergy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

and power densities. A separator that is too thin can compromise mechanical strength and safety. Thickness should be uniform to support many charging cycles. 25.4 μm (1.0 mil) is generally the standard width. The thickness of a polymer separator can be measured using the T411 om-83 method developed under the auspices of the Technical Association of the Pulp and Paper Industry.

; Porosity: The separator must have sufficient pore density to hold liquid electrolyte that enables ions to move between the electrodes. Excessive porosity hinders the ability of the pores to close, which is vital to allow the separator to shut down an overheated battery. Porosity can be measured using liquid or gas absorption methods according to the American Society for Testing and Materials (ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

) D-2873. Typically, a Li-ion battery separator provides porosity of 40%.

; Pore size: Pore size must be smaller than the particle size of the electrode components, including the active materials and conducting additives. Ideally the pores should be uniformly distributed while also having a tortuous structure. This ensures a uniform current distribution throughout the separator while suppressing the growth of Li on the anode. The distribution and structure of pores can be analyzed using a Capillary Flow Porometer or a Scanning Electron Microscope

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that ...

.

; Permeability: The separator must not limit performance. Polymer separators typically increase the resistance of the electrolyte by a factor of four to five. The ratio of the resistance of the electrolyte-filled separator to the resistance of the electrolyte alone is called the MacMullin number. Air permeability

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

* A fiber, a single filament of natural material, such as cotton, linen or wool, or artificial material such as nylon, polyester, metal or mineral fiber, or huma ...

can be used indirectly to estimate the MacMullin number. Air permeability is expressed in terms of the Gurley value, the time required for a specified amount of air to pass through a specified area of the separator under a specified pressure. The Gurley value reflects the tortuosity of the pores, when the porosity and thickness of the separator is fixed. A separator with uniform porosity is vital to battery life cycle. Deviations from uniform permeability produce uneven current density distribution, which causes the formation of crystals on the anode.

; Mechanical strength: There are multiple factors that contribute to the overall mechanical profile of a separator.

; Tensile strength

: The separator must be strong enough to withstand the tension of the winding operation during battery assembly. Additionally, the separator must not change dimensions from a tensile stress, or the cathode and anode could come into contact, shorting the battery. Tensile strength is typically defined in both the machine (winding) direction and the transverse direction, in terms of Young’s modulus. Large Young’s moduli in the machine direction provide dimensional stability, as strain is inversely proportional to strength.: Tensile strength is highly dependent on separator processing and final microstructure. Dry processed separators have anisotropic strength profiles, having the greatest strength in the machine direction, due to the orientation of the fibrils that form via a crazing mechanism during processing. Wet processed separators have a more isotropic strength profile, having comparable values in both machine and transverse directions.

; Puncture strength

:To prevent electrical shorting (battery failure), the separator must not yield to stresses applied by particles or structures on its surface. Puncture strength is defined as applied force needed to force a probe through the separator.

; Wettability: The electrolyte must fill the entire battery assembly, requiring the separator to "wet" easily with the electrolyte. Furthermore, the electrolyte should be able to permanently wet the separator, preserving the cycle life. There is no generally accepted method used to test wettability

Wetting is the ability of a liquid to displace gas to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. These interactions occur in the presence of either a gaseous phase or an ...

, other than observation.

; Thermal stability: The separator must remain stable over a wide temperature range without curling or puckering, laying completely flat.

; Thermal shutdown: Separators in lithium-ion batteries must offer the ability to shut down at a temperature slightly lower than that at which thermal runaway

Thermal runaway describes a process that is accelerated by increased temperature, in turn releasing Thermal energy, energy that further increases temperature. Thermal runaway occurs in situations where an increase in temperature changes the cond ...

occurs, while retaining its mechanical properties.

Defects

Many structural defects can form in polymer separators due to temperature changes. These structural defects can result in a thicker separators. Furthermore, there can be intrinsic defects in the polymers themselves, such as polyethylene often begins to deteriorate during the stages of polymerization, transportation, and storage. Additionally, defects such as tears or holes can form during the synthesis of polymer separators. There are also other sources of defects can come from doping the polymer separator.Use in Li-ion Batteries

Polymer separators, similar to battery separators in general, act as a separator of the anode and cathode in the Li-ion battery while also enabling the movement of ions through the cell. Additionally, many of the polymer separators, typically multilayer polymer separators, can act as “shutdown separators”, which are able to shut down the battery if it becomes too hot during the cycling process. These multilayered polymer separators are generally composed of one or more polyethylene layers which serve to shut down the battery and at least one polypropylene layer which acts as a form of mechanical support for the separator. Separators are also subjected to numerous stresses during battery assembly and battery usage. Common stresses include tensile stresses from dry/wet processes and compressive stresses from the volumetric expansion of electrodes and required forces to ensure sufficient contact between components. Dendritic lithium growths are another common source of stress. These stresses are often applied concurrently, creating a complex stress field that separators must withstand. Additionally, standard battery operation leads to the cyclic application of these stresses. These cyclic conditions can mechanically fatigue separators, which reduces strength, leading to eventual device failure.Other types of battery separators

In addition to polymer separators, there are several other types of separators. There are nonwovens, which consist of a manufactured sheet, web, or mat of directionally or randomly oriented fibers. Supported liquid membranes, which consist of a solid and liquid phase contained within a microporous separator. Additionally there are also polymer electrolytes which can form complexes with different types of alkali metal salts, which results in the production of ionic conductors which serve as solid electrolytes. Another type of separator, a solid ion conductor, can serve as both a separator and the electrolyte in a battery. Plasma technology was used to modify a polyethylene membrane for enhanced adhesion, wettability and printability. These are usually performed by modifying the membrane on only its outermost several molecular levels. This allows the surface to behave differently without modifying the properties of the remainder. The surface was modified withacrylonitrile

Acrylonitrile is an organic compound with the formula and the structure . It is a colorless, volatile liquid. It has a pungent odor of garlic or onions. Its molecular structure consists of a vinyl group () linked to a nitrile (). It is an im ...

via a plasma coating technique. The resulting acrylonitrile-coated membrane was named PiAn-PE. The surface characterization demonstrated that PiAN-PE's enhanced adhesion resulted from the increased polar component of surface energy.

The sealed rechargeable nickel–metal hydride battery

A nickel–metal hydride battery (NiMH or Ni–MH) is a type of rechargeable battery. The chemical reaction at the positive electrode is similar to that of the nickel–cadmium cell (NiCd), with both using nickel oxide hydroxide (NiOOH). Ho ...

offers significant performance and environmental friendliness above alkaline rechargeable batteries. Ni/MH, like the lithium-ion battery, provides high energy and power density with long cycle lives. This technology's greatest problem is its inherent high corrosion rate in aqueous solutions. The most commonly used separators are porous insulator films of polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More speciali ...

, nylon or cellophane. Acrylic compounds can be radiation-grafted onto these separators to make their properties more wettable and permeable. Zhijiang Cai and co-workers developed a solid polymer membrane gel separator. This was a polymerization product of one or more monomer

A monomer ( ; ''mono-'', "one" + '' -mer'', "part") is a molecule that can react together with other monomer molecules to form a larger polymer chain or two- or three-dimensional network in a process called polymerization.

Classification

Chemis ...

s selected from the group of water-soluble

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

The extent of the solub ...

ethylenically unsaturated amide

In organic chemistry, an amide, also known as an organic amide or a carboxamide, is a chemical compound, compound with the general formula , where R, R', and R″ represent any group, typically organyl functional group, groups or hydrogen at ...

s and acid. The polymer-based gel also includes a water swellable polymer, which acts as a reinforcing element. Ionic species are added to the solution and remain embedded in the gel after polymerization.

Ni/MH batteries of bipolar design (bipolar batteries) are being developed because they offer some advantages for applications as storage systems for electric vehicles. This solid polymer membrane gel separator could be useful for such applications in bipolar design. In other words, this design can help to avoid short-circuits occurring in liquid-electrolyte systems.

Inorganic polymer separators have also been of interest as use in lithium-ion batteries. Inorganic particulate film/poly(methyl methacrylate) (PMMA)

Poly(methyl methacrylate) (PMMA) is a list of synthetic polymers, synthetic polymer derived from methyl methacrylate. It is a transparency (optics), transparent thermoplastic, used as an engineering plastic. PMMA is also known as acrylic, acryl ...

/inorganic particulate film trilayer separators are prepared by dip-coating

Dip coating is an industrial coating process which is used, for example, to manufacture bulk products such as coated fabrics and condoms and specialised coatings for example in the biomedical field. Dip coating is also commonly used in academic ...

inorganic particle layers on both sides of PMMA thin films. This inorganic trilayer membrane is believed to be an inexpensive, novel separator for application in lithium-ion batteries from increased dimensional and thermal stability.

References

{{reflist, 30em Electric battery Polymers Membrane technology