|

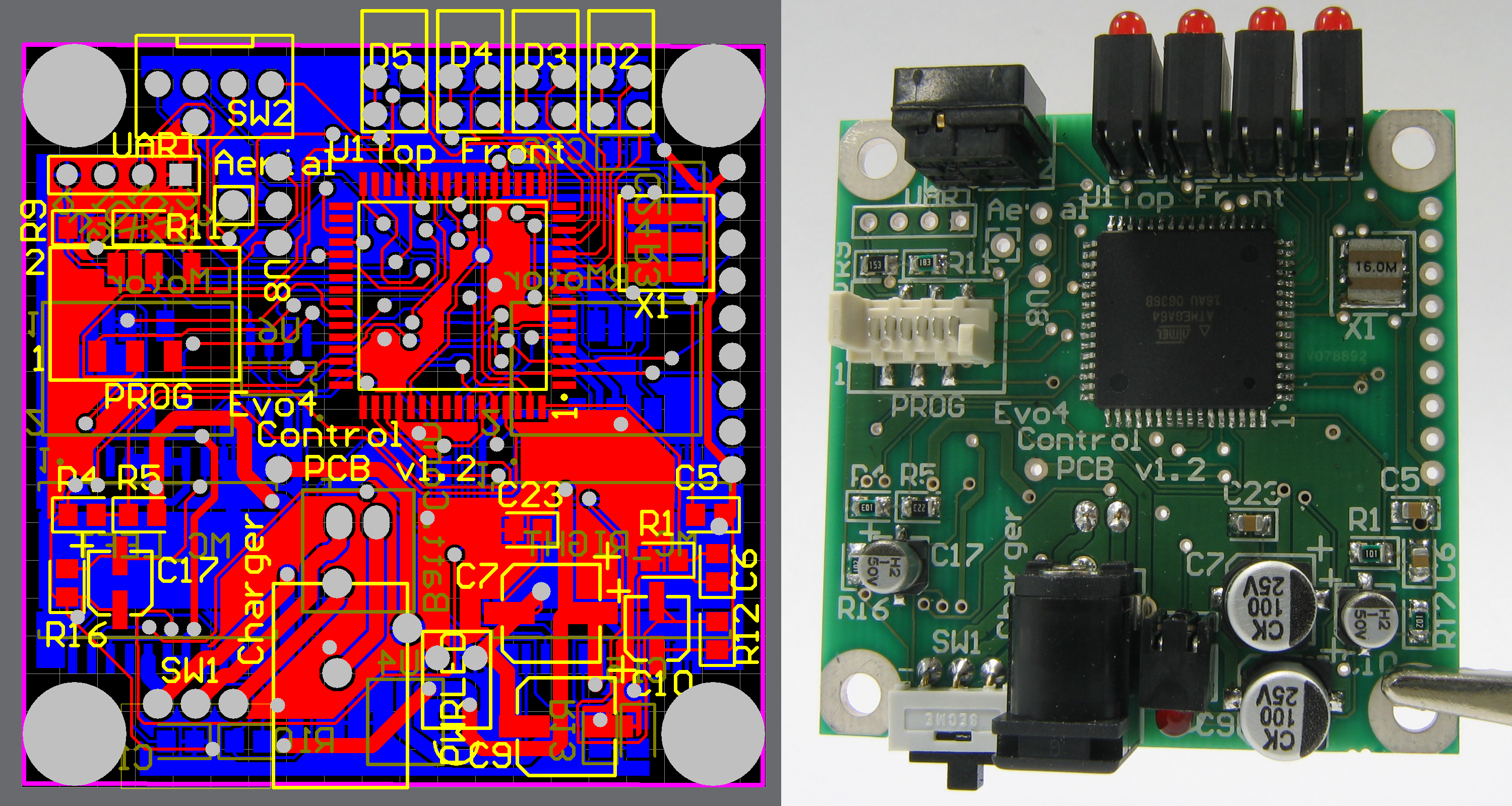

Printed Circuit Board Fabrication

Printed circuit board manufacturing is the process of manufacturing bare printed circuit board, printed circuit boards (PCBs) and populating them with electronic components. It includes all the processes to produce the full assembly of a board into a functional circuit board. In board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated (depaneled). Various techniques, such as silk screening and photoengraving, replicate the desired copper patterns on the PCB layers. Multi-layer boards are created by laminating different layers under heat and pressure. Holes for Via (electronics), vias (vertical connections between layers) are also drilled. The final assembly involves placing components onto the PCB and soldering them in place. This process can include through-hole technology (in which the component goes through the board) or surface-mount technology (SMT) (in which the component lays on top of the board). Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PCBs Hanging In Electroplating Machine

Polychlorinated biphenyls (PCBs) are organochlorine compounds with the formula Carbon, C12Hydrogen, H10−''x''Chloride, Cl''x''; they were once widely used in the manufacture of carbonless copy paper, as heat transfer fluids, and as dielectric and coolant fluids for electrical equipment. They are highly toxic and carcinogenic chemical compounds, formerly used in industrial and consumer electronic products, whose production was banned internationally by the Stockholm Convention on Persistent Organic Pollutants in 2001. Because of their longevity, PCBs are still widely in use, even though their manufacture has declined drastically since the 1960s, when a multitude of problems was identified. With the discovery of PCBs' environmental toxicity, and classification as persistent organic pollutants, their production was banned for most uses by United States federal law on January 1, 1978. The International Agency for Research on Cancer (IARC) rendered PCBs as definite carcinogens i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ground Plane

In electrical engineering, a ground plane is an electrically conductive surface, usually connected to electrical ground. Ground planes are typically made of copper or aluminum, and they are often located on the bottom of printed circuit boards (PCBs). The term has two different meanings in separate areas of electrical engineering. * In antenna theory, a ground plane is a conducting surface large in comparison to the wavelength, such as the Earth, which is connected to the transmitter's ground wire and serves as a reflecting surface for radio waves. * In printed circuit boards, a ground plane is a large area of copper foil on the board which is connected to the power supply ground terminal and serves as a return path for current from different components on the board. In Telecommunications, a ground plane is a flat or nearly flat horizontal conducting surface that serves as part of an antenna, to reflect the radio waves from the other antenna elements. In monopole ante ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hatched Copper Pour

In electronics, the term copper pour refers to an area on a printed circuit board filled with copper (the metal used to make connections in printed circuit boards). Copper pour is commonly used to create a ground plane. Another reason for using copper pour is to reduce the amount of etching Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ... fluid used during manufacturing. Features A distinctive feature of copper pour is the ''backoff'' (or ''stand-off'') - a certain distance between the copper pour and any tracks or pads not belonging to the same electrical net. A copper pour therefore looks like it flows around other components, with the exception of pads which are connected to the copper pour using thermal connections. Many early PCBs have a "hatched copper pour", sometimes ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Test Coupon (PCB)

A coupon or test coupon is a printed circuit board (PCB) used to test the quality of a printed wiring board (PWB) fabrication process. Test coupons are fabricated on the same panelization (PCB), panel as the PWBs, typically at the edges. Coupons are then inspected to ensure proper layer alignment, electrical connectivity, and cross sectioned to inspect internal structures. Coupons can be designed custom for a PWB or selected from a vendor library. Overview A coupon is designed to include traces and vias with the same dimensions and structures as those of the main PWB. It is standard practice to locate coupons on the edges of a panel, from which multiple PWBs are fabricated, to verify the consistency of plating, etching, and lamination across the whole panel. The use of coupons for testing is a necessary step in accurately and reliably monitoring fabrication quality and consistency. References {{Reflist Further reading * https://www.polarinstruments.com/support/si/AP8186.htm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Panel Fiducial

A fiducial marker or fiducial is an object placed in the field of view of an image for use as a point of reference or a measure. It may be either something placed into or on the imaging subject, or a mark or set of marks in the reticle of an optical instrument. Applications Microscopy In high-resolution optical microscopy, fiducials can be used to actively stabilize the field of view. Stabilization to better than 0.1 nm is achievable. Physics In physics, 3D computer graphics, and photography, fiducials are reference points: fixed points or lines within a scene to which other objects can be related or against which objects can be measured. Cameras outfitted with Réseau plates produce these reference marks (also called Réseau crosses) and are commonly used by NASA. Such marks are closely related to the timing marks used in optical mark recognition. Geographical survey Airborne geophysical surveys also use the term "fiducial" as a sequential reference number in the mea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tooling Hole

Tooling may refer to: * Machine tools and the tooling, such as cutting tools, fixtures, and accessories, that is used on them ** Cutting tool (machining), any of hundreds of kinds of cutters ** Fixture (tool), a fixed workholding or support device ** Jig (tool), a movable workholding or support device ** Tool management, keeping track of, and maximizing efficient use of, all the tooling * Tooling University, a training program of SME (society) that teaches machinists about machine tools and tooling * Agile tooling, the process of using modular means to design tooling that is produced by additive manufacturing or 3D printing methods to enable quick prototyping and responses to tooling and fixture needs * Programming tools, a set of apps that supports software development Software development is the process of designing and Implementation, implementing a software solution to Computer user satisfaction, satisfy a User (computing), user. The process is more encompassing than Comp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gerber Format

The Gerber format is an open, ASCII, vector format for printed circuit board (PCB) designs. It is the ''de facto'' standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill data, etc. The standard file extension is .GBR or .gbr though other extensions like .GB, .geb or .gerber are also used. It is documented by The Gerber Layer Format Specification and some related (but less universally supported) extensions such as XNC drill files and GerberJob to convey information about the entire PCB, as opposed to single layers. Gerber is used in PCB fabrication data. PCBs are designed on a specialized electronic design automation (EDA) or a computer-aided design (CAD) system. The CAD systems output PCB fabrication data to allow fabrication of the board. This data typically contains a Gerber file for each image layer (copper layers, solder mask, legend or silk...). Gerber is also the standard image input format for all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Routing (electronic Design Automation)

In electronic design, wire routing, commonly called simply routing, is a step in the design of printed circuit boards (PCBs) and integrated circuits (ICs). It builds on a preceding step, called placement, which determines the location of each active element of an IC or component on a PCB. After placement, the routing step adds wires needed to properly connect the placed components while obeying all design rules for the IC. Together, the placement and routing steps of IC design are known as place and route. The task of all routers is the same. They are given some pre-existing polygons consisting of pins (also called terminals) on cells, and optionally some pre-existing wiring called preroutes. Each of these polygons are associated with a net, usually by name or number. The primary task of the router is to create geometries such that all terminals assigned to the same net are connected, no terminals assigned to different nets are connected, and all design rules are obeyed. A ro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Signal Trace

In electronics, a signal trace or circuit trace on a printed circuit board (PCB) or integrated circuit (IC) is the equivalent of a wire for conducting signals. Each trace consists of a flat, narrow part of the copper Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ... foil that remains after etching. Signal traces are usually narrower than power or ground traces because the current carrying requirements are usually much less. See also * Ground plane * Stripline * Microstrip References Electrical connectors Printed circuit board manufacturing {{electronics-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stripline

In electronics, stripline is a transverse electromagnetic (TEM) transmission line medium invented by Robert M. Barrett of the Air Force Cambridge Research Centre in the 1950s. Stripline is the earliest form of planar transmission line. Description A stripline circuit uses a flat strip of metal which is sandwiched between two parallel ground planes. The insulating material of the substrate forms a dielectric. The width of the strip, the thickness of the substrate and the relative permittivity of the substrate determine the characteristic impedance of the strip which is a transmission line. As shown in the diagram, the central conductor need not be equally spaced between the ground planes. In the general case, the dielectric material may be different above and below the central conductor. A stripline that uses air as the dielectric material is known as an air stripline. To prevent the propagation of unwanted modes, the two ground planes must be shorted together. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstrip

Microstrip is a type of electrical transmission line which can be fabricated with any technology where a conductor is separated from a ground plane by a dielectric layer known as ''substrate''. Microstrip lines are used to convey microwave-frequency signals. Typical realisation technologies are printed circuit board (PCB), alumina coated with a dielectric layer or sometimes silicon or some other similar technologies. Microwave components such as antennas, couplers, filters, power dividers etc. can be formed from microstrip, with the entire device existing as the pattern of metallization on the substrate. Microstrip is thus much less expensive than traditional waveguide technology, as well as being far lighter and more compact. Microstrip was developed by ITT laboratories as a competitor to stripline (first published by Grieg and Engelmann in the December 1952 IRE proceedings). The disadvantages of microstrip compared with waveguide is the generally lower power handling c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

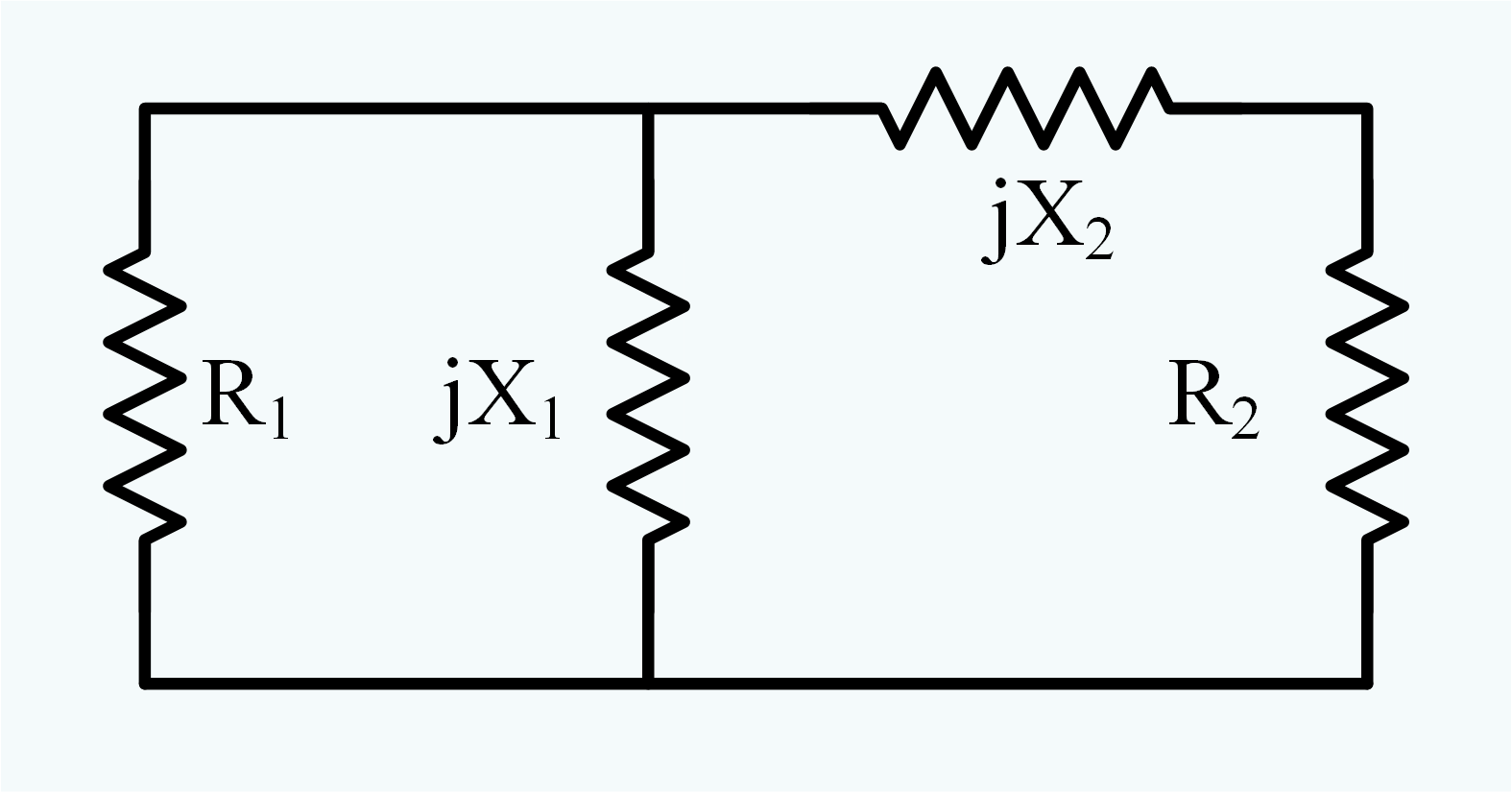

Line Impedance

In electrical engineering, impedance matching is the practice of designing or adjusting the input impedance or output impedance of an electrical device for a desired value. Often, the desired value is selected to maximize power transfer or minimize signal reflection. For example, impedance matching typically is used to improve power transfer from a radio transmitter via the interconnecting transmission line to the antenna. Signals on a transmission line will be transmitted without reflections if the transmission line is terminated with a matching impedance. Techniques of impedance matching include transformers, adjustable networks of lumped resistance, capacitance and inductance, or properly proportioned transmission lines. Practical impedance-matching devices will generally provide best results over a specified frequency band. The concept of impedance matching is widespread in electrical engineering, but is relevant in other applications in which a form of energy, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |