|

Reboiler

Reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. The heat supplied to the column by the reboiler at the bottom of the column is removed by the condenser at the top of the column. Proper reboiler operation is vital to effective distillation. In a typical classical distillation column, all the vapor driving the separation comes from the reboiler. The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides the heat required for the vaporization. Types of reboilers The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosyphon

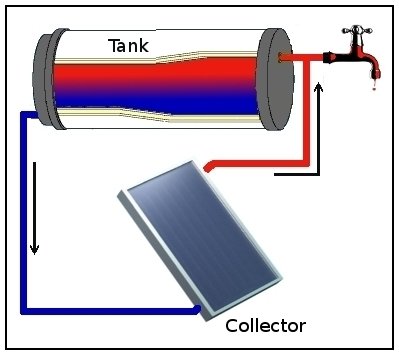

A thermosiphon (or thermosyphon) is a device that employs a method of passive heat transfer, heat exchange based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those occurring in a wood-fire chimney or solar chimney. This circulation can either be open-loop, as when the substance in a holding tank is passed in one direction via a heated transfer tube mounted at the bottom of the tank to a distribution point — even one mounted above the originating tank — or it can be a vertical closed-loop circuit with return to the original container. Its purpose is to simplify the transfer of liquid or gas while avoiding the cost and complexity of a conventional pump. Simple thermosiphon Natural convection of the liq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosyphon Reboiler

A thermosiphon (or thermosyphon) is a device that employs a method of passive heat exchange based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those occurring in a wood-fire chimney or solar chimney. This circulation can either be open-loop, as when the substance in a holding tank is passed in one direction via a heated transfer tube mounted at the bottom of the tank to a distribution point — even one mounted above the originating tank — or it can be a vertical closed-loop circuit with return to the original container. Its purpose is to simplify the transfer of liquid or gas while avoiding the cost and complexity of a conventional pump. Simple thermosiphon Natural convection of the liquid starts whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement There are three primary classifications of heat exchangers according to their flow arrangeme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shell And Tube Heat Exchanger

A shell-and-tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc. Theory and application Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through all the tubes in parallel and the other flows outside the tubes, but inside the shell, typically in counterflow. Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. Cross-baffles can be used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy. Mechanical pumps serve in a wide range of applications such as Water well pump, pumping water from wells, aquarium filtering, pond filtering and Water aeration, aeration, in the car industry for Water cooling, water-cooling and fuel injection, in the energy industry for Pumping (oil well), pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and Penile implant, penile prosthesis. When a pump contains two or more pump mechanisms with fluid being directed to flow through them in series, it is called a ''multi-stage pump''. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distillation

Distillation, also classical distillation, is the process of separating the component substances of a liquid mixture of two or more chemically discrete substances; the separation process is realized by way of the selective boiling of the mixture and the condensation of the vapors in a still. Distillation can operate over a wide range of pressures from 0.14 bar (e.g., ethylbenzene/ styrene) to nearly 21 bar (e.g., propylene/propane) and is capable of separating feeds with high volumetric flowrates and various components that cover a range of relative volatilities from only 1.17 ( o-xylene/ m-xylene) to 81.2 (water/ ethylene glycol). Distillation provides a convenient and time-tested solution to separate a diversity of chemicals in a continuous manner with high purity. However, distillation has an enormous environmental footprint, resulting in the consumption of approximately 25% of all industrial energy use. The key issue is that distillation operates based on phase changes, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perry's Chemical Engineers' Handbook

''Perry's Chemical Engineers' Handbook'' (also known as ''Perry's Handbook'', ''Perry's'', or ''The Chemical Engineer's Bible'') was first published in 1934 and the most current ninth edition was published in July 2018. It has been a source of chemical engineering knowledge for chemical engineers, and a wide variety of other engineers and scientists, through eight previous editions spanning more than 80 years. Subjects The subjects covered in the book include: physical properties of chemicals and other materials; mathematics; thermodynamics; heat transfer; mass transfer; fluid dynamics In physics, physical chemistry and engineering, fluid dynamics is a subdiscipline of fluid mechanics that describes the flow of fluids – liquids and gases. It has several subdisciplines, including (the study of air and other gases in motion ...; chemical reactors and chemical reaction kinetics; transport and storage of fluid; heat transfer equipment; psychrometry and evaporative cool ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distillation Design

''Distillation Design'' is a book which provides complete coverage of the design of industrial distillation columns for the petroleum refining, chemical and petrochemical plants, natural gas processing, pharmaceutical, food and alcohol distilling industries. It has been a classical chemical engineering textbook since it was first published in February 1992. The subjects covered in the book include: *''Vapor–liquid equilibrium(VLE)'': Vapor–liquid K values, relative volatilities, ideal and non-ideal systems, phase diagrams, calculating bubble points and dew points *''Key fractional distillation concepts'': theoretical stages, x-y diagrams, multicomponent distillation, column composition and temperature profiles *''Process design and optimization'': minimum reflux and minimum stages, optimum reflux, short-cut methods, feed entry location *''Rigorous calculation methods'': Bubble point method, sum rates method, numerical methods (Newton–Raphson In numerical analysis, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiling

Boiling or ebullition is the rapid phase transition from liquid to gas or vapor, vapour; the reverse of boiling is condensation. Boiling occurs when a liquid is heated to its boiling point, so that the vapour pressure of the liquid is equal to the pressure exerted on the liquid by the Standard atmosphere (unit), surrounding atmosphere. Boiling and evaporation are the two main forms of liquid vapourization. There are two main types of boiling: nucleate boiling, where small bubbles of vapour form at discrete points; and critical heat flux boiling, where the boiling surface is heated above a certain critical temperature and a film of vapour forms on the surface. Transition boiling is an intermediate, unstable form of boiling with elements of both types. The boiling point of water is 100 °C or 212 °F but is lower with the decreased atmospheric pressure found at higher altitudes. Boiling water is used as a method of making it potable by killing Microorganism, microbes an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vaporization

Vaporization (or vapo(u)risation) of an element or compound is a phase transition from the liquid phase to vapor. There are two types of vaporization: evaporation and boiling. Evaporation is a surface phenomenon, whereas boiling is a bulk phenomenon (a phenomenon in which the whole object or substance is involved in the process). Evaporation Evaporation is a phase transition from the liquid phase to vapor (a state of substance below critical temperature) that occurs at temperatures below the boiling temperature at a given pressure. Evaporation occurs ''on the surface''. Evaporation only occurs when the partial pressure of vapor of a substance is less than the equilibrium vapor pressure. For example, due to constantly decreasing pressures, vapor pumped out of a solution will eventually leave behind a cryogenic liquid. Boiling Boiling is also a phase transition from the liquid phase to gas phase, but boiling is the formation of vapor as bubbles of vapor ''below the surface'' of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many forms of polymerization and different systems exist to categorize them. In chemical compounds, polymerization can occur via a variety of reaction mechanisms that vary in complexity due to the functional groups present in the reactants and their inherent steric effects. In more straightforward polymerizations, alkenes form polymers through relatively simple radical reactions; in contrast, reactions involving substitution at a carbonyl group require more complex synthesis due to the way in which reactants polymerize. As alkenes can polymerize in somewhat straightforward radical reactions, they form useful compounds such as polyethylene and polyvinyl chloride (PVC), which are produced in high tonnages each year due to their usefulnes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |