|

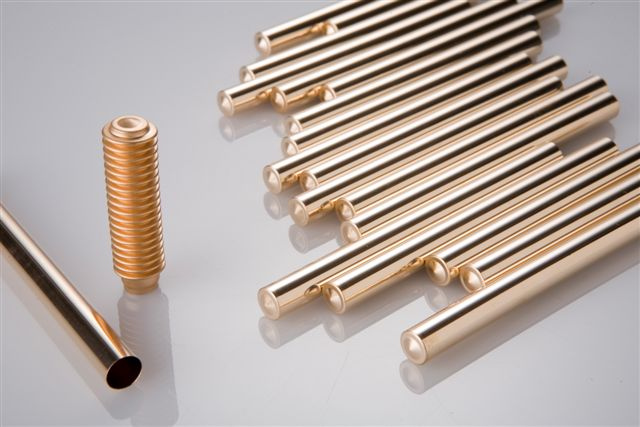

Metal Bellows

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength. They are used both for their ability to deform under pressure and to provide a hermetic seal that allows movement. Precision bellows technology of the 20th and 21st century is centered on metal bellows with less demanding applications using ones made of rubber and plastic. These products bear little resemblance to the original leather bellows used traditionally in fireplaces and forges. Types There are three main types of metal bellows: formed, welded and electroformed. Formed bellows are produced by reworking tubes, normally produced by deep drawing, with a variety of processes, including cold forming (rolling), and hydroforming. They are also called convoluted bellows or sylphons. We ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

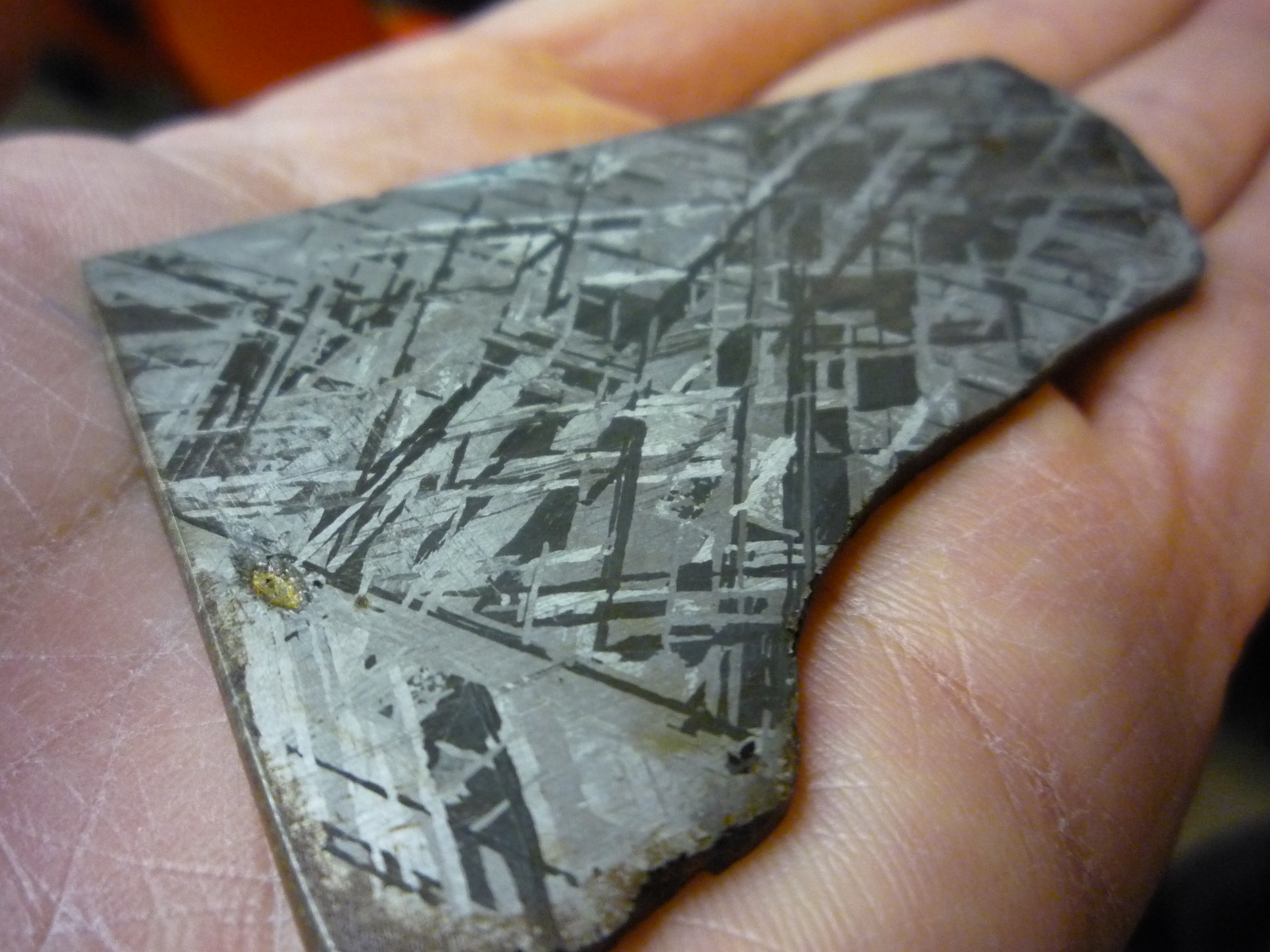

Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Actuator

An actuator is a machine element, component of a machine that produces force, torque, or Displacement (geometry), displacement, when an electrical, Pneumatics, pneumatic or Hydraulic fluid, hydraulic input is supplied to it in a system (called an actuating system). The effect is usually produced in a controlled way. An actuator translates such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover". An actuator requires a control device (which provides control signal) and a source of energy. The control signal is relatively low in energy and may be voltage, electric current, Compressed air, pneumatic, or hydraulic fluid pressure, or even human power. In the electric, hydraulic, and pneumatic sense, it is a form of automation, automation or automatic control. The displacement achieved is commonly linear or rotational, as exemplified by linear motors and rotary motors, respectively. Rotary motion is more natural for s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bourdon Gauge

Pressure measurement is the measurement of an applied force by a fluid (liquid or gas) on a surface. Pressure is typically measured in unit of measurement, units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges, vacuum gauges or compound gauges (vacuum & pressure). The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge. A vacuum gauge is used to measure pressures lower than the ambient atmospheric pressure, which is set as the zero point, in negative values (for instance, −1 bar or −760 mmHg equals total vacuum). Most gauges measure pressure relative to atmospheric pressure as the zero point, so this form of reading is simply referred to as "gauge pressure". However, anything greater than total vacuum is technically a form of pressure. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leakage (chemistry)

A leak is a way (usually an opening) for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually unintended and therefore undesired. The word ''leak'' usually refers to a gradual loss; a sudden loss is usually called a ''spill''. The matter leaking in or out can be gas, liquid, a highly viscous paste, or even a solid such as a powdered or granular solid or other solid particles. Types and possible causes Types of leak openings include a puncture, gash, rust or other corrosion hole, very tiny ''pinhole leak'' (possibly in imperfect welds), crack or microcrack, or inadequate sealing between components or parts joined. When there is a puncture, the size and shape of the leak can often be seen, but in many other cases, the size and shape of the leak opening may not be so obvious. In many cases, the location of a leak can be de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

End Face Mechanical Seal

In mechanical engineering, an end-face mechanical seal (often shortened to mechanical seal) is a type of seal used in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing (otherwise known as gland packing) to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications. An end-face mechanical seal uses both rigid and flexible elements that maintain contact at a sealing interface and slide on each other, allowing a rotating element to pass through a sealed case. The elements are both hydraulically and mechanically loaded with a spring or other device to maintain contact. For similar designs using flexible elements, see radial shaft seal (or "lip seal") and O-ring. Mechanical seal fundamentals An end ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dielectric Gas

A dielectric gas, or insulating gas, is a dielectric material in gaseous state. Its main purpose is to prevent or rapidly quench electric discharges. Dielectric gases are used as electrical insulators in high voltage applications, e.g. transformers, circuit breakers (namely sulfur hexafluoride circuit breakers), switchgear (namely high voltage switchgear), radar waveguides, etc. For high voltage applications, a good dielectric gas should have high dielectric strength, high thermal stability and chemical inertness against the construction materials used, non-flammability and low toxicity, low boiling point, good heat transfer properties, and low cost. The most common dielectric gas is air, due to its ubiquity and low cost. Another commonly used gas is a dry nitrogen. In special cases, e.g., high voltage switches, gases with good dielectric properties and very high breakdown voltages are needed. Highly electronegative elements, e.g., halogens, are favored as they rapidly recombi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Panel (engineering)

A control panel is a flat, often vertical, area where control or monitoring instruments are displayed or it is an enclosed unit that is the part of a system that users can access, such as the control panel of a security system (also called control unit). They are found in factories to monitor and control machines or production lines and in places such as nuclear power plants, ships, aircraft and mainframe computers. Older control panels are most often equipped with push buttons and analog instruments, whereas nowadays in many cases touchscreens are used for monitoring and control purposes. Gallery Flat panels File:FS Clemenceau (R98), engine control panel.jpg, Control panel of the engines of the '' Clémenceau'' aircraft carrier File:INS Shivalik IVCS.JPG, Control panel with touchscreen for the frigate INS Shivalik File:Kontrollpult Flammrohrkessel 1.jpg, Control panel from two Horizontal Return Tubular boiler File:S-IB_Networks_panel.jpg, One of the control panels from the K ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Voltage

Voltage, also known as (electrical) potential difference, electric pressure, or electric tension, is the difference in electric potential between two points. In a Electrostatics, static electric field, it corresponds to the Work (electrical), work needed per unit of Electric charge, charge to move a positive Test particle#Electrostatics, test charge from the first point to the second point. In the SI unit, International System of Units (SI), the SI derived unit, derived unit for voltage is the ''volt'' (''V''). The voltage between points can be caused by the build-up of electric charge (e.g., a capacitor), and from an electromotive force (e.g., electromagnetic induction in a Electric generator, generator). On a macroscopic scale, a potential difference can be caused by electrochemical processes (e.g., cells and batteries), the pressure-induced piezoelectric effect, and the thermoelectric effect. Since it is the difference in electric potential, it is a physical Scalar (physics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Direct Current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow through semiconductors, electrical insulation, insulators, or even through a vacuum as in electron beam, electron or ion beams. The electric current flows in a constant direction, distinguishing it from alternating current (AC). A archaism, term formerly used for this type of current was galvanic current. The abbreviations ''AC'' and ''DC'' are often used to mean simply ''alternating'' and ''direct'', as when they modify ''Electric current, current'' or ''voltage''. Direct current may be converted from an alternating current supply by use of a rectifier, which contains Electronics, electronic elements (usually) or electromechanical elements (historically) that allow current to flow only in one direction. Direct current may be converted into alt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Low Voltage

In electrical engineering, low voltage is a relative term, the definition varying by context. Different definitions are used in electric power transmission and distribution, compared with electronics design. Electrical safety codes define "low voltage" circuits that are exempt from the protection required at higher voltages. These definitions vary by country and specific codes or regulations. IEC Definition The International Electrotechnical Commission (IEC) standard IEC 61140:2016 defines Low voltage as 0 to 1000 V AC RMS or 0 to 1500 V DC.IEC 61140:2016 Chapter 4.2 Other standards such as IEC 60038 defines ''supply system low voltage'' as voltage in the range 50 to 1000 V AC or 120 to 1500 V DC in ''IEC Standard Voltages'' which defines power distribution system voltages around the world. In electrical power systems ''low voltage'' most commonly refers to the mains voltages as used by domestic and light industrial and commercial consumers. "Low volta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure Deformation (mechanics)#Strain, strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an Electrical insulation, insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmons came up with an original way to measure the force introduced into the sample b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |