|

Volvo LV81-series

The Volvo LV80/90-series was a medium size truck produced by Swedish automaker Volvo between 1935 and 1940. History Volvo presented a new medium-sized truck in 1935. The truck was available in two versions: the smaller LV80-series, with a side-valve engine and the larger LV90-series, with an overhead valve engine. On this generation of trucks the engine and cab was moved forward so that the engine was mounted above the front axle, not behind as before. This gives a better load distribution between the front and rear axle, resulting in reduced rear axle load. After a year the older DC engine of the LV90-series was replaced by the bigger FC engine. Both engines were offered in Hesselman version. Engines Gallery File:Volvo LV 84D Fire Engine 1936.jpg, 1936 Volvo LV84 fire engine A fire engine or fire truck (also spelled firetruck) is a vehicle, usually a specially designed or modified truck, that functions as a firefighting apparatus. The primary purposes of a fire eng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

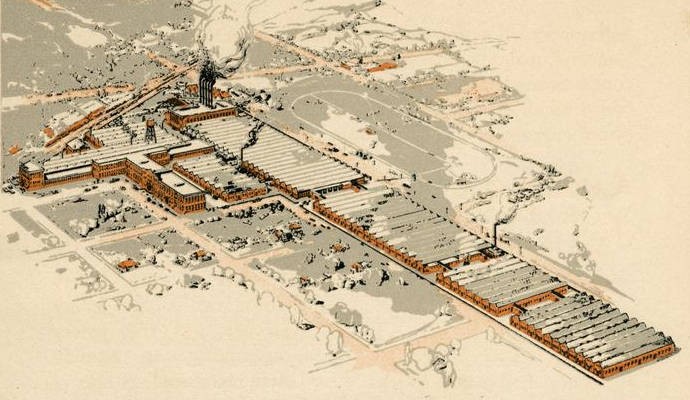

Volvo

The Volvo Group (; legally Aktiebolaget Volvo, shortened to AB Volvo, stylized as VOLVO) is a Swedish multinational manufacturing corporation headquartered in Gothenburg. While its core activity is the production, distribution and sale of trucks, buses and construction equipment, Volvo also supplies marine and industrial drive systems and financial services. In 2016, it was the world's second-largest manufacturer of heavy-duty trucks with its subsidiary Volvo Trucks. Volvo was founded in 1927. Initially involved in the automobile industry, Volvo expanded into other manufacturing sectors throughout the twentieth century. Automobile manufacturer Volvo Cars, also based in Gothenburg, was part of AB Volvo until 1999, when it was sold to the Ford Motor Company. Since 2010 Volvo Cars has been owned by the automotive company Geely Holding Group. Both AB Volvo and Volvo Cars share the Volvo logo and cooperate in running the Volvo Museum in Gothenburg, Sweden. The corporation was first ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volvo LV71-series

The Volvo LV71-series was a medium size truck produced by Swedish automaker Volvo between 1932 and 1935. History Volvo introduced the LV71-series in the spring of 1932. The truck was built on two different wheelbases: 3.4 and 4.1 m. There were two weight classes: LV71 and LV72 with a payload of 2.5 tonnes and LV73 and LV74 with a payload of 3 tonnes. The six-cylinder engine had a displacement of 3268 cc. The bore was 79.4 mm and the stroke was 110 mm. The maximum power output was 65 hp. The LV 71 had a wheelbase of 3400 mm. The LV 72 had a wheelbase of 4100 mm. The frame length ( LV 71 ) was 5010 mm. The front track width was 1500 mm, and the rear track width was 1550 mm. The fuel tank had a capacity of 50 liters . The medium-sized truck series also included Volvo's first forward control truck, LV75. The cab was moved forward so that the driver sat beside the engine instead of the gear box like a conventional truck. This gives a better weight distribution between the front and r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volvo Roundnose

The Volvo LV120/130/140/150-series, or the Roundnose was a medium-size truck produced by Swedish automaker Volvo between 1939 and 1954. History The "Roundnose" was introduced in the autumn of 1939, in conjunction with the outbreak of the Second World War. The truck was originally built in three versions. The smallest LV120-series had the same side-valve engine as the Sharpnose. The larger LV125-series and the sturdier LV130-series had the same overhead valve engine as its predecessor LV90. During the war, many of these trucks were equipped with wood gas generators. 1944 saw the introduction of the LV140-series with the big FE engine which replaced the LV180/190-series. In 1946 the Roundnose became the first Volvo truck offered with a diesel engine. The LV150-series was equipped with Volvo's VDA pre-chamber diesel engine. All versions were updated in the early 1950s. The LV120-series became the L220-series with a stronger ED engine. The LV140-series became the L230-series, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-six Engine

A straight-six engine (also referred to as an inline-six engine; abbreviated I6 or L6) is a piston engine with six cylinders arranged in a straight line along the crankshaft. A straight-six engine has perfect primary and secondary engine balance, resulting in fewer vibrations than other designs of six or fewer cylinders. Until the mid-20th century, the straight-six layout was the most common design for engines with six cylinders. However, V6 engines gradually became more common in the 1970s and by the 2000s, V6 engines had replaced straight-six engines in most light automotive applications. Characteristics In terms of packaging, straight-six engines are almost always narrower than a V6 engine or V8 engine, but longer than straight-four engines, V6s, and most V8s. Compared to V-configuration engines with similar power and displacement, the straight configuration has fewer injectors, a single head, and a single exhaust manifold, all contributing to better reliability and perfor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-synchronous Transmission

A non-synchronous transmission, also called a crash gearbox, is a form of manual transmission based on gears that do not use synchronizing mechanisms. They require the driver to manually synchronize the transmission's input speed (engine RPM) and output speed (driveshaft speed). Non-synchronous transmissions are found primarily in various types of industrial machinery; such as tractors and semi-tractors. Non-synchronous manual transmissions are also found on motorcycles, in the form of constant-mesh sequential manual transmissions. Prior to the 1950s and 1960s, most cars used constant-mesh (and also sliding-mesh) but non-synchronous transmissions. History Most early automobiles were rear-engined, using a single-speed transmission and belt-drive to power the rear wheels. In 1891, the French Panhard et Levassor automobile used a three-speed manual transmission and is considered to have set the template for multi-speed manual transmissions in motor vehicles. This transmis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automaker

The automotive industry comprises a wide range of companies and organizations involved in the design, development, manufacturing, marketing, selling, repairing, and modification of motor vehicles. It is one of the world's largest industries by revenue (from 16% such as in France up to 40% in countries such as Slovakia). The word ''automotive'' comes from the Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Sperry (1860–1930), first came into use to describe automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers pioneering the horseless carriage. Early car manufacturing involved manual assembly by a human worker. The process evolved from engineers working on a stationary car to a conveyor belt system where the car passed through multiple stations of more specialized engineers. In the 1960s, robotic equipment was introduced, and most ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Side-valve Engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the Cam-in-block, engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1960s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aviation engine, aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valve, poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Valve Engine

An overhead valve engine, abbreviated (OHV) and sometimes called a pushrod engine, is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with flathead (or "sidevalve") engines, where the valves were located below the combustion chamber in the engine block. Although an overhead camshaft (OHC) engine also has overhead valves, the common usage of the term "overhead valve engine" is limited to engines where the camshaft is located in the engine block. In these traditional OHV engines, the motion of the camshaft is transferred using pushrods (hence the term "pushrod engine") and rocker arms to operate the valves at the top of the engine. However, some designs have the camshaft in the cylinder head but still sit below or alongside the valves (the Ford CVH and Opel CIH are good examples), so they can essentially be considered overhead valve designs. Some early intake-over-exhaust engines used a hybrid design combining eleme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axle Load

The axle load of a wheeled vehicle is the total weight bearing on the roadway for all wheels connected to a given axle. Axle load is an important design consideration in the engineering of roadways and railways, as both are designed to tolerate a maximum weight-per-axle (axle load); exceeding the maximum rated axle load will cause damage to the roadway or railway tracks. Railway use On railways, a given section of tracks is designed to support a maximum axle load. The maximum axle load is determined by train speeds, weight of rails, density of sleepers and fixtures, amount and standard of ballast, and strength of bridges and earthworks. Higher operating speeds can be achieved by reducing axle loads and increased load-carrying capacity. Operating above the specified load can cause catastrophic failure of track components. The diameter of the wheels also affects the maximum axle load of a Talgo RD wagon. United Kingdom The standard rail weight for British railways is now . Befo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hesselman Engine

The Hesselman engine is a hybrid between a petrol engine and a diesel engine. It was designed and introduced in 1925 by Sweden, Swedish engineer Jonas Hesselman. In a Hesselman engine, fuel is not injected during the suction stroke along with the air, as would be the case in a conventional Otto cycle engine, but is instead injected during the compression stroke slightly ahead of the spark. Hesselman engines typically have lower efficiencies than diesel engines but can run on the same fuels without needing to sustain high compression ratios, and therefore could be made smaller, lighter and cheaper. Most Hesselman engines were built during the 1930s and 1940s by firms in Sweden and the United States for use in both heavy vehicles and stationary industrial applications. Operation During the engine's operating cycle, air is first drawn into the cylinder through an intake valve and given a rotary motion as a result of its tangential direction of entry. Air is compressed on the " ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volvo Sidevalve Straight-6 Engine ...

Penta DB was an engine model produced by AB Pentaverken. The 1929 introduced engine was a side-valve engine with a cast-iron block and seven main bearings, and the first straight-six engine used in Volvos. Four other variants followed after. These engines powered all six-cylinder Volvo passenger cars and taxi cabs, as well as the company's small trucks between 1929 and 1958. Versions: See also * List of Volvo engines References * Volvo Personvagnar-från 20-tal till 80-tal av Björn-Eric Lindh, 1984. {{ISBN, 91-86442-06-6 Pentadb Volvo The Volvo Group (; legally Aktiebolaget Volvo, shortened to AB Volvo, stylized as VOLVO) is a Swedish multinational manufacturing corporation headquartered in Gothenburg. While its core activity is the production, distribution and sale of truck ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Side Valve

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1960s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited on one side of the cylinder(s), though s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |