|

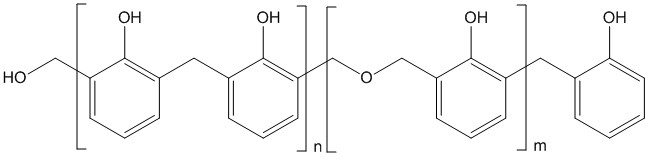

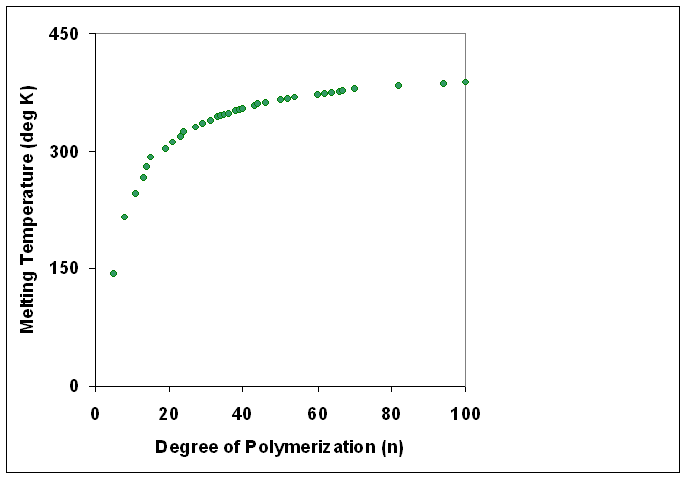

Novolac

Novolaks (sometimes: novolacs) are low molecular weight polymers derived from phenols and formaldehyde. They are related to Bakelite, which is more highly crosslinked. The term comes from Swedish "lack" for lacquer and Latin "novo" for new, since these materials were envisioned to replace natural lacquers such as copal resin. Typically novolaks are prepared by the condensation of phenol or a mixture of p- and m-cresol with formaldehyde (as formalin). The reaction is acid catalyzed. Oxalic acid is often used because it can be subsequently removed by thermal decomposition. Novolaks have a degree of polymerization of approximately 20-40. The branching density, determined by the processing conditions, m- vs p-cresol ratio, as well as CH2O/cresol ratio is typically around 15%. Novolaks are especially important in microelectronics where they are used as photoresist materials. They are also used as tackifiers in rubber. See also * Phenol formaldehyde resin * Epoxy Epoxy is th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phenol Formaldehyde Resin

Phenol formaldehyde resins (PF), also called phenolic resins or phenoplasts, are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commercial synthetic resins. They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives. They were at one time the primary material used for the production of circuit boards but have been largely replaced with epoxy resins and fiberglass cloth, as with fire-resistant FR-4 circuit board materials. There are two main production methods. One reacts phenol and formaldehyde directly to produce a thermosetting network polymer, while the other restricts the formaldehyde to produce a prepolymer known as novolac which can be moulded and then cured with the addition of more formaldehyde and heat.A. Gardziella, L.A. Pilato, A. Knop, Phenolic Resins: Chemistry, Applications, Standa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photoresist

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronics industry. The process begins by coating a substrate with a light-sensitive organic material. A patterned mask is then applied to the surface to block light, so that only unmasked regions of the material will be exposed to light. A solvent, called a developer, is then applied to the surface. In the case of a positive photoresist, the photo-sensitive material is degraded by light and the developer will dissolve away the regions that were exposed to light, leaving behind a coating where the mask was placed. In the case of a negative photoresist, the photosensitive material is strengthened (either polymerized or cross-linked) by light, and the developer will dissolve away only the regions that were not exposed to light, leaving behind a coating in areas w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tackifier

Tackifiers are chemical compounds used in formulating adhesives to increase tack, the stickiness of the surface of the adhesive. They are usually low-molecular weight compounds with high glass transition temperature. At low strain rate, they provide higher stress compliance, and become stiffer at higher strain rates. Tackifiers tend to have low molecular weight, and glass transition and softening temperature above room temperature, providing them with suitable viscoelastic properties. Tackifiers frequently represent most of both weight percentage and cost of hot melt adhesives and pressure-sensitive adhesives. In hot melt adhesives they can comprise up to about 40% of total mass. Tackifiers are usually resins (e.g. rosins and their derivates, terpenes and modified terpenes, aliphatic, cycloaliphatic and aromatic resins (C5 aliphatic resins, C9 aromatic resins, and C5/C9 aliphatic/aromatic resins), hydrogenated hydrocarbon resins, and their mixtures, terpene-phenol resins (TPR, u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microelectronics

Microelectronics is a subfield of electronics. As the name suggests, microelectronics relates to the study and manufacture (or microfabrication) of very small electronic designs and components. Usually, but not always, this means micrometre-scale or smaller. These devices are typically made from semiconductor materials. Many components of a normal electronic design are available in a microelectronic equivalent. These include transistors, capacitors, inductors, resistors, diodes and (naturally) insulators and conductors can all be found in microelectronic devices. Unique wiring techniques such as wire bonding are also often used in microelectronics because of the unusually small size of the components, leads and pads. This technique requires specialized equipment and is expensive. Digital integrated circuits (ICs) consist of billions of transistors, resistors, diodes, and capacitors. Analog circuits commonly contain resistors and capacitors as well. Inductors are u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Resins

Synthetic resins are industrially produced resins, typically viscosity, viscous substances that convert into rigid polymers by the process of curing (chemistry), curing. In order to undergo curing, resins typically contain reactive end groups, such as acrylates or epoxides. Some synthetic resins have properties similar to natural plant resins, but many do not. Synthetic resins are of several classes. Some are manufactured by esterification of organic compounds. Some are thermosetting plastics in which the term "resin" is loosely applied to the reactant(s), the product, or both. "Resin" may be applied to one of two monomers in a copolymer, the other being called a "hardener", as in epoxy resins. For thermosetting plastics that require only one monomer, the monomer compound is the "resin". For example, liquid methyl methacrylate is often called the "resin" or "casting resin" while in the liquid state, before it polymerizes and "sets". After setting, the resulting poly(methyl methac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastics

Plastics are a wide range of synthetic or semisynthetic materials composed primarily of polymers. Their defining characteristic, plasticity, allows them to be molded, extruded, or pressed into a diverse range of solid forms. This adaptability, combined with a wide range of other properties such as low weight, durability, flexibility, chemical resistance, low toxicity, and low-cost production, has led to their widespread use around the world. While most plastics are produced from natural gas and petroleum, a growing minority are produced from renewable resources like polylactic acid. Between 1950 and 2017, 9.2 billion metric tons of plastic are estimated to have been made, with more than half of this amount being produced since 2004. In 2023 alone, preliminary figures indicate that over 400 million metric tons of plastic were produced worldwide. If global trends in plastic demand continue, it is projected that annual global plastic production will exceed 1.3 billion tons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phenol Formaldehyde Resins

Phenol (also known as carbolic acid, phenolic acid, or benzenol) is an aromaticity, aromatic organic compound with the molecular chemical formula, formula . It is a white crystalline solid that is volatility (chemistry), volatile and can catch fire. The molecule consists of a phenyl group () bonded to a hydroxy group (). Mildly acidic, it requires careful handling because it can cause chemical burns. It is acutely Toxicity, toxic and is considered a health hazard. Phenol was first extracted from coal tar, but today is produced on a large scale (about 7 million tonnes a year) from petroleum-derived feedstocks. It is an important industrial commodity as a precursor (chemistry), precursor to many materials and useful compounds, and is a liquid when manufactured. It is primarily used to synthesize plastics and related materials. Phenol and its chemical derivative (chemistry), derivatives are essential for production of polycarbonates, epoxy, epoxies, Explosive, explosives such as p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Degree Of Polymerization

The degree of polymerization, or DP, is the number of structural unit, monomeric units in a macromolecule or polymer or oligomer molecule. For a homopolymer, there is only one type of monomeric unit and the ''number-average'' degree of polymerization is given by \overline_n\equiv\overline_n=\frac, where \overline_n is the Molar mass distribution#Number average molar mass, number-average molecular weight and M_0 is the molecular weight of the monomer unit. The overlines indicate arithmetic mean values. For most industrial purposes, degrees of polymerization in the thousands or tens of thousands are desired. This number does not reflect the variation in molecule size of the polymer that typically occurs, it only represents the mean number of monomeric units. Some authors, however, define DP as the number of repeat units, where for copolymers the repeat unit may not be identical to the monomeric unit.Fried J.R. "Polymer Science and Technology" (Pearson Prentice-Hall, 2nd edn 2003), p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

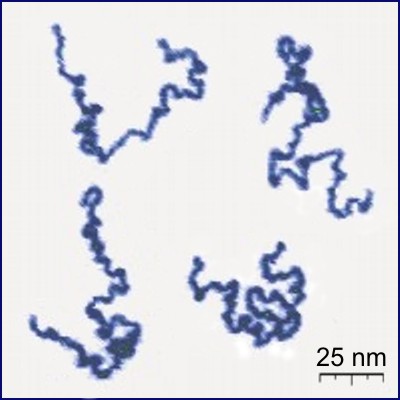

Polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compound (chemistry), compounds, produces unique physical property, physical properties including toughness, high rubber elasticity, elasticity, viscoelasticity, and a tendency to form Amorphous solid, amorphous and crystallization of polymers, semicrystalline structures rath ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Decomposition

Thermal decomposition, or thermolysis, is a chemical decomposition of a substance caused by heat. The decomposition temperature of a substance is the temperature at which the substance chemically decomposes. The reaction is usually endothermic as heat is required to break chemical bonds in the compound undergoing decomposition. If decomposition is sufficiently exothermic, a positive feedback loop is created producing thermal runaway and possibly an explosion or other chemical reaction. Decomposition temperature definition A simple substance (like water) may exist in equilibrium with its thermal decomposition products, effectively halting the decomposition. The equilibrium fraction of decomposed molecules increases with the temperature. Since thermal decomposition is a kinetic process, the observed temperature of its beginning in most instances will be a function of the experimental conditions and sensitivity of the experimental setup. For a rigorous depiction of the process, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |