|

Olefin Fiber

Olefin fiber is a synthetic fiber made from a polyolefin, such as polypropylene or polyethylene. It is used in wallpaper, carpeting, ropes, and vehicle interiors. Olefin's advantages are its strength, colorfastness and comfort, its resistance to staining, mildew, abrasion, and sunlight, and its good bulk and cover. History Italy began production of olefin fibers in 1957. The chemist Giulio Natta successfully formulated olefin suitable for more textile applications. Both Natta and Karl Ziegler were later awarded the Nobel Prize for their work on transition metal catalysis of olefins to fiber, also known as Ziegler–Natta catalysis. Production of olefin fibers in the U.S. began in 1960. Olefin fibers account for 16% of all manufactured fibers. Major fiber properties Olefin fibers have great bulk and cover while having low specific gravity. This means “Warmth without the weight.” The fibers have low moisture absorption, but they can wick moisture and dry quickly. Olefin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Fiber

Synthetic fibers or synthetic fibres (in British English; see spelling differences) are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms, such as plants like cotton or fur from animals. They are the result of extensive research by scientists to replicate naturally occurring animal and plant fibers. In general, synthetic fibers are created by extruding fiber-forming materials through spinnerets, forming a fiber. These are called synthetic or artificial fibers. The word polymer comes from a Greek prefix "poly" which means "many" and suffix "mer" which means "single units". (Note: each single unit of a polymer is called a monomer). The first synthetic fibres Nylon was the first commercially successful synthetic thermoplastic polymer. DuPont began its research project in 1927. The first nylon, nylon 66, was synthesized on February 28, 1935, by Wallace Hume Carothers at DuPont's research facili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Melt Spinning

Melt spinning is a metal forming technique that is typically used to form thin ribbons of metal or alloys with a particular atomic structure. Some important commercial applications of melt-spun metals include high-efficiency transformers (Amorphous metal transformer), sensory devices, telecommunications equipment, and power electronics. A typical melt spinning process involves casting molten metal by jetting it onto a rotating wheel or drum, which is cooled internally, usually by water or liquid nitrogen. The molten material rapidly solidifies upon contact with the large, cold surface area of the drum. The rotation of the drum constantly removes the solidified product while exposing new surface area to the molten metal stream, allowing for continuous production. The resulting ribbon is then directed along the production line to be packaged or machined into further products. The cooling rates achievable by melt spinning are on the order of 104–106 Kelvins per second (K/s). Co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastolefin

Elastolefin is a fiber composed of at least 95% (by weight) of macromolecules partially cross-linked, made of ethylene Ethylene (IUPAC name: ethene) is a hydrocarbon which has the formula or . It is a colourless, flammable gas with a faint "sweet and musky" odour when pure. It is the simplest alkene (a hydrocarbon with carbon–carbon bond, carbon–carbon doub ... and at least one other olefin. When stretched to one and a half times its original length, it recovers rapidly to its original length. It therefore will stretch up to 50% and recover. Recent updates to EU fabric labelling directive to include elastolefin in Anex I and II. Low crystallinity polyolefin elastomers that have a cross-linked structure have been developed by the DOW Chemical Company in 2002. The trade name of the elastolefin fibers is DOW XLA, the fibers when under lower stress have the ability to expand when larger strains are applied. The DOW XLA fibers were designed to have high thermal and chemical r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alkene

In organic chemistry, an alkene, or olefin, is a hydrocarbon containing a carbon–carbon double bond. The double bond may be internal or at the terminal position. Terminal alkenes are also known as Alpha-olefin, α-olefins. The International Union of Pure and Applied Chemistry (IUPAC) Preferred IUPAC name, recommends using the name "alkene" only for Open-chain compound, acyclic hydrocarbons with just one double bond; alkadiene, alkatriene, etc., or polyene for acyclic hydrocarbons with two or more double bonds; cycloalkene, cycloalkadiene, etc. for Cyclic compound, cyclic ones; and "olefin" for the general class – cyclic or acyclic, with one or more double bonds. Acyclic alkenes, with only one double bond and no other functional groups (also known as mono-enes) form a homologous series of hydrocarbons with the general formula with ''n'' being a >1 natural number (which is two hydrogens less than the corresponding alkane). When ''n'' is four or more, isomers are possible, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thinsulate

Thinsulate is a brand of synthetic fiber thermal insulation used in winter clothing. The word is a portmanteau of the words ''thin'' and ''insulate'', trademarked by 3M. The material is made by the 3M Corporation and was first sold in 1979. It was originally marketed as an inexpensive alternative to down; at the time, 3M claimed it was twice as warm as an equivalent amount of any natural material. Originally designed for clothing, it later became popular as an acoustic damping material. In 1997, 3M generated US$150 million in annual revenue from the product.Fiedler, Terry"The quiet Thinsulate; 3M again capitalizes on both name, performance with brand extensions.(BUSINESS)."Star Tribune (Minneapolis, MN). The Star Tribune Company. 1997. HighBeam Research. 13 Sep. 2018 . Its development originated from other microfibre products made by 3M. It has been used in US army clothing since the mid 1980s. Description Thinsulate fibers are about in diameter, which is thinner than the poly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tyvek

Tyvek () is a brand of synthetic flashspun high-density polyethylene fibers. The name ''Tyvek'' is a registered trademark of the American multinational chemical company DuPont, which discovered and commercialized Tyvek in the late 1950s and early 1960s. Tyvek's properties—such as being difficult to tear but easily cut, and waterproof against liquids while allowing water vapor to penetrate—have led to it being used in a variety of applications. Tyvek is often used as housewrap, a synthetic material used to protect buildings during construction, or as personal protective equipment (PPE). History Tyvek is a nonwoven product consisting of spun bond olefin fiber. It was first discovered in 1955 by a researcher for the DuPont textile company working in an experimental lab, who noticed a type of white fluff coming out of a pipe. That fluff was a form of polyethylene, which DuPont requested a patent for within a year of the discovery. After technologies improved during the next ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydroentanglement

Hydroentanglement is a bonding process for wet or dry fibrous webs made by either carding, airlaying or wet-laying, the resulting bonded fabric being a nonwoven. It uses fine, high pressure jets of water which penetrate the web, hit the conveyor belt (or "wire" as in papermaking conveyor) and bounce back causing the fibres to entangle. Hydroentanglement is sometimes known as spunlacing, this term arising because the early nonwovens were entangled on conveyors with a patterned weave which gave the nonwovens a lacy appearance. It can also be regarded as a two-dimensional equivalent of spinning fibres into yarns prior to weaving. The water pressure has a direct bearing on the gsm, and strength of the web, and very high pressures not only entangle but can also split fibres into micro- and nano-fibres which give the resulting hydroentangled nonwoven a leatherlike or even silky texture. This type of nonwoven can be as strong and tough as woven fabrics made from the same fibres. Compos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gel Spinning

A gel is a semi-solid that can have properties ranging from soft and weak to hard and tough. Gels are defined as a substantially dilute cross-linked system, which exhibits no flow when in the steady state, although the liquid phase may still diffuse through this system. Gels are mostly liquid by mass, yet they behave like solids because of a three-dimensional cross-linked network within the liquid. It is the cross-linking within the fluid that gives a gel its structure (hardness) and contributes to the adhesive stick (tack). In this way, gels are a dispersion of molecules of a liquid within a solid medium. The word ''gel'' was coined by 19th-century Scottish chemist Thomas Graham by clipping from ''gelatine''. The process of forming a gel is called gelation. Composition Gels consist of a solid three-dimensional network that spans the volume of a liquid medium and ensnares it through surface tension effects. This internal network structure may result from physical bonds s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

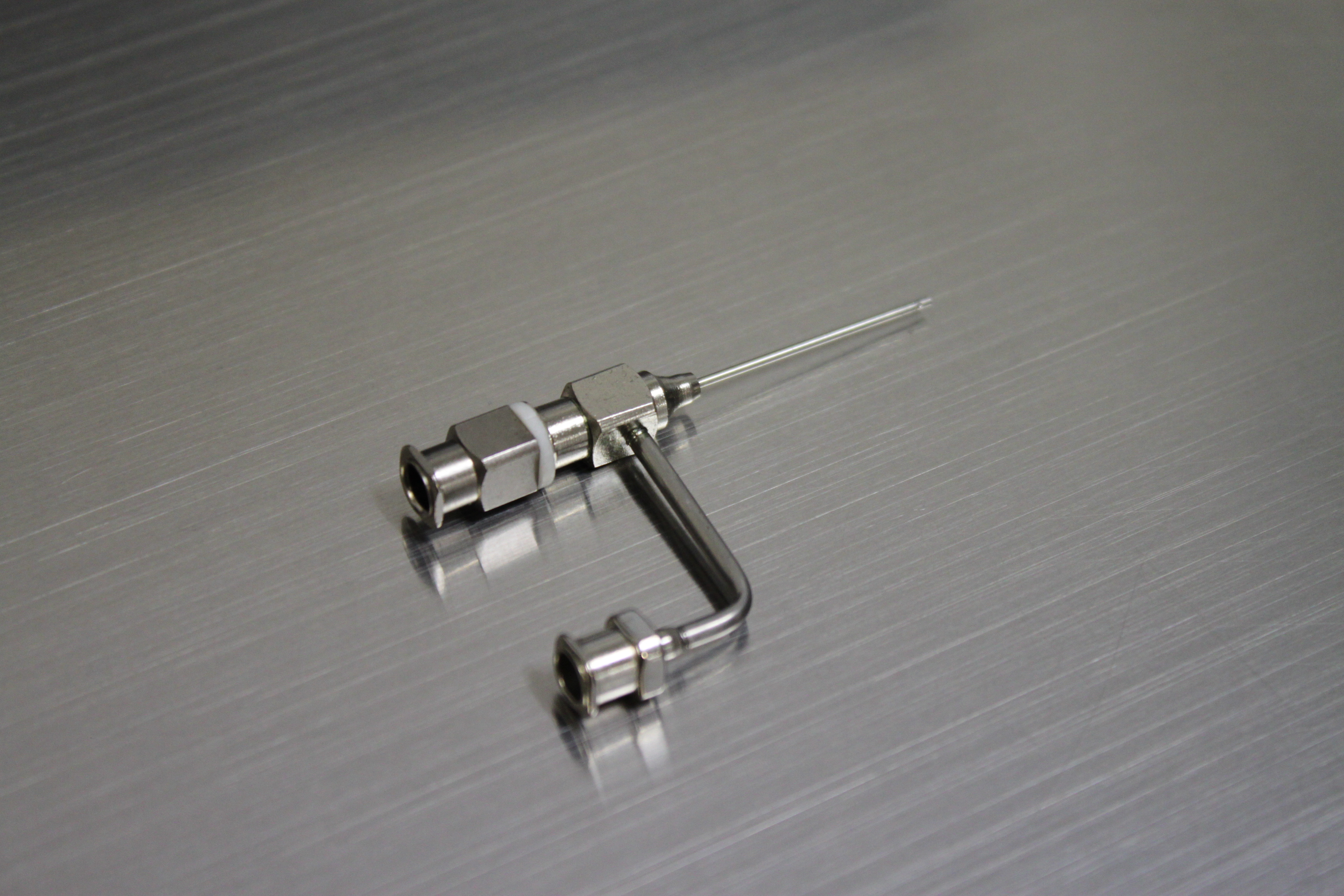

Spinneret (polymers)

A spinneret is a device used to extrude a polymer solution or polymer melt to form fibers. Streams of viscous polymer exit via the spinneret into air or liquid leading to a phase inversion which allows the polymer to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber formation process is similar to the production process for cotton candy. The fiber production process is generally referred to as "spinning". Depending on the type of spinneret used, either solid or hollow fibers can be formed. Spinnerets are also used for electrospinning and electrospraying applications. They are sometimes called ''coaxial needles,'' or ''coaxial emitters.'' Spinnerets are usually made of metals with melting points too low to withstand the heating processes employed in industrial metallurgy, and thus are generally not used to form metallic fibers. See also * Electrospinning * Hollow fiber membrane * Spinning (polyme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propylene

Propylene, also known as propene, is an unsaturated organic compound with the chemical formula . It has one double bond, and is the second simplest member of the alkene class of hydrocarbons. It is a colorless gas with a faint petroleum-like odor. Propylene is a product of combustion from forest fires, cigarette smoke, and motor vehicle and aircraft exhaust. It was discovered in 1850 by A. W. von Hoffmann's student Captain (later Major General) John Williams Reynolds as the only gaseous product of thermal decomposition of amyl alcohol to react with chlorine and bromine. Production Steam cracking The dominant technology for producing propylene is steam cracking, using propane as the feedstock. Cracking propane yields a mixture of ethylene, propylene, methane, hydrogen gas, and other related compounds. The yield of propylene is about 15%. The other principal feedstock is naphtha, especially in the Middle East and Asia. Propylene can be separated by fractional distill ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include Polyisobutene, polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds (polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |