|

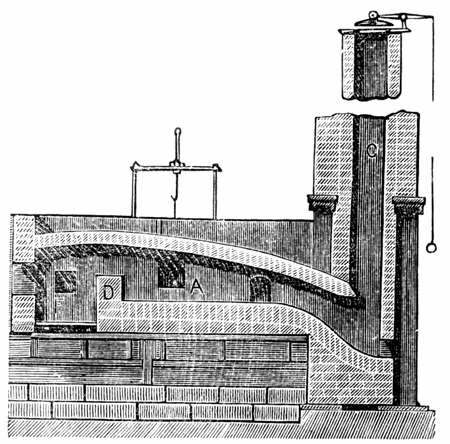

Puddling Furnace

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an Redox, oxidizing environment to burn the carbon, resulting in wrought iron. It was one of the most important processes for making the first appreciable volumes of valuable and useful wrought iron, bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery forge, finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Abraham Darby I

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I (14 April 1677 – 5 May 1717, the first and best known of Abraham Darby (other), several men of that name), was a British ironmaster and foundryman. Born into an Kingdom of England, English Quaker family that played an important role in the Industrial Revolution, Darby developed a method of producing pig iron in a blast furnace fuelled by Coke (fuel), coke rather than charcoal. This was a major step forward in the production of iron as a raw material for the Industrial Revolution. Early life Abraham Darby was the son of John Darby, a yeoman farmer and locksmith by trade, and his wife Ann Baylies. He was born at Wren's Nest in Woodsetton, Dudley, Woodsetton, Staffordshire, now part of Dudley, West Midlands (county), West Midlands. He was descended from nobility; his great-grandmother Jane was an illegitimate child of Edward Sutton, 5th Baron Dudle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Peter Onions

Peter Onions (1724 – 1798) was an English ironmaster and the inventor of an early puddling process used for the refining of pig iron into wrought iron. Biography Onions was born in Broseley, Shropshire, later moving to Merthyr Tydfil in Wales. He married Elizabeth Guest, sister of John Guest, a founder of Guest, Keen and Nettlefold, which is today the British conglomerate GKN In 1783, Onions received patent number 1370 for his invention. Henry Cort Henry Cort (c. 1740 – 23 May 1800) was an English ironware producer who was formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron (or bar iron) using innovative productio ... later improved on Onion's process during the development of his puddling furnace. References 1724 births 1798 deaths Businesspeople from Shropshire Foundrymen British ironmasters Engineers from Shropshire People from Broseley People of the Industrial Revolution Briti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Atmosphere Of Earth

The atmosphere of Earth is composed of a layer of gas mixture that surrounds the Earth's planetary surface (both lands and oceans), known collectively as air, with variable quantities of suspended aerosols and particulates (which create weather features such as clouds and hazes), all retained by gravity of Earth, Earth's gravity. The atmosphere serves as a protective buffer between the Earth's surface and outer space, shields the surface from most meteoroids and ultraviolet solar irradiance, solar radiation, keeps it warm and reduces diurnal temperature variation (temperature extremes between daytime, day and night) through heat retention (greenhouse effect), redistributes heat and moisture among different regions via air currents, and provides the atmospheric chemistry, chemical and climate conditions allowing life to exist and evolution, evolve on Earth. By mole fraction (i.e., by quantity of molecules), dry air contains 78.08% nitrogen, 20.95% oxygen, 0.93% argon, 0.04% carbon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Allotropes Of Oxygen

There are several known allotropy, allotropes of oxygen. The most familiar is oxygen, molecular oxygen (), present at significant levels in Atmosphere of Earth, Earth's atmosphere and also known as dioxygen or triplet oxygen. Another is the highly reactive ozone (). Others are: *Atomic oxygen (), a Radical (chemistry), free radical. *Singlet oxygen (), one of two metastable states of molecular oxygen. *Tetraoxygen (), another metastable form. *Solid oxygen, existing in six variously colored phases, of which one is octaoxygen (, red oxygen) and another one metallic (ζ-oxygen). Atomic oxygen Atomic oxygen, denoted O or O1, is very reactive, as the individual atoms of oxygen tend to quickly bond with nearby molecules. Its lowest-energy electronic state is a Triplet state, spin triplet, designated by the term symbol 3P. On Earth's surface, it exists naturally for a very short time. In outer space, the presence of ample ultraviolet radiation results in a low Earth orbit atmosphere in w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Reverbatory Furnace

A reverberatory furnace is a metallurgy, metallurgical or process Metallurgical furnace, furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''rebounding'' or ''Reflection (physics), reflecting'', not in the acoustics, acoustic sense of ''echoing''. Operation Chemistry determines the optimum relationship between the fuel and the material, among other variables. The reverberatory furnace can be contrasted on the one hand with the blast furnace, in which fuel and material are mixed in a single chamber, and, on the other hand, with crucible, Muffle furnace, muffling, or Retort, retort furnaces, in which the subject material is isolated from the fuel and all of the products of combustion including gases and flying ash. There are, however, a great many furnace designs, and the terminology of metallurgy has not been very consistently defined, so it is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

River Severn

The River Severn (, ), at long, is the longest river in Great Britain. It is also the river with the most voluminous flow of water by far in all of England and Wales, with an average flow rate of at Apperley, Gloucestershire. It rises in the Cambrian Mountains in mid Wales, at an altitude of , on the Plynlimon massif, which lies close to the Ceredigion/Powys border near Llanidloes. The river then flows through Shropshire, Worcestershire and Gloucestershire. The county towns of Shrewsbury, Worcester, England, Worcester and Gloucester lie on its course. The Severn's major tributaries are the River Vyrnwy, Vyrnwy, the River Tern, Tern, the River Teme, Teme, the Warwickshire Avon, and the River Stour, Worcestershire, Worcestershire Stour. By convention, the River Severn is usually considered to end, and the Severn Estuary to begin, after the Prince of Wales Bridge, between Severn Beach in South Gloucestershire and Sudbrook, Monmouthshire. The total area of the estuary's draina ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Cranage Brothers

Thomas and George Cranege (also spelled ''Cranage''), who worked in the ironworking industry in England in the 1760s, are notable for introducing a new method of producing wrought iron from pig iron. Experiment of 1766 The process of converting pig iron into wrought iron (also known as bar iron) was at that time carried out in a finery forge, which was fuelled by charcoal. Charcoal was a limited resource, but coal, more widely available, could not be used because the sulphur in coal would adversely affect the quality of the wrought iron.W. K. V. Gale, ''Ironworking'', Shire Publications. George Cranege worked in Coalbrookdale in Shropshire, at the ironworks established by Abraham Darby I, and his brother Thomas worked at a forge in Bridgnorth in Shropshire. They suggested to Richard Reynolds, manager of the works at Coalbrookdale, that the conversion process could be done in a reverbatory furnace, where the iron did not mix with the coal. Reynolds was sceptical, but authorized ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Abraham Darby II

Abraham Darby, in his lifetime called Abraham Darby the Younger, referred to for convenience as Abraham Darby II (12 May 1711 – 31 March 1763) was the second man of that name in an English Quaker family that played an important role in the early years of the Industrial Revolution. Life Darby was born in Coalbrookdale, Shropshire to Abraham and Mary (née Sergeant). He followed in his father's footsteps in the Darby foundry business in Coalbrookdale, producing cast iron cooking pots, kettles, and other goods. The Coalbrookdale Company also played an important role in using iron to replace the more expensive brass for cylinders for Thomas Newcomen's steam engines. He and his partners were responsible for a very important innovation in introducing the use of coke pig iron as the feedstock for finery forges. This formed a significant part of the output of Horsehay and Ketley Furnaces, which they built in the late 1750s. His father's successful use of coke pig iron as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with the chemical formula S8. Elemental sulfur is a bright yellow, crystalline solid at room temperature. Sulfur is the tenth most abundant element by mass in the universe and the fifth most common on Earth. Though sometimes found in pure, native form, sulfur on Earth usually occurs as sulfide and sulfate minerals. Being abundant in native form, sulfur was known in ancient times, being mentioned for its uses in ancient India, ancient Greece, China, and ancient Egypt. Historically and in literature sulfur is also called brimstone, which means "burning stone". Almost all elemental sulfur is produced as a byproduct of removing sulfur-containing contaminants from natural gas and petroleum.. Downloahere Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Red Short

Red-short, hot-short refers to brittleness of steels at red-hot temperatures. It is often caused by high sulfur levels, in which case it is also known as sulfur embrittlement. Iron or steel, when heated to above 460 °C (900 °F), glows with a red color. The color of heated iron changes predictably (due to black-body radiation) from dull red through orange and yellow to white, and can be a useful indicator of its temperature. Good quality iron or steel at and above this temperature becomes increasingly malleable and plastic. Red-short iron or steel, on the other hand, becomes crumbly and brittle. Sulfur hot-shortness In steel contaminated by sulfur this embrittlement happens due to the sulfur forming iron sulfide/iron mixtures in the grain boundaries of the metal which have a lower melting point than the steel.Deev et al. (May–June 1982)"Role of iron sulfide in the formation of cracks in weld joints" ''Materials Science'', Vol. 18, No. 3, pp. 109–112. When the ste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sulfide (organic)

In organic chemistry, a sulfide (British English sulphide) or thioether is an organosulfur functional group with the connectivity as shown on right. Like many other sulfur-containing compounds, volatile sulfides have foul odors. A sulfide is similar to an ether except that it contains a sulfur atom in place of the oxygen. The grouping of oxygen and sulfur in the periodic table suggests that the chemical properties of ethers and sulfides are somewhat similar, though the extent to which this is true in practice varies depending on the application. Nomenclature Sulfides are sometimes called thioethers, especially in the old literature. The two organic substituents are indicated by the prefixes. (CH3)2S is called dimethylsulfide. Some sulfides are named by modifying the common name for the corresponding ether. For example, C6H5SCH3 is methyl phenyl sulfide, but is more commonly called thioanisole, since its structure is related to that for anisole, C6H5OCH3. The modern systemati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |