Seiton on:

[Wikipedia]

[Google]

[Amazon]

5S (Five S) is a workplace organization method that uses a list of five

5S (Five S) is a workplace organization method that uses a list of five

Rudra Sil, Publisher: Ann Arbor, Mich. : University of Michigan Press, 2002

is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

* Reduce time loss looking for an item by reducing the number of unnecessary items.

* Reduce the chance of distraction by unnecessary items.

* Simplify inspection.

* Increase the amount of available, useful space.

* Increase safety by eliminating obstacles.

Implementation:

* Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

* Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

* Keep the working floor clear of materials except for those that are in use for production.

is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

* Reduce time loss looking for an item by reducing the number of unnecessary items.

* Reduce the chance of distraction by unnecessary items.

* Simplify inspection.

* Increase the amount of available, useful space.

* Increase safety by eliminating obstacles.

Implementation:

* Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

* Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

* Keep the working floor clear of materials except for those that are in use for production.

is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Goals:

* Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

* Keep the workplace safe and easy to work in.

* Keep the workplace clean and pleasing to work in.

* When in place, anyone not familiar to the environment must be able to detect any problems within in 5 seconds.

Implementation:

* Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

* Inspect the workplace and equipment while cleaning.

is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Goals:

* Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

* Keep the workplace safe and easy to work in.

* Keep the workplace clean and pleasing to work in.

* When in place, anyone not familiar to the environment must be able to detect any problems within in 5 seconds.

Implementation:

* Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

* Inspect the workplace and equipment while cleaning.

Perform regular audits using 5s audit checklist to ensure that all defined standards are being implemented and followed.

* Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

Perform regular audits using 5s audit checklist to ensure that all defined standards are being implemented and followed.

* Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

5S (Five S) is a workplace organization method that uses a list of five

5S (Five S) is a workplace organization method that uses a list of five Japanese

Japanese may refer to:

* Something from or related to Japan, an island country in East Asia

* Japanese language, spoken mainly in Japan

* Japanese people, the ethnic group that identifies with Japan through ancestry or culture

** Japanese diaspor ...

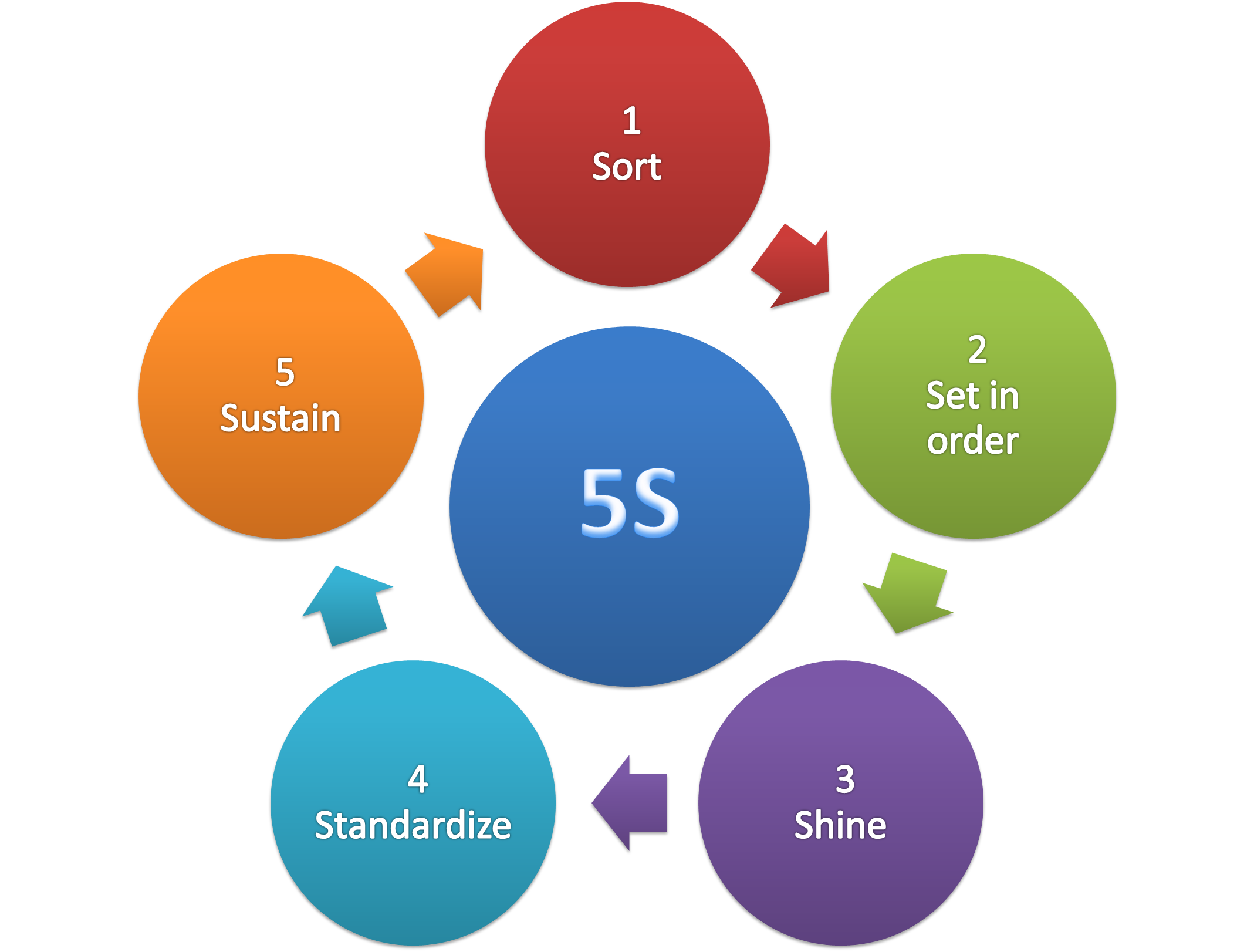

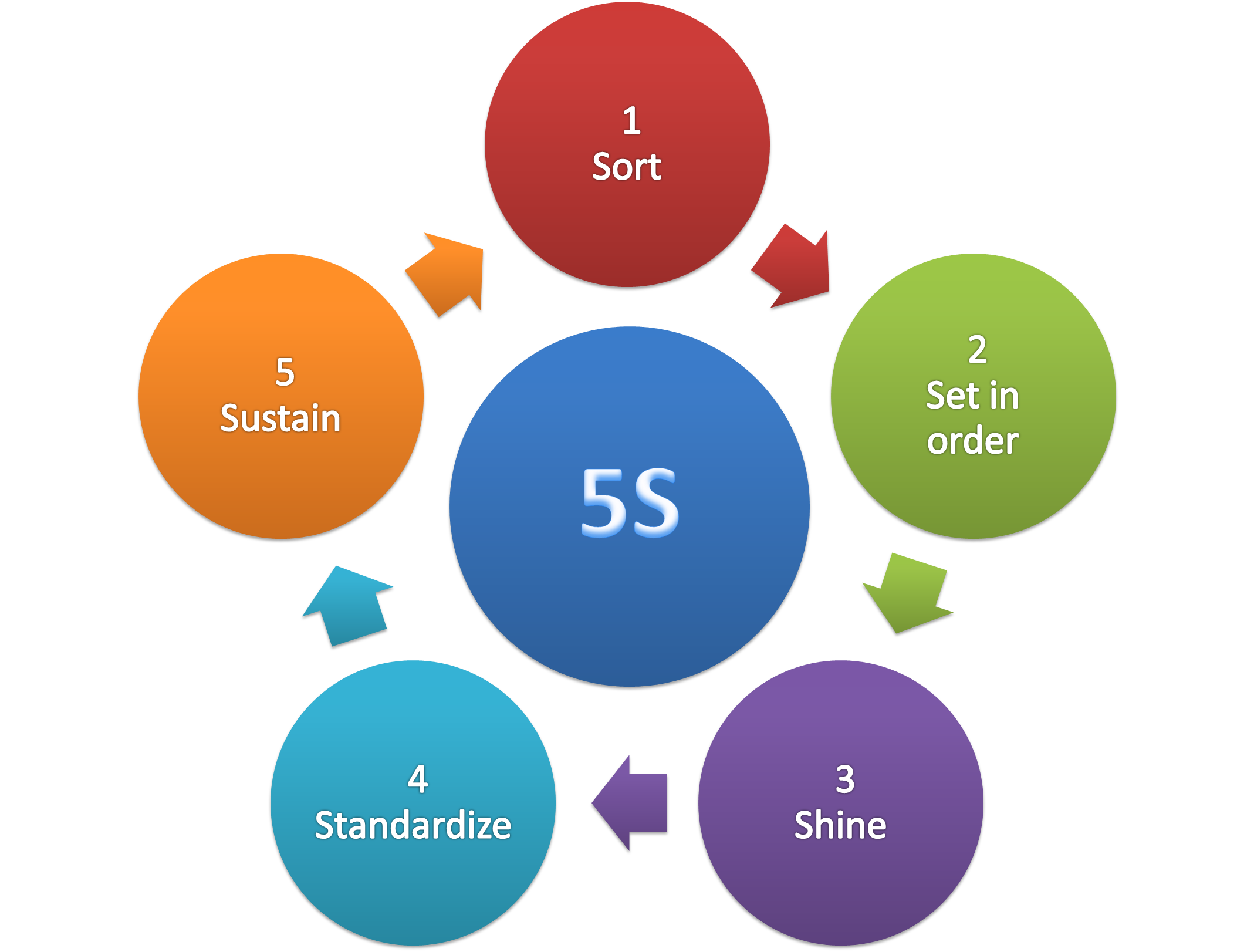

words: , , , , and . These have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. The list describes how to organize a work space for efficiency and effectiveness by identifying and sorting the items used, maintaining the area and items, and sustaining the new organizational system. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work.

In some organisations, 5S has become 6S, the sixth element being ''safety'' (''safe'').

Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as '' visual control'', '' visual workplace'', or ''visual factory''. Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For example, a workplace-organization photo from Tennant Company (a Minneapolis

Minneapolis is a city in Hennepin County, Minnesota, United States, and its county seat. With a population of 429,954 as of the 2020 United States census, 2020 census, it is the state's List of cities in Minnesota, most populous city. Locat ...

-based manufacturer) quite similar to the one accompanying this article appeared in a manufacturing-management book in 1986.

Origins

5S was developed in Japan and has been identified as one of the techniques that enabled just-in-time manufacturing. Two major frameworks for understanding and applying 5S to business environments have arisen, one proposed by Takahashi and Osada, the other by Hiroyuki Hirano. Hirano provided a structure to improve programs with a series of identifiable steps, each building on its predecessor. Before this Japanese management framework, a similar "scientific management" was proposed by Alexey Gastev and the USSR Central Institute of Labour (CIT) in Moscow.Managing «modernity»: work, community, and authority in late-industrializing Japan and RussiaRudra Sil, Publisher: Ann Arbor, Mich. : University of Michigan Press, 2002

Each ''S''

There are five 5S phases. They can be translated to English as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. Other translations are possible.Sort ( )

is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

* Reduce time loss looking for an item by reducing the number of unnecessary items.

* Reduce the chance of distraction by unnecessary items.

* Simplify inspection.

* Increase the amount of available, useful space.

* Increase safety by eliminating obstacles.

Implementation:

* Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

* Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

* Keep the working floor clear of materials except for those that are in use for production.

is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

* Reduce time loss looking for an item by reducing the number of unnecessary items.

* Reduce the chance of distraction by unnecessary items.

* Simplify inspection.

* Increase the amount of available, useful space.

* Increase safety by eliminating obstacles.

Implementation:

* Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

* Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

* Keep the working floor clear of materials except for those that are in use for production.

Set in order ( )

(Sometimes shown as ''Straighten'') is putting all necessary items in the optimal place for fulfilling their function in the workplace. Goal: * Make theworkflow

Workflow is a generic term for orchestrated and repeatable patterns of activity, enabled by the systematic organization of resources into processes that transform materials, provide services, or process information. It can be depicted as a seque ...

smooth and easy.

Implementation:

* Arrange work stations in such a way that all tooling/equipment is in close proximity, in an easy to reach spot and in a logical order adapted to the work performed. Place components according to their uses, with the frequently used components being nearest to the workplace.

* Arrange all necessary items so that they can be easily selected for use. Make it easy to find and pick up necessary items.

* Assign fixed locations for items. Use clear labels, marks or hints so that items are easy to return to the correct location and so that it is easy to spot missing items.

Shine ( )

is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Goals:

* Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

* Keep the workplace safe and easy to work in.

* Keep the workplace clean and pleasing to work in.

* When in place, anyone not familiar to the environment must be able to detect any problems within in 5 seconds.

