|

Oilite

Oilite is a brand of self-lubricating bearing that is made from metal alloys with pores that channel lubricants between the bearing itself and the shaft. It is manufactured from different types of material. Traditional Oilite is mostly made of copper with approximately 10% tin and up to 1% iron, while both Super Oilite and Super Oilite 16 are primarily made of iron with about 20% copper and, in the case of the latter, up to 1% graphite. Oilite is currently a registered trademark of Beemer Precision, Inc. History One of the core engineers of Chrysler, Carl Breer, had an idea to pack graphite with metal in 1927, despite the fact that GM earlier failed to make a bushing from compressed copper and graphite. He hired engineer William Sherwood and metallurgist Bill Caulkins, who succeeded in sintering copper, tin and graphite in a furnace without oxygen. Oilite was developed by Chrysler in 1930, originally as bearings for water pumps and spring shackles, and without oil as the porou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A ball bearing A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts. The term "bearing" is derived from the verb " to bear"; a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest bearings are bearing surfaces, cut or formed into a part, with varying degrees of control over the form, size, roughness, and location of the surface. Other bearings are separate devices installed into a machine or mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reaming

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press. Construction A typical reamer consists of a set of parallel straight or helical cutting edges along the length of a cylindrical body. Each cutting edge is ground at a slight angle and with a slight undercut below the cutting edge. Reamers must combine both hardness in the cutting edges, for long life, and toughness, so that the tool does not fail under the normal forces of use. They should only be used to remove small amounts of material. This ensures a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors (floor and overhead) as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys. Industries where used Conveyor systems are used widespread across a range of industries due to the numerous benefits they provide. * Conveyors are able to safely t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheave

Sheave without a rope A pulley is a wheel on an axle or shaft enabling a taut cable or belt passing over the wheel to move and change direction, or transfer power between itself and a shaft. A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain. History The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991–1802 BC) and Mesopotamia in the early 2nd millennium BC. In Roman Egypt, Hero of Alexandria (c. 10–70 AD) identified the pulley as one of six simple machines used to lift weights. Pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulleys are also assembled as part of belt and chain drives in order to transmit power from one rotating shaft to another. Plutarch's ''Parallel Lives'' recounts a scene where Archimedes proved the effectiveness of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Winch

A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the tension (physics), tension of a rope or wire rope (also called "cable" or "wire cable"). In its simplest form, it consists of a Bobbin, spool (or drum) attached to a hand crank (mechanism), crank. Traditionally, winches on ships accumulated wire or rope on the drum; those that do not accumulate, and instead pass on the wire/rope (see yacht photo above), are called Capstan_(nautical), capstans. Despite this, sailboat capstans are most often referred to as winches. Winches are the basis of such machines as tow trucks, steam shovels and elevators. More complex designs have gear assemblies and can be powered by electric, hydraulic, pneumatic or internal combustion drives. It might include a solenoid brake and/or a Mechanical brake stretch wrapper, mechanical brake or ratchet (device), ratchet and pawl which prevents it unwinding unless the pawl is retracted. The rope may b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Farm Equipment

Agricultural machinery relates to the mechanical structures and devices used in farming or other agriculture. There are many types of such equipment, from hand tools and power tools to tractors and the farm implements that they tow or operate. Machinery is used in both organic and nonorganic farming. Especially since the advent of mechanised agriculture, agricultural machinery is an indispensable part of how the world is fed. Agricultural machinery can be regarded as part of wider agricultural automation technologies, which includes the more advanced digital equipment and agricultural robotics. While robots have the potential to automate the three key steps involved in any agricultural operation (diagnosis, decision-making and performing), conventional motorized machinery is used principally to automate only the performing step where diagnosis and decision-making are conducted by humans based on observations and experience. History The Industrial Revolution With the coming o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by Pressing (metalworking), pressing or abrasion (mechanical), abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elasticity (physics), elastic stiffness, plasticity (physics), plasticity, deformation (mechanics), strain, strength of materials, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are cer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of the processes involved is called tribology, and has a history of more than 2000 years. Friction can have dramatic consequences, as illustrated by the use of friction created by rubbing pieces of wood together to start a fire. Another important consequence of many types of friction can be wear, which may lead to performance degradation or damage to components. It is known that frictional energy losses account for about 20% of the total energy expenditure of the world. As briefly discussed later, there are many different contributors to the retarding force in friction, ranging from asperity deformation to the generation of charges and changes in local structure. When two bodies in contact move relative to each other, due to these variou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a corporate spin-off, spin-off from DuPont (1802–2017), DuPont, which originally invented the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high-molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances Wetting, wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low polarizability, electric polarizability of fluorine. PTFE has one of the lowest Friction#Coefficient of friction, coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for Cookware and bakeware, pans and other Cookware and bakeware, cookware. It is Chemically inert, non-reactive, partly because of the strength of car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine Oil

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Gas, steam, and water turbines have a casing around the blades that contains and controls the working fluid. Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. History Hero of Alexandria demonstrated th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

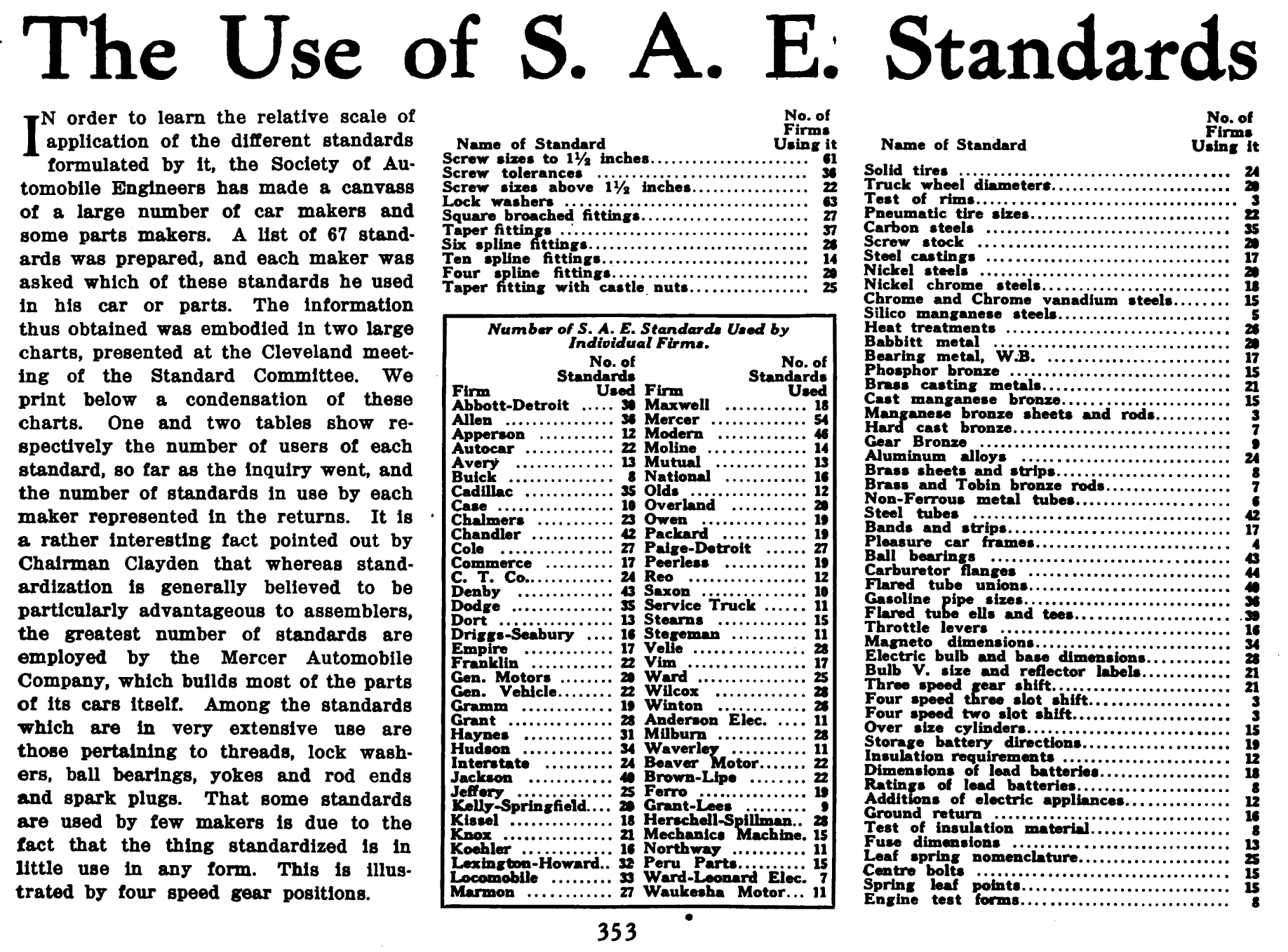

SAE International

SAE International is a global professional association and standards organization based in Warrendale, Pennsylvania, United States. Formerly the Society of Automotive Engineers, the organization adopted its current name in 2006 to reflect both its international membership and the increased scope of its activities beyond automotive engineering and the automotive industry to include aerospace and other transport industries, as well as commercial vehicles including autonomous vehicles such as self-driving cars, trucks, surface vessels, drones, and related technologies. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. History In the early 1900s there were dozens of automobile manufacturers in the United States, and many more w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

United States Military Standard

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the United States Department of Defense. Standardization is beneficial in achieving interoperability, ensuring products meet certain requirements, commonality, reliability, total cost of ownership, compatibility with logistics systems, and similar defense-related objectives. Defense standards are also used by other non-defense government organizations, technical organizations, and industry. This article discusses definitions, history, and usage of defense standards. Related documents, such as defense handbooks and defense specifications, are also addressed. Definition of document types Although the official definitions differentiate between several types of documents, all of these documents go by the general rubric of "military standard", including defense specifications, handbooks, and standards. Str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |