|

Monobloc Engine

''Monobloc'' refers to a component that is made in one block or casting. A monobloc engine or en bloc engine is an internal-combustion piston engine some of whose major components (such as cylinder head, cylinder block, or crankcase) are formed, usually by casting, as a single integral unit, rather than being assembled later. This has the advantages of improving mechanical stiffness, and improving the reliability of the sealing between them. ''Monobloc'' techniques date back to the beginnings of the internal combustion engine. Use of this term has changed over time, usually to address the most pressing mechanical problem affecting the engines of its day. There have been three distinct uses of the technique: * Cylinder head and cylinder * Cylinder block * Cylinder block and crankcase In most cases, any use of the term describes single-unit construction that is opposed to the more common contemporary practice. Where the monobloc technique has later become the norm, the specific term ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bentley 3 Litre

The Bentley 3 Litre was a car Chassis#Vehicles, chassis manufactured by Bentley. The company's first, it was developed from 1919 and made available to customers' coachbuilders from 1921 to 1929. The Bentley was very much larger than the 1368 cc Bugattis that dominated racing at the time, but double the size of engine and strength compensated for the extra weight. The 4000 lb (1800 kg) car won the 24 Hours of Le Mans in 1924, with drivers John Duff and Frank Clement (racing driver), Frank Clement, and again in 1927, this time in Super Sports form, with drivers S. C. H. "Sammy" Davis and Dudley Benjafield. Its weight, size, and speed prompted Ettore Bugatti to call it "the fastest truck, lorry in the world", which was regarded as a compliment. Built in 3 main variants, Blue label, Red Label Speed models all carrying a 5-year warranty, and the coveted and rare Green Label 100 mph cars, which only carried a 12-month warranty reflecting the high state of tune. Coachwork ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a surface integrity, precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinder (engine), cylinders for internal combustion engines, air bearing spindle (tool), spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing machines A honing machine is a precision tool used in machining to improve the surface finish and dimensional accuracy of component. It operates by using abrasive honing tools, which rotate and reciprocate inside the components, typically a cylinder or bore. This process enhances the internal surface quality ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chrome Plating

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. A chrome plated part is called ''chrome'', or is said to have been ''chromed''. The chromium layer can be decorative, provide corrosion resistance, facilitate cleaning, and increase surface hardness. Sometimes a less expensive substitute for chrome, such as nickel, may be used for aesthetic purposes. Chromium compounds used in electroplating are toxic. In most countries, their disposal is tightly regulated. Some fume suppressants used to control the emission of airborne chromium from plating baths are also toxic, making disposal even more difficult. Process The preparation and chrome plating of a part typically includes some or all of these steps: * Surface preparation * Manual cleaning to remove dirt and surface impurities * Removal of remaining organic contaminants using emulsion cleaning, alkaline cleaning, anodic electrocleaning, or solvent cle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lycoming Engines

Lycoming Engines is a major American manufacturer of aircraft engines. With a factory in Williamsport, Pennsylvania, Lycoming produces a line of horizontally opposed, air-cooled, four, six and eight-cylinder engines. The company has built more than 325,000 piston aircraft engines and powers more than half the world's general aviation fleet, both rotary and fixed wing."History: Decades of Pioneering Spirit" official website of Lycoming Engines, retrieved August 9, 2023 Lycoming has been a principal pioneer of turbine engines for medium and large helicopters, and has also produced engines for small jetliners and business jets.Angelucci, Enzo: ''Airplanes: From the Dawn of Flight to the Present Day,'' 1982 ed., Greenwich House / Arlington House, U.K.; retrieved Aug ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continental Engine

Continental Aerospace Technologies is an aircraft engine manufacturer located at the Brookley Aeroplex in Mobile, Alabama, United States. It was originally spun off from automobile engine manufacturer Continental Motors Company in 1929 and owned by Teledyne Technologies from 1969 until December 2010. The company is now part of Aviation Industry Corporation of China (AVIC), which is a Government of the People's Republic of China state-owned aerospace company headquartered in Beijing. Although Continental is most well known for its engines for light aircraft, it was also contracted to produce the air-cooled V-12 AV-1790-5B gasoline engine for the U.S. Army's M47 Patton tank and the diesel AVDS-1790-2A and its derivatives for the M48, M60 Patton, and Merkava main battle tanks. The company also produced engines for various independent manufacturers of automobiles, tractors, and stationary equipment (pumps, generators, and machinery drives) from the 1920s to the 1960s. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Franklin Engine Company

The Franklin Engine Company was an American manufacturer of aircraft engines. Its designs were used primarily in the civilian market, both in fixed wing and helicopter designs. It was briefly directed towards automobile engines as part of the Tucker Car Corporation, returning to aviation when that company failed. The company was later purchased by the Government of Poland. History The firm began as the H. H. Franklin Co. in 1902 in Syracuse, New York, US, to produce Franklin air-cooled automobiles. Barely surviving bankruptcy in 1933, the company was purchased by a group of ex-employees and renamed Air-cooled Motors in 1937. While the company kept the name of "Air-cooled Motors," its engines continued to be marketed under the Franklin name. Engineers Carl Doman and Ed Marks kept the company alive through the depression by manufacturing air-cooled truck and industrial engines. During World War II Air-cooled Motors was very successful producing helicopter and airplane engines. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

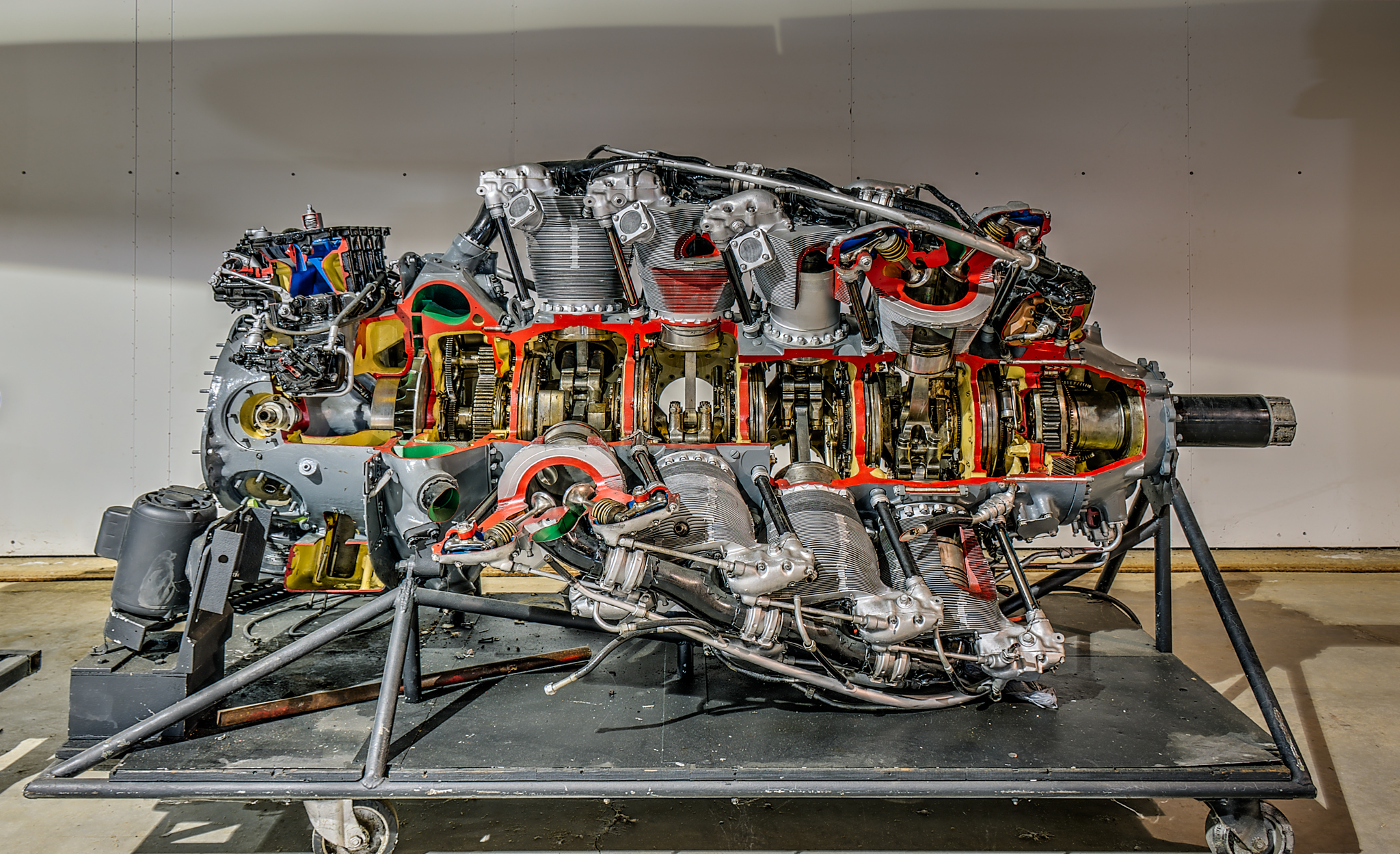

Pratt & Whitney R-4360

The Pratt & Whitney R-4360 Wasp Major is an American 28-cylinder four-row radial piston aircraft engine designed and built during World War II. At , it is the largest-displacement aviation piston engine to be mass-produced in the United States, and at the most powerful. First run in 1944, it was the last of the Pratt & Whitney Wasp family, and the culmination of its maker's piston engine technology. The war was over before it could power airplanes into combat. It powered many of the last generation of large piston-engined aircraft before turbojets, but was supplanted by equivalent (and superior) powered turboprops (such as the Allison T56). Its main rival was the twin-row, 18-cylinder, nearly displacement, up to Wright R-3350 Duplex-Cyclone, first run some seven years earlier (May 1937). Design and development The R-4360 was a 28-cylinder four-row air-cooled radial engine. Each row of seven air-cooled cylinders possessed a slight angular offset from the previous, forming a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radial Engine

The radial engine is a reciprocating engine, reciprocating type internal combustion engine, internal combustion engine configuration in which the cylinder (engine), cylinders "radiate" outward from a central crankcase like the spokes of a wheel. It resembles a stylized Star polygon, star when viewed from the front, and is called a "star engine" in some other languages. The radial configuration was commonly used for aircraft engines before gas turbine engines became predominant. Engine operation Since the axes of the cylinders are coplanar, the connecting rods cannot all be directly attached to the crankshaft unless mechanically complex forked connecting rods are used, none of which have been successful. Instead, the pistons are connected to the crankshaft with a master-and-articulating-rod assembly. One piston, the uppermost one in the animation, has a master rod with a direct attachment to the crankshaft. The remaining pistons pin their connecting rods' attachments to rings ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Haynes Publishing

Haynes Owner's Workshop Manuals (commonly known as Haynes Manuals) is a series of manuals from the British and American publisher Haynes Group Limited. The series focuses primarily on the maintenance and repair of vehicles. The manuals are aimed at beginner and advanced DIY consumers rather than professional mechanics. Later, the series was expanded to include a range of parody practical lifestyle manuals in the same style for a range of topics, including domestic appliances, personal computers, digital cameras, model railways, sport, and animal care. Haynes also published the humorous Bluffer's Guides. Additionally, Haynes has released parody manuals based on popular fictional series, including ''Star Trek'' and '' Thomas and Friends''. Haynes manuals owns and licenses a number of DIY brands including Clymer, Chilton, Gregorys, and Rellim. History The Haynes manuals are named after John Harold Haynes (1938–2019) OBE. In 1956, while Haynes was at school, he publish ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Buzzard

The Rolls-Royce Buzzard is a British piston aero engine of capacity that produced about . Designed and built by Rolls-Royce Limited it is a V12 engine of bore and stroke. Only 100 were made. A further development was the Rolls-Royce R engine. The Buzzard was developed by scaling-up the Rolls-Royce Kestrel Engine.Rubbra 1990, p. 59. Variants ''List from Lumsden''. ;Buzzard IMS, (H.XIMS) :(1927), Maximum power , nine engines produced at Derby. ;Buzzard IIMS, (H.XIIMS) :(1932-33), Maximum power , reduced propeller drive ratio (0.553:1), 69 engines produced at Derby. ;Buzzard IIIMS, (H.XIVMS) :(1931-33), Maximum power , further reduced propeller drive ratio (0.477:1), 22 engines produced at Derby. Applications * Blackburn Iris Mark V * Blackburn M.1/30 * Blackburn Perth * Handley Page H.P.46 * Kawanishi H3K * Short Sarafand The Short S.14 Sarafand was a British biplane flying boat built by Short Brothers. It was planned as a general reconnaissance aircraft for mili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supercharging

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. It is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gases. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and increase power outputs, especially with reduced engine displacements. Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |