Laser Machining on:

[Wikipedia]

[Google]

[Amazon]

Laser beam machining (LBM) is a form of

Laser beam machining (LBM) is a form of

Laser beam machining (LBM) is a form of

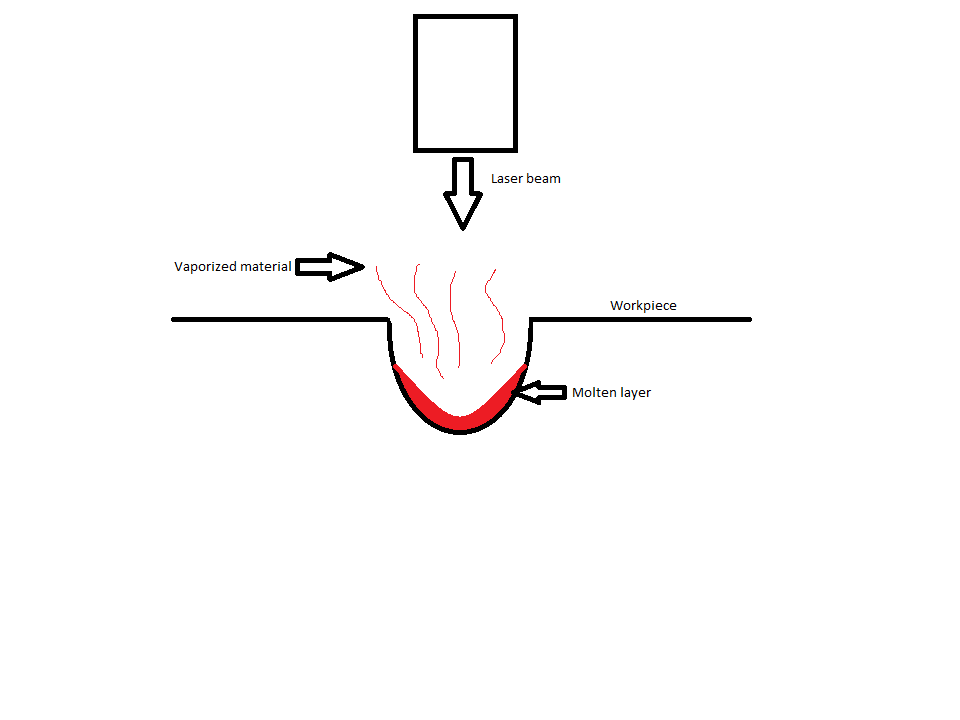

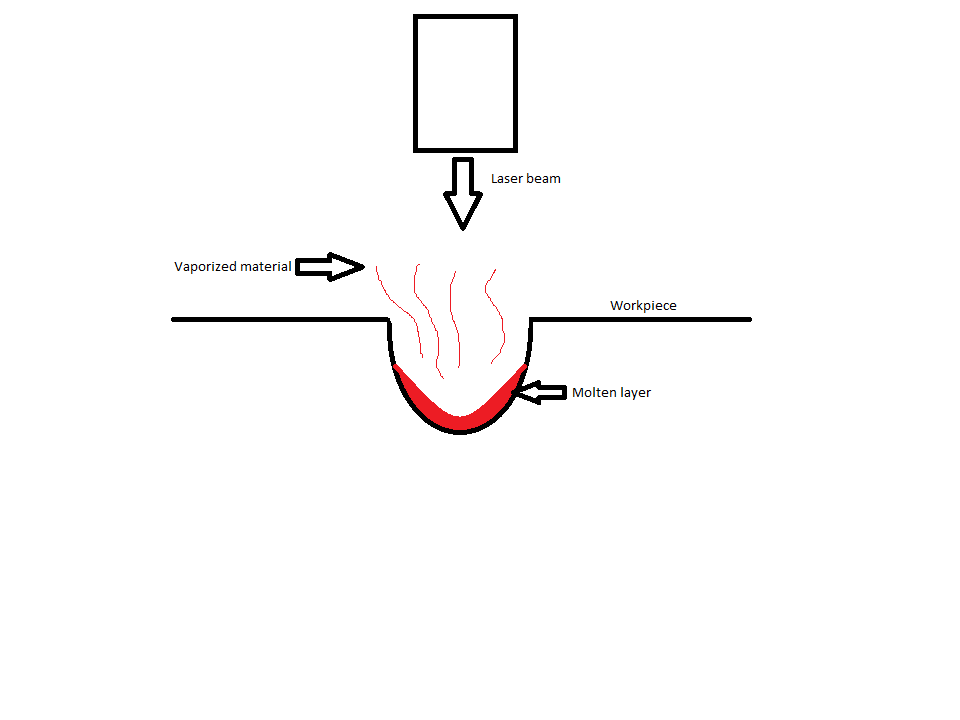

Laser beam machining (LBM) is a form of machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

that uses heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, ato ...

directed from a laser beam

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of rad ...

. This process uses thermal energy

The term "thermal energy" is often used ambiguously in physics and engineering. It can denote several different physical concepts, including:

* Internal energy: The energy contained within a body of matter or radiation, excluding the potential en ...

to remove material from metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

lic or nonmetallic surfaces. The high frequency of monochromatic light

{{More citations needed, date=May 2023

In physics, monochromatic radiation is electromagnetic radiation with a single constant frequency or wavelength. When that frequency is part of the visible spectrum (or near it) the term monochromatic light ...

will fall on the surface, thus heating, melting

Melting, or fusion, is a physical process that results in the phase transition of a substance from a solid to a liquid. This occurs when the internal energy of the solid increases, typically by the application of heat or pressure, which inc ...

and vaporizing

Vaporization (or vapo(u)risation) of an element or compound is a phase transition from the liquid phase to vapor. There are two types of vaporization: evaporation and boiling. Evaporation is a surface phenomenon, whereas boiling is a bulk phenomen ...

the material due to the impinge of photons (see Coulomb explosion).

Laser beam machining is best suited for brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. ...

materials with low conductivity, but can be used on most materials.

Laser beam machining can be done on glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

without melting the surface. With photosensitive glass

Photosensitive glass, also called photostructurable glass (PSG) or photomachinable glass, is a glass in the lithium-silicate family of glasses onto which images can be etched using shortwave radiations, such as ultraviolet. Photosensitive glass ...

, the laser alters the chemical structure of the glass allowing it to be selectively etched. The glass is also referred to as photomachinable glass. The advantage of photomachinable glass is that it can produce precisely vertical walls and the native glass is suitable for many biological applications such as substrates for genetic analysis.

Types of lasers

There are many different types of lasers including gas, solid states lasers, andexcimer

An excimer (originally short for excited dimer) is a short-lived polyatomic molecule formed from two species that do not form a stable molecule in the ground state. In this case, formation of molecules is possible only if such atom is in an elec ...

.

Some of the most commonly used gases consist of; He-Ne, Ar, and Carbon dioxide laser

The carbon-dioxide laser (CO2 laser) was one of the earliest gas lasers to be developed. It was invented by C. Kumar N. Patel, Kumar Patel of Bell Labs in 1964 and is still one of the most useful types of laser. Carbon dioxide, Carbon-dioxide lase ...

.

Solid-state laser

A solid-state laser is a laser that uses a active laser medium, gain medium that is a solid, rather than a liquid as in dye lasers or a gas as in gas lasers. Semiconductor-based lasers are also in the solid state, but are generally considered as ...

s are designed by doping a rare element into various host materials. Unlike in gas lasers, solid state lasers are pumped optically by flash lamps or arc lamps. Ruby is one of the frequently used host materials in this type of laser. A ruby laser

A ruby laser is a solid-state laser that uses a synthetic ruby crystal as its gain medium. The first working laser was a ruby laser made by Theodore H. "Ted" Maiman at Hughes Research Laboratories on May 16, 1960.

Ruby lasers produce pulses of ...

is a type of the solid state laser whose laser medium is a synthetic ruby crystal. The synthetic ruby rod is optically pumped using a xenon flashtube before it is used as an active laser medium.

YAG is an abbreviation for yttrium aluminum garnet which are crystals that are used for solid-state lasers while Nd:YAG refers to neodymium-doped yttrium aluminum garnet crystals that are used in the solid-state lasers as the laser mediate.

YAG lasers emit a wavelength of light waves with high energy. Nd:glass is neodymium–doped gain media made of either silicate or phosphate materials that are used in fiber laser

A fiber laser (or fibre laser in Commonwealth English) is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They ar ...

.

Cutting depth

The cutting depth of a laser is directly proportional to the quotient obtained by dividing the power of the laser beam by the product of the cutting velocity and the diameter of the laser beam spot. : where ''t'' is the depth of cut, ''P'' is the laser beam power, ''v'' is the cutting velocity, and ''d'' is the laser beam spot diameter. The depth of the cut is also influenced by the workpiece material. The material's reflectivity, density, specific heat, and melting point temperature all contribute to the lasers ability to cut the workpiece. The following table shows the ability of different lasers to cut different materials:Applications

Lasers can be used forwelding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

, cladding, marking, surface treatment, drilling, and cutting among other manufacturing processes. It is used in the automobile, shipbuilding, aerospace, steel, electronics, and medical industries for precision machining of complex parts.

Laser welding is advantageous in that it can weld at speeds of up to 100 mm/s as well as the ability to weld dissimilar metals. Laser cladding is used to coat cheap or weak parts with a harder material in order to improve the surface quality. Drilling and cutting with lasers is advantageous in that there is little to no wear on the cutting tool as there is no contact to cause damage.

Milling with a laser is a three dimensional process that requires two lasers, but drastically cuts costs of machining parts. Lasers can be used to change the surface properties of a workpiece.

The appliance of laser beam machining varies depending on the industry. In light manufacturing the machine is used to engrave and to drill other metals. In the electronic industry laser beam machining is used for wire stripping and skiving of circuits. In the medical industry it is used for cosmetic surgery and hair removal.

Advantages

# Since the rays of a laser beam are monochromatic and parallel (i.e. zeroetendue

Etendue or étendue (; ) is a property of light in an optical system, which characterizes how "spread out" the light is in area and angle. It corresponds to the beam parameter product (BPP) in Gaussian beam optics. Other names for etendue inclu ...

) it can be focused to a small diameter and can produce as much as 100 MW of power for a square millimeter of area.

# Laser beam machining has the ability to engrave or cut nearly all materials, where traditional cutting methods may fall short.

# There are several types of lasers, and each have different uses.

# The cost of maintaining lasers is moderately low due to the low rate of wear and tear, as there is no physical contact between the tool and the workpiece.

# The machining provided by laser beams is high precision, and most of these processes do not require additional finishing.

# Laser beams can be paired with gases to help the cutting process be more efficient, help minimize oxidization of surfaces, and/or keep the workpiece surface free from melted or vaporized material.

Disadvantages

# The initial cost of acquiring a laser beam is moderately high. There are many accessories that aid in the machining process, and as most of these accessories are as important as the laser beam itself the startup cost of machining is raised further. # Handling and maintaining the machining requires highly trained individuals. Operating the laser beam is comparatively technical, and services from an expert may be required. # Laser beams are not designed to produce mass metal processes. # Laser beam machining consumes a lot of energy. # Deep cuts are difficult with workpieces with high melting points and usually cause a taper.See also

*Laser cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutt ...

* Laser beam quality

In laser science, laser beam quality defines aspects of the beam illumination pattern and the merits of a particular laser beam's propagation and transformation properties (space-bandwidth criterion). By observing and recording the beam pattern, f ...

References

Further reading

* * {{Authority control Laser machining Machining