Pyrometers on:

[Wikipedia]

[Google]

[Amazon]

A pyrometer is a type of remote-sensing thermometer used to measure the temperature of distant objects. Various forms of pyrometers have historically existed. In the modern usage, it is a device that from a distance determines the temperature of a surface from the amount of the thermal radiation it emits, a process known as pyrometry and sometimes

The earliest example of a pyrometer thought to be in existence is th

The earliest example of a pyrometer thought to be in existence is th

Hindley Pyrometer

held by the London Science Museum, dating from 1752, produced for the Royal collection. The pyrometer was a well known enough instrument that it was described in some detail by the mathematician The first

The first

The tuyère pyrometer patent

Optical Pyrometer

{{Authority control Radiometry Thermometers Combustion Measuring instruments Metallurgical processes Infrared imaging English inventions 18th-century inventions

radiometry

Radiometry is a set of techniques for measurement, measuring electromagnetic radiation, including visible light. Radiometric techniques in optics characterize the distribution of the radiation's power (physics), power in space, as opposed to phot ...

.

The word pyrometer comes from the Greek word for fire, "πῦρ" (''pyr''), and ''meter'', meaning to measure. The word pyrometer was originally coined to denote a device capable of measuring the temperature of an object by its incandescence

Incandescence is the emission of electromagnetic radiation (including visible light) from a hot body as a result of its high temperature. The term derives from the Latin verb ''incandescere,'' to glow white. A common use of incandescence is ...

, visible light emitted by a body which is at least red-hot. Modern pyrometers or infrared thermometers also measure the temperature of cooler objects, down to room temperature, by detecting their infrared radiation flux.

Principle

It is based on the principle that the intensity of light received by the observer depends upon distance of observer from source and temperature of distant source. A modern pyrometer has an optical system and a detector. The optical system focuses the thermal radiation onto the detector. The output signal of the detector (temperature ''T'') is related to the thermal radiation orirradiance In radiometry, irradiance is the radiant flux ''received'' by a ''surface'' per unit area. The SI unit of irradiance is the watt per square metre (W⋅m−2). The CGS unit erg per square centimetre per second (erg⋅cm−2⋅s−1) is often used ...

of the target object through the Stefan–Boltzmann law, the constant of proportionality σ, called the Stefan–Boltzmann constant and the emissivity ε of the object.

:

This output is used to infer the object's temperature from a distance, with no need for the pyrometer to be in thermal contact with the object; most other thermometers (e.g. thermocouples and resistance temperature detectors (RTDs)) are placed in thermal contact with the object, and allowed to reach thermal equilibrium.

Pyrometry of gases presents difficulties. These are most commonly overcome by using thin filament pyrometry or soot pyrometry. Both techniques involve small solids in contact with hot gases.

History

The earliest example of a pyrometer thought to be in existence is th

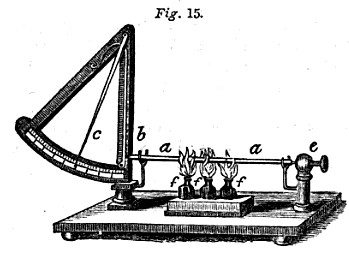

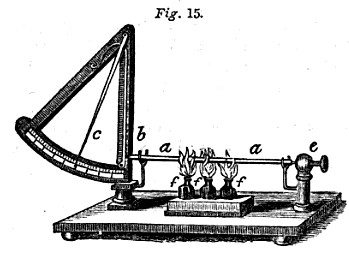

The earliest example of a pyrometer thought to be in existence is thHindley Pyrometer

held by the London Science Museum, dating from 1752, produced for the Royal collection. The pyrometer was a well known enough instrument that it was described in some detail by the mathematician

Euler

Leonhard Euler ( , ; 15 April 170718 September 1783) was a Swiss mathematician, physicist, astronomer, geographer, logician and engineer who founded the studies of graph theory and topology and made pioneering and influential discoveries in ma ...

in 1760.

The potter Josiah Wedgwood invented a different type of pyrometer to measure the temperature in his kilns, which first compared the color of clay fired at known temperatures, but was eventually upgraded to measuring the shrinkage of pieces of clay, which depended on kiln temperature. Later examples used the expansion of a metal bar.

In 1860s-1870s brothers William and Werner Siemens developed a platinum resistance thermometer, initially to measure temperature in undersea cables, but then adapted for measuring temperatures in metallurgy up to 1000 C, hence deserving a name of a pyrometer.

disappearing-filament pyrometer

The disappearing-filament pyrometer is an optical pyrometer, in which the temperature of a glowing incandescent object is measured by comparing it to the light of a heated filament. Invented independently in 1901 by Ludwig Holborn and Ferdinan ...

was built by L. Holborn and F. Kurlbaum in 1901. This device had a thin electrical filament between an observer's eye and an incandescent object. The current through the filament was adjusted until it was of the same colour (and hence temperature) as the object, and no longer visible; it was calibrated to allow temperature to be inferred from the current.

The temperature returned by the vanishing filament pyrometer and others of its kind, called brightness pyrometers, is dependent on the emissivity of the object. With greater use of brightness pyrometers, it became obvious that problems existed with relying on knowledge of the value of emissivity. Emissivity was found to change, often drastically, with surface roughness, bulk and surface composition, and even the temperature itself.

To get around these difficulties, the ratio or two-color pyrometer was developed. They rely on the fact that Planck's law

In physics, Planck's law describes the spectral density of electromagnetic radiation emitted by a black body in thermal equilibrium at a given temperature , when there is no net flow of matter or energy between the body and its environment.

At ...

, which relates temperature to the intensity of radiation emitted at individual wavelengths, can be solved for temperature if Planck's statement of the intensities at two different wavelengths is divided. This solution assumes that the emissivity is the same at both wavelengths and cancels out in the division. This is known as the gray body assumption. Ratio pyrometers are essentially two brightness pyrometers in a single instrument. The operational principles of the ratio pyrometers were developed in the 1920s and 1930s, and they were commercially available in 1939.

As the ratio pyrometer came into popular use, it was determined that many materials, of which metals are an example, do not have the same emissivity at two wavelengths.

For these materials, the emissivity does not cancel out and the temperature measurement is in error. The amount of error depends on the emissivities and the wavelengths where the measurements are taken. Two-color ratio pyrometers cannot measure whether a material's emissivity is wavelength dependent.

To more accurately measure the temperature of real objects with unknown or changing emissivities, multiwavelength pyrometers were envisioned at the US National Institute of Standards and Technology and described in 1992. Multiwavelength pyrometers use three or more wavelengths and mathematical manipulation of the results to attempt to achieve accurate temperature measurement even when the emissivity is unknown, changing, and different at all wavelengths.

Applications

file:Smelter-pyrometer.png, upright=2, A tuyère pyrometer. (1) Display. (2) Optical. (3) Fibre optic cable and periscope. (4) Pyrometer tuyère adapter having: i. Bustle pipe connection. ii. Tuyère clamp. iii. Clamp washer. iv. Clamp stud c/w and fastening hardware. v. Gasket. vi. Noranda tuyère silencer. vii. Valve seat. viii. Ball. (5) Pneumatic cylinder: i. Smart cylinder assembly with Internal proximity switch. ii. Guard plate assembly. iii. Temporary flange cover plate, used to cover periscope entry hole on tuyère adapter when no cylinder is installed on the tuyère. (6) Operator station panel. (7) Pyrometer light station. (8) Limit switches. (9) 4 conductor cab tire. (10) Ball Valve. (11) Periscope air pressure switch. (12) Bustle pipe air pressure switch. (13) Airline filter/regulator. (14) Directional control valve, sub-plate, silencer and speed control mufflers. (15) 2" nom. low pressure air hose, 40m length. Pyrometers are suited especially to the measurement of moving objects or any surfaces that cannot be reached or cannot be touched. Contemporary multispectral pyrometers are suitable for measuring high temperatures inside combustion chambers of gas turbine engines with high accuracy. Temperature is a fundamental parameter in metallurgical furnace operations. Reliable and continuous measurement of the metal temperature is essential for effective control of the operation. Smelting rates can be maximized,slag

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-prod ...

can be produced at the optimum temperature, fuel consumption is minimized and refractory life may also be lengthened. Thermocouples were the traditional devices used for this purpose, but they are unsuitable for continuous measurement because they melt and degrade.

Salt bath furnaces operate at temperatures up to 1300 °C and are used for heat treatment. At very high working temperatures with intense heat transfer between the molten salt and the steel being treated, precision is maintained by measuring the temperature of the molten salt. Most errors are caused by slag

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-prod ...

on the surface which is cooler than the salt bath.

The ''tuyère pyrometer'' is an optical instrument for temperature measurement through the tuyeres which are normally used for feeding air or reactants into the bath of the furnace.

A steam boiler may be fitted with a pyrometer to measure the steam temperature in the superheater

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming. There ar ...

.

A hot air balloon is equipped with a pyrometer for measuring the temperature at the top of the envelope in order to prevent overheating of the fabric.

Pyrometers may be fitted to experimental gas turbine engines to measure the surface temperature of turbine blades. Such pyrometers can be paired with a tachometer to tie the pyrometer output with the position of an individual turbine blade. Timing combined with a radial position encoder allows engineers to determine the temperature at exact points on blades moving past the probe.

See also

* Aethrioscope * Tasimeter * ThermographyReferences

External links

*The tuyère pyrometer patent

Optical Pyrometer

{{Authority control Radiometry Thermometers Combustion Measuring instruments Metallurgical processes Infrared imaging English inventions 18th-century inventions