Implementation:

* Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

* Inspect the workplace and equipment while cleaning.

is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Goals:

* Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

* Keep the workplace safe and easy to work in.

* Keep the workplace clean and pleasing to work in.

* When in place, anyone not familiar to the environment must be able to detect any problems within in 5 seconds.

Implementation:

* Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

* Inspect the workplace and equipment while cleaning.

Sustaining hygiene ( )

is to maintain hygiene and cleanliness. This is the actual translation. It was often misrepresented as "standardize" simply to suit the 5S acronym. The original concept had nothing to do with standardize or uniformity (To seek uniformity in a setting where the tasks are not uniform is simply absurd). Goal: * Establish procedures and schedules to ensure the cleanliness of workplace. Implementation: * Develop a work structure that will support the new practices and make it part of the daily routine. * Ensure everyone knows their responsibilities of performing the sorting, organizing and cleaning. * Use photos and visual controls to help keep everything as it should be. * Review the status of 5S implementation regularly using audit checklists.Sustain/self-discipline ( )

or sustain is the developed processes by self-discipline of the workers. Also translates as "do without being told". Goal: * Ensure that the 5S approach is followed. Implementation: * Organize training sessions. * Perform regular audits using 5s audit checklist to ensure that all defined standards are being implemented and followed.

* Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

Perform regular audits using 5s audit checklist to ensure that all defined standards are being implemented and followed.

* Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

6S

The 6S methodology represents an advanced form of the 5S methodology, incorporatingSafety

Safety is the state of being protected from harm or other danger. Safety can also refer to the control of recognized hazards in order to achieve an acceptable level of risk.

Meanings

The word 'safety' entered the English language in the 1 ...

as a key element. This change positions Safety at the forefront, stressing its critical role in operational settings. Safety's integration fundamentally alters the approach to organizing workplaces, ensuring that safety considerations are integral from the outset. The 6S model promotes a comprehensive strategy where safety and operational processes are interlinked and equally important. This adaptation underscores the importance of active hazard

A hazard is a potential source of harm. Substances, events, or circumstances can constitute hazards when their nature would potentially allow them to cause damage to health, life, property, or any other interest of value. The probability of that ...

prevention and a robust safety culture in improving overall workplace efficiency and employee health. To successfully implement the 6S Lean method in your workplace, organizations require:

# A deep understanding and prior experience with the 5S methodology.

# A mechanism for hazard identification and reporting.

# Industry-specific safety training for heightened safety awareness.

# A commitment to conduct regular discussions with employees about the principles and practices of 5S/6S.

# Endorsement and continuous support from senior management, including the allocation of necessary resources.

7S

The 7S methodology incorporates 6S safety, and adds a new element for oversight or spirit.Variety of applications

5S methodology has expanded from manufacturing and is now being applied to a wide variety of industries including health care, education, and government. Visual management and 5S can be particularly beneficial in health care because a frantic search for supplies to treat an in-trouble patient (a chronic problem in health care) can have dire consequences. Although the origins of the 5S methodology are in manufacturing, it can also be applied toknowledge economy

The knowledge economy, or knowledge-based economy, is an economic system in which the production of goods and services is based principally on knowledge-intensive activities that contribute to advancement in technical and scientific innovation. ...

work, with information, software, or media in the place of physical product.

In lean product and process development

The output of engineering and design in a lean enterprise is information, the theory behind using 5S here is "Dirty, cluttered, or damaged surfaces attract the eye, which spends a fraction of a second trying to pull useful information from them every time we glance past. Old equipment hides the new equipment from the eye and forces people to ask which to use".See also

*Japanese aesthetics

Japanese aesthetics comprise a set of ancient ideals that include '' wabi'' (transient and stark beauty), '' sabi'' (the beauty of natural patina and aging), and '' yūgen'' (profound grace and subtlety). These ideals, and others, underpin much of ...

*Just-in-time manufacturing

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufa ...

* Kaikaku

*Kaizen

is a Japanese concept in business studies which asserts that significant positive results may be achieved due the cumulative effect of many, often small (and even trivial), improvements to all aspects of a company's operations. Kaizen is put ...

*Kanban

Kanban ( meaning signboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The ...

*Lean manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is ...

* Muda

*'' Gogyo'' (traditional Japanese philosophy)

References

{{Authority control Methodology Japanese business terms Lean manufacturing Occupational safety and health