Coldharbour Mill on:

[Wikipedia]

[Google]

[Amazon]

Coldharbour Mill, near the village of

The main Tonedale site in Wellington was the largest integrated mill site in the South West of England, covering 10 acres of land and forming the hub of the Fox Brothers woollen manufacturing 'empire'. It is believed to have been the only 'Twin Vertical Woollen Factory' in the world - that is, making both

The main Tonedale site in Wellington was the largest integrated mill site in the South West of England, covering 10 acres of land and forming the hub of the Fox Brothers woollen manufacturing 'empire'. It is believed to have been the only 'Twin Vertical Woollen Factory' in the world - that is, making both

However, the French Revolution and the invasion of Flanders in 1793 caused very serious difficulties for Exeter cloth merchants, and in 1794 the Weres were forced to cancel major worsted yarn orders.

Napoleon's Italian campaigns of 1796-7 closed the Italian market for English cloth, and then Spain entered the war as an ally of France, leading to the confiscation of Exeter cloth. Only six vessels cleared from the Exe with cloth in 1797, and two in 1798; a far cry from the 1768 despatch of 330,414 pieces of cloth. Some Exeter merchants, such as

However, the French Revolution and the invasion of Flanders in 1793 caused very serious difficulties for Exeter cloth merchants, and in 1794 the Weres were forced to cancel major worsted yarn orders.

Napoleon's Italian campaigns of 1796-7 closed the Italian market for English cloth, and then Spain entered the war as an ally of France, leading to the confiscation of Exeter cloth. Only six vessels cleared from the Exe with cloth in 1797, and two in 1798; a far cry from the 1768 despatch of 330,414 pieces of cloth. Some Exeter merchants, such as

The mill site contains a wide variety of subsidiary buildings, including stabling, a

The mill site contains a wide variety of subsidiary buildings, including stabling, a

Thomas Fox's brother Edward was part owner of a Cornish mine, and was instrumental in installing an early example of a

Thomas Fox's brother Edward was part owner of a Cornish mine, and was instrumental in installing an early example of a

The mill contains a number of other steam powered exhibits, including a working Ashworth fire pump, already at Coldharbour, but repaired in 1984 with components from Bliss Mill; a very rare example of a low pressure wagon boiler dating from the late 1700s; and a (non-operational) steam powered flue fan.

The mill contains a number of other steam powered exhibits, including a working Ashworth fire pump, already at Coldharbour, but repaired in 1984 with components from Bliss Mill; a very rare example of a low pressure wagon boiler dating from the late 1700s; and a (non-operational) steam powered flue fan.

Coldharbour Mill Museum website

{{coord, 50.9016, -3.3353, type:landmark_region:GB, display=title Industrial buildings completed in 1799 Textile mills completed in the 18th century Local museums in Devon Industry museums in England Steam museums in England Textile museums in the United Kingdom Grade II* listed buildings in Devon Grade II* listed industrial buildings Grade II* listed watermills Grade II* listed museum buildings Preserved beam engines Industrial Revolution Preserved stationary steam engines Watermills in Devon Industrial buildings in England Spinning Museums established in 1981 Industrial archaeological sites in Devon Woollen mills Wool organizations

Uffculme

Uffculme (, ) is a village and civil parish located in the Mid Devon district of Devon, England. Situated in the Blackdown Hills National Landscape, Blackdown Hills on the B3440, close to the M5 motorway and the Bristol–Exeter line, Bristol– ...

in Devon

Devon ( ; historically also known as Devonshire , ) is a ceremonial county in South West England. It is bordered by the Bristol Channel to the north, Somerset and Dorset to the east, the English Channel to the south, and Cornwall to the west ...

, England, is one of the oldest woollen textile mills

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful good ...

in the world, having been in continuous production since 1797. The mill was one of a number owned by Fox Brothers, and is designated by English Heritage

English Heritage (officially the English Heritage Trust) is a charity that manages over 400 historic monuments, buildings and places. These include prehistoric sites, a battlefield, medieval castles, Roman forts, historic industrial sites, Lis ...

as a Grade II* listed building

In the United Kingdom, a listed building is a structure of particular architectural or historic interest deserving of special protection. Such buildings are placed on one of the four statutory lists maintained by Historic England in England, Hi ...

.

Location

Coldharbour Mill can be found just off junction 27 of the M5 motorway near the village ofUffculme

Uffculme (, ) is a village and civil parish located in the Mid Devon district of Devon, England. Situated in the Blackdown Hills National Landscape, Blackdown Hills on the B3440, close to the M5 motorway and the Bristol–Exeter line, Bristol– ...

, and near to the border with Somerset

Somerset ( , ), Archaism, archaically Somersetshire ( , , ) is a Ceremonial counties of England, ceremonial county in South West England. It is bordered by the Bristol Channel, Gloucestershire, and Bristol to the north, Wiltshire to the east ...

. The headquarters for the mill was at Tonedale in Wellington

Wellington is the capital city of New Zealand. It is located at the south-western tip of the North Island, between Cook Strait and the Remutaka Range. Wellington is the third-largest city in New Zealand (second largest in the North Island ...

. The water provided by the nearby River Culm

The River Culm flows through the Devon Redlands in Devon, England and is the longest tributary of the River Exe. It rises in the Blackdown Hills at a spring near RAF Culmhead in Somerset, and flows west through Hemyock, then Culmstock (in th ...

was a prime factor in Thomas Fox's decision to purchase the existing grist mill

A gristmill (also: grist mill, corn mill, flour mill, feed mill or feedmill) grinds cereal grain into flour and Wheat middlings, middlings. The term can refer to either the grinding mechanism or the building that holds it. Grist is grain that h ...

. In 1797, he wrote to his brother "I have purchased the premises at Uffculme for eleven hundred guineas, which I do not think dear as they include about fifteen acres of very fine meadow land. The buildings are but middling, but the stream good."Fox, Hubert ''Quaker Homespun, The Life of Thomas Fox of Wellington, Serge Maker and Banker 1747-1821'' privately printed

The roads in the area at the time were very poor, and finished cloth had to be carried by pack horses to the nearby ports of Topsham and Exeter

Exeter ( ) is a City status in the United Kingdom, cathedral city and the county town of Devon in South West England. It is situated on the River Exe, approximately northeast of Plymouth and southwest of Bristol.

In Roman Britain, Exeter w ...

, or by carrier's cart to Bridgwater, Bristol and London (a twelve-day journey).

History

It appears that there has been a mill of some description near the Coldharbour site since Saxon times. The Domesday Book recording two mills in the Uffculme area. At its peak the company employed approximately 5,000 people and owned and operated nine mills and factories in Somerset, Devon, andOxfordshire

Oxfordshire ( ; abbreviated ''Oxon'') is a ceremonial county in South East England. The county is bordered by Northamptonshire and Warwickshire to the north, Buckinghamshire to the east, Berkshire to the south, and Wiltshire and Glouceste ...

. One of the most notable satellite mills was that of William Bliss & Sons, built in 1872 after a disastrous fire in the original mill. Located in Chipping Norton

Chipping Norton is a market town and Civil parishes in England, civil parish in the Cotswolds in the West Oxfordshire district of Oxfordshire, England, about south-west of Banbury and north-west of Oxford. The United Kingdom Census 2011, 201 ...

, the William Bliss site was one of the grandest mills in England, complete with reading room, chapel and workers cottages. Fox Brothers bought it in 1920.  The main Tonedale site in Wellington was the largest integrated mill site in the South West of England, covering 10 acres of land and forming the hub of the Fox Brothers woollen manufacturing 'empire'. It is believed to have been the only 'Twin Vertical Woollen Factory' in the world - that is, making both

The main Tonedale site in Wellington was the largest integrated mill site in the South West of England, covering 10 acres of land and forming the hub of the Fox Brothers woollen manufacturing 'empire'. It is believed to have been the only 'Twin Vertical Woollen Factory' in the world - that is, making both worsted

Worsted ( or ) is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead (from Old English ''Wurðestede'', "enclosure place"), a village in the English county of Norfolk. T ...

and woollen

Woolen (American English) or woollen (Commonwealth English) is a type of yarn made from carded wool. Woolen yarn is soft, light, stretchy, and full of air. It is thus a good insulator, and makes a good knitting yarn. Woolen yarn is in contrast t ...

products, and controlling the entire process from fleece to finished cloth in-house.

The founders

The ancestors of the mill owners, the Fox family (no relation toGeorge Fox

George Fox (July 1624 Old Style and New Style dates, O.S. – 13 January 1691 Old Style and New Style dates, O.S.) was an English Dissenters, English Dissenter, who was a founder of the Quakers, Religious Society of Friends, commonly known as t ...

, founder of the Religious Society of Friends

Quakers are people who belong to the Religious Society of Friends, a historically Protestant Christian set of denominations. Members refer to each other as Friends after in the Bible, and originally, others referred to them as Quakers ...

, or Quakers) and the Were family, were early Quaker converts. During George Fox's first visit to Devonshire in 1655, he went to the house of Nicholas Tripe and his wife, who became 'convinced'. Their daughter, Anstice, married George Croker of Plymouth, and they were much persecuted for their beliefs. Their daughter Tabitha married Francis Fox of St. Germans, Cornwall, a serge Serge may refer to:

*Serge (fabric), a type of twill fabric

*Serge (llama) (born 2005), a llama in the Cirque Franco-Italien and internet meme

*Serge (name), a masculine given name (includes a list of people with this name)

*Serge (post), a hitchi ...

maker. The family remained in Cornwall, becoming merchants and shipping agents, and in 1745 the grandson of Francis and Tabitha, Edward Fox of Eggeshall near Wadebridge, married Anne Were, the daughter of a Wellington serge maker, Thomas Were. (In 1749, Edward's cousin, George Croker Fox, married Mary Were, the sister of Anne). Thomas Were was a very successful manufacturer, and had inherited the WRE trademark, which certified the quality of his cloth.Fox, Joseph Hoyland ''The Woollen Manufacture at Wellington, Somerset. Compiled from the Records of the Old Family Business'' Arthur Humphreys, London 1914 His great-great grandfather John Were of Pinksmoor was credited with owning a fulling mill

Fulling, also known as tucking or walking ( Scots: ''waukin'', hence often spelt waulking in Scottish English), is a step in woollen clothmaking which involves the cleansing of woven cloth (particularly wool) to eliminate (lanolin) oils, dirt, ...

. During one of the visits of Edward to his father-in-law, it was suggested that one of Edward and Anne's sons should join the Wellington woollen manufacturing business. After four years of study overseas, Edward's son Thomas Fox moved to Wellington, and became a partner of Were and Company in 1772, aged 25. Thomas and his wife Sarah Smith, built in 1801, then lived in, Tone Dale House

Tone Dale House (or Tonedale House) is a Grade II listed country house built in 1801 or 1807 by Thomas Fox in Wellington, Somerset, England. Wellington lies west of Taunton in the vale of Taunton Deane, from the Devon border. Tone Dale House, ...

, Wellington - the house is still lived in by a Fox, five generations later, by Ben and Victoria Fox. In 1826, when his sons were partners (the Weres having relinquished their shares), the business was renamed Fox Brothers.

The family were prominent in local affairs, and subscribed £1,044 5s 6d in shares in the Grand Western Canal

The Grand Western Canal ran between Taunton in Somerset and Tiverton, Devon, Tiverton in Devon in the United Kingdom. The canal had its origins in various plans, going back to 1796, to link the Bristol Channel and the English Channel by a canal ...

between 1809 and 1813, Thomas having considered the original proposal of 1792 with considerable reticence: "People hereaway seem now as much too eager to engage in Canals as they have been too backward for many years. The almost incredible sum of £900,000 was lately subscribed at Wells in about two hours for cutting one from Taunton to Bristol. Whilst this delyrium continues the writer is neither disposed to subscribe himself nor to recommend his friends doing it, as he doubts whilst such money pours in on them in such abundance it may be badly husbanded."

Banking

In 1787, Were and Company ran short of ready cash, and decided to print their own bank notes - effectively "promises to pay". On 30 October, Thomas printed 500 notes of five guineas each. The notes were well received by local businesses. In 1797, an invasion scare resulted in a shortage of gold and cash, and Thomas Fox issued 3,000 five guinea notes, and seventy six £20 notes in order to enable his business to continue its expansion. TheFox, Fowler and Company

Fox, Fowler, and Company was a British private bank, based in Wellington, Somerset, Wellington, Somerset. The company was founded in 1787 as a supplementary business to the main activities of the Fox Brothers, Fox family, shepherd, sheep-herding ...

bank eventually had over fifty branches in the West Country, and was authorised to issue its own bank notes

A banknote or bank notealso called a bill (North American English) or simply a noteis a type of paper money that is made and distributed ("issued") by a bank of issue, payable to the bearer on demand. Banknotes were originally issued by commer ...

until 1921, the year it was taken over by Lloyds Bank - itself founded by a Quaker, Sampson Lloyd. One of the original £5 notes is on display at Tone Dale House

Tone Dale House (or Tonedale House) is a Grade II listed country house built in 1801 or 1807 by Thomas Fox in Wellington, Somerset, England. Wellington lies west of Taunton in the vale of Taunton Deane, from the Devon border. Tone Dale House, ...

, the family home which Thomas Fox built, in 1801.

Textile products

Exeter was the centre of the mediaeval woollen trade in England, with cloth being exported to the Continental markets of France, Holland and Germany. Kersey, a sturdy cloth, was superseded by serge, so that by 1681 95% of the Exeter cloth export was serge.Clark, E.A.G. ''The ports of the Exe estuary 1660-1860'' University of Exeter 1960 As already mentioned, the Were family were major suppliers of serge cloth to the Continent, especially Holland. Whilst using the ports of London and Bristol as well, Topsham was a major port for the Were export trade. We have a contemporary description of the Exeter trade in serge byCelia Fiennes

Celia Fiennes (7 June 1662 – 10 April 1741) was an English traveller and writer. She explored England on horseback at a time when travel for its own sake was unusual, especially for women.

Early life

Born at Newton Tony, Wiltshire,"June 7t ...

(1662–1741):

However, the French Revolution and the invasion of Flanders in 1793 caused very serious difficulties for Exeter cloth merchants, and in 1794 the Weres were forced to cancel major worsted yarn orders.

Napoleon's Italian campaigns of 1796-7 closed the Italian market for English cloth, and then Spain entered the war as an ally of France, leading to the confiscation of Exeter cloth. Only six vessels cleared from the Exe with cloth in 1797, and two in 1798; a far cry from the 1768 despatch of 330,414 pieces of cloth. Some Exeter merchants, such as

However, the French Revolution and the invasion of Flanders in 1793 caused very serious difficulties for Exeter cloth merchants, and in 1794 the Weres were forced to cancel major worsted yarn orders.

Napoleon's Italian campaigns of 1796-7 closed the Italian market for English cloth, and then Spain entered the war as an ally of France, leading to the confiscation of Exeter cloth. Only six vessels cleared from the Exe with cloth in 1797, and two in 1798; a far cry from the 1768 despatch of 330,414 pieces of cloth. Some Exeter merchants, such as Barings

Barings LLC is a global investment management firm owned by Massachusetts Mutual Life Insurance Company ( MassMutual). It operates as a subsidiary of MassMutual Financial Group, a diversified financial services organization.

As of December 31, ...

, moved to London - the Weres changed production to ''long ell

An ell (from Proto-Germanic *''alinō'', cognate with Latin ''ulna'') is a northwestern European unit of measurement, originally understood as a cubit (the combined length of the forearm and extended hand). The word literally means "arm", an ...

s'', a fine white serge, for the East India Company

The East India Company (EIC) was an English, and later British, joint-stock company that was founded in 1600 and dissolved in 1874. It was formed to Indian Ocean trade, trade in the Indian Ocean region, initially with the East Indies (South A ...

. A letter from Thomas Fox to Green and Walford, factors, is to be found in the Fox Brothers Letter Book archive:

With the termination of the monopoly of the East India Company's charter in 1833 through the Government of India Act 1833

The Government of India Act 1833 ( 3 & 4 Will. 4. c. 85), sometimes called the East India Company Act 1833 or the Charter Act 1833, was an act of the Parliament of the United Kingdom, later retitled as the Saint Helena Act 1833. It extended th ...

(3 & 4 Will. 4 c. 85), the trade in long ells to China declined, and Thomas Fox developed the production of flannel

Flannel is a soft woven fabric, of varying fineness. Flannel was originally made from carded wool or worsted yarn, but is now often made from either wool, cotton, or synthetic fiber. Flannel is commonly used to make tartan clothing, blankets, ...

, which was sold in the home market and to America. Following his Quaker beliefs, Thomas Fox refused to sell flannel to the East India Company when he heard it would be used in the manufacture of cartridges.

In 1881, as a result of losses in the First Boer War

The First Boer War (, ), was fought from 16 December 1880 until 23 March 1881 between the United Kingdom of Great Britain and Ireland, United Kingdom and Boers of the Transvaal (as the South African Republic was known while under British ad ...

, a Parliamentary Commission sought to equip the army with khaki

The color khaki (, ) is a light shade of tan (color), tan with a slight yellowish tinge.

Khaki has been used by many armies around the world for uniforms and equipment, particularly in arid or desert regions, where it provides camouflage rela ...

uniform. Fox Brothers decided to bid for the contract, reasoning that the new contract for 5,000 puttee

file:Puttees from American Infantry Chauchat.jpg, Close-up of a World War I era United States Army infantryman's puttees

A puttee (also spelled ''puttie'', adapted from the Hindi language, Hindi ''wikt:पट्टी, paṭṭī'', meaning "band ...

s would save lives, as well as create employment. Fox Brothers went on to be the major producer of puttees, manufacturing some 850 miles of the cloth in World War I.

In support of the flannel emphasis, in 1865 Coldharbour Mill moved over to producing worsted yarn rather than woollen yarn. This necessitated the need for more power to drive new combing machines. (Worsted yarn is made from sheep with long hair fleeces and the wool has to be combed to ensure that all the fibres are parallel.)

Coldharbour Mill classifies itself as "a working wool museum" and as such runs its museum machinery to demonstrate how woollen products were made. The demonstration products (including worsted yarn, tartan cloth, and rugs) are made available for sale. The mill has four registered tartans - Devon Original (1284), Devon Companion (1283), Somerset (831), and Blackdown Hills (6711).

Architecture

English Heritage wrote a Historic Buildings Report (B/065/2001) about the mill complex, and described the site as "probably one of the best-preserved textile mill complexes in the country. It retains the full range of buildings and power system features which characterised the development of the 19th century textile mill with much of the machinery that was used at the site in the 20th century."Williams, Mike ''Coldharbour Mill Historic Buildings Report (B/065/2001)'' English Heritage 2001 Coldharbour Mill was primarily always used for the production of woolyarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. '' Thread'' is a type of yarn intended for sewing by hand or machine. Modern ...

for the weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

frames of the Wellington mill. The original grist mill was probably a three-storey building, and the original sale notice of 1788 states "The Stream divides in two Parts, one at each End of the House, and they are in a Manner two separate Mills, under the same Roof". A legal dispute of 1834 contains a detailed map of the water courses, which are in their existing positions, with a leat to the front and rear of the grist mill.

The foundations of the main mill were mentioned in a letter of 15 April 1799, stating that they were 50 feet from the grist mill - further away than the current building, but at a point where the wall is thicker today. The mill building of 39 feet wide by 123 feet long was very large for its time. Thomas Fox wrote to his machinery supplier describing how the new mill building was to operate:

An inventory of 1802 suggests that spinning was to be carried out on hand-powered spinning jennies, with a waterwheel (costing £450) powering the carding

In Textile manufacturing, textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver (textiles), sliver suitable for subsequent processing. This is achieved by passi ...

machines. By 1816 the mill contained worsted

Worsted ( or ) is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead (from Old English ''Wurðestede'', "enclosure place"), a village in the English county of Norfolk. T ...

spinning frames, and in 1822 a new waterwheel costing £1,500 had been installed.

The main mill building was expanded at various times, with a two-story extension added to the north; a fireproof stone staircase to the east; a wheelhouse; a fourth floor to the main building; and an adjacent combing

Combing is a method for preparing carding, carded fibre for spinning (textiles), spinning. Combing aligns fibers in parallel before spinning to produce a smoother, stronger, and more lustrous yarn. The process of combing is accompanied by ''gil ...

shed built over the tail race leat flowing from the waterwheel.

Steam power came to the mill in three major building phases. In 1865 a beam engine house was built, together with a boiler house and the first chimney on the site. In the 1890s a second beam engine arrived, the boiler house was extended and the existing chimney built, and then in 1910 the existing horizontal engine was fitted, the Green's economiser

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, ...

house added and the boiler house extended again.

The mill site contains a wide variety of subsidiary buildings, including stabling, a

The mill site contains a wide variety of subsidiary buildings, including stabling, a linhay

A linhay ( ) is a type of farm building found particularly in Devon and Somerset, South West England. It is characterised as a two-storeyed building with an open front, with ''tallet'' or hay-loft above and livestock housing below. It often has ...

, a gas retort house (see below), a carpenter's workshop, an air raid shelter from WWII, worker's cottages, and the manager's house. The tail race which takes the water away from the waterwheel is unusual in that it runs under the combing shed in a wide culvert, before briefly reappearing and then running underground again for some 200 metres.

Sources of power

Coldharbour Mill is unusual to have used both water and steam power right up to the time of its demise as a commercial venture. The water power was believed to have been used for the night shift up until 1978.Water power

The English Heritage report states "it is possible that the wheel pit and parts of the wheel itself are the remnants of the new wheel which was recorded in the Stock Book of 1822...and should be considered of considerable historic significance". The cast and wrought iron high breast-shot wheel is 18 feet in diameter by 14 feet wide, with 48 buckets. It is part of a very unusual survival of a combined water and steam powered drive system, as it continued to be used after the 1910 addition of the horizontal steam engine, and the drive mechanism is still in place. The wheel is turning most days.Steam power

Thomas Fox's brother Edward was part owner of a Cornish mine, and was instrumental in installing an early example of a

Thomas Fox's brother Edward was part owner of a Cornish mine, and was instrumental in installing an early example of a Boulton and Watt

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the Engl ...

engine. Edward told Thomas about this new technology, with the result that James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was f ...

was invited to Wellington in 1782, just six months after his patent for the sun and planet gear

The sun and planet gear is a method of converting reciprocating motion to rotary motion and was used in the first rotative beam engines.

It was invented by the Scotland, Scottish engineer William Murdoch, an employee of Boulton and Watt, but wa ...

that allowed reciprocating motion. Thomas missed the meeting, but wrote to him afterwards:

However, the visit came to nothing, partly due to the very high cost of coal, and partly due to the discontent about mechanisation, which would culminate in the later Luddite

The Luddites were members of a 19th-century movement of English textile workers who opposed the use of certain types of automated machinery due to concerns relating to worker pay and output quality. They often destroyed the machines in organ ...

Movement. A letter in 1785 from Thomas states

Thus it was that the first mechanised wool spinning machinery, purchased from Backhouse of Darlington, were powered by horses. These arrived in September 1791, bringing the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

to the West Country. It was evident from a letter of 1786 that Thomas wished he could have had a cheap source of coal, as in those parts of the country fed by canals:

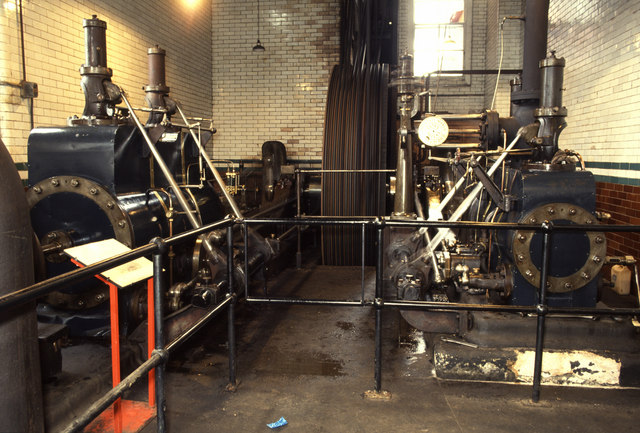

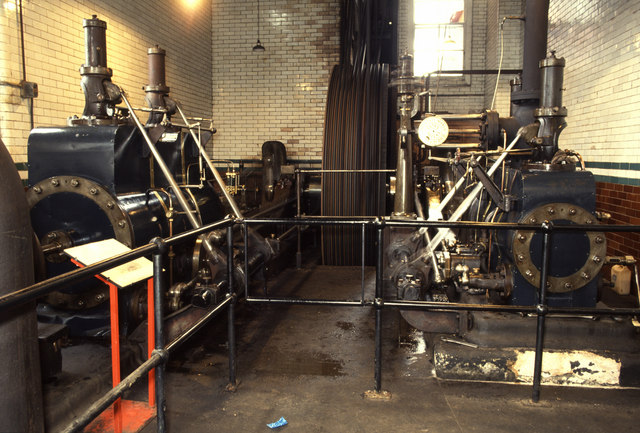

Although the Wellington mill purchased a steam engine for £90 (and a £20 boiler) in 1840, Coldharbour Mill did not get a steam engine until 1865, by which time the Bristol and Exeter Railway

The Bristol and Exeter Railway (B&ER) was an English railway company formed to connect Bristol and Exeter. It was built on the broad gauge and its engineer was Isambard Kingdom Brunel. It opened in stages between 1841 and 1844. It was allied wi ...

was supplying cheap coal to Tiverton Junction. The mill has two Lancashire boiler

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and t ...

s in the boiler house, only one of which is still operational. Initially a 25 hp beam engine

A beam engine is a type of steam engine where a pivoted overhead Beam (structure), beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used b ...

was installed, followed by a second beam engine in the 1890s (possibly 1896). A Pollit & Wigzell 300 hp, cross compound engine superseded the beam engines in 1910 and continued in use, along with the water wheel, until Fox Brothers closed the mill in April 1981. Today the cross compound steam engine remains fully operational and runs regularly at steam up weekends. It drives the shafting on all five floors of the mill via an operational rope drive

A rope drive is a form of belt drive, used for mechanical power transmission.

Rope drives use a number of circular section ropes, rather than a single flat belt, flat or V-belt.

Multiple rope drive

The first multiple rope drive was a 9-rop ...

. In 1993 a salvaged 1867 Kittoe and Brotherhood beam engine was painstakingly restored and installed at the mill, in one of the disused beam engine sheds.

The mill contains a number of other steam powered exhibits, including a working Ashworth fire pump, already at Coldharbour, but repaired in 1984 with components from Bliss Mill; a very rare example of a low pressure wagon boiler dating from the late 1700s; and a (non-operational) steam powered flue fan.

The mill contains a number of other steam powered exhibits, including a working Ashworth fire pump, already at Coldharbour, but repaired in 1984 with components from Bliss Mill; a very rare example of a low pressure wagon boiler dating from the late 1700s; and a (non-operational) steam powered flue fan.

Electrical power

Coldharbour Mill also had a small water turbine for electricity generation, which used the 14 foot head of water between the upper leat and the tail race. No references have been found to it in any register of Devon hydro-electric schemes, and it was unlikely to have generated any more than 3 kW peak power. The exit is visible today in the tail race leat, but nothing else is believed to exist. Two generators were installed in the beam engine house after the beam engines were removed and these were driven by the Pollit and Wigzell engine. The flat belt pulley system is still in existence. It is believed that this was used for lighting rather than running the machines.Gas production

Coldharbour Mill generated its own coal gas on site for lighting the mill (and thus enabling the machinery to be run all night). Although the retorts have been removed and disposed of, the Gas Retort house which housed the retort bench is still standing. In fact, the original gas retorts have been discovered in the leat, where they served as weir components. English Heritage classifies the late 19th century Gas Retort House as ''a very rare survival'' of gas-making facilities.Textile machinery

At the time of its closure in April 1981, Coldharbour Mill still had its textile machinery in position. The majority of these machines have been preserved (though not all are exhibited), and have been augmented with weaving machines rescued from the closure of the Tonedale site. The lowest part of the site, the level 1 combing shed, dealt with the initial cleaning and combing of the unwashed wool. The process involved a number of separate stages, each with a specialised machine. The eight opening gill machines (made by Taylor Wadsworth & Co.) opened up the fleeces and prepared the wool for washing in a large back-washer with steam heated rollers. Following the washing, further gill boxes produced successively combed fibres, which were passed to a circular Noble combing machine. This machine separated the fibres into long "Tops" and the short poor quality fibres. Although these machines are preserved on site, they are no longer in use today. British wool tops are purchased in, dyed into standard colours, and then up to ten strands of tops are fed into the Intersecting Gill Box (manufactured by Prince Smith and Stells in 1959). The gill box starts the process of drawing out the fibres, and also enables new colours to be created by blending together the standard colours. The output of the gill box is termed a sliver. This particular machine has a mechanism to ensure the weight of the sliver is constant, which is important to ensure the final yarn thickness is constant. The next process is to draw the slivers out further, and to give the fibres a small twist to strengthen the resulting slubbing such that it can be wound onto abobbin

A bobbin or spool is a spindle or cylinder, with or without flanges, on which yarn, thread, wire, tape or film is wound. Bobbins are typically found in industrial textile machinery, as well as in sewing machines, fishing reels, tape measures ...

. At Coldharbour Mill, this is demonstrated on a Price Smith and Stells draw box of 1959. The bobbins from this machine are then placed in a further draw box by Prince Smith and Stells, this time an 1898 machine, and the thread from a pair of bobbins is drawn out to a seventh of its diameter, and given a light twist. If this output is to be used for Aran

Aran may refer to:

Places Azerbaijan

Villages and municipalities:

* Aran, Aghjabadi

* Aran, Lerik

* Aran, Shaki

* Aran, Tovuz

* Aran, Yevlakh

Iran

* Aran, Alborz, a village in Alborz Province

* Aran, Nain, a village in Isfahan Province

* Ar ...

yarn production, it is termed a roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialise ...

, and is sent on to the spinning frame

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

Historical context

In 1 ...

. However, if the slubbing is for double knitting

Double knitting is a form of hand knitting in which two fabrics are knitted simultaneously on one pair of needles. The fabrics may be inseparable, as in ''interlock knitted fabrics'', or they can simply be two unconnected fabrics. In principle, ...

yarn, the slubbing must go through another reduction on a draw box.

The museum today

The museum is owned and run by a not-for-profit charitable trust, Registered Charity No. 1123386. It has a number of educational programmes for schools including Victorian Drama; Materials & Fibres; and Britain at War. The mill is home to a number of other exhibits: * AWorld War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

exhibit

* Extensive displays on puttee manufacturing

* The West Country Historic Omnibus & Transport Trust archive

* Visiting exhibitions

References

External links

Coldharbour Mill Museum website

{{coord, 50.9016, -3.3353, type:landmark_region:GB, display=title Industrial buildings completed in 1799 Textile mills completed in the 18th century Local museums in Devon Industry museums in England Steam museums in England Textile museums in the United Kingdom Grade II* listed buildings in Devon Grade II* listed industrial buildings Grade II* listed watermills Grade II* listed museum buildings Preserved beam engines Industrial Revolution Preserved stationary steam engines Watermills in Devon Industrial buildings in England Spinning Museums established in 1981 Industrial archaeological sites in Devon Woollen mills Wool organizations