|

Sharpening

Sharpening is the process of creating or refining a blade, the edge joining two non-coplanar faces into a converging apex, thereby creating an edge of appropriate shape on a tool or implement designed for cutting. Improving sharpness is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness. Tools and materials There are many ways of sharpening tools. Malleable metal surfaces such as bronze, iron and mild steel may be formed by beating or peening a flat surface into a sharp edge. This process also causes work hardening. An abrasive material may be rubbed against the cutting edge to be sharpened. The most traditional abrasive material is a natural stone such as sandstone or granite. Modern synthetic grinding wheels and flat sharpening stones can be manufactured in precise grades of abrasiveness according to the intended pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Stone

Sharpening stones, or whetstones, are used to sharpening, sharpen the edges of steel tools such as knife, knives through grinding and Honing (metalworking), honing. Such stones come in a wide range of shapes, sizes, and material compositions. They may be flat, for working flat edges, or shaped for more complex edges, such as those associated with some wood carving or woodturning tools. They may be composed of natural quarried material or from man-made material. They come in various grades, which refer to the Mesh (scale), grit size of the abrasive particles in the stone. (Grit size is given as a number, which indicates the spatial density of the particles; a higher number denotes a higher density and therefore smaller particles, which give a finer finish to the surface of the sharpened object.) Stones intended for use on a workbench are called bench stones, while small, portable ones, whose size makes it hard to draw large blades uniformly over them, especially "in the field", ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness (the microscopic shape of the cutting edge) or sharpness (the narrowness of the cutting edge) to blade edges. They are flat, oval, or round in Cross section (geometry), cross-section and up to long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via Wear, adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel, restoring both the cutting edge fine shape (keenness) and thinness (sharpness). The term "hone" is associated with light maintenance performed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

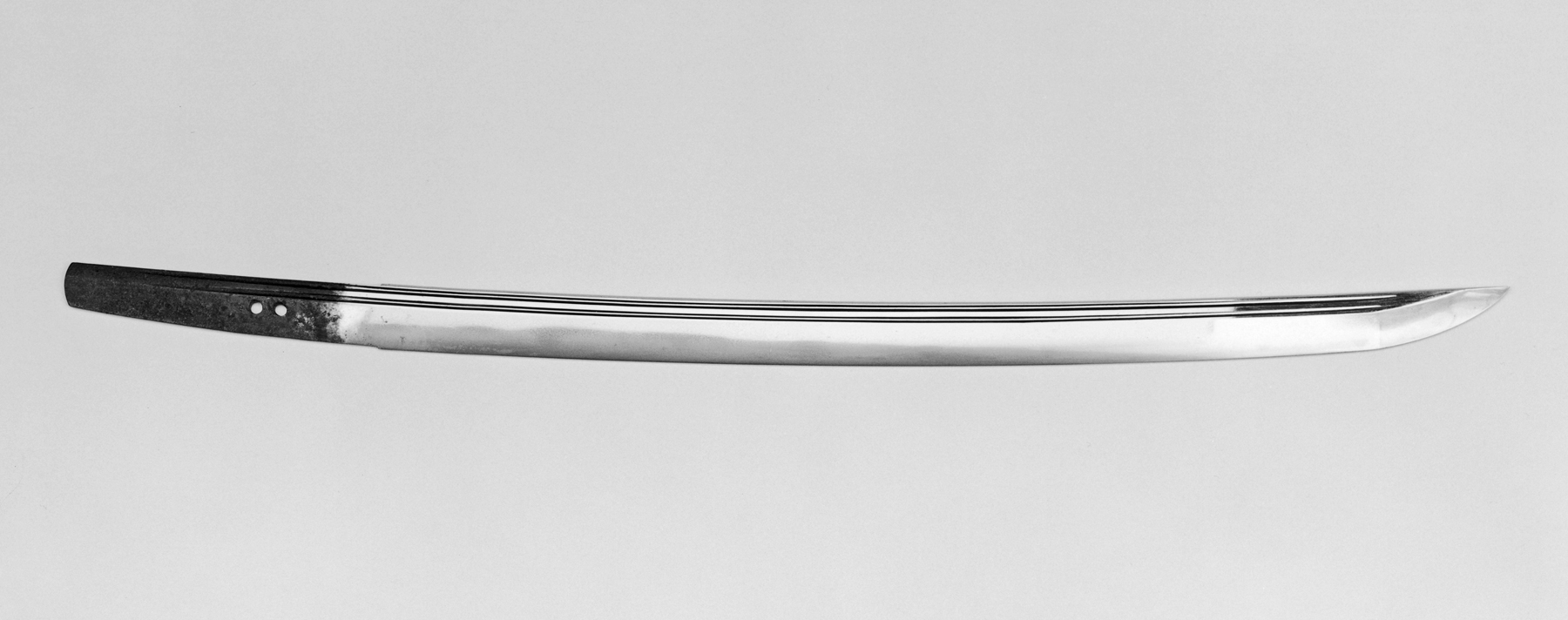

Blade

A blade is the Sharpness (cutting), sharp, cutting portion of a tool, weapon, or machine, specifically designed to puncture, chop, slice, or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are intended to cut. This includes early examples made from flaked stones like flint or obsidian, evolving through the ages into metal forms like copper, bronze, and iron, and culminating in modern versions made from steel or ceramics. Serving as one of humanity's oldest tools, blades continue to have wide-ranging applications, including in combat, cooking, and various other everyday and specialized tasks. Blades function by concentrating force at the cutting edge. Design variations, such as serrated edges found on bread knives and saws, serve to enhance this force concentration, adapting blades for specific functions and materials. Blades thus hold a significant place both historically and in contemporary society, reflecting an evolution i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives. Abrasives are extremely commonplace and are used very extensively in a wide variety of industrial, domestic, and technological applications. This gives rise to a large variation in the physical and chemical composition of abrasives as well as the shape of the abrasive. Some common uses for abrasives include grinding, polishing, buffing, honing, cutting, drilling, sharpening, lapping, and sanding (see abrasive machining). (For simplicity, "mineral" in this article will be used loosely to refer to both minerals and mineral-like substances ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Razor Strop

A razor strop or simply a strop (sometimes called a razor strap or strap) is a flexible strip of leather, canvas, denim fabric, balsa wood, or other soft material, used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool such as a chisel. In many cases stropping re-aligns parts of the blade edge that have been bent out of alignment. In other cases, especially when an abrasive polishing compound is used, stropping may remove a small amount of metal (functionally equivalent to lapping). Stropping can also burnish (i.e., push metal around on) the blade. The strop may be a hanging strop or a hand-held paddle. Various abrasive compounds may be applied to the strop to aid in polishing the blade while stropping to obtain a mirror-like finish. Common abrasive compounds include half-micron diamonds, green chromium(III) oxide, white rouge (aluminum oxide), and jeweller's rouge (iron(III) oxide). Use Stropping is traditionally associated with straig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machete

A machete (; ) is a broad blade used either as an agricultural implement similar to an axe, or in combat like a long-bladed knife. The blade is typically long and usually under thick. In the Spanish language, the word is possibly a diminutive form of the word ''macho'', which was used to refer to sledgehammers. Alternatively, its origin may be ''makhaira, machaera'', the name given by the Greeks and Romans to the falcata. It is the origin of the English language equivalent term ''matchet'', though this is rarely used. In much of the English-speaking Caribbean, such as Jamaica, Barbados, Guyana, Grenada, and Trinidad and Tobago, the term ''cutlass'' is used for these agricultural tools. Uses Agriculture In various tropical and subtropical countries, the machete is frequently used to cut through rainforest undergrowth and for agricultural purposes (e.g. cutting sugar cane). Besides this, in Latin America a common use is for such household tasks as cutting large foodstu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpness (cutting)

Sharpness refers to the ability of a blade, point, or cutting implement to cut through materials with minimal force, and can more specifically be defined as the capacity of a surface to initiate the cut.S. Schuldt, G. Arnold, J. Kowalewski, Y. Schneider, H. Rohm,Analysis of the sharpness of blades for food cutting, ''Journal of Food Engineering'', Volume 188 (2016), pp. 13–20, ISSN 0260-8774, DOI: https://doi.org/10.1016/j.jfoodeng.2016.04.022. Sharpness depends on factors such as the edge angle, edge width, and the fineness of the cutting edge, and is aided by material hardness. This quality is found in a variety of naturally occurring forms, including certain kinds of Rock (geology), rock, in plant thorns and spines, and in animal teeth, claws, horns, and other structures serving various purposes. Sharpness is also a critical attribute for man-made tools ranging from kitchen knives and scissors to industrial cutting equipment, as it allows the user of a sharp implement to eff ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Wheel

Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines. The wheels are generally made with composite material. This consists of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the ''bond'' in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available depending on the intended usage for the wheel. They may also be made from a solid steel or aluminium disc with particles bonded to the surface. Today most grinding wheels are artificial composites made with artificial aggregates, but the history of grinding wheels began with natural composite stones, such as those used for millstones. The manufacture of these wheels is a precise and tightly controlled process, due not only to the inherent safety risks of a spinning disc, but also the composition and uniformity required to prevent that disc fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compression (physical), compressive and shearing (physics), shearing phenomenon, and occurs only when the total stress (physics), stress generated by the cutting implement exceeds the ultimate Strength of materials, strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saw Blade Sharpening Machine

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws. Saws began as serrated materials, and when mankind learned how to use iron, it became the preferred material for saw blades of all kinds. There are numerous types of hand saws and mechanical saws, and different types of blades and cuts. Description A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. Terminology A number of terms are used to describe saws. Kerf The narrow channel left behind by the saw and (relatedly) the measure of its width is known as the kerf. As such, it also refers to the wasted material that is turned into sawdust, and becomes a factor in measurements when making cuts. For example, cutting an 8-foot (2.4 meter) piece of wood into 1 foot (30 cm) sect ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Razor

A razor is a bladed tool primarily used in the removal of body hair through the act of shaving. Kinds of razors include straight razors, safety razors, disposable razors, and electric razors. While the razor has been in existence since before the Bronze Age (the oldest razor-like object has been dated to 18,000 BC), the most common types of razors currently used are the safety razor and the electric razor. History Razors have been identified from many Bronze Age cultures. These were made of bronze or obsidian and were generally oval-shaped, with a small tang protruding from one of the short ends.Warwickshire County Council: New Prehistoric Archaeology Objects "Even further awa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |