autoclave on:

[Wikipedia]

[Google]

[Amazon]

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or

Downward displacement (or gravity-type): : As steam enters the chamber, it fills the upper areas first as it is less dense than air. This process compresses the air to the bottom, forcing it out through a drain which often contains a temperature sensor. Only when air evacuation is complete does the discharge stop. Flow is usually controlled by a steam trap or a solenoid valve, but bleed holes are sometimes used. As the steam and air mix, it is also possible to force out the mixture from locations in the chamber other than the bottom.

;Steam pulsing: : Air dilution by using a series of steam pulses, in which the chamber is alternately pressurized and then depressurized to near atmospheric pressure.

; Vacuum pumps: : A vacuum pump sucks air or air/steam mixtures from the chamber.

;Superatmospheric cycles: : Achieved with a vacuum pump. It starts with a vacuum followed by a steam pulse followed by a vacuum followed by a steam pulse. The number of pulses depends on the particular autoclave and cycle chosen.

;Subatmospheric cycles: : Similar to the superatmospheric cycles, but chamber pressure never exceeds atmospheric pressure until they pressurize up to the sterilizing temperature.

Stovetop autoclaves used in poorer or non-medical settings do not always have automatic air removal programs. The operator is required to manually perform steam pulsing at certain pressures as indicated by the gauge.

Image:Autoclave stove top.jpg, Stovetop autoclaves, also known as pressure cooker—the simplest of autoclaves

File:Autoclave machine.jpg, The machine on the right is an autoclave used for processing substantial quantities of laboratory equipment prior to reuse, and infectious material prior to disposal. (The machines on the left and in the middle are washing machines.)

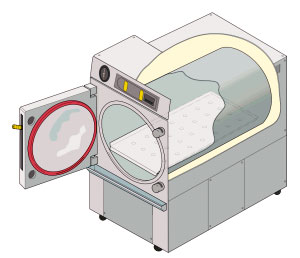

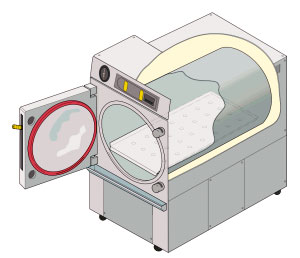

File:Systec H-Series Autoclaves.jpg, Horizontal high-capacity autoclave with cylindrical chamber

File:Pass-through-autoclaves-1-231x300.jpg, Illustration of a cylindrical-chamber pass-through autoclave

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature

Temperature is a physical quantity that quantitatively expresses the attribute of hotness or coldness. Temperature is measurement, measured with a thermometer. It reflects the average kinetic energy of the vibrating and colliding atoms making ...

. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites.

Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at for 30–60 minutes at a gauge pressure of 103 kPa depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek ''auto-'', ultimately meaning self, and Latin ''clavis'' meaning key, thus a self-locking device.

Uses

Sterilization autoclaves are widely used inmicrobiology

Microbiology () is the branches of science, scientific study of microorganisms, those being of unicellular organism, unicellular (single-celled), multicellular organism, multicellular (consisting of complex cells), or non-cellular life, acellula ...

and mycology

Mycology is the branch of biology concerned with the study of fungus, fungi, including their Taxonomy (biology), taxonomy, genetics, biochemistry, biochemical properties, and ethnomycology, use by humans. Fungi can be a source of tinder, Edible ...

, medicine

Medicine is the science and Praxis (process), practice of caring for patients, managing the Medical diagnosis, diagnosis, prognosis, Preventive medicine, prevention, therapy, treatment, Palliative care, palliation of their injury or disease, ...

and prosthetics fabrication, tattooing and body piercing, and funerary practice. They vary in size and function depending on the media to be sterilized and are sometimes called retort in the chemical and food industries.

Typical loads include laboratory glassware, other equipment and waste, surgical instruments, and medical waste.

A notable recent and increasingly popular application of autoclaves is the pre-disposal treatment and sterilization of waste material, such as pathogenic hospital waste. Machines in this category largely operate under the same principles as conventional autoclaves in that they are able to neutralize (but not eliminate) potentially infectious agents by using pressurized steam and superheated water.

Autoclaves are also widely used to cure composites, especially for melding multiple layers without any voids that would decrease material strength, and in the vulcanization of rubber. The high heat and pressure that autoclaves generate help to ensure that the best possible physical properties are repeatable. Manufacturers of spars for sailboats have autoclaves well over long and wide, and some autoclaves in the aerospace industry are large enough to hold whole airplane fuselages made of layered composites.

A thermal effluent decontamination system functions as a single-purpose autoclave designed for the sterilization of liquid waste and effluent.

Air removal

It is very important to ensure that all of the trapped air is removed from the autoclave before activation, as trapped air is a very poor medium for achieving sterility. Steam at can achieve a desired level of sterility in three minutes, while achieving the same level of sterility in hot air requires two hours at . Methods of air removal include: ;In medicine

A medical autoclave is a device that uses steam to sterilize equipment and other objects. This means that allbacteria

Bacteria (; : bacterium) are ubiquitous, mostly free-living organisms often consisting of one Cell (biology), biological cell. They constitute a large domain (biology), domain of Prokaryote, prokaryotic microorganisms. Typically a few micr ...

, viruses, fungi

A fungus (: fungi , , , or ; or funguses) is any member of the group of eukaryotic organisms that includes microorganisms such as yeasts and mold (fungus), molds, as well as the more familiar mushrooms. These organisms are classified as one ...

, and spore

In biology, a spore is a unit of sexual reproduction, sexual (in fungi) or asexual reproduction that may be adapted for biological dispersal, dispersal and for survival, often for extended periods of time, in unfavourable conditions. Spores fo ...

s are inactivated. However, prion

A prion () is a Proteinopathy, misfolded protein that induces misfolding in normal variants of the same protein, leading to cellular death. Prions are responsible for prion diseases, known as transmissible spongiform encephalopathy (TSEs), w ...

s, such as those associated with Creutzfeldt–Jakob disease, and some toxins released by certain bacteria, such as Cereulide, may not be destroyed by autoclaving at the typical 134 °C for three minutes or 121 °C for 15 minutes and instead should be immersed in sodium hydroxide (1M NaOH) and heated in a gravity displacement autoclave at 121 °C for 30 min, cleaned, rinsed in water and subjected to routine sterilization. Although a wide range of archaea

Archaea ( ) is a Domain (biology), domain of organisms. Traditionally, Archaea only included its Prokaryote, prokaryotic members, but this has since been found to be paraphyletic, as eukaryotes are known to have evolved from archaea. Even thou ...

species, including '' Geogemma barossii (Strain 121)'', can survive and even reproduce at temperatures found in autoclaves, their growth rate is so slow at the lower temperatures in the less extreme environments occupied by humans that it is unlikely they could compete with other organisms. None of them are known to be infectious or otherwise pose a health risk to humans; in fact, their biochemistry is so different from that of humans, and their multiplication rate is so slow, that microbiologists need not worry about them.

Autoclaves are found in many medical settings, laboratories, and other places that need to ensure the sterility of an object. Many procedures today employ single-use items rather than sterilizable, reusable items. This first happened with hypodermic needles, but today many surgical instruments (such as forceps

Forceps (: forceps or considered a plural noun without a singular, often a pair of forceps; the Latin plural ''forcipes'' is no longer recorded in most dictionaries) are a handheld, hinged instrument used for grasping and holding objects. Forcep ...

, needle holders, and scalpel handles) are commonly single-use rather than reusable items (see waste autoclave).

Because damp heat is used, heat-labile products (such as some plastics) cannot be sterilized this way or they will melt. Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, Textile, rags, poaceae, grasses, Feces#Other uses, herbivore dung, or other vegetable sources in water. Once the water is dra ...

and other products that may be damaged by steam must also be sterilized another way. In all autoclaves, items should always be separated to allow the steam to penetrate the load evenly.

Autoclaving is often used to sterilize medical waste prior to disposal in the standard municipal solid waste stream. This application has become more common as an alternative to incineration due to environmental and health concerns about the combustion by-products emitted by incinerators, especially from the small units which were commonly operated at individual hospitals. Incineration or a similar thermal oxidation process is still generally mandated for pathological waste and other very toxic or infectious medical waste. For liquid waste, an effluent decontamination system is the equivalent hardware.

In dentistry, autoclaves provide sterilization of dental instruments.

In most of the industrialized world medical-grade autoclaves are regulated medical devices. Many medical-grade autoclaves are therefore limited to running regulator-approved cycles. Because they are optimized for continuous hospital use, they favor rectangular designs, require demanding maintenance regimens, and are costly to operate. (A properly calibrated medical-grade autoclave uses thousands of gallons of water each day, independent of task, with correspondingly high electric power consumption.)

In research

Autoclaves are used in education, research, biomedical research, pharmaceutical research and industrial settings to sterilize lab instruments and glassware, process waste loads prior to disposal, prepare culture media and liquid media, and artificially age materials for testing. Although autoclaves produced for use in medicine may be used in research settings, labs may opt for "research-grade" autoclaves. These are specifically designed for non-medical applications. Research autoclaves often use a “jacketless” design where steam is generated directly in the pressure chamber using heating coils (rather than relying on a “steam jacket” and independent steam generator, as is the case in high-throughput medical autoclaves). Research-grade autoclaves do not have to meet stringent requirements associated with sterilizing instruments that will be directly used on humans. Instead they can prioritize efficiency, programming flexibility, ease-of-use, and sustainability. In 2016, the Office of Sustainability at the University of California, Riverside (UCR) conducted a study of autoclave efficiency in their genomics and entomology research labs, tracking several units' power and water consumption. They found that, even when functioning within intended parameters, the medical-grade autoclaves used in their research labs were each consuming 700 gallons of water and 90 kWh of electricity per day (1,134MWh of electricity and 8.8 million gallons of water per year), because they consumed energy and water continuously, even when not in use. UCR's research-grade autoclaves performed the same tasks with equal effectiveness, but used 83% less energy and 97% less water. The University of Alabama at Birmingham (UAB) completed a similar study in 2023 in order to assess the performance differences between similar-sized jacketed and non-jacketed autoclaves performing identical tasks in a research setting. They monitored side-by-side autoclaves in a facility running cycles indicative of the most common load and sterilization tasks used by their researchers campuswide. UAB found that jacketed autoclaves consumed significantly more water (44–50 gallons per cycle) and house steam (25–41 pounds per cycle) than non-jacketed autoclaves, which used less than 2 gallons of water and no house steam per cycle, regardless of cycle type or task. The higher water use by jacketed autoclaves resulted in an estimated water cost of $764 per jacketed autoclave per year, compared to $23 for non-jacketed autoclaves. With over 100 steam-jacketed autoclaves on campus, the author calculated that using jacketed autoclaves for research tasks translated into an additional $74,000 in annual excess spending for UAB. In addition, jacketed autoclaves had a higher initial purchase price than non-jacketed equivalents (37% more). The author also noted anecdotal reports of electrical utility and maintenance cost savings associated with non-jacketed autoclaves. Research autoclaves display a wide range of designs and sizes, and are frequently tailored to their use and load type. Common variations include either a cylindrical or square pressure chamber, air- or water-cooling systems, and vertically or horizontally opening chamber doors (which may be electrically or manually powered). Research-grade autoclaves may be configured for "pass-through" operation. This makes it possible to maintain absolute isolation between "clean" and potentially contaminated work areas. Pass-through research autoclaves are especially important in BSL-3 or BSL-4 facilities.Quality assurance

In order to sterilize items effectively, it is important to use optimal parameters when running an autoclave cycle. A 2017 study performed by the Johns Hopkins Hospital biocontainment unit tested the ability of pass-through autoclaves to decontaminate loads of simulated biomedical waste when run on the factory default setting. The study found that 18 of 18 (100%) mock patient loads (6 PPE, 6 linen, and 6 liquid loads) passed sterilization tests with the optimized parameters compared to only 3 of 19 (16%) mock loads that passed with use of the factory default settings. There are physical, chemical, and biological indicators that can be used to ensure that an autoclave reaches the correct temperature for the correct amount of time. If a non-treated or improperly treated item can be confused for a treated item, then there is the risk that they will become mixed up, which, in some areas such as surgery, is critical. Chemical indicators on medical packaging and autoclave tape change color once the correct conditions have been met, indicating that the object inside the package, or under the tape, has been appropriately processed. Autoclave tape is only a marker that steam and heat have activated the dye. The marker on the tape does not indicate complete sterility. A more difficult challenge device, named the Bowie-Dick device after its inventors, is also used to verify a full cycle. This contains a full sheet of chemical indicator placed in the center of a stack of paper. It is designed specifically to prove that the process achieved full temperature and time required for a normal minimum cycle of 134 °C for 3.5–4 minutes. To prove sterility, biological indicators are used. Biological indicators contain spores of a heat-resistant bacterium, '' Geobacillus stearothermophilus''. If the autoclave does not reach the right temperature, the spores will germinate when incubated and theirmetabolism

Metabolism (, from ''metabolē'', "change") is the set of life-sustaining chemical reactions in organisms. The three main functions of metabolism are: the conversion of the energy in food to energy available to run cellular processes; the co ...

will change the color of a pH-sensitive chemical. Some physical indicators consist of an alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

designed to melt only after being subjected to a given temperature for the relevant holding time. If the alloy melts, the change will be visible.

Some computer-controlled autoclaves use an F0 (F-nought) value to control the sterilization cycle. F0 values are set for the number of minutes of sterilization equivalent to at above atmospheric pressure for 15 minutes. Since exact temperature control is difficult, the temperature is monitored, and the sterilization time adjusted accordingly.

Additional images

References

External links

* * {{Authority control Laboratory equipment Medical equipment