|

Needle Bearing

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least four times longer than their diameter. Like all bearings, they are used to reduce the friction of a rotating surface. Compared to ball bearings and ordinary roller bearings, needle bearings have a greater surface area in contact with the races, so they can support a greater load. They are also thinner, so they require less clearance between the axle and the surrounding structure. Needle bearings are heavily used in automobile components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least eight needle bearings (four in each U joint) and often more if it is particularly long, or operates on steep slopes. See also * Race (bearing) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy. Mechanical pumps serve in a wide range of applications such as Water well pump, pumping water from wells, aquarium filtering, pond filtering and Water aeration, aeration, in the car industry for Water cooling, water-cooling and fuel injection, in the energy industry for Pumping (oil well), pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and Penile implant, penile prosthesis. When a pump contains two or more pump mechanisms with fluid being directed to flow through them in series, it is called a ''multi-stage pump''. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Race (bearing)

The rolling-elements of a rolling-element bearing ride on races. The large race that goes into a bore is called the ''outer race'', and the small race that the shaft rides in is called the ''inner race''. Design In the case of ball bearings, the bearing has inner and outer ''races'' and a set of balls. Each race is a ring with a groove where the balls rest. The groove is usually shaped so the ball is a slightly loose fit in the groove. Thus, in principle, the ball contacts each race at a single point. However, a load on an infinitely small point would cause infinitely high contact pressure. In practice, the ball deforms (flattens) slightly where it contacts each race, much as a tire flattens where it touches the road. The race also dents slightly where each ball presses on it. Thus, the contact between ball and race is of finite size and has finite pressure. The deformed ball and race do not roll entirely smoothly because different parts of the ball are moving at different spe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grade (slope)

The grade (US) or gradient (UK) (also called stepth, slope, incline, mainfall, pitch or rise) of a physical feature, landform or constructed line is either the elevation angle of that surface to the horizontal plane, horizontal or its tangent. It is a special case of the slope, where zero indicates horizontal plane, horizontality. A larger number indicates higher or steeper degree of "tilt". Often slope is calculated as a ratio of "rise" to "run", or as a fraction ("rise over run") in which ''run'' is the horizontal distance (not the distance along the slope) and ''rise'' is the vertical distance. Slopes of existing physical features such as canyons and hillsides, bank (geography), stream and river banks, and stream bed, beds are often described as grades, but typically the word "grade" is used for human-made surfaces such as roads, landscape grading, roof pitches, rail tracks, railroads, aqueduct (watercourse), aqueducts, and pedestrian or bicycle routes. The grade may refer to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

U Joint

A universal joint (also called a universal coupling or U-joint) is a joint or coupling connecting rigid shafts whose axes are inclined to each other. It is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges located close together, oriented at 90° to each other, connected by a cross shaft. The universal joint is not a constant-velocity joint. U-joints are also sometimes called by various eponymous names, as follows: * Cardan joint, after Gerolamo Cardano, a polymath of the 16th century who contributed to knowledge of various clever mechanisms, including gimbals * Hooke joint or Hooke's joint, after Robert Hooke, a polymath of the 17th century who contributed to knowledge of various clever mechanisms * Spicer joint, after Clarence W. Spicer and the Spicer Manufacturing Company, who manufactured U joints * Hardy Spicer joint, after the Hardy Spicer brand, a successor to the Spicer brand History The main concept of the universal joint is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Driveshaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power, torque, and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. As torque carriers, drive shafts are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a splined joint or prismatic joint. History The term ''driveshaft'' first appeared during the mid-19th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission (mechanics)

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (industrialist), Louis Renault (who founded Renault, Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam engine, steam-powered devices. Applications of these devices included pumps, mill (grinding), mills and Hoist (device), hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and Horsepower, power output of an interna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Compressor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor. Many compressors can be staged, that is, the gas is compressed several times in steps or stages, to increase discharge pressure. Often, the second stage is physically smaller than the primary stage, to accommodate the already compressed gas without reducing its pressure. Each stage further compresses the gas and increases its pressure and also temperature (if inter cooling between stages is not used). Types Compressors are similar to pumps: both increase the pressure on a fluid (such as a gas) and both can transport the fluid through a pipe (material), pipe. The main distinction is that the focus of a compressor is to change the density or volume of the fluid, which is mostly only achievable on gases. Gases are compressible, while liquids are relatively incompressible, so compressors are rarely used for liquids. The main actio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocker Arm

A rocker arm is a valvetrain component that typically transfers the motion of a pushrod in an overhead valve engine, overhead valve internal combustion engine to the corresponding intake/exhaust poppet valve, valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction there. Overview The most common use of a rocker arm is to transfer the up and down motion of a pushrod in an overhead valve engine, overhead valve (OHV) internal combustion engine to the corresponding intake/exhaust poppet valve, valve. In an OHV engine the camshaft located within the engine block below the cylinder bank(s) pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm located at the top of the cylinder head, which causes the rocker arm to pivot downward on the top of the valve, opening it. To redu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing,ISO 15 is a bearing which carries a load by placing rolling elements (such as balls, cylinders, or cones) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings is a set of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls onto it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and spheres or cylinders called "rollers" tig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

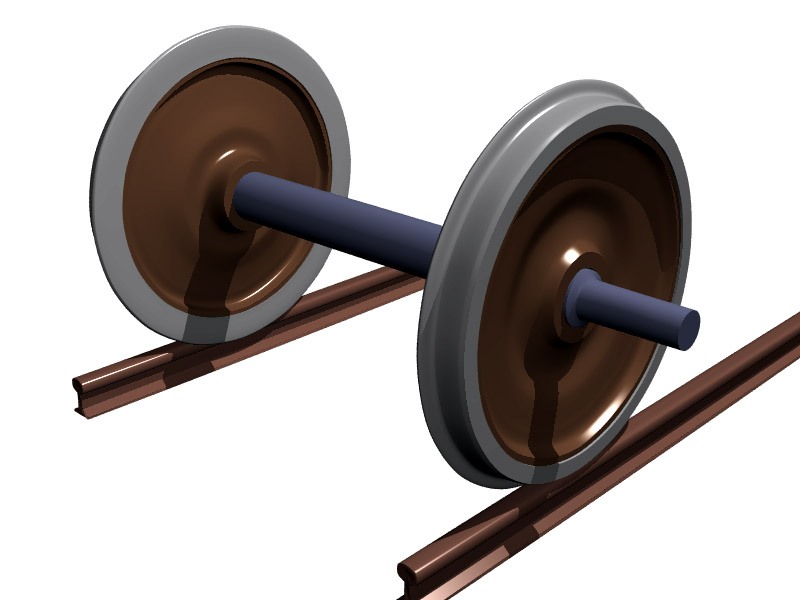

Axle

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing (mechanical), bearings or Bushing (bearing), bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type of axle is referred to as a ''spindle (tool), spindle''. Terminology On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft that rotates with the wheel, being either Bolt (fastener), bolted or rotating spline, splined in fixed relation to it, is called an ''axle'' or ''axle shaft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Tolerance

Engineering tolerance is the permissible limit or limits of variation in: # a physical dimension; # a measured value or physical property of a material, manufactured object, system, or service; # other measured values (such as temperature, humidity, etc.); # in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel (see structure gauge and loading gauge); # in mechanical engineering, the space between a bolt and a nut or a hole, etc. Dimensions, properties, or conditions may have some variation without significantly affecting functioning of systems, machines, structures, etc. A variation beyond the tolerance (for example, a temperature that is too hot or too cold) is said to be noncompliant, rejected, or exceeding the tolerance. Considerations when setting tolerances A primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |