|

Nanostructured Film

A nanostructured film is a film resulting from engineering of nanoscale features, such as dislocations, grain boundaries, defects, or twinning. In contrast to other nanostructures, such as nanoparticles, the film itself may be up to several microns thick, but possesses a large concentration of nanoscale features homogeneously distributed throughout the film. Like other nanomaterials, nanostructured films have sparked much interest as they possess unique properties not found in bulk, non-nanostructured material of the same composition. In particular, nanostructured films have been the subject of recent research due to their superior mechanical properties, including strength, hardness, and corrosion resistance compared to regular films of the same material. Examples of nanostructured films include those produced by grain boundary engineering, such as nano-twinned ultra-fine grain copper, or dual phase nanostructuring, such as crystalline metal and amorphous metallic glass nanocompo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundary

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boundaries'' are those with a misorientation less than about 15 degrees. Generally speaking they are composed o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Twinning

Crystal twinning occurs when two or more adjacent crystals of the same mineral are oriented so that they share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals that are tightly bonded to each other. The surface along which the lattice points are shared in twinned crystals is called a composition surface or twin plane. Crystallographers classify twinned crystals by a number of twin laws. These twin laws are specific to the crystal structure. The type of twinning can be a diagnostic tool in mineral identification. Deformation twinning, in which twinning develops in a crystal in response to a shear stress, is an important mechanism for permanent shape changes in a crystal.Courtney, Thomas H. (2000) ''Mechanical Behavior of Materials'', 2nd ed. McGraw Hill. Definition Twinning is a form of symmetrical intergrowth between two or more adjacent crystals of the same mineral. It differs from the ordinary random ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoparticle

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead. Nanoparticles are usually distinguished from microparticles (1-1000 µm), "fine particles" (sized between 100 and 2500 nm), and "coarse particles" (ranging from 2500 to 10,000 nm), because their smaller size drives very different physical or chemical properties, like colloidal properties and ultrafast optical effects or electric properties. Being more subject to the brownian motion, they usually do not sediment, like colloidal particles that conversely are usually understood to range from 1 to 1000 nm. Being much smaller than the wavelengths of visible light (400-700 nm), nan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strength Of Materials

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties (geometric properties) such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered. The theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable metallic form (native metals). This led to very early human use in several regions, from circa 8000 BC. Thousands of years later, it was the first metal to be smelted from sulfide ores, circa 5000 BC; the first metal to be cast into a shape in a mold, c. 4000 BC; and the first metal to be purposely alloyed with another metal, tin, to create br ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sputtering

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and can be an unwelcome source of wear in precision components. However, the fact that it can be made to act on extremely fine layers of material is utilised in science and industry—there, it is used to perform precise etching, carry out analytical techniques, and deposit thin film layers in the manufacture of optical coatings, semiconductor devices and nanotechnology products. It is a physical vapor deposition technique. Physics When energetic ions collide with atoms of a target material, an exchange of momentum takes place between them. These ions, known as "incident ions", set off collision cascades in the target. Such cascades can take many paths; some recoil back toward the surface of the target. If a collision cascade reache ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission Electron Microscopy

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a grid. An image is formed from the interaction of the electrons with the sample as the beam is transmitted through the specimen. The image is then magnified and focused onto an imaging device, such as a fluorescent screen, a layer of photographic film, or a sensor such as a scintillator attached to a charge-coupled device. Transmission electron microscopes are capable of imaging at a significantly higher resolution than light microscopes, owing to the smaller de Broglie wavelength of electrons. This enables the instrument to capture fine detail—even as small as a single column of atoms, which is thousands of times smaller than a resolvable object seen in a light microscope. Transmission electron microscopy is a major analytical method ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

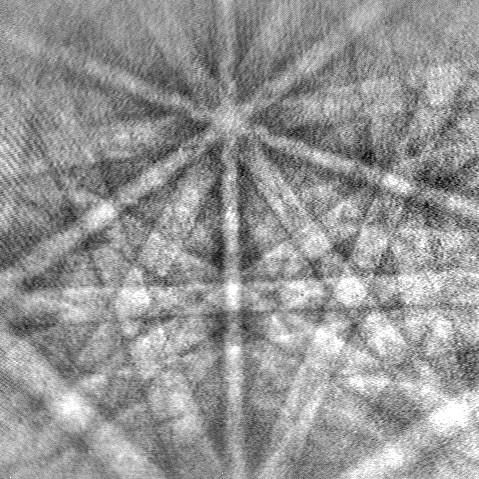

Electron Backscatter Diffraction

Electron backscatter diffraction (EBSD) is a scanning electron microscope–based microstructural-crystallographic characterization technique commonly used in the study of crystalline or polycrystalline materials. The technique can provide information about the structure, crystal orientation, phase, or strain in the material. These types of studies have been carried out using X-ray diffraction (XRD), neutron diffraction and/or electron diffraction in a Transmission electron microscope and spatially resolved acoustic spectroscopy ( SRAS) which analyses elastic waves instead of analysing a diffraction event. The choice of which technique is adopted depends upon various factors, including spatial resolution, area/volume analysed, and whether the measurements are static or dynamical. Geometry For an EBSD measurement a flat/polished crystalline specimen is placed in the SEM chamber at a highly tilted angle (~70° from horizontal) towards the diffraction camera, to increase the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Focused Ion Beam

Focused ion beam, also known as FIB, is a technique used particularly in the semiconductor industry, materials science and increasingly in the biological field for site-specific analysis, deposition, and ablation of materials. A FIB setup is a scientific instrument that resembles a scanning electron microscope (SEM). However, while the SEM uses a focused beam of electrons to image the sample in the chamber, a FIB setup uses a focused beam of ions instead. FIB can also be incorporated in a system with both electron and ion beam columns, allowing the same feature to be investigated using either of the beams. FIB should not be confused with using a beam of focused ions for direct write lithography (such as in proton beam writing). These are generally quite different systems where the material is modified by other mechanisms. Ion beam source Most widespread instruments are using liquid metal ion sources (LMIS), especially gallium ion sources. Ion sources based on elemental gold an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |