|

Mud Pump

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to ) down the drill string and back up the Annulus (oil well), annulus. A mud pump is an important part of the equipment used for oil well drilling. Classification According to the acting type Mud pumps can be divided into single-acting pump and double-acting pump according to the completion times of the suction and drainage acting in one cycle of the piston's reciprocating motion. According to the quantity of liners (piston/plunger) Mud pumps come in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is used. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill String

A drill string on a drilling rig is a column, or string, of drill pipe that transmits drilling fluid (via the mud pumps) and torque (via the kelly drive or top drive) to the Well drilling#Drill bits in mechanical drilling, drill bit. The term is loosely applied to the assembled collection of the smuggler pool, drill collars, tools and drill bit. The drill string is hollow so that drilling fluid can be pumped down through it and circulated back up the Annulus (oil well), annulus (the void between the drill string and the casing/open hole). Components The drill string is typically made up of three sections: * Bottom hole assembly (BHA) * Transition pipe, which is often heavyweight drill pipe (HWDP) * Drill pipe Bottom hole assembly (BHA) The Bottom Hole Assembly (BHA) is made up of: a Well drilling#Drill bits in mechanical drillings, drill bit, which is used to break up the rock Geologic formation, formations; drill collars, which are heavy, thick-walled tubes used to a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annulus (oil Well)

The annulus of an oil well or water well is any void between any piping, tubing or casing and the piping, tubing, or casing immediately surrounding it.SchlumbergeOilfield Glossary: Term 'annulus', retrieved 18 February 2010. It is named after the corresponding geometric concept. The presence of an annulus gives the ability to circulate fluid in the well, provided that excess drill cuttings have not accumulated in the annulus, preventing fluid movement and possibly sticking the pipe in the borehole. For a new well in the process of being drilled, this would be the void between the drill string and the formation being drilled. An easy way to visualise this would be to stand a straw (purple in diagram) straight up in the center of a glass of water. All of the water in between the straw and the sides of the glass would be the annulus (yellow area in diagram), with the straw itself representing the drill string and the sides of the glass representing the formation. While dril ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Measurement While Drilling

A drilling rig is used to create a borehole or well (also called a wellbore) in the earth's sub-surface, for example in order to extract natural resources such as gas or oil. During such drilling, data is acquired from the drilling rig sensors for a range of purposes such as: decision-support to monitor and manage the smooth operation of drilling; to make detailed records (or well log) of the geologic formations penetrated by a borehole; to generate operations statistics and performance benchmarks such that improvements can be identified, and to provide well planners with accurate historical operations-performance data with which to perform statistical risk analysis for future well operations. The terms measurement while drilling (MWD), and logging while drilling (LWD) are not used consistently throughout the industry. Although these terms are related, within the context of this section, the term measurement while drilling refers to directional-drilling measurements, e.g. for deci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Logging While Drilling

Logging while drilling (LWD) is a technique of conveying well logging tools of the formation data during drilling operations into the well borehole downhole as part of the bottom hole assembly (BHA). Although the terms Measurement while drilling (MWD) and LWD are related, within the context of this section, the term MWD refers to directional-drilling measurements, e.g., for decision support for the smooth operation of the drilling, while LWD refers to measurements concerning the geological formation made while drilling. WD tools work with its measurement while drilling (MWD) system to transmit partial or complete measurement results to the surface via typically a drilling mud pulser or other improved techniques, while LWD tools are still in the borehole, which is called "real-time data". Complete measurement results can be downloaded from LWD tools after they are pulled out of hole, which is called "memory data". LWD, while sometimes risky and expensive, has the advantage of mea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crosshead

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long stroke reciprocating engines (either internal combustion or steam) and reciprocating compressors to eliminate sideways force on the piston. The crosshead also allows the connecting rod to move freely outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston were attached directly to the connecting rod as in a trunk engine. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine. Overview On smaller engines, the connecting rod links the piston and the crankshaft directly, but this transmits sideways forces to the piston, since the crankpin (and thus the direction the force is applied) moves from side to side with the rotary motion of the crank. These transverse forces are tolerable in a relatively smal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

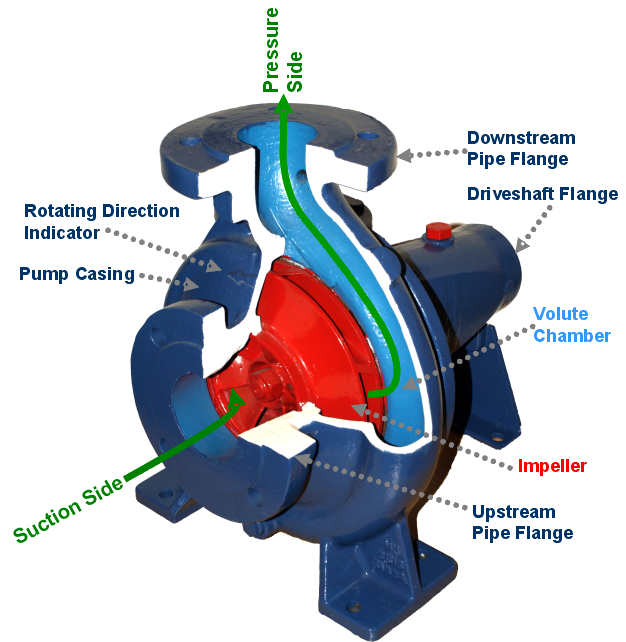

Centrifugal Pump

Centrifugal pumps are used to transport fluids by the Energy transformation, conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or Volute (pump), volute chamber (casing), from which it exits. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering. A centrifugal fan is commonly used to implement an Air handler, air handling unit or vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting potential energy of water ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Pump

A diaphragm pump (also known as a Membrane pump) is a positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic or teflon diaphragm and suitable valves on either side of the diaphragm (check valve, butterfly valves, flap valves, or any other form of shut-off valves) to pump a fluid. There are three main types of diaphragm pumps: * Those in which the diaphragm is sealed with one side in the fluid to be pumped, and the other in air or hydraulic fluid. The diaphragm is flexed, causing the volume of the pump chamber to increase and decrease. A pair of non-return check valves prevent reverse flow of the fluid. * Those employing volumetric positive displacement where the prime mover of the diaphragm is electro-mechanical, working through a crank or geared motor drive, or purely mechanical, such as with a lever or handle. This method flexes the diaphragm through simple mechanical action, and one side of the diaphragm is open to air. * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |