|

Smooth Clean Surface

Smooth clean surface (SCS) is a process applied to hot rolled sheet metal and coils to remove nearly all mill scale and clean the steel surface. The SCS process feeds hot rolled sheet steel, either as individual blanks or as a continuous strip that is uncoiled, into the SCS "brushing machine". Within the machine the steel is passed between sets of rotating roller brushes that spin on an axis perpendicular to the sheet's direction of travel. The roller brush exterior is an engineered abrasive, similar to Scotchbrite, that makes contact with the steel under pressure. Each roller brush spins against the steel at a speed of 900 to 1000 revolutions per minute, "scrubbing away" the outer layers of mill scale – hematite and magnetite – and most of the inner layer, wüstite. The remaining wüstite layer is only a few micrometres thick and highly polished to a smooth surface. Three such roller brushes are typically applied to each surface of the steel sheet, for a total of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Roll Brushes In SCS Machine

Roll may refer to: Physics and engineering * Rolling, a motion of two objects with respect to each-other such that the two stay in contact without sliding * Roll angle (or roll rotation), one of the 3 angular degrees of freedom of any stiff body (for example a vehicle), describing motion about the longitudinal axis ** Roll (aviation), one of the aircraft principal axes of rotation of an aircraft (angle of tilt to the left or right measured from the longitudinal axis) ** Roll (ship motion), one of the ship motions' principal axes of rotation of a ship (angle of tilt to the port or starboard measured from the longitudinal axis) * Rolling ''manoeuvre'', a manoeuvre of any stiff body (for example a vehicle) around its roll axis: ** Roll, an aerobatic maneuver with an airplane, usually referring to an aileron roll, but sometimes instead a barrel roll, rudder roll or slow roll ** Kayak roll, a maneuver used to right a capsized kayak ** Roll program, an aerodynamic maneuver performe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Hot Rolled

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

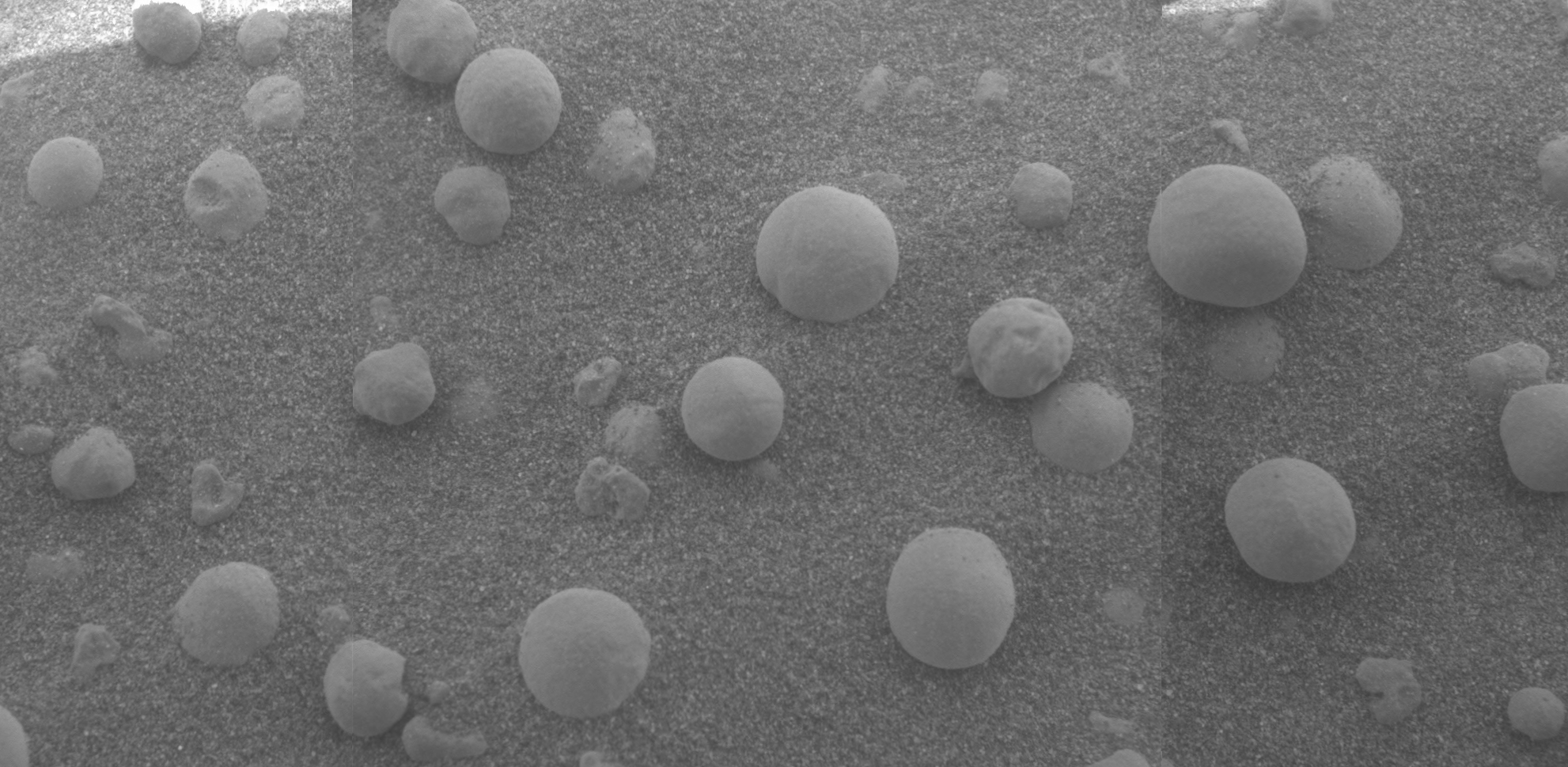

Mill Scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite). Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are produced by passing red hot iron or steel billets through rolling mills. Mill scale is bluish-black in color. It is usually less than thick, and initially adheres to the steel surface and protects it from atmospheric corrosion provided no break occurs in this coating. Because it is electrochemically cathodic to steel, any break in the mill scale coating will cause accelerated corrosion of steel exposed at the break. Mill scale is thus a boon for a while, until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . It has the same crystal structure as corundum () and ilmenite (). With this it forms a complete solid solution at temperatures above . Hematite occurs naturally in black to steel or silver-gray, brown to reddish-brown, or red colors. It is mined as an important ore mineral of iron. It is electrically conductive. Hematite varieties include ''kidney ore'', ''martite'' ( pseudomorphs after magnetite), ''iron rose'' and ''specularite'' ( specular hematite). While these forms vary, they all have a rust-red streak. Hematite is not only harder than pure iron, but also much more brittle. The term ''kidney ore'' may be broadly used to describe botryoidal, mammillary, or reniform hematite. Maghemite is a polymorph of hematite (γ-) with the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Magnetite

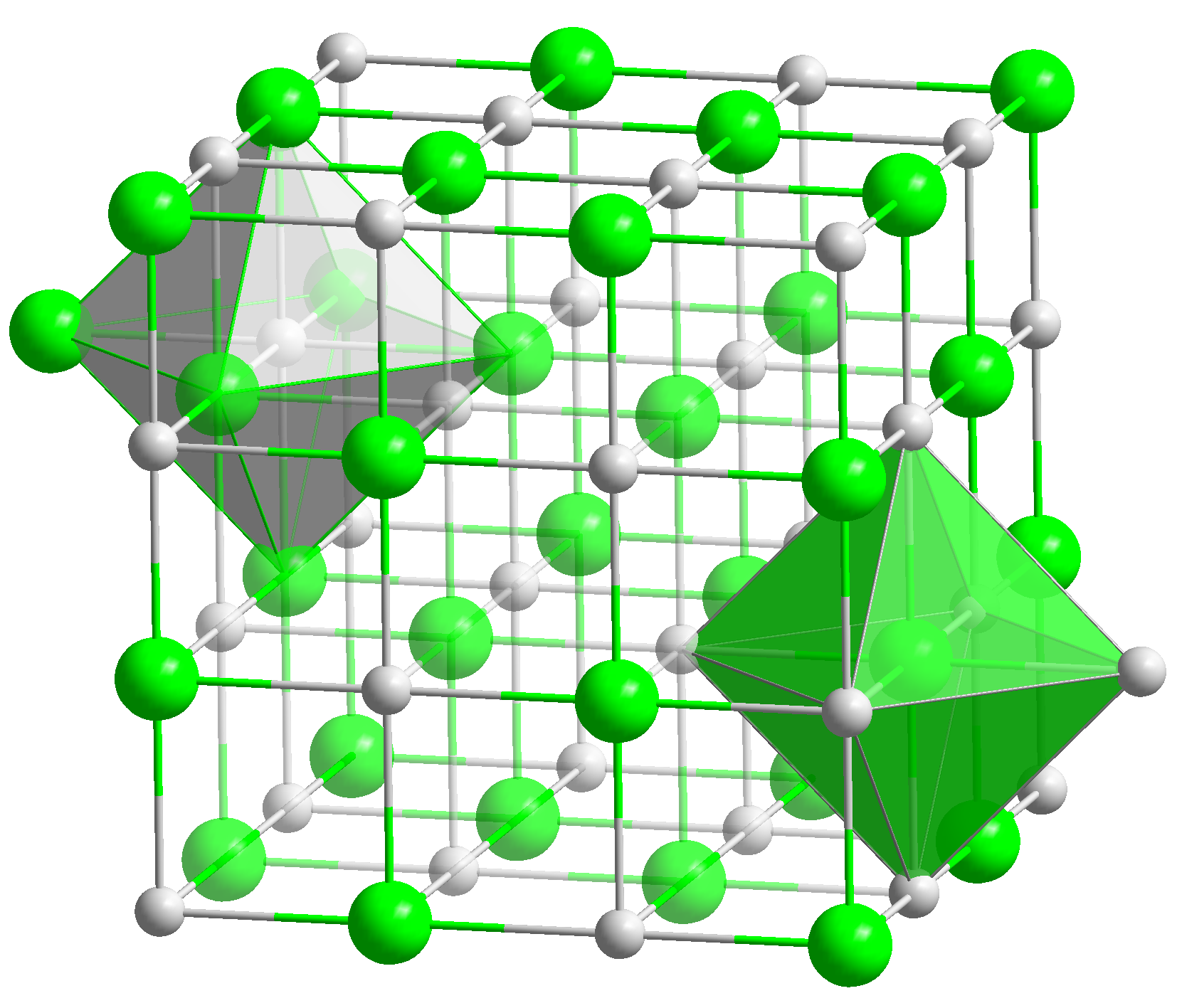

Magnetite is a mineral and one of the main iron ores, with the chemical formula . It is one of the iron oxide, oxides of iron, and is ferrimagnetism, ferrimagnetic; it is attracted to a magnet and can be magnetization, magnetized to become a permanent magnet itself. With the exception of extremely rare native iron deposits, it is the most magnetic of all the naturally occurring minerals on Earth. Naturally magnetized pieces of magnetite, called lodestone, will attract small pieces of iron, which is how ancient peoples first discovered the property of magnetism. Magnetite is black or brownish-black with a metallic luster, has a Mohs scale of mineral hardness, Mohs hardness of 5–6 and leaves a black streak (mineralogy), streak. Small grains of magnetite are very common in igneous rocks, igneous and metamorphic rocks. The chemical IUPAC name is iron(II,III) oxide and the common chemical name is ''ferrous-ferric oxide''. Properties In addition to igneous rocks, magnetite als ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Wüstite

Wüstite ( Fe O, sometimes also written as Fe0.95O) is a mineral form of mostly iron(II) oxide found with meteorites and native iron. It has a grey colour with a greenish tint in reflected light. Wüstite crystallizes in the isometric-hexoctahedral crystal system in opaque to translucent metallic grains. It has a Mohs hardness of 5 to 5.5 and a specific gravity of 5.88. Wüstite is a typical example of a non-stoichiometric compound. Wüstite was named after Fritz Wüst (1860–1938), a German metallurgist and founding director of the ''Kaiser-Wilhelm-Institut für Eisenforschung'' (presently Max Planck Institute for Iron Research GmbH). In addition to its type locality in Germany, it has been reported from Disko Island, Greenland; the Jharia coalfield, Jharkhand, India; and as inclusions in diamonds in a number of kimberlite pipes. It also is reported from deep sea manganese nodules. Its presence indicates a highly reducing environment. Wüstite redox buffer I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Eco Pickled Surface

Eco pickled surface (EPS) is a process applied to hot rolled sheet steel to remove all surface oxides (mill scale) and clean the steel surface. Steel which has undergone the EPS process acquires a high degree of resistance to subsequent development of surface oxide (rust), so long as it does not come into direct contact with moisture. EPS was developed by The Material Works, Ltd., which has filed several patent applications covering the process. It is primarily intended to be a replacement of the acid pickling process wherein steel strip is immersed in solutions of hydrochloric and sulfuric acids to chemically remove oxides. Overview of the EPS process The EPS process (see Figure 2) begins with hot rolled strip steel in coil form. This steel pays off of an uncoiler, then passes through a machine which serves the purpose of "scale breaker", "leveler" or both. This machine (see Figure 2) works the material between sets of hardened rollers. This has the effect of removing the cur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Surface Roughness

Surface roughness or simply roughness is the quality of a surface of not being smooth and it is hence linked to human ( haptic) perception of the surface texture. From a mathematical perspective it is related to the spatial variability structure of surfaces, and inherently it is a multiscale property. It has different interpretations and definitions depending on the disciplines considered. In surface metrology, surface roughness is a component of surface finish (surface texture). It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth. Roughness is typically assumed to be the high-frequency, short-wavelength component of a measured surface. However, in practice it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for a purpose. Role and effect Roughness plays an important role in determin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Corrosion Prevention

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen, or hydroxide. Rusting, the formation of red-orange iron oxides, is a well-known example of electrochemical corrosion. This type of corrosion typically produces oxides or salts of the original metal and results in a distinctive coloration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including mechanical strength, appearance, and permeability to liquids and gases ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |