|

Delidding

Decapping (decapsulation) or delidding of an integrated circuit (IC) is the process of removing the protective cover or integrated heat spreader (IHS) of an integrated circuit so that the contained die is revealed for visual inspection of the micro circuitry imprinted on the die. This process is typically done in order to debug a manufacturing problem with the chip, or possibly to copy information from the device, to check for counterfeit chips or to reverse engineer it. Companies such as TechInsights and ChipRebel decap, take die shots of, and reverse engineer chips for customers. Modern integrated circuits can be encapsulated in plastic, ceramic, or epoxy packages. Delidding may also be done to test the chip for radiation-tolerance with a heavy-ion beam or in an effort to reduce the operating temperatures of an integrated circuit such as a processor, by replacing the thermal interface material (TIM) between the die and the IHS with a higher-quality TIM. With care, it's possibl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Heat Spreader

A heat spreader transfers energy as heat from a hotter source to a colder heat sink or heat exchanger. There are two thermodynamic types, passive and active. The most common sort of passive heat spreader is a plate or block of material having high thermal conductivity, such as copper, aluminum, or diamond. An active heat spreader speeds up heat transfer with expenditure of energy as work supplied by an external source. A heat pipe uses fluids inside a sealed case. The fluids circulate either passively, by spontaneous convection, triggered when a threshold temperature difference occurs; or actively, because of an impeller driven by an external source of work. Without sealed circulation, energy can be carried by transfer of fluid matter, for example externally supplied colder air, driven by an external source of work, from a hotter body to another external body, though this is not exactly heat transfer as defined in physics. Exemplifying increase of Entropy (energy dispersal), ent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

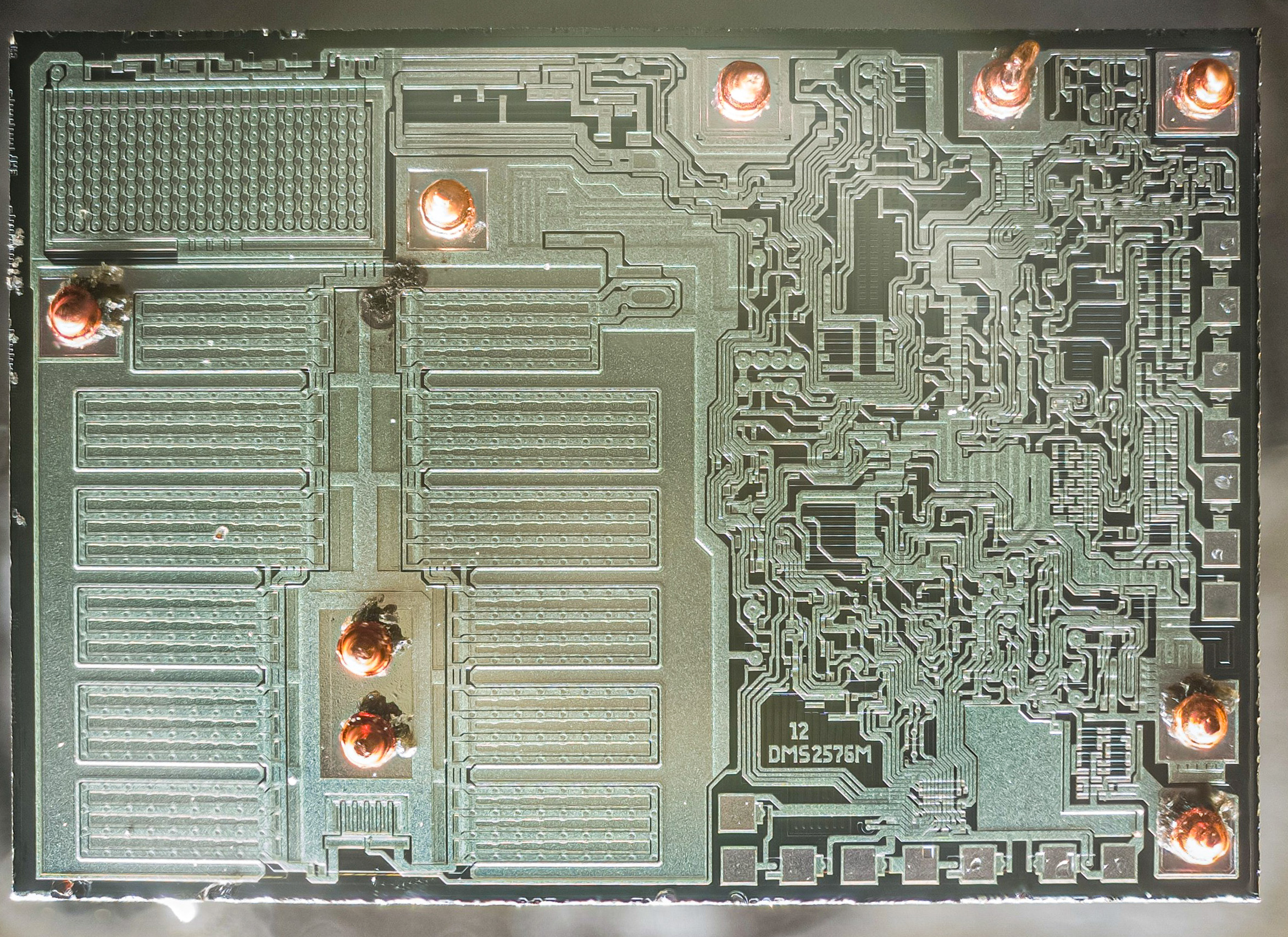

Die Shot

A die shot or die photography is a photo or recording of the layout of an integrated circuit, showings its design with any packaging removed. A die shot can be compared with the cross-section of an (almost) two-dimensional computer chip, on which the design and construction of various tracks and components can be clearly seen. Due to the high complexity of modern computer chips, die-shots are often displayed colourfully, with various parts coloured by diffraction within the parts of the die, using special lighting or even manually. Methods A die shot is a picture of a computer chip without its housing or packaging. There are two ways to capture such a chip "naked" on a photo; by either taking the photo before a chip is packaged or by removing its package. Avoiding the package Taking a photo before the chip ends up in a housing is typically preserved to the chip manufacturer, because the chip is packed fairly quickly in the production process to protect the sensitive very sma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components are etched onto a small, flat piece ("chip") of semiconductor material, usually silicon. Integrated circuits are used in a wide range of electronic devices, including computers, smartphones, and televisions, to perform various functions such as processing and storing information. They have greatly impacted the field of electronics by enabling device miniaturization and enhanced functionality. Integrated circuits are orders of magnitude smaller, faster, and less expensive than those constructed of discrete components, allowing a large transistor count. The IC's mass production capability, reliability, and building-block approach to integrated circuit design have ensured the rapid adoption of standardized ICs in place of designs using discre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (integrated Circuit)

A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is Semiconductor fabrication, fabricated. Typically, integrated circuits are produced in large batches on a single wafer (electronics), wafer of electronic-grade Monocrystalline silicon, silicon (EGS) or other semiconductor (such as Gallium arsenide, GaAs) through processes such as photolithography. The wafer is cut (wafer dicing, diced) into many pieces, each containing one copy of the circuit. Each of these pieces is called a die. There are three commonly used plural forms: ''dice'', ''dies,'' and ''die''. To simplify handling and integration onto a printed circuit board, most dies are integrated circuit packaging, packaged in List of electronic component packaging types, various forms. Manufacturing process Most dies are composed of silicon and used for integrated circuits. The process begins with the production of Single crystal, monocrystalline sili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Visual Inspection

Visual inspection is a common method of quality control, data acquisition, and data analysis. Visual Inspection, used in maintenance of facilities, mean inspection of equipment and structures using either or all of raw human senses such as vision, hearing, touch and smell and/or any non-specialized inspection equipment. Inspections requiring Ultrasonic, X-Ray equipment, Infrared, etc. are not typically regarded as visual inspection as these Inspection methodologies require specialized equipment, training and certification. Quality control A study of the visual inspection of small integrated circuits found that the modal duration of eye fixations of trained inspectors was about 200 ms. The most accurate inspectors made the fewest eye fixations and were the fastest. When the same chip was judged more than once by an individual inspector the consistency of judgment was very high whereas the consistency between inspectors was somewhat less. Variation by a factor of six in inspectio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were fired clay bricks used for building house walls and other structures. Other pottery objects such as pots, vessels, vases and figurines were made from clay, either by itself or mixed with other materials like silica, hardened by sintering in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial, and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as semiconductors. The word '' ceramic'' comes from the Ancient Greek word (), meaning ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Interface Material

A thermal interface material (shortened to TIM) is any material that is inserted between two components in order to enhance the thermal coupling between them. A common use is heat dissipation, in which the TIM is inserted between a heat-producing device (e.g. an integrated circuit) and a heat-dissipating device (e.g. a heat sink). There are intensive studies in developing several kinds of TIM with different target applications. At each interface, a thermal resistance exists and impedes heat dissipation. In addition, the electronic performance and device lifetime can degrade dramatically under continuous overheating and large thermal stress at the interfaces. Many recent efforts have been dedicated to developing and improving TIMs: These effort include minimizing the thermal boundary resistance between layers and enhancing thermal management performance, while addressing application requirements such as low thermal stress between materials of different thermal expansion coefficient ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Etching

Plasma etching is a form of plasma processing used to fabricate integrated circuits. It involves a high-speed stream of glow discharge (Plasma (physics), plasma) of an appropriate gas mixture being shot (in pulses) at a sample. The plasma source, known as etch species, can be either charged (ions) or neutral (atoms and radical (chemistry), radicals). During the process, the plasma generates volatile etch products at room temperature from the chemical reactions between the elements of the material etched and the reactive species generated by the plasma. Eventually the atoms of the shot element embed themselves at or just below the surface of the target, thus modifying the physical properties of the target. Mechanisms Plasma generation A plasma is a high energetic condition in which a lot of processes can occur. These processes happen because of electrons and atoms. To form the plasma electrons have to be accelerated to gain energy. Highly energetic electrons transfer the energy to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IC Package

Integrated circuits and certain other electronic components are put into protective packages to allow easy handling and assembly onto printed circuit boards and to protect the devices from damage. A very large number of package types exist. Some package types have standardized dimensions and tolerances, and are registered with trade industry associations such as JEDEC and Pro Electron. Other types are proprietary designations that may be made by only one or two manufacturers. Integrated circuit packaging is the last assembly process before testing and shipping devices to customers. Occasionally specially-processed integrated circuit dies are prepared for direct connections to a substrate without an intermediate header or carrier. In flip chip systems the IC is connected by solder bumps to a substrate. In beam-lead technology, the metallized pads that would be used for wire bonding connections in a conventional chip are thickened and extended to allow external connections to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfuric Acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid (English in the Commonwealth of Nations, Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen, and hydrogen, with the molecular formula . It is a colorless, odorless, and Viscosity, viscous liquid that is Miscibility, miscible with water. Pure sulfuric acid does not occur naturally due to its Dehydration reaction, strong affinity to water vapor; it is Hygroscopy, hygroscopic and readily absorbs water vapor from the Atmosphere of Earth, air. Concentrated sulfuric acid is a strong oxidant with powerful dehydrating properties, making it highly corrosive towards other materials, from rocks to metals. Phosphorus pentoxide is a notable exception in that it is not dehydrated by sulfuric acid but, to the contrary, dehydrates sulfuric acid to sulfur trioxide. Upon addition of sulfuric acid to water, a considerable amount of heat is releas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |