odometry on:

[Wikipedia]

[Google]

[Amazon]

Odometry is the use of data from motion sensors to estimate change in position over time. It is used in

Odometry is the use of data from motion sensors to estimate change in position over time. It is used in

Odometry is the use of data from motion sensors to estimate change in position over time. It is used in

Odometry is the use of data from motion sensors to estimate change in position over time. It is used in robotics

Robotics is the interdisciplinary study and practice of the design, construction, operation, and use of robots.

Within mechanical engineering, robotics is the design and construction of the physical structures of robots, while in computer s ...

by some legged or wheeled robot

A robot is a machine—especially one Computer program, programmable by a computer—capable of carrying out a complex series of actions Automation, automatically. A robot can be guided by an external control device, or the robot control, co ...

s to estimate their position relative to a starting location. This method is sensitive to errors due to the integration of velocity measurements over time to give position estimates. Rapid and accurate data collection, instrument calibration

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known ...

, and processing are required in most cases for odometry to be used effectively.

The word ''odometry'' is composed of the Greek words ''odos'' (meaning "route") and ''metron'' (meaning "measure").

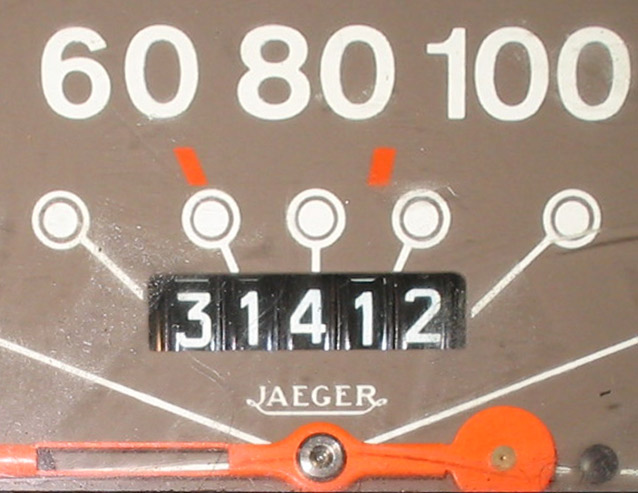

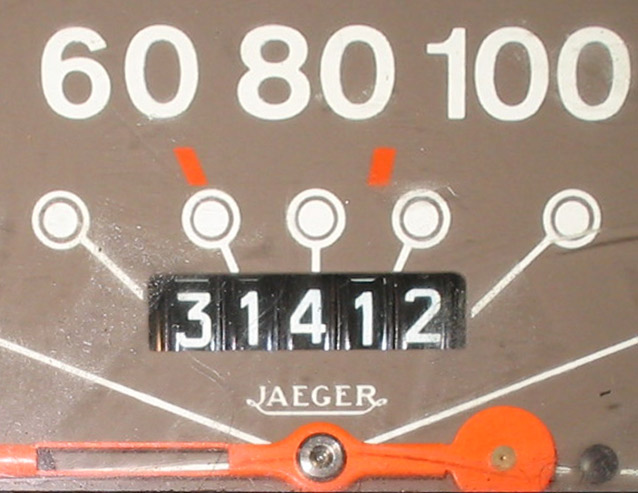

Example

Suppose a robot hasrotary encoder

A rotary encoder, also called a shaft encoder, is an electro-mechanical device that converts the angle, angular position or motion of a shaft or axle to Analog signal, analog or Digital signal, digital output signals.

There are two main types of ...

s on its wheels or on its legged joints. It drives forward for some time and then would like to know how far it has traveled. It can measure how far the wheels have rotated, and if it knows the circumference of its wheels, compute the distance.

Train operations are also frequent users of odometrics. Typically, a train gets an absolute position by passing over stationary sensors in the tracks, while odometry is used to calculate relative position while the train is between the sensors.

More sophisticated example

Suppose a simple robot has two wheels, both capable of moving forward or in reverse, positioned parallel to each other and equidistant from the robot's center. Additionally, each motor has a rotary encoder, allowing determination of whether either wheel has traveled one "unit" forward or reverse along the floor. This unit is defined as the ratio of the wheel's circumference to the encoder's resolution. If the left wheel were to move forward one unit while the right wheel remained stationary, then the right wheel acts as a pivot, and the left wheel traces a circular arc in the clockwise direction. Since one's unit of distance is usually tiny, one can approximate by assuming that this arc is a line. Thus, the original position of the left wheel, the final position of the left wheel, and the position of the right wheel form a triangle, which one can call ''A''. Also, the original position of the center, the final position of the center, and the position of the right wheel form a triangle which one can call ''B''. Since the center of the robot is equidistant to either wheel, and as they share the angle formed at the right wheel, triangles ''A'' and ''B'' are similar triangles. In this situation, the magnitude of the change of position of the center of the robot is one half of a unit. The angle of this change can be determined using thelaw of sines

In trigonometry, the law of sines (sometimes called the sine formula or sine rule) is a mathematical equation relating the lengths of the sides of any triangle to the sines of its angles. According to the law,

\frac \,=\, \frac \,=\, \frac \,=\ ...

.

See also

*Dead reckoning

In navigation, dead reckoning is the process of calculating the current position of a moving object by using a previously determined position, or fix, and incorporating estimates of speed, heading (or direction or course), and elapsed time. T ...

* Visual odometry

External links

* {{Authority control Robot control