Metalworkers on:

[Wikipedia]

[Google]

[Amazon]

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft,

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft,

By the historical periods of the Pharaohs in Egypt, the Vedic Kings in India, the

By the historical periods of the Pharaohs in Egypt, the Vedic Kings in India, the

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools.

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools.Mechanics of metal cutting.

mechanicalsite.com, retrieved 2019-14-05. Each of these categories contains various processes. Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product. '' Marking out'' (also known as layout) is the process of transferring a design or pattern to a workpiece and is the first step in the handcraft of metalworking. It is performed in many industries or hobbies, although in industry, the repetition eliminates the need to mark out every individual piece. In the metal trades area, marking out consists of transferring the engineer's plan to the workpiece in preparation for the next step, machining or manufacture. '' Calipers'' are hand tools designed to precisely measure the distance between two points. Most calipers have two sets of flat, parallel edges used for inner or outer diameter measurements. These calipers can be accurate to within one-thousandth of an inch (25.4 μm). Different types of calipers have different mechanisms for displaying the distance measured. Where larger objects need to be measured with less precision, a tape measure is often used.

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

*

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

*

Plastic deformation involves using heat or pressure to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized. In bulk metal forming, the workpiece is generally heated up.

* Cold sizing

* Extrusion

*

Plastic deformation involves using heat or pressure to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized. In bulk metal forming, the workpiece is generally heated up.

* Cold sizing

* Extrusion

*

* Raising

* Roll forming

*

* Raising

* Roll forming

*

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Chapter 4: Turning Tools and Operations

American Machinist, January 2010 A ''lathe'' is a machine tool which spins a block or cylinder of material so that when abrasive, cutting, or deformation tools are applied to the workpiece, it can be shaped to produce an object which has rotational symmetry about an

Parting: The tool is fed radially into the workpiece to cut off the end of a part.

Threading: A tool is fed along and across the outside or inside surface of rotating parts to produce external or internal

Boring: A single-point tool is fed linearly and parallel to the axis of rotation to create a round hole.

Knurling: Uses a tool to produce a rough surface texture on the work piece. Frequently used to allow grip by hand on a metal part. Modern computer numerical control (CNC) lathes and (CNC) machining centres can do secondary operations like milling by using driven tools. When driven tools are used the work piece stops rotating and the driven tool executes the machining operation with a rotating cutting tool. The CNC machines use x, y, and z coordinates in order to control the turning tools and produce the product. Most modern day CNC lathes are able to produce most turned objects in 3D. Nearly all types of metal can be turned, although more time & specialist cutting tools are needed for harder workpieces.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

Schneider, George. "Chapter 1: Cutting Tool Materials", ''American Machinist'', October, 2009

Schneider, George. "Cutting Tool Applications: Chapter 2 Metal Removal Methods", ''American Machinist'', November, 2009

Videos about metalworking

published by Institut für den Wissenschaftlichen Film. Available in the AV-Portal of the German National Library of Science and Technology.

Evidences of Metalworking History Reference

{{Authority control Metal industry M M 9th-millennium BC establishments

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft,

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metal

A native metal is any metal that is found pure in its metallic form in nature. Metals that can be found as native deposits singly or in alloys include aluminium, antimony, arsenic, bismuth, cadmium, chromium, cobalt, indium, iron, manganese, m ...

s like gold with simple hand tools, through the smelting of ores and hot forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which i ...

of harder metals like iron, up to highly technical modern processes such as machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft.

Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Modern metalworking workshops, typically known as machine shop

A machine shop or engineering workshop (UK) is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plast ...

s, hold a wide variety of specialized or general-use machine tools capable of creating highly precise, useful products. Many simpler metalworking techniques, such as blacksmithing, are no longer economically competitive on a large scale in developed countries; some of them are still in use in less developed countries, for artisanal or hobby work, or for historical reenactment.

Prehistory

The oldest archaeological evidence of copper mining and working was the discovery of a copper pendant in northern Iraq from 8,700 BCE. The earliest substantiated and dated evidence of metalworking in theAmericas

The Americas, which are sometimes collectively called America, are a landmass comprising the totality of North and South America. The Americas make up most of the land in Earth's Western Hemisphere and comprise the New World.

Along with th ...

was the processing of copper in Wisconsin, near Lake Michigan

Lake Michigan is one of the five Great Lakes of North America. It is the second-largest of the Great Lakes by volume () and the third-largest by surface area (), after Lake Superior and Lake Huron. To the east, its basin is conjoined with that o ...

. Copper was hammered until it became brittle, then heated so it could be worked further. In America, this technology is dated to about 4000–5000 BCE. The oldest gold artifacts in the world come from the Bulgarian Varna Necropolis and date from 4450 BCE.

Not all metal required fire to obtain it or work it. Isaac Asimov

yi, יצחק אזימאװ

, birth_date =

, birth_place = Petrovichi, Russian SFSR

, spouse =

, relatives =

, children = 2

, death_date =

, death_place = Manhattan, New York City, U.S.

, nationality = Russian (1920–1922)Soviet (192 ...

speculated that gold was the "first metal". His reasoning being, that, by its chemistry

Chemistry is the science, scientific study of the properties and behavior of matter. It is a natural science that covers the Chemical element, elements that make up matter to the chemical compound, compounds made of atoms, molecules and ions ...

, it is found in nature as nuggets of pure gold. In other words, gold, as rare as it is, is sometimes found in nature as a native metal

A native metal is any metal that is found pure in its metallic form in nature. Metals that can be found as native deposits singly or in alloys include aluminium, antimony, arsenic, bismuth, cadmium, chromium, cobalt, indium, iron, manganese, m ...

. Some metals can also be found in meteors. Almost all other metals are found in ores, a mineral-bearing rock, that require heat or some other process to liberate the metal. Another feature of gold is that it is workable as it is found, meaning that no technology beyond a stone hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as w ...

and anvil

An anvil is a metalworking tool consisting of a large block of metal (usually forged or cast steel), with a flattened top surface, upon which another object is struck (or "worked").

Anvils are as massive as practical, because the higher th ...

is needed to work the metal. This is a result of gold's properties of malleability

Ductility is a List of materials properties, mechanical property commonly described as a material's amenability to Drawing (manufacturing), drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a materia ...

and ductility. The earliest tools were stone, bone, wood, and sinew

A tendon or sinew is a tough, high-tensile-strength band of dense fibrous connective tissue that connects muscle to bone. It is able to transmit the mechanical forces of muscle contraction to the skeletal system without sacrificing its ability ...

, all of which sufficed to work gold.

At some unknown time, the process of liberating metals from rock by heat became known, and rocks rich in copper, tin, and lead came into demand. These ores were mined wherever they were recognized. Remnants of such ancient mines have been found all over Southwestern Asia

Western Asia, West Asia, or Southwest Asia, is the westernmost subregion of the larger geographical region of Asia, as defined by some academics, UN bodies and other institutions. It is almost entirely a part of the Middle East, and includes Ana ...

. Metalworking was being carried out by the South Asian inhabitants of Mehrgarh between 7000 and 3300 BCE.Possehl, Gregory L. (1996). ''Mehrgarh'' in ''Oxford Companion to Archaeology'', Brian Fagan (Ed.). Oxford University Press. The end of the beginning of metalworking occurs sometime around 6000 BCE when copper smelting became common in Southwestern Asia.

Ancient civilisations knew of seven metals. Here they are arranged in order of their oxidation potential (in volts):

* Iron +0.44 V,

* Tin +0.14 V

* Lead +0.13 V

* Copper −0.34 V

*Mercury

Mercury commonly refers to:

* Mercury (planet), the nearest planet to the Sun

* Mercury (element), a metallic chemical element with the symbol Hg

* Mercury (mythology), a Roman god

Mercury or The Mercury may also refer to:

Companies

* Merc ...

−0.79 V

* Silver −0.80 V

* Gold −1.50 V.

The oxidation potential is important because it is one indicator of how tightly bound to the ore the metal is likely to be. As can be seen, iron is significantly higher than the other six metals while gold is dramatically lower than the six above it. Gold's low oxidation is one of the main reasons that gold is found in nuggets. These nuggets are relatively pure gold and are workable as they are found.

Copper ore, being relatively abundant, and tin ore became the next important substances in the story of metalworking. Using heat to smelt copper from ore, a great deal of copper was produced. It was used for both jewelry and simple tools. However, copper by itself was too soft for tools requiring edges and stiffness. At some point tin was added into the molten copper and bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals, such as phosphorus, or metalloids such ...

was developed thereby. Bronze is an alloy of copper and tin. Bronze was an important advance because it had the edge-durability and stiffness that pure copper lacked. Until the advent of iron, bronze was the most advanced metal for tools and weapons in common use (see Bronze Age for more detail).

Outside Southwestern Asia, these same advances and materials were being discovered and used around the world. People in China

China, officially the People's Republic of China (PRC), is a country in East Asia. It is the world's most populous country, with a population exceeding 1.4 billion, slightly ahead of India. China spans the equivalent of five time zones and ...

and Great Britain began using bronze with little time being devoted to copper. Japan

Japan ( ja, 日本, or , and formally , ''Nihonkoku'') is an island country in East Asia. It is situated in the northwest Pacific Ocean, and is bordered on the west by the Sea of Japan, while extending from the Sea of Okhotsk in the north ...

ese began the use of bronze and iron almost simultaneously. In the Americas it was different. Although the peoples of the Americas knew of metals, it was not until the European colonisation that metalworking for tools and weapons became common. Jewelry and art were the principal uses of metals in the Americas prior to European influence.

About 2700 BCE, production of bronze was common in locales where the necessary materials could be assembled for smelting, heating, and working the metal. Iron was beginning to be smelted and began its emergence as an important metal for tools and weapons. The period that followed became known as the Iron Age.

History

By the historical periods of the Pharaohs in Egypt, the Vedic Kings in India, the

By the historical periods of the Pharaohs in Egypt, the Vedic Kings in India, the Tribes of Israel

The Twelve Tribes of Israel ( he, שִׁבְטֵי־יִשְׂרָאֵל, translit=Šīḇṭēy Yīsrāʾēl, lit=Tribes of Israel) are, according to Hebrew Bible, Hebrew scriptures, the descendants of the biblical Patriarchs (Bible), patriarch ...

, and the Maya civilization in North America

North America is a continent in the Northern Hemisphere and almost entirely within the Western Hemisphere. It is bordered to the north by the Arctic Ocean, to the east by the Atlantic Ocean, to the southeast by South America and the Car ...

, among other ancient populations, precious metal

Precious metals are rare, naturally occurring metallic chemical elements of high economic value.

Chemically, the precious metals tend to be less reactive than most elements (see noble metal). They are usually ductile and have a high lustre. ...

s began to have value attached to them. In some cases rules for ownership, distribution, and trade were created, enforced, and agreed upon by the respective peoples. By the above periods metalworkers were very skilled at creating objects of adornment, religious artifacts, and trade instruments of precious metals (non-ferrous), as well as weaponry usually of ferrous metals and/or alloys. These skills were well executed. The techniques were practiced by artisans, blacksmiths, atharvavedic practitioners, alchemists, and other categories of metalworkers around the globe. For example, the granulation

Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material. It is applied in several technological processes in the chemical and pharmaceutical industries. Typically, granulation i ...

technique was employed by numerous ancient cultures before the historic record shows people traveled to far regions to share this process. Metalsmith

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest list of metalworking occupations, metalworking o ...

s today still use this and many other ancient techniques.

As time progressed, metal objects became more common, and ever more complex. The need to further acquire and work metals grew in importance. Skills related to extracting metal ores from the earth began to evolve, and metalsmiths became more knowledgeable. Metalsmiths became important members of society. Fates and economies of entire civilizations were greatly affected by the availability of metals and metalsmiths. The metalworker depends on the extraction of precious metals to make jewelry, build more efficient electronics, and for industrial and technological applications from construction to shipping containers to rail, and air transport

Aviation includes the activities surrounding mechanical flight and the aircraft industry. ''Aircraft'' includes fixed-wing and rotary-wing types, morphable wings, wing-less lifting bodies, as well as lighter-than-air craft such as hot air ...

. Without metals, goods and services would cease to move around the globe on the scale we know today.

General processes

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools.

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools.mechanicalsite.com, retrieved 2019-14-05. Each of these categories contains various processes. Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product. '' Marking out'' (also known as layout) is the process of transferring a design or pattern to a workpiece and is the first step in the handcraft of metalworking. It is performed in many industries or hobbies, although in industry, the repetition eliminates the need to mark out every individual piece. In the metal trades area, marking out consists of transferring the engineer's plan to the workpiece in preparation for the next step, machining or manufacture. '' Calipers'' are hand tools designed to precisely measure the distance between two points. Most calipers have two sets of flat, parallel edges used for inner or outer diameter measurements. These calipers can be accurate to within one-thousandth of an inch (25.4 μm). Different types of calipers have different mechanisms for displaying the distance measured. Where larger objects need to be measured with less precision, a tape measure is often used.

Casting

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

*

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

* Centrifugal casting Centrifugal casting is a metallurgical manufacturing process by casting that may refer to either:

* Centrifugal casting (industrial), on an industrial scale

* Centrifugal casting (silversmithing), for a smaller scale

See also: Spin casting

Sp ...

* Die casting

* Sand casting

* Shell casting

* Spin casting

Forming processes

These ''forming'' processes modify metal or workpiece by deforming the object, that is, without removing any material. Forming is done with a system of mechanical forces and, especially for bulk metal forming, with heat.Bulk forming processes

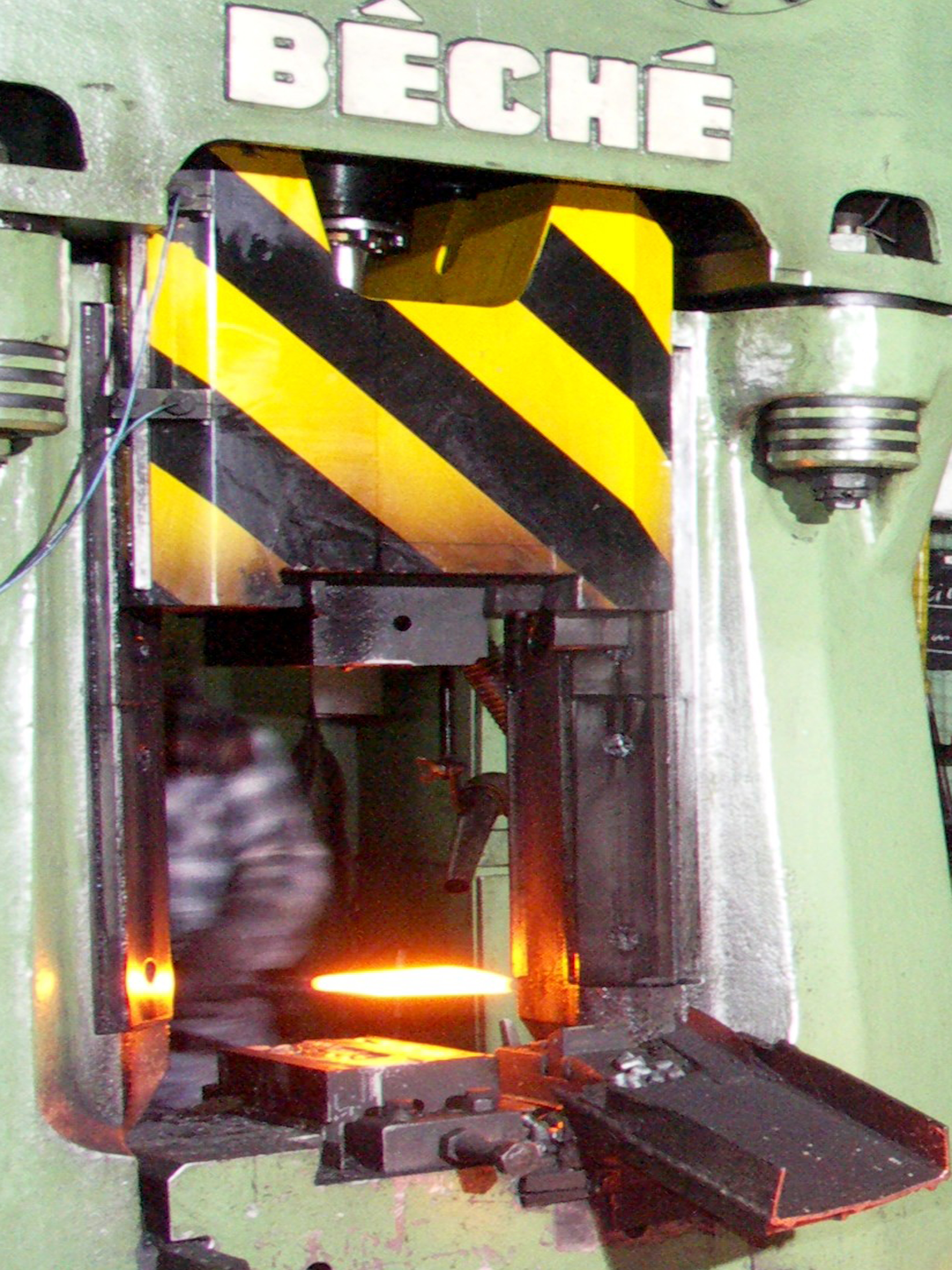

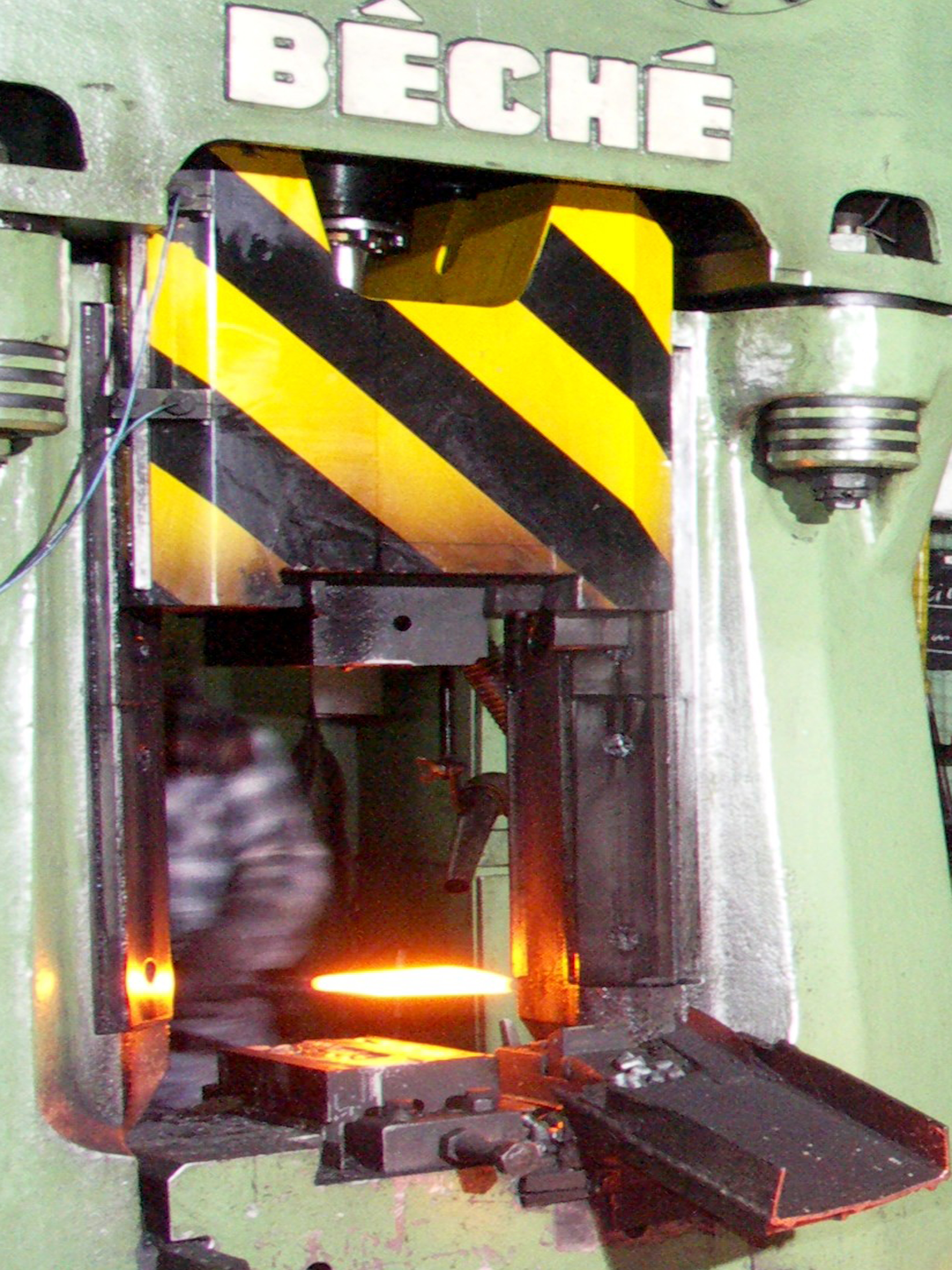

Plastic deformation involves using heat or pressure to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized. In bulk metal forming, the workpiece is generally heated up.

* Cold sizing

* Extrusion

*

Plastic deformation involves using heat or pressure to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized. In bulk metal forming, the workpiece is generally heated up.

* Cold sizing

* Extrusion

* Drawing

Drawing is a form of visual art in which an artist uses instruments to mark paper or other two-dimensional surface. Drawing instruments include graphite pencils, pen and ink, various kinds of paints, inked brushes, colored pencils, crayons, ...

* Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which i ...

* Powder metallurgy

* Friction drilling

* Rolling

* Burnishing

Sheet (and tube) forming processes

These types of forming process involve the application of mechanical force at room temperature. However, some recent developments involve the heating of dies and/or parts. Advancements in automated metalworking technology have made progressive die stamping possible which is a method that can encompass punching, coining, bending and several other ways below that modify metal at less cost while resulting in less scrap. * Bending * Coining *Decambering {{No footnotes, date=July 2009

Decambering is the metalworking process of removing camber, or horizontal bend, from strip shaped materials. The material may be finite length sections or continuous coils. Decambering resembles flattening or levellin ...

* Deep drawing (DD)

* Flowforming

* Hydroforming (HF)

* Hot metal gas forming

* Hot press hardening

* Incremental forming (IF)

* Spinning

Spin or spinning most often refers to:

* Spinning (textiles), the creation of yarn or thread by twisting fibers together, traditionally by hand spinning

* Spin, the rotation of an object around a central axis

* Spin (propaganda), an intentionally b ...

, Shear forming

Shear forming, also referred as shear spinning, is similar to metal spinning. In shear spinning the area of the final piece is approximately equal to that of the flat sheet metal blank. The wall thickness is maintained by controlling the gap bet ...

or Flowforming  * Raising

* Roll forming

*

* Raising

* Roll forming

* Roll bending

A roll bender is a mechanical jig having three rollers used to bend a metal bar into a circular arc. The rollers freely rotate about three parallel axes, which are arranged with uniform horizontal spacing. Two outer rollers, usually immobile, cr ...

* Repoussé and chasing

* Rubber pad forming

* Shearing

* Stamping

* Superplastic forming (SPF)

* Wheeling using an English wheel (wheeling machine)

Cutting processes

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-r ...

and excess metal.

Cutting processes fall into one of three major categories:

* Chip producing processes most commonly known as machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

* Burning, a set of processes wherein the metal is cut by oxidizing a kerf to separate pieces of metal

* Miscellaneous specialty process, not falling easily into either of the above categories

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at ra ...

a hole in a metal part is the most common example of a chip producing process. Using an oxy-fuel cutting torch to separate a plate of steel into smaller pieces is an example of burning. Chemical milling is an example of a specialty process that removes excess material by the use of etching chemicals and masking chemicals.

There are many technologies available to cut metal, including:

*Manual technologies: saw, chisel

A chisel is a tool with a characteristically shaped cutting edge (such that wood chisels have lent part of their name to a particular grind) of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, stru ...

, shear or snips

*Machine technologies: turning, milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using rota ...

, drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at ra ...

, grinding, sawing

*Welding/burning technologies: burning by laser, oxy-fuel burning, and plasma

Plasma or plasm may refer to:

Science

* Plasma (physics), one of the four fundamental states of matter

* Plasma (mineral), a green translucent silica mineral

* Quark–gluon plasma, a state of matter in quantum chromodynamics

Biology

* Blood pla ...

*Erosion technologies: by water jet Water jet may refer to:

* A jet of water under pressure, like in an ornamental fountain

* Pump-jet, a marine propulsion mechanism for jetskis and other types of boats

* Water jet cutter, a tool for cutting and the machining of engineering material ...

, electric discharge, or abrasive flow machining.

*Chemical technologies: Photochemical machining

Cutting fluid or coolant is used where there is significant friction and heat at the cutting interface between a cutter such as a drill or an end mill and the workpiece. Coolant is generally introduced by a spray across the face of the tool and workpiece to decrease friction and temperature at the cutting tool/workpiece interface to prevent excessive tool wear. In practice there are many methods of delivering coolant.

Milling

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to ...

), and a worktable that can move in multiple directions (usually two dimensions and y axisrelative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under computer numerical control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pie ...

(CNC), and can perform a vast number of complex operations, such as slot cutting, planing, drilling and threading, rabbeting, routing

Routing is the process of selecting a path for traffic in a network or between or across multiple networks. Broadly, routing is performed in many types of networks, including circuit-switched networks, such as the public switched telephone netw ...

, etc. Two common types of mills are the horizontal mill and vertical mill.

The pieces produced are usually complex 3D objects that are converted into x, y, and z coordinates that are then fed into the CNC machine and allow it to complete the tasks required. The milling machine can produce most parts in 3D, but some require the objects to be rotated around the x, y, or z coordinate axis (depending on the need). Tolerances come in a variety of standards, depending on the locale. In countries still using the imperial system, this is usually in the thousandths of an inch (unit known as ''thou''), depending on the specific machine. In many other European countries, standards following the ISO are used instead.

In order to keep both the bit and material cool, a high temperature coolant is used. In most cases the coolant is sprayed from a hose directly onto the bit and material. This coolant can either be machine or user controlled, depending on the machine.

Materials that can be milled range from aluminum to stainless steel and almost everything in between. Each material requires a different speed on the milling tool and varies in the amount of material that can be removed in one pass of the tool. Harder materials are usually milled at slower speeds with small amounts of material removed. Softer materials vary, but usually are milled with a high bit speed.

The use of a milling machine adds costs that are factored into the manufacturing process. Each time the machine is used coolant is also used, which must be periodically added in order to prevent breaking bits. A milling bit must also be changed as needed in order to prevent damage to the material. Time is the biggest factor for costs. Complex parts can require hours to complete, while very simple parts take only minutes. This in turn varies the production time as well, as each part will require different amounts of time.

Safety is key with these machines. The bits are traveling at high speeds and removing pieces of usually scalding hot metal. The advantage of having a CNC milling machine is that it protects the machine operator.

Turning

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, GeorgeChapter 4: Turning Tools and Operations

American Machinist, January 2010 A ''lathe'' is a machine tool which spins a block or cylinder of material so that when abrasive, cutting, or deformation tools are applied to the workpiece, it can be shaped to produce an object which has rotational symmetry about an

axis of rotation

Rotation around a fixed axis is a special case of rotational motion. The fixed-axis hypothesis excludes the possibility of an axis changing its orientation and cannot describe such phenomena as wobbling or precession. According to Euler's rota ...

. Examples of objects that can be produced on a lathe include candlestick holders, crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting ...

s, camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems ...

s, and bearing mounts.

Lathes have four main components: the bed, the headstock, the carriage, and the tailstock. The bed is a precise & very strong base which all of the other components rest upon for alignment. The headstock's spindle secures the workpiece with a chuck, whose jaws (usually three or four) are tightened around the piece. The spindle rotates at high speed, providing the energy to cut the material. While historically lathes were powered by belts from a line shaft, modern examples uses electric motors. The workpiece extends out of the spindle along the axis of rotation above the flat bed. The carriage is a platform that can be moved, precisely and independently parallel and perpendicular to the axis of rotation. A hardened cutting tool is held at the desired height (usually the middle of the workpiece) by the toolpost. The carriage is then moved around the rotating workpiece, and the cutting tool gradually removes material from the workpiece. The tailstock can be slid along the axis of rotation and then locked in place as necessary. It may hold centers to further secure the workpiece, or cutting tools driven into the end of the workpiece.

Other operations that can be performed with a single point tool on a lathe are:

Chamfering: Cutting an angle on the corner of a cylinder.Parting: The tool is fed radially into the workpiece to cut off the end of a part.

Threading: A tool is fed along and across the outside or inside surface of rotating parts to produce external or internal

threads

Thread may refer to:

Objects

* Thread (yarn), a kind of thin yarn used for sewing

** Thread (unit of measurement), a cotton yarn measure

* Screw thread, a helical ridge on a cylindrical fastener

Arts and entertainment

* ''Thread'' (film), 2016 ...

.Boring: A single-point tool is fed linearly and parallel to the axis of rotation to create a round hole.

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at ra ...

: Feeding the drill into the workpiece axially.Knurling: Uses a tool to produce a rough surface texture on the work piece. Frequently used to allow grip by hand on a metal part. Modern computer numerical control (CNC) lathes and (CNC) machining centres can do secondary operations like milling by using driven tools. When driven tools are used the work piece stops rotating and the driven tool executes the machining operation with a rotating cutting tool. The CNC machines use x, y, and z coordinates in order to control the turning tools and produce the product. Most modern day CNC lathes are able to produce most turned objects in 3D. Nearly all types of metal can be turned, although more time & specialist cutting tools are needed for harder workpieces.

Threading

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

Grinding

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an abrasive wheel

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

The wheels are generally made with composite material . This consists of coarse-particle aggregate press ...

as the cutting device. This wheel can be made up of various sizes and types of stones, diamonds or inorganic materials.

The simplest grinder is a bench grinder or a hand-held angle grinder, for deburring parts or cutting metal with a zip-disc.

Grinders have increased in size and complexity with advances in time and technology. From the old days of a manual toolroom grinder sharpening endmills for a production shop, to today's 30000 RPM CNC auto-loading manufacturing cell producing jet turbines, grinding processes vary greatly.

Grinders need to be very rigid machines to produce the required finish. Some grinders are even used to produce glass scales for positioning CNC machine axis. The common rule is the machines used to produce scales be 10 times more accurate than the machines the parts are produced for.

In the past grinders were used for finishing operations only because of limitations of tooling. Modern grinding wheel materials and the use of industrial diamonds or other man-made coatings (cubic boron nitride) on wheel forms have allowed grinders to achieve excellent results in production environments instead of being relegated to the back of the shop.

Modern technology has advanced grinding operations to include CNC controls, high material removal rates with high precision, lending itself well to aerospace applications and high volume production runs of precision components.

Filing

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a machinist

A machinist is a tradesperson or trained professional who not only operates machine tools, but also has the knowledge of tooling and materials required to create set ups on machine tools such as milling machines, grinders, lathes, and drilling ...

to work to fine tolerances and was the hallmark of the craft. Today filing is rarely used as a production technique in industry, though it remains as a common method of deburring.

Other

Broaching

The BROACH warhead is a Tandem-charge, multi-stage warhead developed by Team BROACH; BAE Systems Global Combat Systems Munitions, Thales Missile Electronics and QinetiQ. BROACH stands for ''Bomb Royal Ordnance Augmented CHarge''.

Development of ...

is a machining operation used to cut keyways into shafts. Electron beam machining (EBM) is a machining process where high-velocity electrons are directed toward a work piece, creating heat and vaporizing the material. Ultrasonic machining

Ultrasonic machining is a subtractive manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The t ...

uses ultrasonic vibrations to machine very hard or brittle materials.

Joining processes

Welding

''Welding'' is afabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

*Semiconductor device fabrication, the process used t ...

process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, but sometimes pressure is used in conjunction with heat, or by itself, to produce the weld.

Many different energy sources can be used for welding, including a gas flame, an electric arc, a laser, an electron beam, friction, and ultrasound. While often an industrial process, welding can be done in many different environments, including open air, underwater and in space. Regardless of location, however, welding remains dangerous, and precautions must be taken to avoid burns, electric shock

Electrical injury is a physiological reaction caused by electric current passing through the body. The injury depends on the density of the current, tissue resistance and duration of contact. Very small currents may be imperceptible or produce ...

, poisonous fumes, and overexposure to ultraviolet light.

Brazing

''Brazing'' is a joining process in which a filler metal is melted and drawn into a capillary formed by the assembly of two or more work pieces. The filler metal reacts metallurgically with the workpieces and solidifies in the capillary, forming a strong joint. Unlike welding, the work piece is not melted. Brazing is similar to soldering, but occurs at temperatures in excess of . Brazing has the advantage of producing less thermal stresses than welding, and brazed assemblies tend to be more ductile than weldments because alloying elements can not segregate and precipitate. Brazing techniques include, flame brazing, resistance brazing, furnace brazing, diffusion brazing, inductive brazing and vacuum brazing.Soldering

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

Riveting

''Riveting'' is one of the most ancient metalwork joining processes. Its use declined markedly during the second half of the 20th century, but it still retains important uses in industry and construction, and in artisan crafts such as jewellery, medieval armouring and metal couture in the early 21st century. The earlier use of rivets is being superseded by improvements in welding and componentfabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

*Semiconductor device fabrication, the process used t ...

techniques.

A rivet is essentially a two-headed and unthreaded bolt

The BOLT Browser was a web browser for mobile phones including feature phones and smartphones that can run Java ME applications. The BOLT Browser was offered free of charge to consumers and by license to mobile network operators and handset manuf ...

which holds two other pieces of metal together. Holes are drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to ...

ed or punched through the two pieces of metal to be joined. The holes being aligned, a rivet is passed through the holes and permanent heads are formed onto the ends of the rivet utilizing hammers and forming dies (by either cold working or hotworking).

Rivets are commonly purchased with one head already formed.

When it is necessary to remove rivets, one of the rivet's heads is sheared off with a cold chisel. The rivet is then driven out with a hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as w ...

and punch.

Mechanical fixings

This includesscrews

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fa ...

, as well as bolts. This is often used as it requires relatively little specialist equipment, and are therefore often used in flat-pack furniture. It can also be used when a metal is joined to another material (such as wood) or a particular metal does not weld well (such as aluminum). This can be done to directly join metals, or with an intermediate material such as nylon. While often weaker than other methods such as welding or brazing, the metal can easily be removed and therefore reused or recycled. It can also be done in conjunction with an epoxy or glue, reverting it's ecological benefits.

Associated processes

While these processes are not primary metalworking processes, they are often performed before or after metalworking processes.Heat treatment

Metals can be heat treated to alter the properties of strength, ductility, toughness, hardness or resistance to corrosion. Common heat treatment processes include annealing, precipitation hardening, quenching, and tempering: * annealing softens the metal by allowing recovery of cold work and grain growth. * quenching can be used to harden alloy steels, or in precipitation hardenable alloys, to trap dissolved solute atoms in solution. * tempering will cause the dissolved alloying elements to precipitate, or in the case of quenched steels, improve impact strength and ductile properties. Often, mechanical and thermal treatments are combined in what is known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high alloy special steels, super alloys and titanium alloys.Plating

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

is a common surface-treatment technique. It involves bonding a thin layer of another metal such as gold, silver, chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

or zinc to the surface of the product by hydrolysis. It is used to reduce corrosion, create abrasion resistance and improve the product's aesthetic appearance. Plating can even change the properties of the original part including conductivity, heat dissipation or structural integrity. There are four main electroplating methods to ensure proper coating and cost effectiveness per product: mass plating, rack plating, continuous plating and line plating.

Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings due to the thicker coating. The four main thermal spray processes include electric wire arc spray, flame (oxy acetylene combustion) spray, plasma spray and high velocity oxy fuel (HVOF) spray.See also

* Bronze and brass ornamental work *List of metalworking occupations

Metalworking occupations include:

The oldest of the metalworking occupations

* Smith (a.k.a. metalsmith), such as blacksmith or silversmith

* Jeweler

* Founder

The machining trades

* Production machinist, which may involve various related mach ...

* Metal testing

* Metalworking hand tools

*Stone mould

Within the history of metalworking, medieval stone moulds are well represented in the Herbert Art Gallery & Museum in Coventry with over 169 examples. The Molding (process), moulds from Coventry are from a highly calcareous mudstone of Jurassic ty ...

General:

*List of manufacturing processes

This tree lists various manufacturing processes arranged by similarity of function.

Casting

*Centrifugal casting (industrial)

*Continuous casting

*Die casting

*Evaporative-pattern casting

**Full-mold casting

**Lost-foam casting

*Investment ...

*Timeline of materials technology

Major innovations in materials technology

BC

*28,000 BC – People wear beads, bracelets, and pendants

*14,500 BC – First pottery, made by the Jōmon people of Japan.

*6th millennium BC – Copper metallurgy is invented and copper is used fo ...

References

External links

Schneider, George. "Chapter 1: Cutting Tool Materials", ''American Machinist'', October, 2009

Schneider, George. "Cutting Tool Applications: Chapter 2 Metal Removal Methods", ''American Machinist'', November, 2009

Videos about metalworking

published by Institut für den Wissenschaftlichen Film. Available in the AV-Portal of the German National Library of Science and Technology.

Evidences of Metalworking History Reference

{{Authority control Metal industry M M 9th-millennium BC establishments