|

Roll-to-roll Processing

In the field of electronic devices, roll-to-roll processing, also known as web processing, reel-to-reel processing or R2R, is the process of creating electronic devices on a roll of flexible plastic, metal foil, or flexible glass. In other fields predating this use, it can refer to any process of applying coating, printing, or performing other processes starting with a roll of a flexible material and re-reeling after the process to create an output roll. These processes, and others such as sheeting, can be grouped together under the general term converting. When the rolls of material have been coated, laminated or printed they can be subsequently slit to their finished size on a slitter rewinder. In electronic devices Large circuits made with thin-film transistors and other devices can be patterned onto these large substrates, which can be up to a few metres wide and long. Some of the devices can be patterned directly, much like an inkjet printer deposits ink. For most se ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

R2R Line

R, or r, is the eighteenth letter of the Latin alphabet, used in the modern English alphabet, the alphabets of other western European languages and others worldwide. Its name in English is ''ar'' (pronounced ), plural ''ars''. The letter is the eighth most common letter in English and the fourth-most common consonant, after , , and . Name The name of the letter in Latin was (), following the pattern of other letters representing continuants, such as , , , , and . This name is preserved in French and many other languages. In Middle English, the name of the letter changed from to , following a pattern exhibited in many other words such as ''farm'' (compare French ) and ''star'' (compare German ). In Hiberno-English, the letter is called or , somewhat similar to ''oar'', ''ore'', ''orr''. The letter R is sometimes referred to as the 'canine letter', often rendered in English as the dog's letter. This Latin term referred to the Latin that was trilled to sound l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

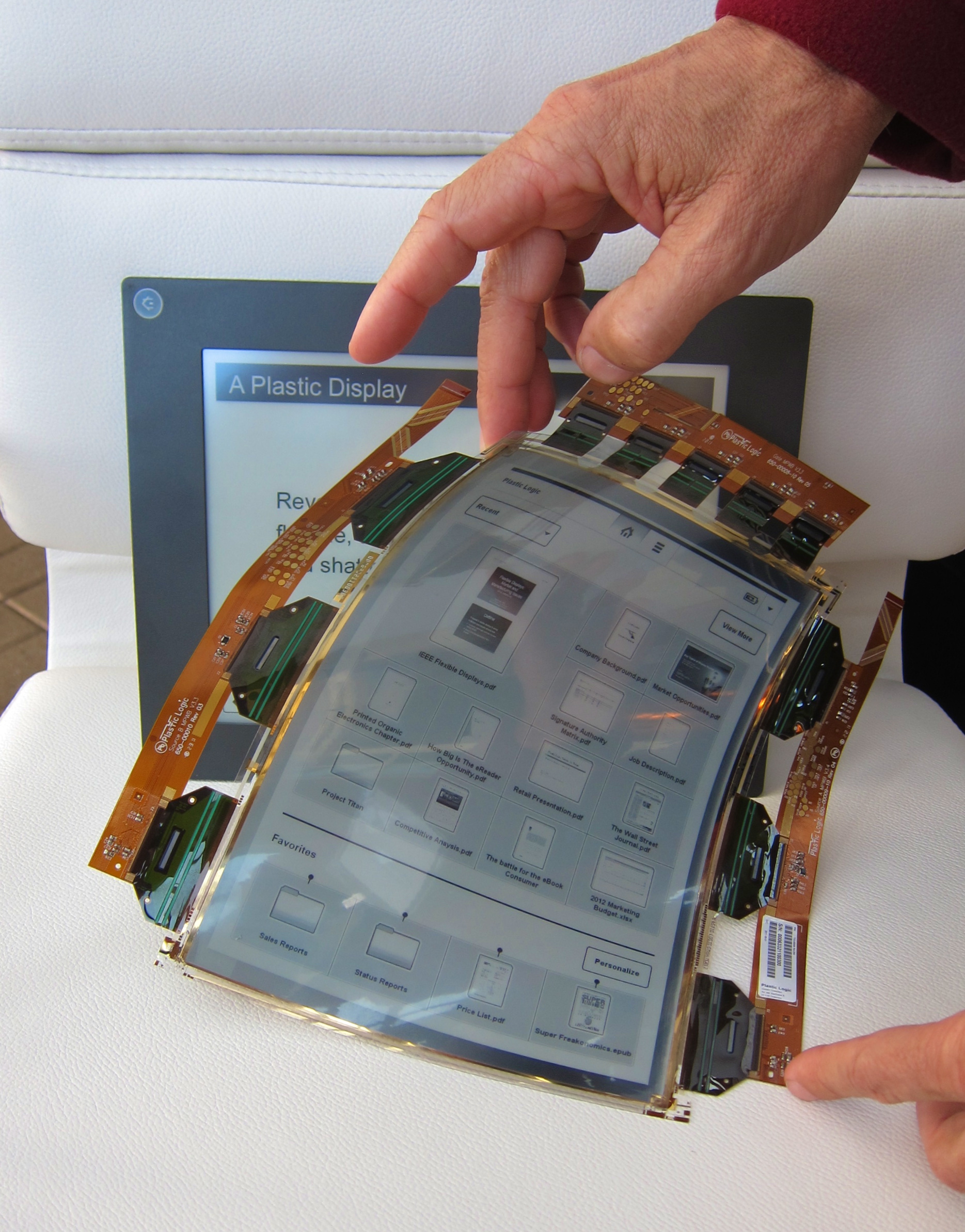

Rollable Display

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices. In recent years there has been a growing interest from numerous consumer electronics manufacturers to apply this display technology in e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted. Technologies involved in building a rollable display include electronic ink, Gyricon, Organic LCD, and OLED. Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity. In 2007, Philips launched a 5-inch, 320 x 240-pixel rollable display based on E Ink’s electrophoretic technology. Some flexible organic light-emitting diode displays have been demons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Web (manufacturing)

A web is a long, thin, and flexible material. Common webs include foil, metal, paper, textile, plastic film, and wire. Common processes carried out on webs include coating, plating, and laminating.. A web is generally processed by moving over rollers. Between processing stages, webs are stored and transported as rolls also known as coils, packages and doffs. The end result or use of web manufacturing is usually sheets. The primary motivation to work with webs instead of sheets is economics. Webs, being continuous, can be made at far higher speeds and do not have the start-stop issues of discrete sheet processing. The size of the web-handling industries is unknown. Related processes *Web processing Web processing is found in a wide variety of other manufacturing including electronics such as circuit boards, construction materials such as roofing, and pharmaceuticals such as drug patches. *Web handling Web handling refers to the processing of a web through a machine with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin Film Solar Cell

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as glass, plastic or metal. Thin-film solar cells are typically a few nanometers ( nm) to a few microns ( μm) thick–much thinner than the wafers used in conventional crystalline silicon (c-Si) based solar cells, which can be up to 200 μm thick. Thin-film solar cells are commercially used in several technologies, including cadmium telluride (CdTe), copper indium gallium diselenide (CIGS), and amorphous thin-film silicon (a-Si, TF-Si). Solar cells are often classified into so-called generations based on the active (sunlight-absorbing) layers used to produce them, with the most well-established or ''first-generation'' solar cells being made of single- or multi-crystalline silicon. This is the dominant technology currently used in most solar PV systems. Most thin-film solar cells are classified as ''second gener ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling (metalworking)

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slitter

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole (the 'log') and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as ''mults'' (short for multiple) or ''pancakes'' if their diameter is much more than their width. For log slitting, the machine used is called a paper sawing machine or a paper roll saw, which typically uses a circular saw or band saw to cut rolls into narrower ones. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. "Slitting" refers to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Electronics

Printed electronics is a set of printing methods used to create electrical devices on various substrates. Printing typically uses common printing equipment suitable for defining patterns on material, such as screen printing, flexography, gravure, offset lithography, and inkjet. By electronic-industry standards, these are low-cost processes. Electrically functional electronic or optical inks are deposited on the substrate, creating active or passive devices, such as thin film transistors, capacitors, coils, and resistors. Some researchers expect printed electronics to facilitate widespread, very low-cost, low-performance electronics for applications such as flexible displays, smart labels, decorative and animated posters, and active clothing that do not require high performance. Coatanéa, E., Kantola, V., Kulovesi, J., Lahti, L., Lin, R., & Zavodchikova, M. (2009). Printed Electronics, Now and Future. In Neuvo, Y., & Ylönen, S. (eds.), Bit Bang – Rays to the Future. Helsinki Un ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Low Cost Solar Cell

A solar cell, also known as a photovoltaic cell (PV cell), is an electronic device that converts the energy of light directly into electricity by means of the photovoltaic effect.Solar Cells chemistryexplained.com It is a type of photoelectric cell, a device whose electrical characteristics (such as current, , or resistance) vary when it is exposed to light. Individual solar cell devices are often the electrical building blocks of [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Amorphous Silicon

Amorphous silicon (a-Si) is the non-crystalline form of silicon used for solar cells and thin-film transistors in LCDs. Used as semiconductor material for a-Si solar cells, or thin-film silicon solar cells, it is deposited in thin films onto a variety of flexible substrates, such as glass, metal and plastic. Amorphous silicon cells generally feature low efficiency. As a second-generation thin-film solar cell technology, amorphous silicon was once expected to become a major contributor in the fast-growing worldwide photovoltaic market, but has since lost its significance due to strong competition from conventional crystalline silicon cells and other thin-film technologies such as CdTe and CIGS. Amorphous silicon is a preferred material for the thin film transistor (TFT) elements of liquid crystal displays (LCDs) and for x-ray imagers. Amorphous silicon differs from other allotropic variations, such as monocrystalline silicon—a single crystal, and polycrystalline silico ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Nozzle

Ultrasonic nozzles are a type of spray nozzle that use high frequency vibrations produced by piezoelectric transducers acting upon the nozzle tip that create capillary waves in a liquid film. Once the amplitude of the capillary waves reaches a critical height (due to the power level supplied by the generator), they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization. The primary factors influencing the initial droplet size produced are frequency of vibration, surface tension, and viscosity of the liquid. Frequencies are commonly in the range of 20–180 kHz, beyond the range of human hearing, where the highest frequencies produce the smallest drop size. History In 1962 Dr. Robert Lang followed up on this work, essentially proving a correlation between his atomized droplet size relative to Rayleigh's liquid wavelength. Ultrasonic nozzles were first commercialized by Dr. Harvey L. Berger. . Applications Subseque ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Vapour Deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films. In typical CVD, the wafer (substrate) is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit. Frequently, volatile by-products are also produced, which are removed by gas flow through the reaction chamber. Microfabrication processes widely use CVD to deposit materials in various forms, including: monocrystalline, polycrystalline, amorphous, and epitaxial. These materials include: silicon ( dioxide, carbide, nitride, oxynitride), carbon (fiber, nanofibers, nanotubes, diamond and graphene), fluorocarbons, filaments, tungsten, titanium nitride and various high-κ dielectrics. The term ''chemical vapour deposition'' was coined in 1960 by ''John M. Blocher, Jr.'' who intended to different ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300 MHz and 300 GHz, broadly construed. A more common definition in radio-frequency engineering is the range between 1 and 100 GHz (wavelengths between 30 cm and 3 mm), or between 1 and 3000 GHz (30 cm and 0.1 mm). In all cases, microwaves include the entire super high frequency, super high frequency (SHF) band (3 to 30 GHz, or 10 to 1 cm) at minimum. The boundaries between far infrared, terahertz radiation, microwaves, and ultra-high-frequency (UHF) are fairly arbitrary and differ between different fields of study. The prefix ' in ''microwave'' indicates that microwaves are small (having shorter wavelengths), compared to the radio waves used in prior radio technology. Frequencies in the micr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |