|

Coextrusion

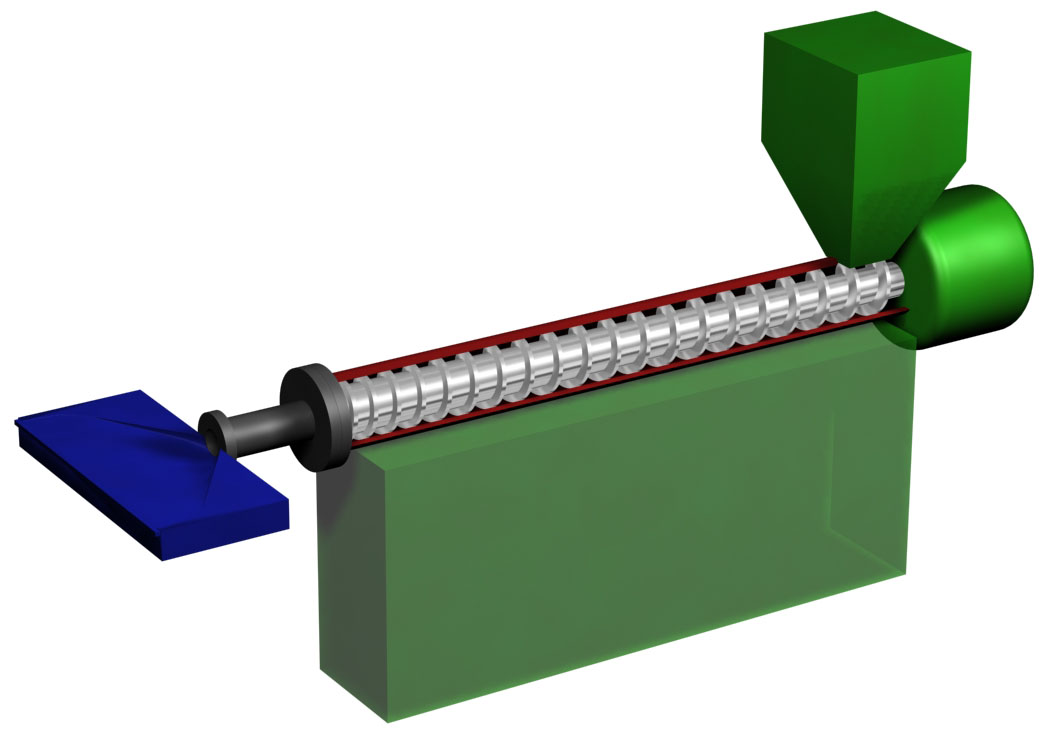

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic ext ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Film

Plastic film is a thin continuous polymeric material. Thicker plastic material is often called a "sheet". These thin plastic membranes are used to separate areas or volumes, to hold items, to act as barriers, or as printable surfaces. Plastic films are used in a wide variety of applications. These include: packaging, plastic bags, labels, building construction, landscaping, electrical fabrication, photographic film, film stock for movies, video tape, etc. Materials Almost all plastics can be formed into a thin film. Some of the primary ones are: * Polyethylene – The most common plastic film is made of one of the varieties of polyethylene: low-density polyethylene, medium-density polyethylene, high-density polyethylene, or linear low-density polyethylene. * Polypropylene – Polypropylene can be made a cast film, biaxially oriented film (BOPP), or as a uniaxially oriented film. * Polyester – BoPET is a biaxially oriented polyester film. * Nylon – BOPA/BON is a Bia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extruder With Sheet Die

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Degradation

Polymer degradation is the reduction in the physical properties of a polymer, such as strength, caused by changes in its chemical composition. Polymers and particularly plastics are subject to degradation at all stages of their product life cycle, including during their initial processing, use, disposal into the environment and recycling. The rate of this degradation varies significantly; biodegradation can take decades, whereas some industrial processes can completely decompose a polymer in hours. Technologies have been developed to both inhibit or promote degradation. For instance, polymer stabilizers ensure plastic items are produced with the desired properties, extend their useful lifespans, and facilitate their recycling. Conversely, biodegradable additives accelerate the degradation of plastic waste by improving its biodegradability. Some forms of plastic recycling can involve the complete degradation of a polymer back into monomers or other chemicals. In general, the e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene. Polypropylene belongs to the group of polyolefins and is Crystallization of polymers#Degree of crystallinity, partially crystalline and Chemical polarity#Nonpolar molecules, non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Polypropylene is the second-most widely produced Commodity plastics, commodity plastic (after polyethylene). History Phillips Petroleum chemists J. Paul Hogan and Robert Banks (chemist), Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization to the isotactic was discovered by Giulio Natta and Karl Rehn in March 1954. This pioneering discovery led to large-scale commercial producti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

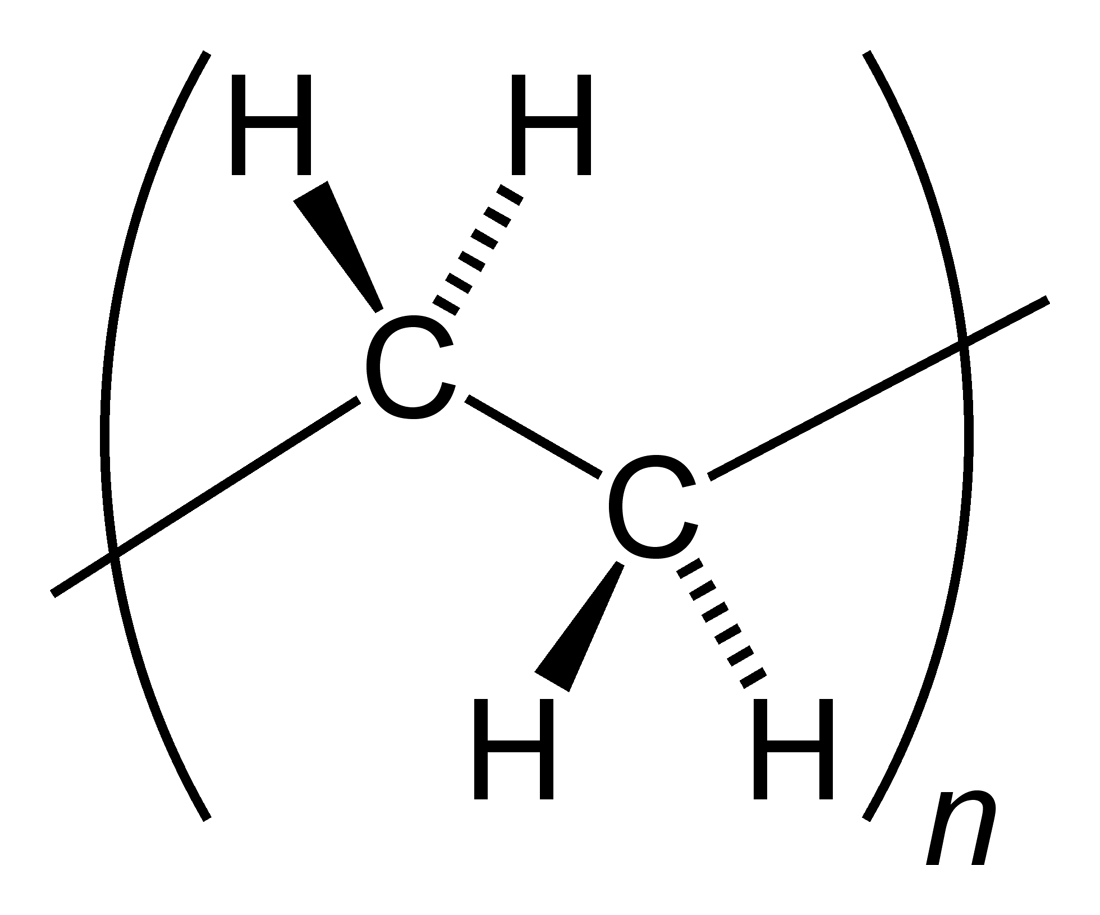

Polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, cups, jars, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'' and many variations thereof. Its properties can be modified further by crosslinking or copolymerization. All forms are nontoxic as well as chemically resilient, contributing to polyethylene's popularity as a multi-use plastic. However, polyethylene's chemical resilience also makes it a long-lived and decomposition-resistant pollutant when disposed of improperly. Being a h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HDPE Pipe Being Extruded

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2008, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 MPa) than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and more opa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resistance Temperature Detector

Resistance thermometers, also called resistance temperature detectors (RTDs), are sensors used to measure temperature. Many RTD elements consist of a length of fine wire wrapped around a heat-resistant ceramic or glass core but other constructions are also used. The RTD wire is a pure material, typically platinum (Pt), nickel (Ni), or copper (Cu). The material has an accurate resistance/temperature relationship which is used to provide an indication of temperature. As RTD elements are fragile, they are often housed in protective probes. RTDs, which have higher accuracy and repeatability, are slowly replacing thermocouples in industrial applications below 600 °Celsius, C. Resistance/temperature relationship of metals Common RTD sensing elements for biomedical application constructed of platinum (Pt), nickel (Ni), or copper (Cu) have a repeatability, repeatable, resistance versus temperature relationship (''R'' vs ''T'') and operating temperature range. The ''R'' vs ''T'' re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the Seebeck effect, and this voltage can be interpreted to measure temperature. Thermocouples are widely used as list of temperature sensors, temperature sensors. Commercial thermocouples are inexpensive, interchangeable, are supplied with standard Electrical connector, connectors, and can measure a wide range of temperatures. In contrast to most other methods of temperature measurement, thermocouples are self-powered and require no external form of excitation. The main limitation with thermocouples is accuracy; system errors of less than one degree Celsius (°C) can be difficult to achieve. Thermocouples are widely used in science and industry. Applications include temperature measurement for kilns, gas turbine exhaust, diesel engines, and o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extruder Screws From Boston Matthews

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Extruder Screw

Plastics are a wide range of synthetic or semisynthetic materials composed primarily of polymers. Their defining characteristic, plasticity, allows them to be molded, extruded, or pressed into a diverse range of solid forms. This adaptability, combined with a wide range of other properties such as low weight, durability, flexibility, chemical resistance, low toxicity, and low-cost production, has led to their widespread use around the world. While most plastics are produced from natural gas and petroleum, a growing minority are produced from renewable resources like polylactic acid. Between 1950 and 2017, 9.2 billion metric tons of plastic are estimated to have been made, with more than half of this amount being produced since 2004. In 2023 alone, preliminary figures indicate that over 400 million metric tons of plastic were produced worldwide. If global trends in plastic demand continue, it is projected that annual global plastic production will exceed 1.3 billion tons by 2 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

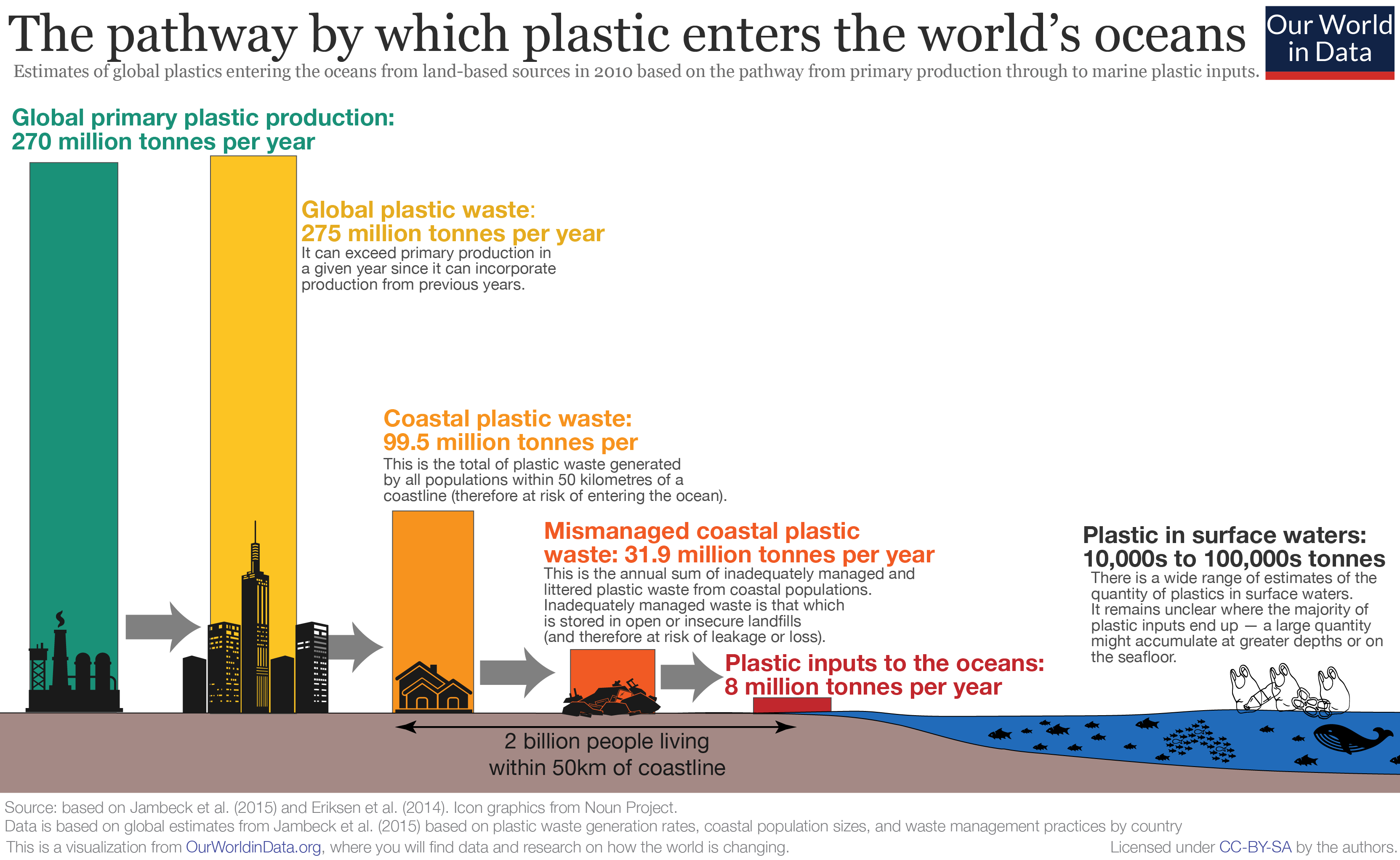

Plastic Pollution

Plastic pollution is the accumulation of plastic objects and particles (e.g. plastic bottles, bags and microbeads) in the Earth's environment that adversely affects humans, wildlife and their habitat. Plastics that act as pollutants are categorized by size into micro-, meso-, or macro debris. Plastics are inexpensive and durable, making them very adaptable for different uses; as a result, manufacturers choose to use plastic over other materials. However, the chemical structure of most plastics renders them resistant to many natural processes of environmental degradation, degradation and as a result they are slow to degrade. Together, these two factors allow large volumes of plastic to enter the environment as mismanaged waste which persists in the ecosystem and travels throughout food webs. Plastic pollution can afflict land, waterways and oceans. It is estimated that 1.1 to 8.8'' ''million tonnes of plastic waste enters the ocean from coastal communities each year. It is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |