Autothermal Reforming on:

[Wikipedia]

[Google]

[Amazon]

Steam reforming or steam methane reforming (SMR) is a method for producing CH4 + H2O <=> CO + 3 H2

The reaction is strongly

The reaction is conducted in multitubular

The reaction is conducted in multitubular

syngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

(hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

and carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

) by reaction of hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and Hydrophobe, hydrophobic; their odor is usually fain ...

s with water. Commonly, natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

is the feedstock. The main purpose of this technology is often hydrogen production

Hydrogen gas is produced by several industrial methods. Nearly all of the world's current supply of hydrogen is created from fossil fuels. Article in press. Most hydrogen is ''gray hydrogen'' made through steam methane reforming. In this process, ...

, although syngas has multiple other uses such as production of ammonia

Ammonia is an inorganic chemical compound of nitrogen and hydrogen with the chemical formula, formula . A Binary compounds of hydrogen, stable binary hydride and the simplest pnictogen hydride, ammonia is a colourless gas with a distinctive pu ...

or methanol

Methanol (also called methyl alcohol and wood spirit, amongst other names) is an organic chemical compound and the simplest aliphatic Alcohol (chemistry), alcohol, with the chemical formula (a methyl group linked to a hydroxyl group, often ab ...

. The reaction is represented by this equilibrium:

:endothermic

An endothermic process is a chemical or physical process that absorbs heat from its surroundings. In terms of thermodynamics, it is a thermodynamic process with an increase in the enthalpy (or internal energy ) of the system.Oxtoby, D. W; Gillis, ...

(Δ''H''SR = 206 kJ/mol).

Hydrogen produced by steam reforming is termed 'grey' hydrogen when the waste carbon dioxide is released to the atmosphere and 'blue' hydrogen when the carbon dioxide is (mostly) captured and stored geologically—see carbon capture and storage

Carbon capture and storage (CCS) is a process by which carbon dioxide (CO2) from industrial installations is separated before it is released into the atmosphere, then transported to a long-term storage location.IPCC, 2021Annex VII: Glossary at ...

. Zero carbon 'green' hydrogen is produced by thermochemical water splitting, using solar thermal, low- or zero-carbon electricity or waste heat, or electrolysis

In chemistry and manufacturing, electrolysis is a technique that uses Direct current, direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of c ...

, using low- or zero-carbon electricity. Zero carbon emissions 'turquoise' hydrogen is produced by one-step methane pyrolysis of natural gas.

Steam reforming of natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

produces most of the world's hydrogen. Hydrogen is used in the industrial synthesis of ammonia and other chemicals.

Reactions

Steam reforming reaction kinetics, in particular usingnickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

-alumina

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium oxide. It is commonly ...

catalysts, have been studied in detail since the 1950s.

Pre-reforming

The purpose of pre-reforming is to break down higher hydrocarbons such aspropane

Propane () is a three-carbon chain alkane with the molecular formula . It is a gas at standard temperature and pressure, but becomes liquid when compressed for transportation and storage. A by-product of natural gas processing and petroleum ref ...

, butane

Butane () is an alkane with the formula C4H10. Butane exists as two isomers, ''n''-butane with connectivity and iso-butane with the formula . Both isomers are highly flammable, colorless, easily liquefied gases that quickly vaporize at ro ...

or naphtha

Naphtha (, recorded as less common or nonstandard in all dictionaries: ) is a flammable liquid hydrocarbon mixture. Generally, it is a fraction of crude oil, but it can also be produced from natural-gas condensates, petroleum distillates, and ...

into methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

(CH4), which allows for more efficient reforming downstream.

Steam reforming

The name-giving reaction is the steam reforming (SR) reaction and is expressed by the equation: Via the water-gas shift reaction (WGSR), additional hydrogen is released by reaction of water with the carbon monoxide generated according to equation Some additional reactions occurring within steam reforming processes have been studied. Commonly the direct steam reforming (DSR) reaction is also included: As these reactions by themselves are highly endothermic (apart from WGSR, which is mildly exothermic), a large amount of heat needs to be added to the reactor to keep a constant temperature. Optimal SMR reactor operating conditions lie within a temperature range of 800 °C to 900 °C at medium pressures of 20-30 bar. High excess of steam is required, expressed by the (molar) steam-to-carbon (S/C) ratio. Typical S/C ratio values lie within the range 2.5:1 - 3:1.Industrial practice

The reaction is conducted in multitubular

The reaction is conducted in multitubular packed bed

In chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packed bed can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structu ...

reactors, a subtype of the plug flow reactor category. These reactors consist of an array of long and narrow tubes which are situated within the combustion chamber of a large industrial furnace

An industrial furnace is a device used to provide heat for an industrial process, typically operating at temperatures above 400 degrees Celsius. These furnaces generate heat by combusting fuel with air or oxygen, or through Electricity, electri ...

, providing the necessary energy to keep the reactor at a constant temperature during operation. Furnace designs vary, depending on the burner configuration they are typically categorized into: top-fired, bottom-fired, and side-fired. A notable design is the Foster-Wheeler terrace wall reformer.

Inside the tubes, a mixture of steam and methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

are put into contact with a nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

catalyst. Catalysts with high surface-area-to-volume ratio

The surface-area-to-volume ratio or surface-to-volume ratio (denoted as SA:V, SA/V, or sa/vol) is the ratio between surface area and volume of an object or collection of objects.

SA:V is an important concept in science and engineering. It is use ...

are preferred because of diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical p ...

limitations due to high operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

. Examples of catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

shapes used are spoked wheels, gear wheels, and rings with holes (''see:'' ''Raschig rings''). Additionally, these shapes have a low pressure drop

Pressure drop (often abbreviated as "dP" or "ΔP") is defined as the difference in total pressure between two points of a fluid carrying network. A pressure drop occurs when frictional forces, caused by the resistance to flow, act on a fluid as i ...

which is advantageous for this application.

Steam reforming of natural gas is 65–75% efficient.

The United States

The United States of America (USA), also known as the United States (U.S.) or America, is a country primarily located in North America. It is a federal republic of 50 U.S. state, states and a federal capital district, Washington, D.C. The 48 ...

produces 9–10 million tons of hydrogen per year, mostly with steam reforming of natural gas. The worldwide ammonia production, using hydrogen derived from steam reforming, was 144 million tonnes in 2018. The energy consumption has been reduced from 100 GJ/tonne of ammonia in 1920 to 27 GJ by 2019.

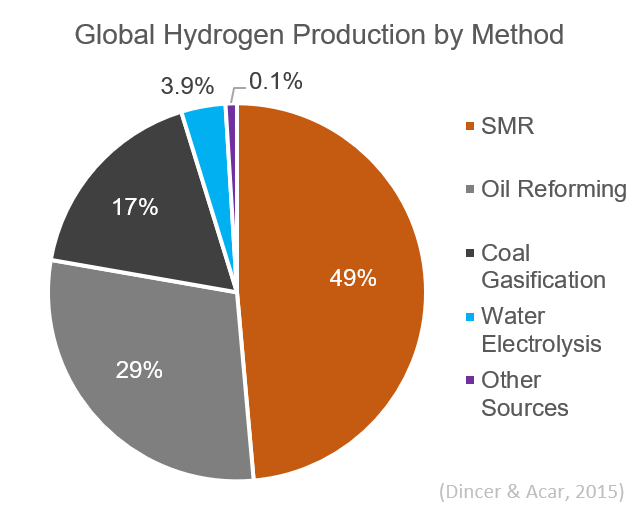

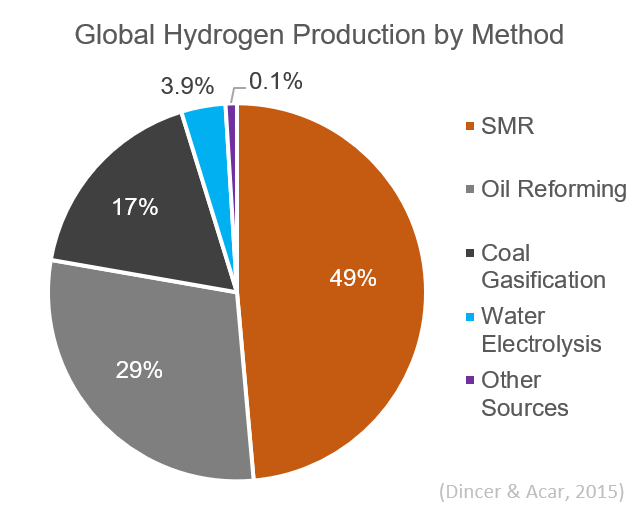

Globally, almost 50% of hydrogen is produced via steam reforming. It is currently the least expensive method for hydrogen production available in terms of its capital cost.

In an effort to decarbonise hydrogen production, carbon capture and storage

Carbon capture and storage (CCS) is a process by which carbon dioxide (CO2) from industrial installations is separated before it is released into the atmosphere, then transported to a long-term storage location.IPCC, 2021Annex VII: Glossary at ...

(CCS) methods are being implemented within the industry, which have the potential to remove up to 90% of CO2 produced from the process. Despite this, implementation of this technology remains problematic, costly, and increases the price of the produced hydrogen significantly.

Autothermal reforming

Autothermal reforming (ATR) uses oxygen and carbon dioxide or steam in a reaction with methane to formsyngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

. The reaction takes place in a single chamber where the methane is partially oxidized. The reaction is exothermic. When the ATR uses carbon dioxide, the H2:CO ratio produced is 1:1; when the ATR uses steam, the H2:CO ratio produced is 2.5:1. The outlet temperature of the syngas is between 950–1100 °C and outlet pressure can be as high as 100 bar.

In addition to reactions – ATR introduces the following reaction:

The main difference between SMR and ATR is that SMR only uses air for combustion as a heat source to create steam, while ATR uses purified oxygen. The advantage of ATR is that the H2:CO ratio can be varied, which can be useful for producing specialty products. Due to the exothermic nature of some of the additional reactions occurring within ATR, the process can essentially be performed at a net enthalpy of zero (Δ''H'' = 0).

Partial oxidation

Partial oxidation (POX) occurs when a sub-stoichiometric fuel-air mixture is partially combusted in a reformer creating hydrogen-rich syngas. POX is typically much faster than steam reforming and requires a smaller reactor vessel. POX produces less hydrogen per unit of the input fuel than steam reforming of the same fuel.Steam reforming at small scale

The capital cost of steam reforming plants is considered prohibitive for small to medium size applications. The costs for these elaborate facilities do not scale down well. Conventional steam reforming plants operate at pressures between 200 and 600 psi (14–40 bar) with outlet temperatures in the range of 815 to 925 °C.For combustion engines

Flared gas and ventedvolatile organic compound

Volatile organic compounds (VOCs) are organic compounds that have a high vapor pressure at room temperature. They are common and exist in a variety of settings and products, not limited to Indoor mold, house mold, Upholstery, upholstered furnitur ...

s (VOCs) are known problems in the offshore industry and in the on-shore oil and gas industry, since both release greenhouse gases into the atmosphere. Reforming for combustion engines utilizes steam reforming technology for converting waste gases into a source of energy.

Reforming for combustion engines is based on steam reforming, where non-methane hydrocarbons ( NMHCs) of low quality gases are converted to synthesis gas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

(H2 + CO) and finally to methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

(CH4), carbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

(CO2) and hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

(H2) - thereby improving the fuel gas quality (methane number).

For fuel cells

There is also interest in the development of much smaller units based on similar technology to producehydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

as a feedstock for fuel cells

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most batteries in req ...

. Small-scale steam reforming units to supply fuel cells

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most batteries in req ...

are currently the subject of research and development, typically involving the reforming of methanol

Methanol (also called methyl alcohol and wood spirit, amongst other names) is an organic chemical compound and the simplest aliphatic Alcohol (chemistry), alcohol, with the chemical formula (a methyl group linked to a hydroxyl group, often ab ...

, but other fuels are also being considered such as propane

Propane () is a three-carbon chain alkane with the molecular formula . It is a gas at standard temperature and pressure, but becomes liquid when compressed for transportation and storage. A by-product of natural gas processing and petroleum ref ...

, gasoline

Gasoline ( North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When for ...

, autogas

Autogas is liquefied petroleum gas (LPG) used as a fuel in internal combustion engines of vehicles as well as in stationary applications such as generators. It is a mixture of propane and butane.

Autogas is widely used as a "green" fuel, ...

, diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

, and ethanol

Ethanol (also called ethyl alcohol, grain alcohol, drinking alcohol, or simply alcohol) is an organic compound with the chemical formula . It is an Alcohol (chemistry), alcohol, with its formula also written as , or EtOH, where Et is the ps ...

.

Disadvantages

The reformer– the fuel-cell system is still being researched but in the near term, systems would continue to run on existing fuels, such as natural gas or gasoline or diesel. However, there is an active debate about whether using these fuels to make hydrogen is beneficial while global warming is an issue.Fossil fuel

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geolog ...

reforming does not eliminate carbon dioxide release into the atmosphere but reduces the carbon dioxide emissions and nearly eliminates carbon monoxide emissions as compared to the burning of conventional fuels due to increased efficiency and fuel cell characteristics. However, by turning the release of carbon dioxide into a point source

A point source is a single identifiable ''localized'' source of something. A point source has a negligible extent, distinguishing it from other source geometries. Sources are called point sources because, in mathematical modeling, these sources ...

rather than distributed release, carbon capture and storage

Carbon capture and storage (CCS) is a process by which carbon dioxide (CO2) from industrial installations is separated before it is released into the atmosphere, then transported to a long-term storage location.IPCC, 2021Annex VII: Glossary at ...

becomes a possibility, which would prevent the release of carbon dioxide to the atmosphere, while adding to the cost of the process.

The cost of hydrogen production by reforming fossil fuels

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geologica ...

depends on the scale at which it is done, the capital cost of the reformer, and the efficiency of the unit, so that whilst it may cost only a few dollars per kilogram of hydrogen at an industrial scale, it could be more expensive at the smaller scale needed for fuel cells.

Challenges with reformers supplying fuel cells

There are several challenges associated with this technology: * The reforming reaction takes place at high temperatures, making it slow to start up and requiring costly high-temperature materials. *Sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

compounds in the fuel will poison certain catalysts, making it difficult to run this type of system from ordinary gasoline

Gasoline ( North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When for ...

. Some new technologies have overcome this challenge with sulfur-tolerant catalysts.

* Coking

Coking is the process of heating coal in the absence of oxygen to a temperature above to drive off the volatile components of the raw coal, leaving behind a hard, strong, porous material with a high carbon content called coke. Coke is predomina ...

would be another cause of catalyst deactivation during steam reforming. High reaction temperatures, low steam-to-carbon ratio (S/C), and the complex nature of sulfur-containing commercial hydrocarbon fuels make coking especially favorable. Olefins, typically ethylene, and aromatics are well-known carbon-precursors, hence their formation must be reduced during steam reforming. Additionally, catalysts with lower acidity were reported to be less prone to coking by suppressing dehydrogenation reactions. H2S, the main product in the reforming of organic sulfur, can bind to all transition metal catalysts to form metal–sulfur bonds and subsequently reduce catalyst activity by inhibiting the chemisorption of reforming reactants. Meanwhile, the adsorbed sulfur species increases the catalyst acidity, and hence indirectly promotes coking. Precious metal catalysts such as Rh and Pt have lower tendencies to form bulk sulfides than other metal catalysts such as Ni. Rh and Pt are less prone to sulfur poisoning by only chemisorbing sulfur rather than forming metal sulfides.

* Low temperature polymer fuel cell membranes can be poisoned by the carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

(CO) produced by the reactor, making it necessary to include complex CO-removal systems. Solid oxide fuel cell

A solid oxide fuel cell (or SOFC) is an Electrochemistry, electrochemical conversion device that produces electricity directly from oxidizing a fuel. Fuel cells are characterized by their electrolyte material; the SOFC has a solid oxide or cera ...

s (SOFC) and molten carbonate fuel cells (MCFC) do not have this problem, but operate at higher temperatures, slowing start-up time, and requiring costly materials and bulky insulation.

* The thermodynamic efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For a he ...

of the process is between 70% and 85% ( LHV basis) depending on the purity of the hydrogen product.

See also

*Biogas

Biogas is a gaseous renewable energy source produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste, Wastewater treatment, wastewater, and food waste. Biogas is produced by anaerobic ...

* Boudouard reaction

* Catalytic reforming

Catalytic reforming is a chemical process used to convert petroleum naphtha, naphthas from crude oil into liquid products called reformates, which are premium "blending stocks" for high-octane gasoline. The process converts low-octane linear hydr ...

* Chemical looping reforming and gasification Chemical looping reforming (CLR) and gasification (CLG) are the operations that involve the use of gaseous carbonaceous feedstock and solid carbonaceous feedstock, respectively, in their conversion to syngas in the chemical looping scheme. The typic ...

* Cracking (chemistry)

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking ...

* Hydrogen pinch

* Hydrogen technologies

Hydrogen technologies are technologies that relate to the production and use of hydrogen as a part hydrogen economy. Hydrogen technologies are applicable for many uses.

Some hydrogen technologies are carbon neutral and could have a role in pre ...

* Industrial gas

Industrial gases are the gaseous materials that are Manufacturing, manufactured for use in Industrial sector, industry. The principal gases provided are nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium and acetylene, although many other ...

* Lane hydrogen producer

* Methane pyrolysis (for Hydrogen)

* Partial oxidation Partial oxidation (POX) is a type of chemical reaction. It occurs when a substoichiometric fuel-air mixture is partially combusted in a reformer, creating a hydrogen-rich syngas which can then be put to further use, for example in a fuel cell. A d ...

* PROX

PROX is an acronym for PReferential OXidation, that refers to the preferential oxidation of carbon monoxide in a gas mixture by a catalyst. It is intended to remove trace amounts of CO from H2/CO/CO2 mixtures produced by steam reforming and water- ...

* Reformed methanol fuel cell

Reformed Methanol Fuel Cell (RMFC) or Indirect Methanol Fuel Cell (IMFC) systems are a subcategory of proton-exchange fuel cells where, the fuel, methanol (CH3OH), is reformed, before being fed into the fuel cell.

RMFC systems offer advantag ...

* Reformer sponge iron cycle

* Syngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

* Timeline of hydrogen technologies

This is a timeline of the history of hydrogen technology.

Timeline

16th century

* c. 1520 – First recorded observation of hydrogen by Paracelsus through dissolution of metals (iron, zinc, and tin) in sulfuric acid.

17th century

* 1625 – F ...

References

{{DEFAULTSORT:Fossil Fuel Reforming Hydrogen production Chemical processes Fuel gas Catalysis Industrial gases