Hot Form Quench on:

[Wikipedia]

[Google]

[Amazon]

Hot Form Quench (HFQ®) - an aluminium hot forming

Hot forming of aluminium alloys consists of four main steps performed on a custom-shaped sheet blank: heating and solutionising (above 450°C), blank transfer,

Hot forming of aluminium alloys consists of four main steps performed on a custom-shaped sheet blank: heating and solutionising (above 450°C), blank transfer,  Although a key benefit of the HFQ process is to enable the production of complex, deep drawn pressings in a single forming operation, it is possible to perform secondary cold pressing operations after the HFQ stage if required.

Although a key benefit of the HFQ process is to enable the production of complex, deep drawn pressings in a single forming operation, it is possible to perform secondary cold pressing operations after the HFQ stage if required.

Typical HFQ applications target

Typical HFQ applications target  Aerospace applications are being developed that include lip skins, nacelles, fairings, wing ribs and

Aerospace applications are being developed that include lip skins, nacelles, fairings, wing ribs and

The main disadvantage of HFQ compared to cold forming of aluminium is a higher cycle time and the requirement for furnace investment and fast presses, although the technology is now being utilised for medium/high volume applications as its adoption becomes more widespread. Given that for aluminium parts produced in high volume 60-80% of the component can be raw material, once cycle times for the HFQ process are below 30 seconds, the incremental costs are relatively low versus the forming benefits.

The main disadvantage of HFQ compared to cold forming of aluminium is a higher cycle time and the requirement for furnace investment and fast presses, although the technology is now being utilised for medium/high volume applications as its adoption becomes more widespread. Given that for aluminium parts produced in high volume 60-80% of the component can be raw material, once cycle times for the HFQ process are below 30 seconds, the incremental costs are relatively low versus the forming benefits.

lightweighting

Lightweighting is a concept in the auto industry about building cars and trucks that are less heavy as a way to achieve better fuel efficiency, battery range, acceleration, braking and handling.JIM MOTAVALLI, OCT. 11, 2012, The New York TimesFo ...

technology - is an industrial stamping process for the production of deep drawn, precise and complex geometry ultra-high strength aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

sheet components. It is the aluminium hot stamping (sometimes also called 'aluminium hot forming') process for age-hardening grades of sheet and has similarities to the press hardening

Hot stamping (also known as press hardening, hot press forming, or hot forming die quenching) is a relatively new technology which allows ultra-high strength steels (typically 22MnB5 boron steel) to be formed into complex shapes, which is not poss ...

of ultra-high strength steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

s. HFQ, the original aluminium hot stamping process, exploits viscoplasticity

Viscoplasticity is a theory in continuum mechanics that describes the rate-dependent inelastic behavior of solids. Rate-dependence in this context means that the deformation (mechanics), deformation of the material depends on the rate at which S ...

of aluminium at high temperatures to facilitate the production of lightweight structures, often replacing steel, composites, castings, extrusions or multiple cold formed pressings.

Hot Form Quench (HFQ) is an aluminum hot stamping process for high strength sheet (typically) 2xxx, 6xxx and 7xxx series alloys, that was initially developed in the early 2000s by Professors Jianguo Lin and Trevor Dean at the University of Birmingham

The University of Birmingham (informally Birmingham University) is a Public university, public research university in Birmingham, England. It received its royal charter in 1900 as a successor to Queen's College, Birmingham (founded in 1825 as ...

and then at Imperial College London

Imperial College London, also known as Imperial, is a Public university, public research university in London, England. Its history began with Prince Albert of Saxe-Coburg and Gotha, Prince Albert, husband of Queen Victoria, who envisioned a Al ...

, both in the UK.

HFQ Technology Associates, a materials technology company based in the UK, has exclusive commercialisation rights for HFQ aluminium hot forming, having acquired in 2024 the assets and know-how from Impression Technologies Limited and Imperial College.At the same time as the first HFQ applications were adopted in automotive applications (the Aston Martin DB11

The Aston Martin DB11 is a two-door grand touring car. It was manufactured as both a coupe and a convertible, the latter known as the Volante. The British carmaker Aston Martin produced the DB11 from 2016 to 2023 when it was replaced by ...

) in 2016, other organisations in the lightweighting ecosystem joined Impression Technologies on a Horizon 2020

The Framework Programmes for Research and Technological Development, also called Framework Programmes or abbreviated FP1 to FP9, are funding programmes created by the European Union/European Commission to support and foster research in the Europe ...

programme called LoCoMaTech with an aim to take the HFQ Technology towards mass volume applications. ITL, having installed the world's first HFQ line at the old Jaguar site at Lyons Park Coventry, has started licensing the HFQ Technology around the world to manufacturers, such as fischer group in Germany, EMI Aerospace in US, and Jet Wagon in China, supplying the automotive and aerospace sectors.

Process

Hot forming of aluminium alloys consists of four main steps performed on a custom-shaped sheet blank: heating and solutionising (above 450°C), blank transfer,

Hot forming of aluminium alloys consists of four main steps performed on a custom-shaped sheet blank: heating and solutionising (above 450°C), blank transfer, quenching

In materials science, quenching is the rapid cooling of a workpiece in water, gas, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, suc ...

(to near ambient temperature) and forming, and artificial aging. In the solutionising step, the blank is heated in a furnace to a temperature where the precipitates in the material dissolve. The solutionising ovens are most effective when designed with forced convection, which is a difference to those used for press hardened steel lines. It is important to note that this hot forming process is different to what is termed Warm Forming, which is performed at under 300°C and results in less formability and finished part strength.

The pressing operation is carried out in a high speed hydraulic, servo-hydraulic or servo press in which the forming tool is cooled to create the necessary quenching to maintain the alloying elements in solid solution. The subsequent ageing process enables precipitation and increases the strength of the components to the required level, typically 300 to 500MPa yield, depending on the aluminium alloy used. Customised proprietary ageing processes have been developed to optimise corrosion performance and/or downstream joining properties

Following the HFQ process, parts can be in-die trimmed or laser trimmed as is typical for press hardened steel parts, dependant on production volume. It is usual for volumes below 10,000 parts per annum to be laser trimmed because of the high cost of the trim tooling; or for higher volumes if flexibility is required for future design changes, such as hole positioning.

Although a key benefit of the HFQ process is to enable the production of complex, deep drawn pressings in a single forming operation, it is possible to perform secondary cold pressing operations after the HFQ stage if required.

Although a key benefit of the HFQ process is to enable the production of complex, deep drawn pressings in a single forming operation, it is possible to perform secondary cold pressing operations after the HFQ stage if required.

Applications

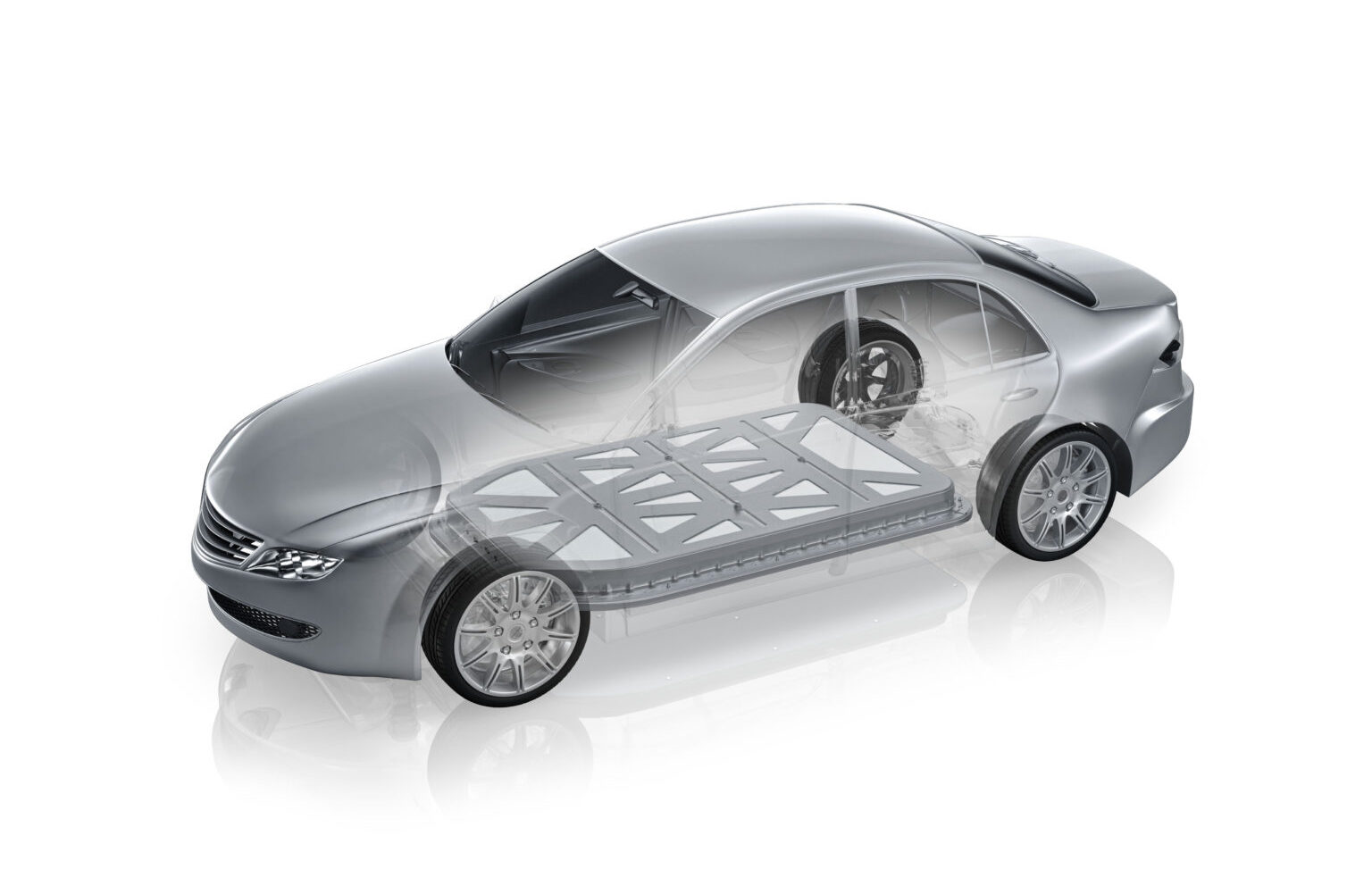

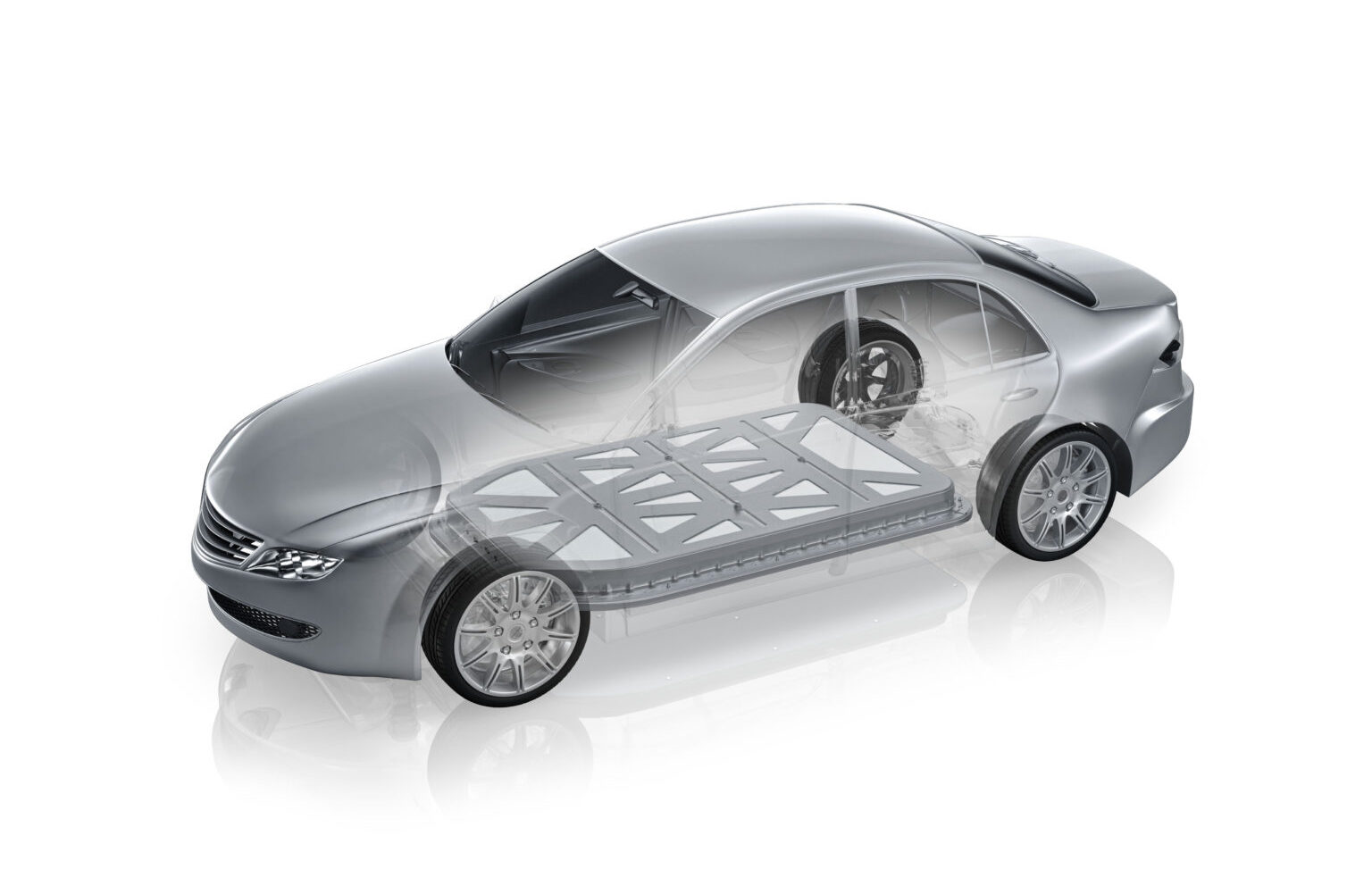

HFQ is used where light-weighting and high levels of part integration are required where aluminium sheet is considered a suitable technical and economic proposition. HFQ can be a solution for applications ranging from several hundred to millions of parts per annum. Aluminium sheet thickness ideal for HFQ range from 0.8mm to 5.0mm. Typical HFQ applications target

Typical HFQ applications target Body in white

Body in white (BIW) is the stage in Automotive industry, automobile manufacturing in which a car body's frame has been joined together, that is before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, sea ...

(BIW) structures and closures including A and B pillars, door rings, cross members, sills, dash panels, rear quarter inners, door inners, tailgate inners and under shields. Recently there has been significant interest in the use of HFQ for battery lids and casings for electric vehicles. Alloys

An alloy is a mixture of chemical elements of which in most cases at least one is a metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties ...

used for these applications include the 6x and 7x series such as 6111, 6082

6 (six) is the natural number following 5 and preceding 7. It is a composite number and the smallest perfect number.

In mathematics

A six-sided polygon is a hexagon, one of the three regular polygons capable of tiling the plane. A hexagon a ...

, 6016 and 7075.

Aerospace applications are being developed that include lip skins, nacelles, fairings, wing ribs and

Aerospace applications are being developed that include lip skins, nacelles, fairings, wing ribs and seats

A seat is a place to sit. The term may encompass additional features, such as back, armrest, head restraint but may also refer to concentrations of power in a wider sense (i.e " seat (legal entity)"). See disambiguation.

Types of seat

The ...

. Other transportation sector applications include electric bicycle frames, motorcycles, and rail structures.

In other sectors, HFQ has been considered to replace heavy castings and machined components, currently made from aluminium where light-weighting or material utilisation are critical factors. There is also some interest in using HFQ for leading edges of turbines

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical ...

, that are subject to leading edge erosion.

A critical consideration in the design of HFQ components is ensuring that the forming simulation is accurate, which is greatly influenced by the quality of the forming material cards for each alloy and the type of lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, ...

used. Even aluminium alloys produced to the same specification can have different formability and end properties, depending on the supplier and the sheet processing lines used. Therefore each grade of aluminium by supplier should be characterised with a common level of high fidelity.

Advantages and disadvantages

HFQ’s main advantage is superior formability for ultra-high strength aluminium alloys, that would otherwise split during conventional cold forming. This leads to extremely deep drawn parts (can be >300mm), sharp radii (r/t of 0.8 of has been demonstrated) and high levels of part integration versus cold formed pressings. In addition, HFQ enables the manufacture of parts from high and ultra-high strength aluminium, which for strength dominant applications facilitates significant weight reductions of circa 20% versus some lower strength cold formed aluminium alloys. Moreover, there is virtually no spring-back - a problem that is inherent in cold forming; with tolerances capable within +/- 0.5mm. When compared tosuperplastic forming

In materials science, superplasticity is a state in which solid crystalline material is deformed well beyond its usual breaking point, usually over about 400% during tensile deformation. Such a state is usually achieved at high homologous temper ...

, which is well-established, HFQ can offer significantly higher production speeds (of up to 5 parts per minute) and a wider range of aluminium grades. Secondary benefits of HFQ include high material utilisation (because of the need for no blank holder); and the ability to use lower cost and more widely available F-temper (as fabricated without extra heat treatment steps by sheet producer) alloy feedstocks and even use highly recycled alloys.

The main disadvantage of HFQ compared to cold forming of aluminium is a higher cycle time and the requirement for furnace investment and fast presses, although the technology is now being utilised for medium/high volume applications as its adoption becomes more widespread. Given that for aluminium parts produced in high volume 60-80% of the component can be raw material, once cycle times for the HFQ process are below 30 seconds, the incremental costs are relatively low versus the forming benefits.

The main disadvantage of HFQ compared to cold forming of aluminium is a higher cycle time and the requirement for furnace investment and fast presses, although the technology is now being utilised for medium/high volume applications as its adoption becomes more widespread. Given that for aluminium parts produced in high volume 60-80% of the component can be raw material, once cycle times for the HFQ process are below 30 seconds, the incremental costs are relatively low versus the forming benefits.

References

{{reflist Aluminium Metalworking