fuller (weapon) on:

[Wikipedia]

[Google]

[Amazon]

A fuller is a rounded or

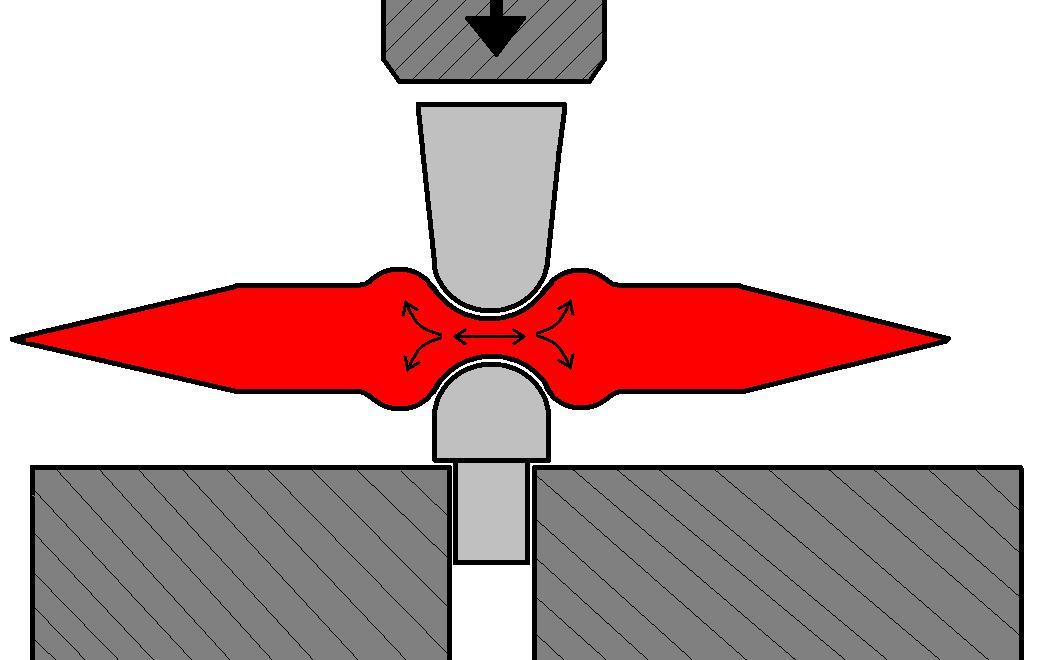

As a blacksmithing tool, a fuller is a type of swage, a tool with a cylindrical or beveled face used to imprint grooves into metal.

Fullers are typically three to six inches long. If a groove is to be applied to both sides of the steel, two fullers may be used at the same time, sandwiching the workpiece in the middle. Often, one fuller will have a peg that holds it securely in the

As a blacksmithing tool, a fuller is a type of swage, a tool with a cylindrical or beveled face used to imprint grooves into metal.

Fullers are typically three to six inches long. If a groove is to be applied to both sides of the steel, two fullers may be used at the same time, sandwiching the workpiece in the middle. Often, one fuller will have a peg that holds it securely in the

File:Bayonet,_knife-sword_(and_scabbard)_(AM_697056-1).jpg, Pattern 1907 bayonet from World War One

File:Bayonet,_knife-sword_(and_scabbard)_(AM_697055-4).jpg, Close-up view of a Pattern 1907 bayonet with hooked quillion

Prussian bayonet clean.jpg, Fully fullered Imperial German S98/05 "Butcher Blade" bayonet

Royal_Navy_Bayonet.jpg, Bayonet attached to the barrel of a British L85A2 rifle. Note the barrel to the left and slot in the blade to attach the wire-cutter scabbard

Jungle carbine bayonet.jpg, Bayonet for the Lee–Enfield rifle No. 5 Mk I " jungle carbine"

World-War-II-US-Military-Bayonets.jpg, US military bayonets; from the top down, they are the M1905, the M1, M1905E1 Bowie point bayonet (a cut down version of the M1905), and the M4 Bayonet for the M1 carbine. The top 3 blades each have fullers.

bevel

A bevelled edge (UK) or beveled edge (US) is an edge of a structure that is not perpendicular to the faces of the piece. The words bevel and chamfer overlap in usage; in general usage, they are often interchanged, while in technical usage, they ...

ed longitudinal groove or slot along the flat side of a blade (e.g., a sword

A sword is an edged and bladed weapons, edged, bladed weapon intended for manual cutting or thrusting. Its blade, longer than a knife or dagger, is attached to a hilt and can be straight or curved. A thrusting sword tends to have a straighter ...

, knife

A knife (: knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least Stone Age, 2.5 million years ago, as e ...

, or bayonet) that serves to both lighten and stiffen the blade, when considering its reduced weight.

Cutting or grinding a fuller into an existing blade will decrease its absolute stiffness due to the removal of material, but much of the strength remains due to the geometry of its shape. When the groove is forged into the blade, it achieves a similar reduction in weight with a relatively small reduction in strength without the wasted material produced by grinding. When impressed during forging, it may be made using a blacksmithing tool that is also called a fuller, a form of spring swage.

When combined with optimal} distal tapers, heat treatment and blade tempering, a fullered blade can be 20% to 35% lighter than a non-fullered blade. The ridges and groove created by the fuller are comparable to an I-beam's flanges and web; this shape aims to optimize the strength and stiffness for a given quantity of material, particularly in the cutting direction.

A fuller is often used to widen a blade

A blade is the Sharpness (cutting), sharp, cutting portion of a tool, weapon, or machine, specifically designed to puncture, chop, slice, or scrape surfaces or materials. Blades are typically made from materials that are harder than those they a ...

during smithing or forging. Fullers are sometimes inaccurately called blood grooves or blood gutters. Channelling blood is not the purpose of a fuller.

Etymology

The term "fuller" is from theMiddle English

Middle English (abbreviated to ME) is a form of the English language that was spoken after the Norman Conquest of 1066, until the late 15th century. The English language underwent distinct variations and developments following the Old English pe ...

''fuliere'', meaning 'one that fulls leatscloth'. It is derived from the Latin

Latin ( or ) is a classical language belonging to the Italic languages, Italic branch of the Indo-European languages. Latin was originally spoken by the Latins (Italic tribe), Latins in Latium (now known as Lazio), the lower Tiber area aroun ...

word ''fullo''. The first recorded use of the term in relation to metal working is 1587. The first recorded use of the term to describe a groove or channel in a blade is 1967.

Tool

anvil

An anvil is a metalworking tool consisting of a large block of metal (usually Forging, forged or Steel casting, cast steel), with a flattened top surface, upon which another object is struck (or "worked").

Anvils are massive because the hi ...

, while the other fuller will have a handle and a flat head, for striking with a hammer. A blade being fullered will generally be slowly pulled through the fullers as it is being hammered, displacing material to the side (rather than removing it) and thereby creating ridges on either side of a groove. These ridges may be hammered flat, widening the blade, or they are often shaped with other swages, increasing the strength of the blade both by creating thicker areas in its cross section and lateral ridges that resist lengthwise deflection.

In addition to being used to "draw out" steel, hammering a short block into a long bar, fullers are also used in the production of items such as hinges and latches, plow parts, and horseshoes.

Japanese blades

In Japanese swordsmithing, fullers have a rich tradition and terminology, enough that there are separate terminologies for the top (''hi'', usually pronounced as ''bi'' when used as the second member of a compound) and bottom (''tome'') ends of the feature. *''Bo-hi'' (): A continuous straight groove of notable width, known as ''katana

A is a Japanese sword characterized by a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands. Developed later than the ''tachi'', it was used by samurai in feudal Japan and worn with the edge fa ...

-bi on tantō''. With ''soe-bi'' (), a secondary narrow groove follows the inner straight length of the main one. With ''tsure-bi'' (), the secondary is similar but continues beyond the straight length.

:*''Futasuji-hi'' (): Two parallel grooves.

:*''Shobu-hi'' (): A groove shaped like the leaf

A leaf (: leaves) is a principal appendage of the plant stem, stem of a vascular plant, usually borne laterally above ground and specialized for photosynthesis. Leaves are collectively called foliage, as in "autumn foliage", while the leav ...

of an iris plant.

:*''Naginata-hi'' (): A miniature ''bo-hi'' whose top is oriented opposite from the blade's, and usually accompanied by a ''soe-bi''. Seen primarily on naginatas.

:*''Kuichigai-hi'' (): Two thin grooves that run the top half of the blade; the bottom half is denoted by the outer groove stopping halfway while the inner one expands to fill the width.

:*''Koshi-bi'' (): A short rounded-top groove found near the bottom of a blade, near to the tang.

*''Tome''

:*''Kaki-toshi'' (): The groove runs all the way down to the end of the tang.

:*''Kaki-nagashi'' (): The groove tapers to a pointed end halfway down the tang.

:*''Kaku-dome'' (): The groove stops as a square end within 3 cm of the tang's upper end.

:*''Maru-dome'' (): Similar to the ''kaku'', except with a rounded-end.

The kukri

TheNepal

Nepal, officially the Federal Democratic Republic of Nepal, is a landlocked country in South Asia. It is mainly situated in the Himalayas, but also includes parts of the Indo-Gangetic Plain. It borders the Tibet Autonomous Region of China Ch ...

i kukri has a terminology of its own, including the "aunlo bal" (finger of strength/force/energy), a relatively deep and narrow fuller near the spine of the blade, which runs (at most) between the handle and the corner of the blade, and the "chirra", which may refer either to shallow fullers in the belly of the blade or a hollow grind of the edge, and of which two or three may be used on each side of the blade.

Gallery

See also

* Corrugated galvanised iron * Fluted armour *Fuller (metalworking)

In metalworking, a fuller is a tool used to shape hot metal. The fuller has a rounded nose, which may be either cylindrical or parabolicc. It may have a handle (an "upper fuller") or a shank (a "lower fuller"). The shank of the lower fuller allow ...

* Swaging

Swaging () is a forging process in which the dimensions of an item are altered using Die (manufacturing), dies into which the item is forced. Swaging is usually a cold working process, but also may be hot working, hot worked.

The term swage ma ...

References

Further reading

* * {{DEFAULTSORT:Fuller (Weapon) Edged and bladed weapons Metalworking tools