|

Nitinol 60

NiTiNOL 60, or 60 NiTiNOL, is a Nickel Titanium alloy (nominally Ni-40wt% Ti) discovered in the late 1950s by the U. S. Naval Ordnance Laboratory (hence the "NOL" portion of the name NiTiNOL). Depending upon the heat treat history, 60 NiTiNOL has the ability to exhibit either superelastic properties in the hardened state or shape memory In metallurgy, a shape-memory alloy (SMA) is an alloy that can be deformed when cold but returns to its pre-deformed ("remembered") shape when heated. It is also known in other names such as memory metal, memory alloy, smart metal, smart alloy, ... characteristics in the softened state. Producing the material in any meaningful quantities, however, proved quite difficult by conventional methods and the material was largely forgotten. The composition and processing parameters have recently been revived by Summit Materials, LLC under the trademarked name SM-100. SM-100 maintains 60 NiTiNOL's combination of superb corrosion resistance [NASA t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel Titanium

Nickel titanium, also known as nitinol, is a metal alloy of nickel and titanium, where the two elements are present in roughly equal atomic percentages. Different alloys are named according to the weight percentage of nickel; e.g., nitinol 55 and nitinol 60. Nitinol alloys exhibit two closely related and unique properties: the shape memory effect and superelasticity (also called pseudoelasticity). Shape memory is the ability of nitinol to undergo Deformation (engineering), deformation at one temperature, stay in its deformed shape when the external force is removed, then recover its original, undeformed shape upon heating above its "transformation temperature." Superelasticity is the ability for the metal to undergo large deformations and immediately return to its undeformed shape upon removal of the external load. Nitinol can undergo elastic deformations 10 to 30 times larger than alternative metals. Whether nitinol behaves with shape memory effect or superelasticity depends on w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Naval Ordnance Laboratory

The Naval Ordnance Laboratory (NOL) was a facility in the White Oak, Maryland, White Oak area of Montgomery County, Maryland. The location is now used as the headquarters of the Food and Drug Administration, U.S. Food and Drug Administration. Origins The U.S. Navy Mine Unit, later the Mine Laboratory at the Washington, D.C., Navy Yard, was established in 1918, and the first Officer in Charge (OIC) arrived in February 1919, marking the beginning of the Laboratory. In 1929 the Mine Laboratory was merged with the Experimental Ammunition Station in Indian Head, Maryland, Indian Head to form the Naval Ordnance Laboratory. NOL began slowly, and it was not until the beginnings of World War II, when Germany's aircraft-laid magnetic mine began to cause serious problems for the Allies of World War II, Allies. As the importance of NOL's work became apparent, it also became apparent that there wasn't enough space at the Navy Yard to accommodate the necessary research facilities. In 1944, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pseudoelasticity

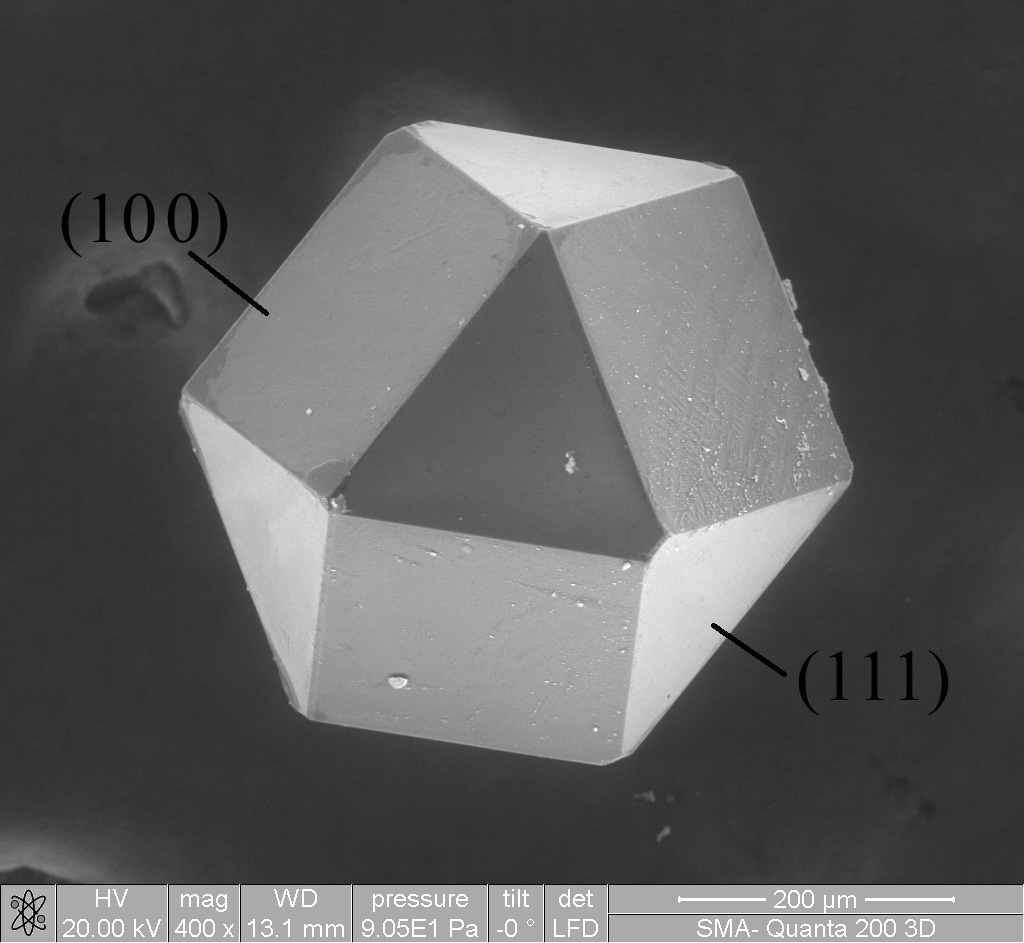

In materials science, pseudoelasticity, sometimes called superelasticity, is an elastic (reversible) response to an applied stress, caused by a phase transformation between the austenitic and martensitic phases of a crystal. It is exhibited in shape-memory alloys. Overview Pseudoelasticity is from the reversible motion of domain boundaries during the phase transformation, rather than just bond stretching or the introduction of defects in the crystal lattice (thus it is not true super elasticity but rather pseudoelasticity). Even if the domain boundaries do become pinned, they may be reversed through heating. Thus, a pseudoelastic material may return to its previous shape (hence, ''shape memory'') after the removal of even relatively high applied strains. One special case of pseudoelasticity is called the Bain Correspondence. This involves the austenite/martensite phase transformation between a face-centered crystal lattice (FCC) and a body-centered tetragonal crystal st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shape-memory Alloy

In metallurgy, a shape-memory alloy (SMA) is an alloy that can be deformed when cold but returns to its pre-deformed ("remembered") shape when heated. It is also known in other names such as memory metal, memory alloy, smart metal, smart alloy, and muscle wire. The "memorized geometry" can be modified by fixating the desired geometry and subjecting it to a thermal treatment, for example a wire can be taught to memorize the shape of a coil spring. Parts made of shape-memory alloys can be lightweight, solid-state alternatives to conventional actuators such as hydraulic, pneumatic, and motor-based systems. They can also be used to make hermetic joints in metal tubing, and it can also replace a sensor-actuator closed loop to control water temperature by governing hot and cold water flow ratio. Overview The two most prevalent shape-memory alloys are copper-aluminium-nickel and nickel-titanium ( NiTi), but SMAs can also be created by alloying zinc, copper, gold and iron. Although ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Summit Materials

A summit is a point on a surface that is higher in elevation than all points immediately adjacent to it. The topographic terms acme, apex, peak (mountain peak), and zenith are synonymous. The term (mountain top) is generally used only for a mountain peak that is located at some distance from the nearest point of higher elevation. For example, a big, massive rock next to the main summit of a mountain is not considered a summit. Summits near a higher peak, with some prominence or isolation, but not reaching a certain cutoff value for the quantities, are often considered ''subsummits'' (or ''subpeaks'') of the higher peak, and are considered part of the same mountain. A pyramidal peak is an exaggerated form produced by ice erosion of a mountain top. For summits that are permanently covered in significant layers of ice, the height may be measured by the highest point of rock (rock height) or the highest point of permanent solid ice (snow height). The highest summit in the world ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States's civil list of government space agencies, space program, aeronautics research and outer space, space research. National Aeronautics and Space Act, Established in 1958, it succeeded the National Advisory Committee for Aeronautics (NACA) to give the American space development effort a distinct civilian orientation, emphasizing peaceful applications in space science. It has since led most of America's space exploration programs, including Project Mercury, Project Gemini, the 1968–1972 Apollo program missions, the Skylab space station, and the Space Shuttle. Currently, NASA supports the International Space Station (ISS) along with the Commercial Crew Program and oversees the development of the Orion (spacecraft), Orion spacecraft and the Sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

440C

440C (UNS designation S44004) is a martensitic 400 series stainless steel, and has the highest carbon content of the 400 stainless steel series. It can be heat treated to reach hardness of 58 to 60 HRC. It can be used to make rolling contact stainless bearings, e.g. ball bearings and roller bearings. It is also used to make knife A knife (: knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least Stone Age, 2.5 million years ago, as e ... blades. 440C has the highest strength, hardness, and wear resistance of all the commonplace 440-series stainless alloys, with high carbon content and moderate corrosion resistance. Composition Mechanical properties References {{SAE International Steel alloys Steels ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-speed Steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material. Compared to high- carbon steel tools, high-speed steels can withstand higher temperatures without losing their temper (hardness), allowing use of faster cutting speeds. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above 60 Rockwell C) and abrasion resistance compared with common carbon and tool steels. There are several different types of high speed steel, such as M42 and M2. History In 1868, English metallurgist Robert Forester Mushet developed Mushet steel, considered the forerunner of modern high-speed steels. It consisted of 2% carbon, 2.5% manganese, and 7% tungsten. The major advantage of this steel was that it hardened when air cooled from a temperature at which most steels had to be quenched for hardening. Over the next 30 years, the most significant change was the replacement of manganese with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel Alloys

This is a list of named alloys grouped alphabetically by the metal with the highest percentage. Within these headings, the alloys are also grouped alphabetically. Some of the main alloying elements are optionally listed after the alloy names. Alloys by base metal Aluminium * AA-8000: used for electrical building wire in the U.S. per the National Electrical Code, replacing AA-1350. * Al–Li (2.45% lithium): aerospace applications, including the Space Shuttle * Alnico (nickel, cobalt): used for permanent magnets * Aluminium–Scandium (scandium) * Birmabright (magnesium, manganese): used in car bodies, mainly used by Land Rover cars. * Devarda's alloy (45% Al, 50% Cu, 5% Zn): chemical reducing agent. * Duralumin (copper) * Hiduminium or R.R. alloys (2% copper, iron, nickel): used in aircraft pistons * Hydronalium (up to 12% magnesium, 1% manganese): used in shipbuilding, resists seawater corrosion * Italma (3.5% magnesium, 0.3% manganese): formerly used to make coinage of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smart Materials

Smart materials, also called intelligent or responsive materials, are designed materials that have one or more properties that can be significantly changed in a controlled fashion by external stimuli, such as stress, moisture, electric or magnetic fields, light, temperature, pH, or chemical compounds. Smart materials are the basis of many applications, including sensors and actuators, or artificial muscles, particularly as electroactive polymers (EAPs). Types There are a number of types of smart material, of which are already common. Some examples are as following: * Piezoelectric materials are materials that produce a voltage when stress is applied. Since this effect also applies in a reverse manner, a voltage across the sample will produce stress within sample. Suitably designed structures made from these materials can, therefore, be made that bend, expand or contract when a voltage is applied. * Shape-memory alloys and shape-memory polymers are materials in which large ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Materials Science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries. The intellectual origins of materials science stem from the Age of Enlightenment, when researchers began to use analytical thinking from chemistry, physics, and engineering to understand ancient, phenomenological observations in metallurgy and mineralogy. Materials science still incorporates elements of physics, chemistry, and engineering. As such, the field was long considered by academic institutions as a sub-field of these related fields. Beginning in the 1940s, materials science began to be more widely recognized as a specific and distinct field of science and engineering, and major technical universities around the world created dedicated schools for its study. Materials scientists emphasize understanding how the history of a material (''processing'') influences its struc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |