|

Sheet Molding Compound

Sheet moulding compound (SMC) or sheet moulding composite is a ready to mould glass-fibre reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls weighing up to 1000 kg. Alternatively the resin and related materials may be mixed on site when a producer wants greater control over the chemistry and filler. SMC is both a process and a reinforced composite material. This is manufactured by dispersing long strands (usually >1”) of chopped fiber, commonly glass fibers or carbon fibers on a bath of thermoset resin (typically polyester resin, vinyl ester resin or epoxy resin). The longer fibers in SMC result in better strength properties than standard bulk moulding compound (BMC) products. Typical applications include demanding electrical applications, corrosion resistant needs, structural components at low cost, automotive, and transit. Process Paste reservoir dispenses a measured amount of specified resin paste onto a plastic car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiberglass

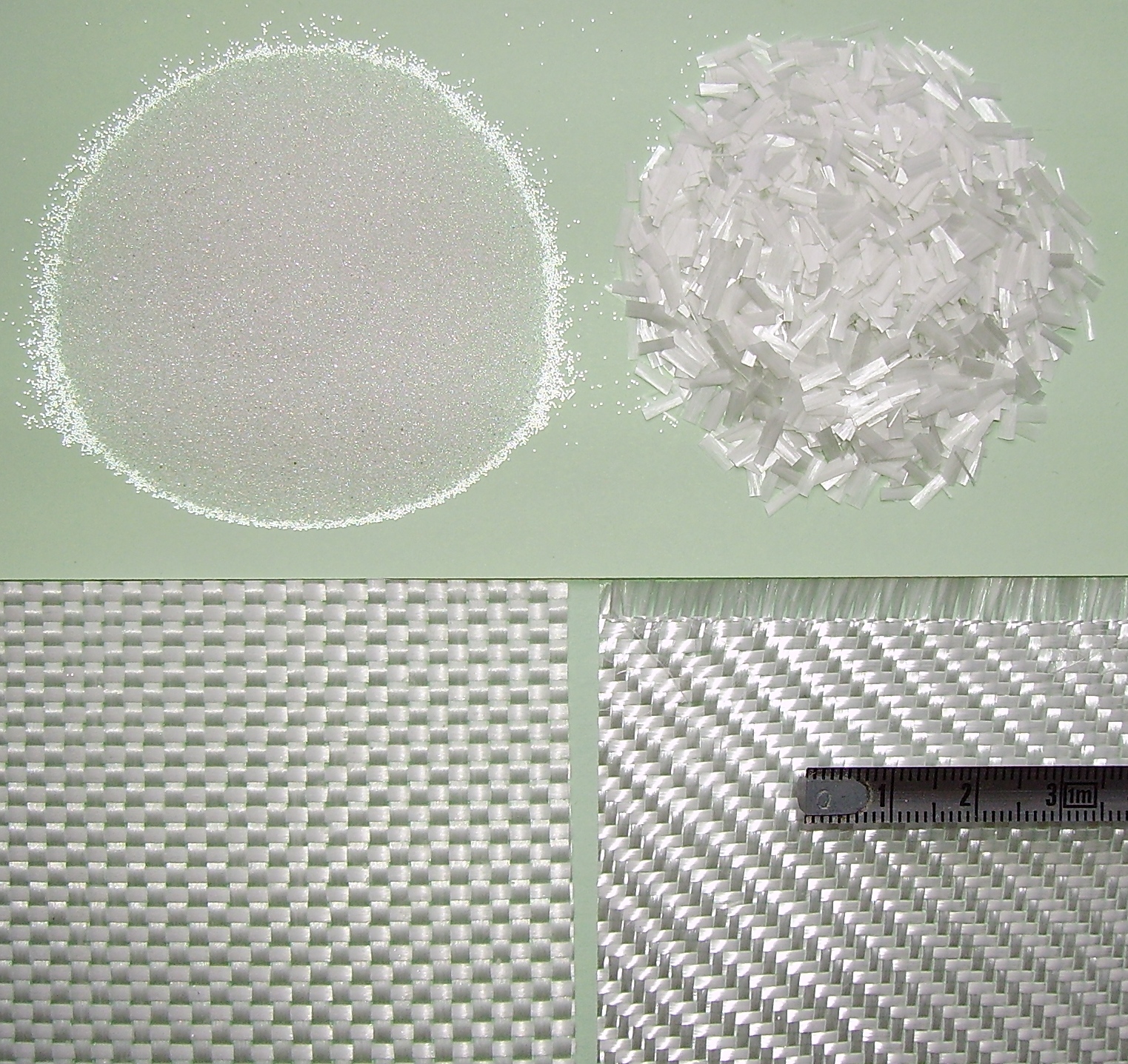

Fiberglass (American English) or fibreglass (English in the Commonwealth of Nations, Commonwealth English) is a common type of fibre-reinforced plastic, fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic Matrix (composite), matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic. Cheaper and more flexible than Carbon-fiber-reinforced polymers, carbon fiber, it is stronger than many metals by weight, non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Moulding Compound

Bulk moulding compound (BMC), bulk moulding composite, or dough moulding compound (DMC), is a ready-to-mold, glass-fiber reinforced thermoset polymer material primarily used in compression moulding, as well as in injection moulding and transfer moulding. Typical applications include demanding electrical applications, corrosion resistant needs, appliance, automotive, and transit. Manufacturing BMC is manufactured by mixing strands (Greater than 1/8” and less than 2") of chopped glass fibers, styrene, an initiator, and filler in a mixer with an unsaturated thermoset resin (commonly polyester resin, vinyl ester resin or epoxy resin). The mixing is done at room temperature and stored at low temperatures to slow down curing prior to molding. The concentration of the mixture can vary depending on application, but is typically 30% glass fibers, 25% filler, and 45% resin, styrene, and initiator. The material is provided in bulk or in logs approximately 4" in diameter. The glass fib ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastics Industry

The plastics industry manufactures polymer materials—commonly called plastics—and offers services in plastics important to a range of industries, including packaging, building and construction, electronics, aerospace, manufacturing and transportation. It is part of the chemical industry. In addition, as mineral oil is the major constituent of plastics, it therefore forms part of the petrochemical industry. Besides plastics production, plastics engineering is an important part of the industrial sector. The latter field is dominated by engineering plastic as raw material because of its better mechanical and thermal properties than the more widely used commodity plastics. Companies Markets According to PlasticsEurope, the top three markets for plastics are packaging, building and construction, and automotive. Production Plastics production has been growing globally. The numbers include thermoplastics and polyurethanes, as well as thermosets, adhesives, coatings, s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CFSMC

CFSMC, or Carbon Fiber Sheet Molding Compound (also known as CSMC or CF-SMC), is a ready to mold carbon fiber reinforced polymer composite material used in compression molding. While traditional SMC utilizes chopped glass fibers in a polymer resin, CFSMC utilizes chopped carbon fibers. The length and distribution of the carbon fibers is more regular, homogeneous, and constant than the standard glass SMC. CFSMC offers much higher stiffness and usually higher strength than standard SMC, but at a higher cost. Manufacturing CF-SMC are made up of carbon tow chunks, spread between two layers of uncured thermosetting resin. The carbon fibre tows are cut from prepreg UD tape. The originating tape can be made up of a certain number of fibres (filaments), thus affecting the properties of the final composite: values can vary from 3 to 50 thousand filaments, while typical tow lengths are within 10 to 50 mm. As for the resin, thermosetting resins are used: possible choices are polyes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forged Composite

Forged composite, commonly referred to as forged carbon, is a type of carbon fiber SMC material composed of small pieces of carbon fiber composite material that are pressed into shape as the resin sets. This is in contrast to most carbon fiber composites, which are made of larger continuous layers that are 'laid up' one at a time, often manually. Forged composite allows for a higher range of shapes to be formed with precision, relative to traditional carbon fiber. It was originally developed jointly between Lamborghini, Callaway Golf Company, and the Lamborghini Lab. It was unveiled at the 2010 Paris Motor Show in a Lamborghini concept car, the Sesto Elemento. The United States trademark for forged composite was filed on July 13, 2010, in the category Toys and Sporting Goods Products by Callaway Golf, while the trademark for Forged Composites was registered in 2018 in the automotive category by Lamborghini. Forged composite contains higher fiber volume content, which combined w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoset Polymer Matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle. They were first used after World War II, and continuing research has led to an increased range of thermoset resins, polymers or plastics, as well as engineering grade thermoplastics. They were all developed for use in the manufacture of polymer composites with enhanced and longer-term service capabilities. Thermoset polymer matrix technologies also find use in a wide diversity of non-structural industrial applications. The foremost types of thermosetting polymers used in structural composites are benzoxazine resins, bis-maleimide resins (BMI), cyanate ester resins, epoxy (epoxide) resins, phenolic (PF) resins, unsaturated polyester ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent (''catalyst'', '' hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

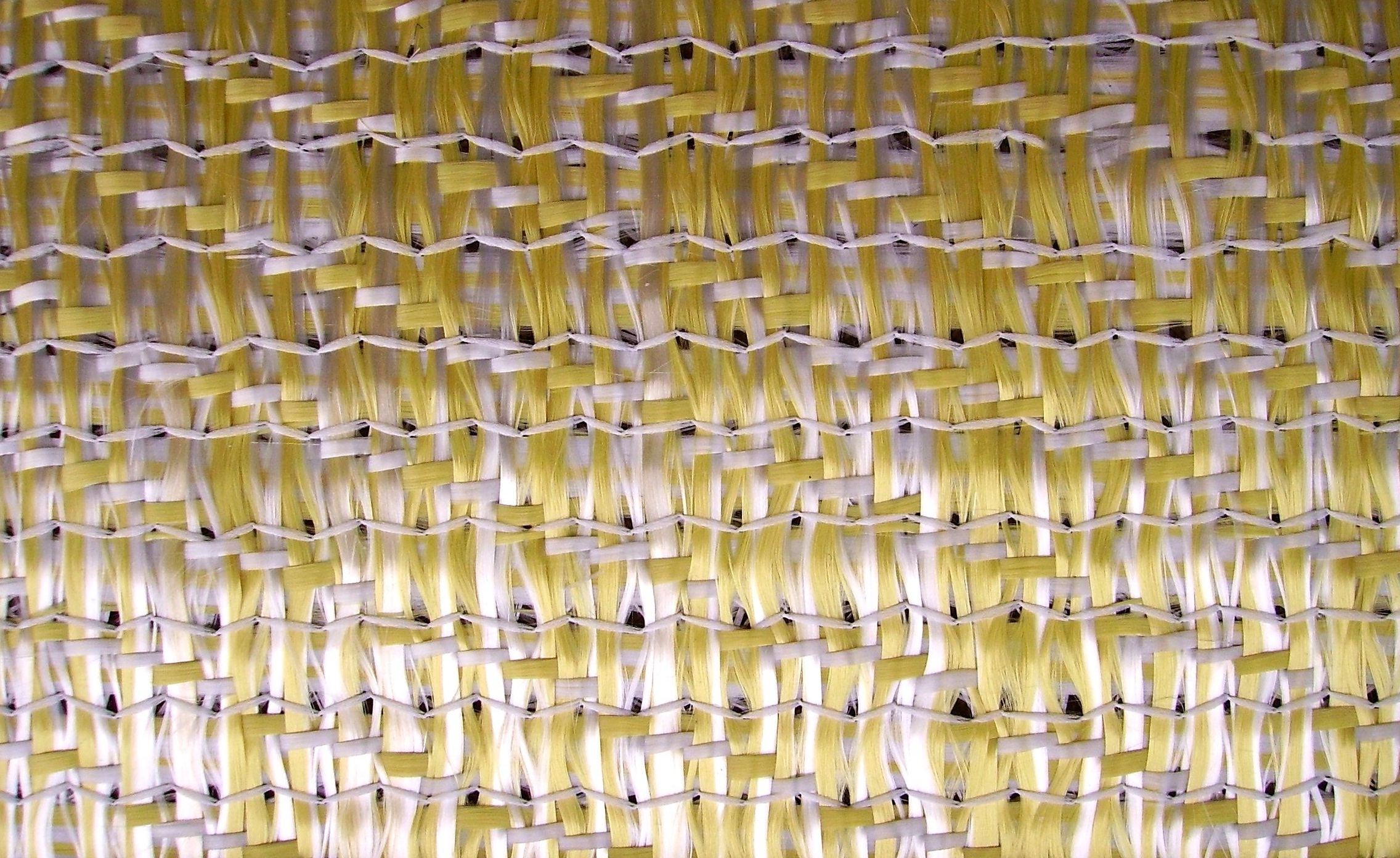

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. History Bakelite was the first fibre-reinforced plastic. Leo Baekeland had originally set out to find a replacement for shellac (made from the excretion of lac bugs). Chemists had begun to recognize that many natural resins and fibres were polymers, and Baekeland investigated the reactions of phenol an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anisotropy

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit very different physical or mechanical properties when measured along different axes, e.g. absorbance, refractive index, conductivity, and tensile strength. An example of anisotropy is light coming through a polarizer. Another is wood, which is easier to split along its grain than across it because of the directional non-uniformity of the grain (the grain is the same in one direction, not all directions). Fields of interest Computer graphics In the field of computer graphics, an anisotropic surface changes in appearance as it rotates about its geometric normal, as is the case with velvet. Anisotropic filtering (AF) is a method of enhancing the image quality of textures on surfaces that are far away and viewed at a shallow angle. Older ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Moulding

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms. Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly oriented fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly intricate parts. Also, it is one of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Moulding Compound

Bulk moulding compound (BMC), bulk moulding composite, or dough moulding compound (DMC), is a ready-to-mold, glass-fiber reinforced thermoset polymer material primarily used in compression moulding, as well as in injection moulding and transfer moulding. Typical applications include demanding electrical applications, corrosion resistant needs, appliance, automotive, and transit. Manufacturing BMC is manufactured by mixing strands (Greater than 1/8” and less than 2") of chopped glass fibers, styrene, an initiator, and filler in a mixer with an unsaturated thermoset resin (commonly polyester resin, vinyl ester resin or epoxy resin). The mixing is done at room temperature and stored at low temperatures to slow down curing prior to molding. The concentration of the mixture can vary depending on application, but is typically 30% glass fibers, 25% filler, and 45% resin, styrene, and initiator. The material is provided in bulk or in logs approximately 4" in diameter. The glass fib ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy Resin

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted ( cross-linked) either with themselves through catalytic homo polymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, composi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |