metal bellows on:

[Wikipedia]

[Google]

[Amazon]

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its

There are three main types of metal bellows: formed, welded and electroformed.

Formed bellows are produced by reworking tubes, normally produced by

There are three main types of metal bellows: formed, welded and electroformed.

Formed bellows are produced by reworking tubes, normally produced by

Bellowstech Electroformed bellows are produced by plating (

NiCoForm Another area of comparison is in metals of construction. Hydroformed and rolled bellows are limited to metals with high plastic elongation characteristics, whereas welded bellows may be fabricated from a wider variety of standard and exotic alloys, such as

high-strength alloys

and

Types of metallic Bellows Deflections

U.S. Bellows, (retrieved March 2012)

yield strength

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and w ...

. They are used both for their ability to deform under pressure and to provide a hermetic seal

A hermetic seal is any type of sealing that makes a given object airtight (preventing the passage of air, oxygen, or other gases). The term originally applied to airtight glass containers but, as technology advanced, it applied to a larger ca ...

that allows movement.

Precision bellows technology of the 20th and 21st century is centered on metal bellows with less demanding applications using ones made of rubber and plastic. These products bear little resemblance to the original leather bellows used traditionally in fireplace

A fireplace or hearth is a structure made of brick, stone or metal designed to contain a fire. Fireplaces are used for the relaxing ambiance they create and for heating a room. Modern fireplaces vary in heat efficiency, depending on the design.

...

s and forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the ...

s.

Types

There are three main types of metal bellows: formed, welded and electroformed.

Formed bellows are produced by reworking tubes, normally produced by

There are three main types of metal bellows: formed, welded and electroformed.

Formed bellows are produced by reworking tubes, normally produced by deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "dee ...

, with a variety of processes, including cold forming

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature at or near room temperature. Such processes are contrasted with hot w ...

(rolling), and hydroforming

Hydroforming is a means of shaping ductile metals such as aluminium, brass, low alloy steel, and stainless steel into lightweight, structurally stiff and strong pieces. One of the largest applications of cost-effective hydroforming is the automot ...

. They are also called convoluted bellows or sylphons.

Welded bellows (also called edge-welded, or diaphragm bellows) are manufactured by welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

a number of individually formed diaphragms to each other. The comparison between the two bellows types generally centers on cost

Cost is the value of money that has been used up to produce something or deliver a service, and hence is not available for use anymore. In business, the cost may be one of acquisition, in which case the amount of money expended to acquire it i ...

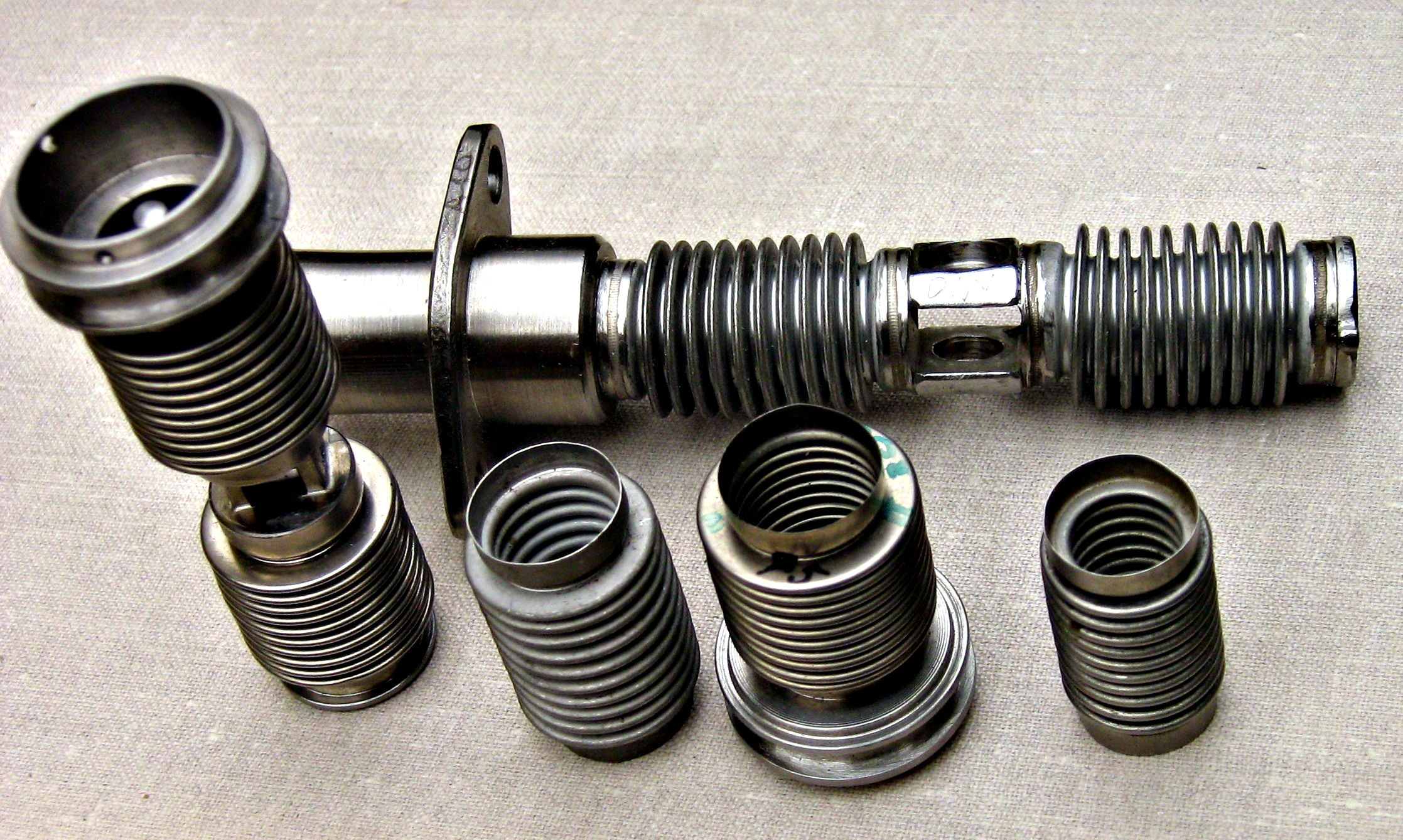

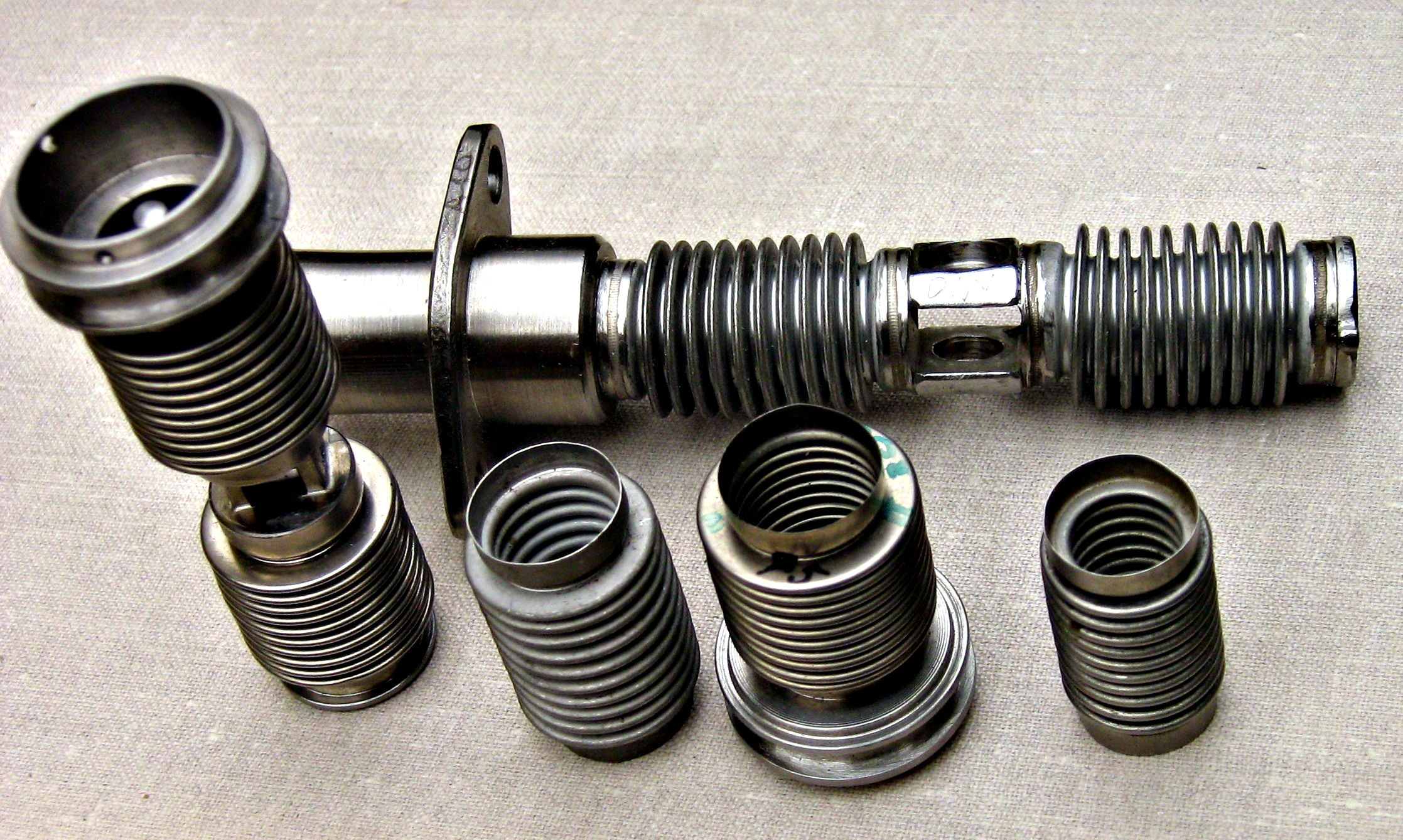

and performance. Hydroformed bellows generally have a high tooling cost, but, when mass-produced, may have a lower piece price. However, hydroformed bellows have lower performance characteristics due to relatively thick walls and high stiffness. Welded metal bellows are produced with a lower initial tooling cost and maintain higher performance characteristics. The drawback of welded bellows is the reduced metal strength at weld joints, caused by the high temperature of welding.Edge Welded Metal BellowsBellowstech Electroformed bellows are produced by plating (

electroforming

Electroforming is a metal forming process in which parts are fabricated through electrodeposition on a model, known in the industry as a mandrel. Conductive (metallic) mandrels are treated to create a mechanical parting layer, or are chemicall ...

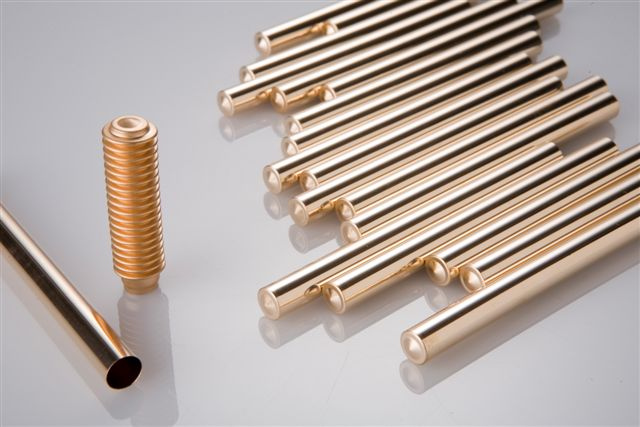

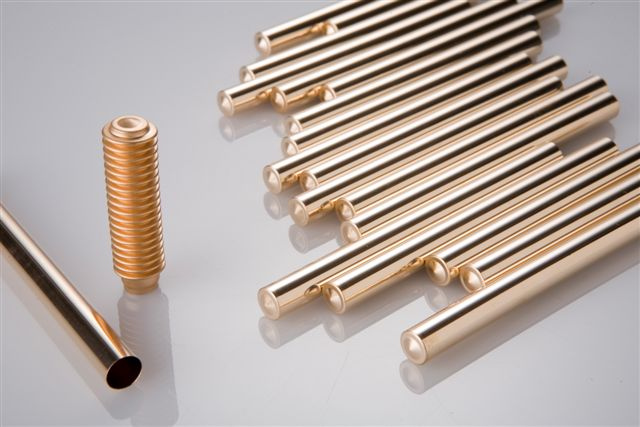

) a metal layer onto a model (mandrel), and subsequently removing the mandrel. They can be produced with modest tooling costs and with thin walls (25 micrometres or less), providing such bellows with high sensitivity and precision in many exacting applications, and may also be produced in shapes that would be exceptionally difficult to produce by other means with little additional difficulty.Precision Metal BellowsNiCoForm Another area of comparison is in metals of construction. Hydroformed and rolled bellows are limited to metals with high plastic elongation characteristics, whereas welded bellows may be fabricated from a wider variety of standard and exotic alloys, such as

stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

and titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

, as well as other high-strength, corrosion-resistant materials. Electroformed bellows can be produced of nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, ithigh-strength alloys

and

copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

.

Applications

Metal bellows are used in a large number of industrial applications. Below you will find a few; *Load cell

A load cell converts a force such as tension, compression, pressure, or torque into a signal (electrical, pneumatic or hydraulic pressure, or mechanical displacement indicator) that can be measured and standardized. It is a force transducer. As t ...

s; A load cell deforms if a certain load in the form of a pressure or a strain is imposed on it. This deformation is then detected by a strain gauge

A strain gauge (also spelled strain gage) is a device used to measure Deformation (mechanics)#Strain, strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an Electrical in ...

through which a low voltage

In electrical engineering, low voltage is a relative term, the definition varying by context. Different definitions are used in electric power transmission and distribution, compared with electronics design. Electrical safety codes define "low vo ...

direct current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow throug ...

is flowing. The change in voltage

Voltage, also known as (electrical) potential difference, electric pressure, or electric tension, is the difference in electric potential between two points. In a Electrostatics, static electric field, it corresponds to the Work (electrical), ...

is detected and made visible on a control panel. A bellows is mounted over the gauge to protect it from outside influences.

* Vacuum interrupters; For the switching of very high voltages in transformer stations a high vacuum, or high pressure dielectric gas must be maintained around the contacts while in service to mitigate arc formation which would damage the contacts and may prevent safe circuit breaking. Here the bellows allow the contacts to move in and out while maintaining a reliable gas-tight seal.

* Mechanical seals; These are mostly used to close the inside of a pump from the outside world to prevent leakage. For that purpose, a mechanical seal is mounted on the pump shaft. As the pump shaft is turning, there has to be a sealing element consisting of a stationary and a rotating ring. To enforce sufficient pressure on the two rings one is fitted with a spring, the bellows allows the free movement of the spring without leakage. The bellows may be constructed such that it also functions as the spring.

* Pressure gauges: If the pressure of aggressive fluids or gases has to be measured, the gauge has to be isolated from the flow. For critical applications, a diaphragm sealing is used instead of a bourdon tube in the gauge. This gives more security than aggressive media will not leak. The diaphragm is a self-contained sensor, transmitting the displacement to the measuring device.

* Sensors: In this application diaphragm or convoluted bellows are completely sealed and filled with a certain gas. Two electrical poles are penetrating the inside of the bellows. By varying the current of those two poles the temperature inside the bellows can be regulated. The expansion or contraction of the bellows is used as an actuator

An actuator is a machine element, component of a machine that produces force, torque, or Displacement (geometry), displacement, when an electrical, Pneumatics, pneumatic or Hydraulic fluid, hydraulic input is supplied to it in a system (called an ...

to control a certain movement.

* Valve sealing: A bellows is used between the housing and the valve stem to seal the inside completely from the outside world. In Europe, this is of particular importance as regulations such as TA Luft prohibit any leakage.

* Couplings for stepper motors and servomotor

A servomotor (or servo motor or simply servo) is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration in a mechanical system. It constitutes part of a servomechanism, and consi ...

s: The flexible part, capable of compensating for misalignment is made by a bellows. It ensures that there is no angular positioning difference between the two coupling halves. This is essential if the positioning accuracy should be extremely precise.

* Exhaust bellows: Running engines cause self vibration. To compensate for those movements and temperature differences resulting in thermal expansion, bellows are used to connect the exhaust gas pipes to the funnel.

* Piping expansion joint

A expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials. They are commonly found between sections of buildings, bridges, s ...

: In this application, a short section of bellows is connected between pipes to absorb thermal movement and vibration, typical in high-vacuum, high-temperature, cryogenic, or high purity systems, and factory-sealed systems that must not allow any gas leakage to or from the interior for a lengthy service life.

* Metal bellows are also used in other products and market segments, including medical

Medicine is the science and Praxis (process), practice of caring for patients, managing the Medical diagnosis, diagnosis, prognosis, Preventive medicine, prevention, therapy, treatment, Palliative care, palliation of their injury or disease, ...

applications like implantable drug pumps, to industrial actuators, to aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial, and military applications. Aerospace engineering consists of aeronautics and astron ...

applications such as altitude

Altitude is a distance measurement, usually in the vertical or "up" direction, between a reference datum (geodesy), datum and a point or object. The exact definition and reference datum varies according to the context (e.g., aviation, geometr ...

sensors and fluid management devices (accumulators, surge arresters, volume compensators, and fluid storage). Metal bellows are also found in space applications, providing reservoirs with potable water as well as accumulators to collect wastewater.

Manufacture

Welded bellows can be fabricated from a variety of exotic metals and alloys, whereas formed bellows are limited to alloys with good elongation –brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. I ...

being a prime example. Welded bellows are not fabricated from brass because of its fundamentally poor weldability. Other advantages to welded bellows include compactness (higher performance in a smaller package), ability to be compressed to solid height with no damage, resistance to nicks and dents, and dramatically greater flexibility.

The welding of metal bellows is a microscopic welding process, typically performed under laboratory conditions at high magnification.

Hydroformed bellows are produced by forcing a metal tube to expand under hydraulic pressure inside a bellows-shaped mold, and assume the convoluted shape of the mold.

Electroformed bellows are produced by plating metal onto a bellows-shaped model (mandrel), and the subsequent mandrel removal by chemical or physical means. Due to the low tooling cost and short manufacturing cycle, electroforming of bellows is not only an inexpensive manufacturing method, but also a perfect prototyping tool.

Deflections

There are a variety of expansion joints and not each one can accept the same types of deflection. The various types of deflections are axial, lateral, angular, torsional, cyclic, or any combination that can occur at the same time.U.S. Bellows, (retrieved March 2012)

References

{{reflist Manufactured goods Mechanics Metallic objects