|

Non Destructive Testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Xray Vault

X-rays (or rarely, ''X-radiation'') are a form of high-energy electromagnetic radiation. In many languages, it is referred to as Röntgen radiation, after the German scientist Wilhelm Conrad Röntgen, who discovered it in 1895 and named it ''X-radiation'' to signify an unknown type of radiation.Novelline, Robert (1997). ''Squire's Fundamentals of Radiology''. Harvard University Press. 5th edition. . X-ray wavelengths are shorter than those of ultraviolet rays and longer than those of gamma rays. There is no universally accepted, strict definition of the bounds of the X-ray band. Roughly, X-rays have a wavelength ranging from 10 nanometers to 10 picometers, corresponding to frequencies in the range of 30 petahertz to 30 exahertz ( to ) and photon energies in the range of 100 eV to 100 keV, respectively. X-rays can penetrate many solid substances such as construction materials and living tissue, so X-ray radiography is widely used in me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

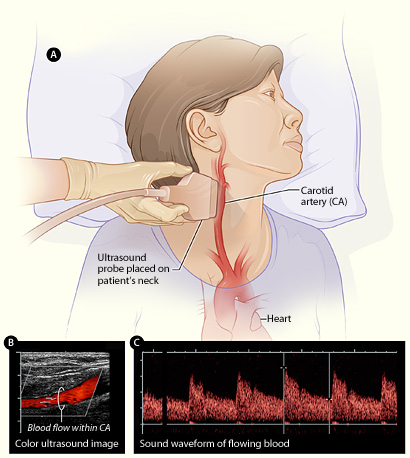

Medical Ultrasonography

Medical ultrasound includes diagnostic techniques (mainly imaging techniques) using ultrasound, as well as therapeutic applications of ultrasound. In diagnosis, it is used to create an image of internal body structures such as tendons, muscles, joints, blood vessels, and internal organs, to measure some characteristics (e.g. distances and velocities) or to generate an informative audible sound. Its aim is usually to find a source of disease or to exclude pathology. The usage of ultrasound to produce visual images for medicine is called medical ultrasonography or simply sonography. The practice of examining pregnant women using ultrasound is called obstetric ultrasonography, and was an early development of clinical ultrasonography. Ultrasound is composed of sound waves with frequencies which are significantly higher than the range of human hearing (>20,000 Hz). Ultrasonic images, also known as sonograms, are created by sending pulses of ultrasound into tissue usin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifetime

Product lifetime or product lifespan is the time interval from when a product is sold to when it is discarded. Product lifetime is slightly different from service life because the latter consider only the effective time the product is used. It is also different from product economic life which refers to the point where maintaining a product is more expensive than replacing it; from product technical life which refers to the maximum period during which a product has the physical capacity to function; and from the functional life which is the time a product should last regardless of external intervention to increase its lifespan. Product lifetime represent an important area of enquiry with regards to product design, the circular economy and sustainable development. This is because products, with the materials involved in their design, production, distribution, use and disposal (across their life cycle), embody carbon due to the energy involved in these processes. Therefore, if produ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often an i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |