|

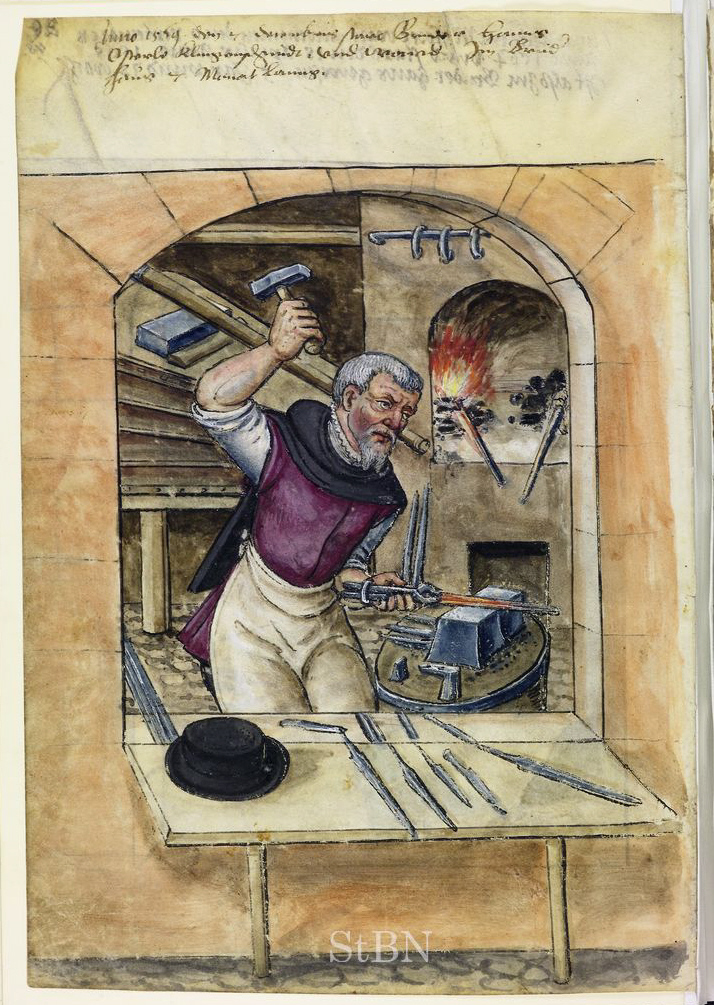

Sword Making

Sword making, historically, has been the work of specialized smiths or metalworkers called bladesmiths or swordsmiths. Swords have been made of different materials over the centuries, with a variety of tools and techniques. While there are many criteria for evaluating a sword, generally the four key criteria are hardness, strength, flexibility and balance. Early swords were made of copper, which bends easily. Bronze swords were stronger. By varying the amount of tin in the alloy, a smith could make different parts of the sword harder or tougher to suit the demands of combat service. The Roman gladius was an early example of swords forged from blooms of steel. A good sword has to be hard enough to hold an edge along a length which can range from to more than . At the same time, it must be strong enough and flexible enough that it can absorb massive shocks at just about any point along its length and not crack or break. Finally, it should be balanced along its length so that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bladesmith

Bladesmithing is the art of making knives, swords, daggers and other blades using a forge, hammer, anvil, and other smithing tools. Bladesmiths employ a variety of metalworking techniques similar to those used by blacksmiths, as well as woodworking for knife and sword handles, and often leatherworking for sheaths. Bladesmithing is an art that is thousands of years old and found in cultures as diverse as China, Japan, India, Germany, Korea, the Middle East, Spain and the British Isles. As with any art shrouded in history, there are myths and misconceptions about the process. While traditionally bladesmithing referred to the manufacture of any blade by any means, the majority of contemporary craftsmen referred to as bladesmiths are those who primarily manufacture blades by means of using a forge to shape the blade as opposed to knifemakers who form blades by use of the stock removal method, although there is some overlap between both crafts. Related trades Many blade smiths were kn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Apa Schwerter

APA most often refers to: * American Psychological Association ** APA style, a writing style guide from the American Psychological Association APA or Apa may also refer to: Entertainment and media * Acolytes Protection Agency, a professional wrestling tag-team * Agency for the Performing Arts, a talent and literary agency * ''Father'' (1966 film) () Government and politics * Administrative Procedure Act (United States), a statute controlling government agency actions * Administrative Procedure Act (Switzerland) * Advance pricing agreement * Approved Publication Arrangement * Accredited parliamentary assistant to a Member of the European Parliament Language * Americanist phonetic notation or the American phonetic alphabet * Southern Athabaskan languages excluding Navajo (ISO 639 code: apa) Organizations and businesses Australia * APA Group (Australia), electricity generation and gas pipeline company * Aborigines Progressive Association * Australian Parkour Association * Aus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quenching

In materials science, quenching is the rapid cooling of a workpiece in water, gas, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. Rapid cooling prevents the formation of cementite structure, instead forcibly dissolving carbon atoms in the ferrite lattice. In steel alloyed with metals such as nickel and manganese, the eutectoid t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work Hardening

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutter inadver ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Photomicrographs of steel. Top: In annealed (slowly cooled) steel, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sword From The Sulu Archipelago, Philippines, Honolulu Museum Of Art

A sword is an edged and bladed weapons, edged, bladed weapon intended for manual cutting or thrusting. Its blade, longer than a knife or dagger, is attached to a hilt and can be straight or curved. A thrusting sword tends to have a straighter blade with a pointed tip. A slashing sword is more likely to be curved and to have a sharpened cutting edge on one or both sides of the blade. Many swords are designed for both thrusting and slashing. The precise definition of a sword varies by historical epoch and geographic region. Historically, the sword developed in the Bronze Age, evolving from the dagger; the Bronze Age sword, earliest specimens date to about 1600 BC. The later Iron Age sword remained fairly short and without a crossguard. The spatha, as it developed in the Late Roman army, became the predecessor of the European sword of the Middle Ages, at first adopted as the Migration Period sword, and only in the High Middle Ages, developed into the classical Knightly sword, ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealing (metallurgy)

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling. In annealing, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness. As the material cools it recrystallizes. For many alloys, including carbon steel, the crystal grain size and phase composition, which ultimately determine the material properties, are dependent on the heating rate and cooling rate. Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuller (metalworking)

In metalworking, a fuller is a tool used to shape hot metal. The fuller has a rounded nose, which may be either cylindrical or parabolicc. It may have a handle (an "upper fuller") or a shank (a "lower fuller"). The shank of the lower fuller allows insertion into the hardy hole of the anvil An anvil is a metalworking tool consisting of a large block of metal (usually Forging, forged or Steel casting, cast steel), with a flattened top surface, upon which another object is struck (or "worked"). Anvils are massive because the hi .... Upper fullers come in "straight" or "cross" varieties, depending on the handle's orientation relative to the face. The fuller is a forging tool used to spread metal. The fuller is placed against the metal stock. Either the fuller (for an upper fuller) or the stock (for a lower fuller) is then struck with a hammer. The fuller's rounded nose spreads the metal more efficiently than the flat face of a hammer. The process leaves ridges in the stock, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compression (physical), compressive and shearing (physics), shearing phenomenon, and occurs only when the total stress (physics), stress generated by the cutting implement exceeds the ultimate Strength of materials, strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filing (metalworking)

Filing is a material removal process in manufacturing. Similar, depending on use, to both sawing and grinding in effect, it is functionally versatile, but used mostly for finishing operations, namely in Burr_(edge), deburring operations. Filing operations can be used on a wide range of materials as a finishing operation. Filing helps achieve workpiece function by removing some excess material and deburring the surface. Sandpaper may be used as a filing tool for other materials, such as wood. Band filing Band Filing takes place on a machine similar to a belt sander or band saw. Band files are sectioned similarly to a chain saw, saw chain so that they can be made from stiff material, as they need to be to effectively remove material yet still work in a constant feed. A band filing operation can be used to remove small amounts of material with good accuracy. The cutting teeth of the file are arranged closely on the file and are used as part of a finishing process.. Reciprocating fili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yakan Ceremonial Sword (panabas)

Yakan may refer to: * Yakan people, a community of the Philippines * Yakan language, a language of the Philippines * Yakan movement, a religious movement in Uganda * Cape Yakan, in Russia People with the name * Adly Yakan Pasha (1864–1933), Egyptian politician * Fathi Yakan (1933–2009), Lebanese cleric and politician * Hesham Yakan (born 1962), Egyptian football player * Ibrahim Yakan (1900–?), Egyptian football player * Tuba Yakan (born 1991), Turkish martial artist See also * Iacan * Yagan (other) * Yaghan (other) * Yaka (other) * Yekan (other) Yekan () may refer to: * Yekan, Armenia * Yekan-e Kahriz, Iran * Yekan-e Olya, Iran * Yekan-e Sadi, Iran See also * Yakan (other) {{geodis ... {{Disambiguation, surname Language and nationality disambiguation pages ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |