|

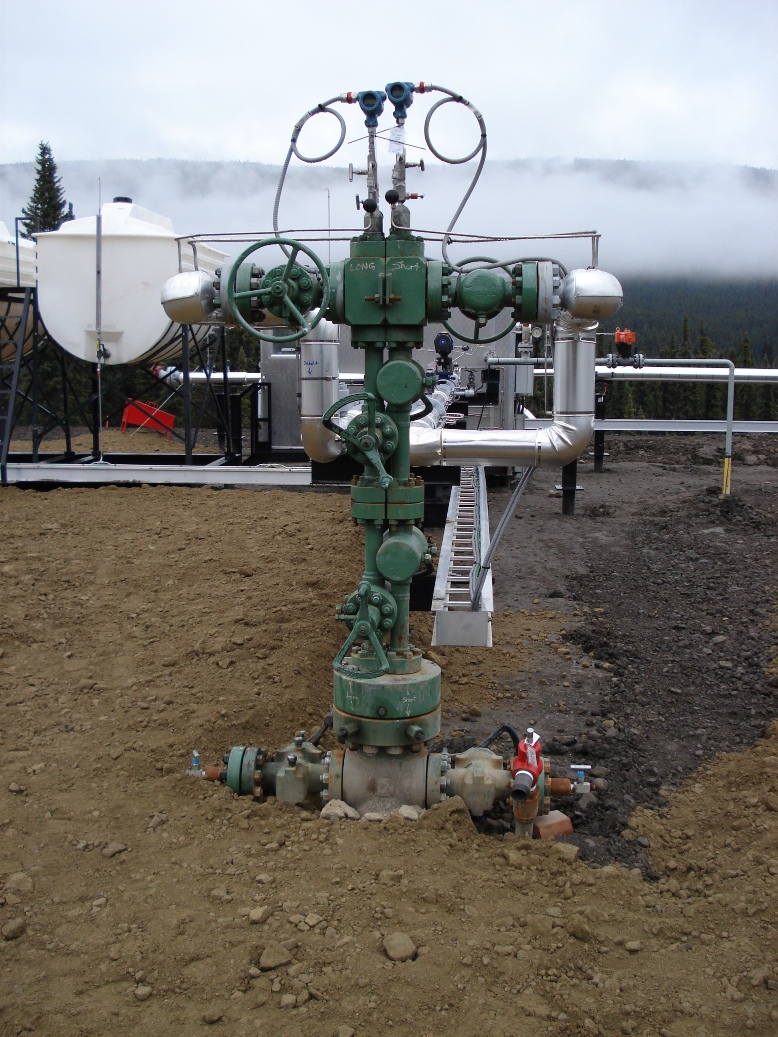

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Well

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well. Wells are created by drilling down into an oil or gas reserve and if necessary equipped with extraction devices such as pumpjacks. Creating the wells can be an expensive process, costing at least hundreds of thousands of dollars, and costing much more when in difficult-to-access locations, e.g., offshore. The process of modern drilling for wells first started in the 19th century but was made more efficient with advances to oil drilling rigs and technology during the 20th century. Wells are frequently sold or exchanged between different oil and gas companies as an asset – in large part because during falls in the price of oil and gas, a well may be unproductive, but if prices rise, even low-production wells may ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blowout Preventer

A blowout preventer (BOP) (pronounced B-O-P) is a specialized valve or similar mechanical device, used to seal, control and monitor oil well, oil and gas wells to prevent Blowout (well drilling), blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves. The earliest blowout preventers; Regan Type K Annulars were used, beginning in the 1930s to cope with extreme erratic pressures and uncontrolled flow (Blowout (well drilling)#Formation kick, formation kick) emanating from a Petroleum reservoir, well reservoir during drilling. Kicks can lead to a potentially catastrophic event known as a blowout. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and Casing (borehole), well casing), tools, and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole lead ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blowout (well Drilling)

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed.'All About Blowout', R. Westergaard, Norwegian Oil Review, 1987 Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil well fire, oil or gas fire. Prior to the advent of pressure control equipment in the 1920s, the uncontrolled release of oil and gas from a well while drilling was common and was known as an oil gusher, gusher or wild well. History Gushers were an icon of oil exploration during the late 19th and early 20th centuries. During that era, the simple drilling techniques, such as drilling rig#Cable tool drilling, cable-tool drilling, and the lack of blowout preventers meant that drillers could not control high-pressure reservoirs. When these high-pressure zones were breached, the oil or natural gas would travel up the well at a high rate, f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Completion (oil And Gas Wells)

Well completion is the process of making a well ready for production (or injection) after drilling operations. This principally involves preparing the bottom of the hole to the required specifications, running in the production tubing and its associated down hole tools as well as perforating and stimulating as required. Sometimes, the process of running in and cementing the casing is also included. After a well has been drilled, should the drilling fluids be removed, the well would eventually close in upon itself. Casing ensures that this will not happen while also protecting the wellstream from outside incumbents, like water or sand. Lower completion (downhole completion) This refers to the portion of the well across the production or injection zone. The well designer has many tools and options available to design the lower completion (downhole completion) according to the conditions of the reservoir. Typically, the lower completion is set across the productive zone using a l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puteal

A puteal (Latin: from puteus ("well") – : putealiaVenetian Wellheads @ Venipedia Accessed May 25, 2012. ) is a classical wellhead built around a 's access opening. Description  The enclosure keeps people from falling down a well otherwise open at grade level.John Weale, ''Rudimentary Dictionary of Terms Used in Architecture, Civil, Architecture, Naval, Building a ...

The enclosure keeps people from falling down a well otherwise open at grade level.John Weale, ''Rudimentary Dictionary of Terms Used in Architecture, Civil, Architecture, Naval, Building a ...

[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Christmas Tree (oil Well)

In petroleum and natural gas extraction, a Christmas tree, or tree, is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well. Overview The first primitive Christmas tree was used by the Hamill Brothers to bring Spindletop under control. It consisted of a T-valve, with a and valve on the vertical pipe, and a 6-inch valve on the horizontal pipe. The vertical valve was closed first, and then the valve to the horizontal pipe. Christmas trees are used on both surface and subsea wells. It is common to identify the type of tree as either "subsea tree" or "surface tree". Each of these classifications has a number of variations. Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees. The deepest installe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casing (borehole)

Casing is a large diameter Pipe (fluid conveyance), pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. The lower portion (and sometimes the entirety) is typically held in place with cement. Deeper strings usually are not cemented all the way to the surface, so the weight of the pipe must be partially supported by a casing hanger in the wellhead. Casing that is cemented in place aids the drilling process in several ways: * Prevents contamination of fresh water well zones. * Prevents unstable upper formations from caving in and sticking the drill string or forming large caverns. * Provides a strong upper foundation to allow use of high-density drilling fluid to continue drilling deeper. * Isolates various zones, which may have different pressures or fluids, in the drilled formations from one another. * Seal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casing Hanger

In petroleum production, the casing hanger is that portion of a wellhead assembly which provides support for the casing string when it is lowered into the wellbore. It serves to ensure that the casing is properly located. When the casing string has been run into the wellbore it is hung off, or suspended, by a casing hanger, which rests on a landing shoulder inside the casing spool. Casing hangers must be designed to take the full weight of the casing, and provide a seal between the casing hanger and the spool. Casing Hangers may also be suspended within the wellhead by means of radial distortion of the wellhead bore e.g. the "Pos-Grip" method. This is installed to support the individual casing strings in the well. It is the landing base or the casing head. This is usually welded or screwed to the top of the surface casing string. The surface casing serves as a foundation pile for the well which transfers the hanging load to the earth. The casing head is prepared with a bowl in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Platforms

An oil platform (also called an oil rig, offshore platform, oil production platform, etc.) is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platforms will also have facilities to accommodate the workers, although it is also common to have a separate accommodation platform linked by bridge to the production platform. Most commonly, oil platforms engage in activities on the continental shelf, though they can also be used in lakes, inshore waters, and inland seas. Depending on the circumstances, the platform may be fixed Platform, fixed to the ocean floor, consist of an artificial island, or floating oil production system, float. In some arrangements the main facility may have storage facilities for the processed oil. Remote subsea wells may also be connected to a platform by flow lines and by umbilical cable, umbilical connections. These sub-sea facilities may include one or more subsea well ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Rig (petroleum)

This article lists the main components of a petroleum onshore drilling rig. Offshore drilling rigs have similar elements, but are configured with a number of different drilling systems to suit drilling in the marine environment. The equipment associated with a rig is to some extent dependent on the type of rig but typically includes at least some of the items listed below. {{clear List of items # Mud tank #Shale shakers # Suction line (mud pump) #Mud pump #Motor or power source #Hose #Drawworks # Standpipe # Kelly hose # Goose-neck # Traveling block # Drill line # Crown block #Derrick # Racking Board (Sometimes referred to as the Monkey Board) #Stand (of drill pipe) # Setback (floor) #Swivel (On newer rigs this may be replaced by a top drive) #Kelly drive #Rotary table # Drill floor # Bell nipple #Blowout preventer (BOP) Annular type #Blowout preventer (BOP) Pipe ram & blind ram #Drill string #Drill bit # Casing head or Wellhead # Flow line Explanation * Bell nipple (#22) i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pumpjack

A pumpjack is the overground drive for a reciprocating piston pump in an oil well. It is used to mechanically lift liquid out of the well if there is not enough bottom hole pressure for the liquid to flow all the way to the surface. The arrangement is often used for onshore wells. Pumpjacks are common in Petroleum reservoir#Oil field, oil-rich areas. Depending on the size of the pump, it generally produces of liquid at each stroke. Often this is an emulsion of crude oil and water. Pump size is also determined by the depth and weight of the oil to remove, with deeper extraction requiring more power to move the increased weight of the discharge column (discharge head). A beam-type pumpjack converts the rotary motion of the motor (usually an electric motor) to the vertical reciprocating motion necessary to drive the polished-rod and accompanying sucker rod and column (fluid) load. The engineering term for this type of mechanism is a Beam engine, walking beam. It was often e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |