|

Microwave Welding

Microwave welding is a plastic welding process that utilizes alternating electromagnetic fields in the microwave band to join thermoplastic base materials that are melted by the phenomenon of dielectric heating. See also * Dielectric heating * Plastic welding Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermopl ... * Radio-frequency welding References {{Metalworking navbox/weld Welding Radio technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Welding

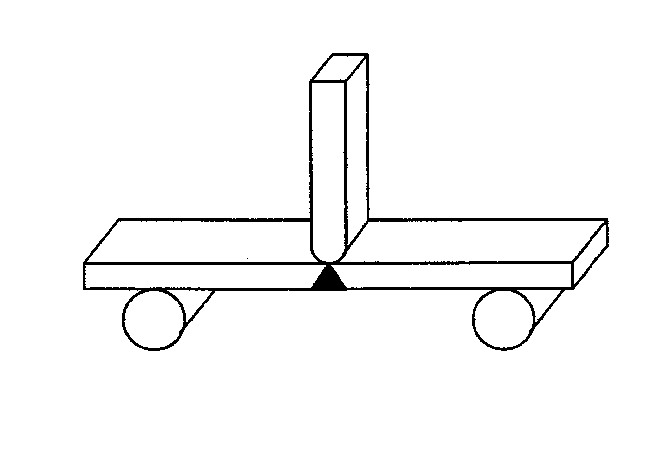

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1. Production of a good quality weld does not only depend on the welding methods, but also weldability of base materials. Therefore, the evaluation of weldability is of higher importance than the welding operation (see rheological weldability) for plastics. Welding techniques A number of techniques are used for welding of semi-finished plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetic Field

An electromagnetic field (also EM field) is a physical field, varying in space and time, that represents the electric and magnetic influences generated by and acting upon electric charges. The field at any point in space and time can be regarded as a combination of an electric field and a magnetic field. Because of the interrelationship between the fields, a disturbance in the electric field can create a disturbance in the magnetic field which in turn affects the electric field, leading to an oscillation that propagates through space, known as an ''electromagnetic wave''. The way in which charges and currents (i.e. streams of charges) interact with the electromagnetic field is described by Maxwell's equations and the Lorentz force law. Maxwell's equations detail how the electric field converges towards or diverges away from electric charges, how the magnetic field curls around electrical currents, and how changes in the electric and magnetic fields influence each other. The Lor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300 MHz and 300 GHz, broadly construed. A more common definition in radio-frequency engineering is the range between 1 and 100 GHz (wavelengths between 30 cm and 3 mm), or between 1 and 3000 GHz (30 cm and 0.1 mm). In all cases, microwaves include the entire super high frequency, super high frequency (SHF) band (3 to 30 GHz, or 10 to 1 cm) at minimum. The boundaries between far infrared, terahertz radiation, microwaves, and ultra-high-frequency (UHF) are fairly arbitrary and differ between different fields of study. The prefix ' in ''microwave'' indicates that microwaves are small (having shorter wavelengths), compared to the radio waves used in prior radio technology. Frequencies in the micr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped, and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dielectric Heating

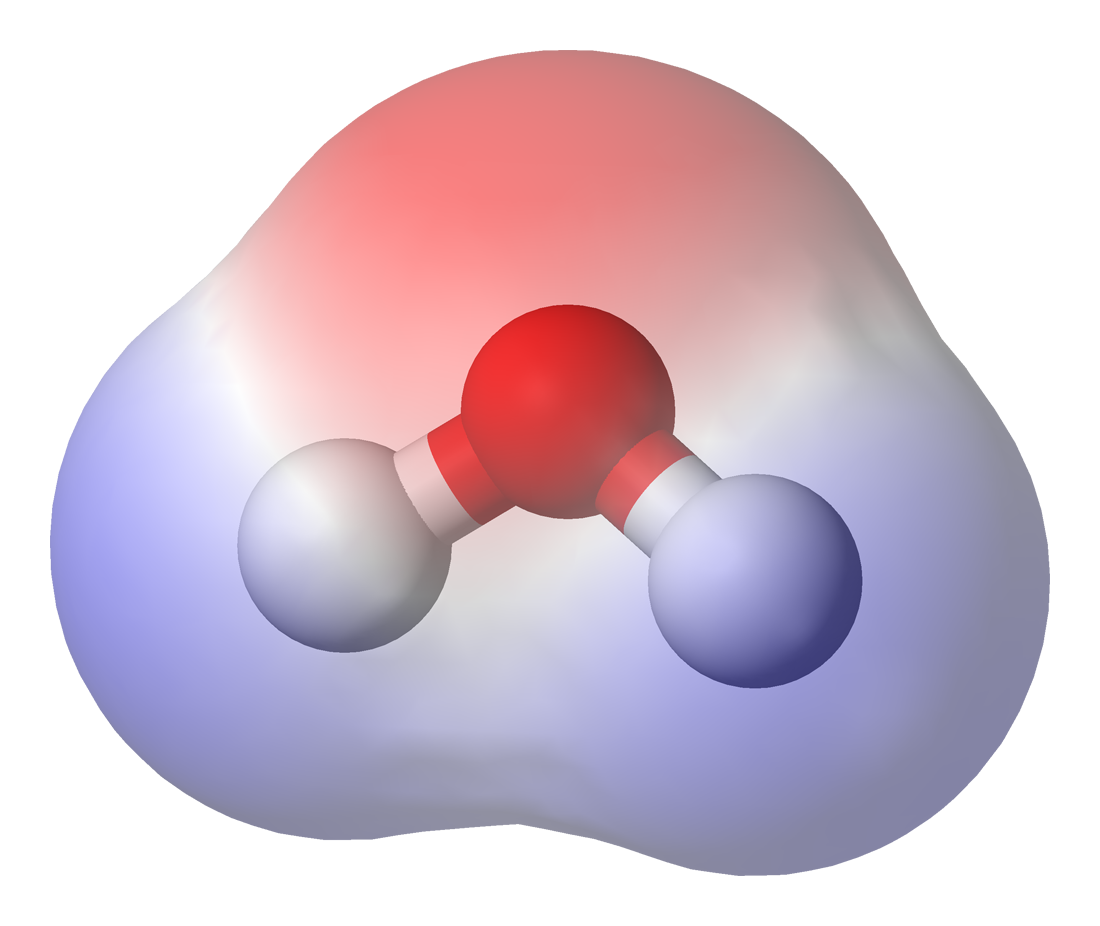

Dielectric heating, also known as electronic heating, radio frequency heating, and high-frequency heating, is the process in which a radio frequency (RF) alternating electric field, or radio wave or microwave electromagnetic radiation heats a dielectric material. At higher frequencies, this heating is caused by molecular dipole rotation within the dielectric. Mechanism Molecular rotation occurs in materials containing polar molecules having an electrical dipole moment, with the consequence that they will align themselves in an electromagnetic field. If the field is oscillating, as in an electromagnetic wave or a rapidly oscillating electric field, these molecules rotate continuously by aligning with it. This is called dipole rotation or dipolar polarisation. As the field alternates, the molecules reverse direction. Rotating molecules push, pull, and collide with other molecules (through electrical forces), distributing the energy to adjacent molecules and atoms in the materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Welding

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1. Production of a good quality weld does not only depend on the welding methods, but also weldability of base materials. Therefore, the evaluation of weldability is of higher importance than the welding operation (see rheological weldability) for plastics. Welding techniques A number of techniques are used for welding of semi-finished plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radio-frequency Welding

Radio-frequency welding, also known as dielectric welding and high-frequency welding, is a plastic welding process that utilizes high-frequency electric fields to induce heating and melting of thermoplastic base materials. The electric field is applied by a pair of electrodes after the parts being joined are clamped together. The clamping force is maintained until the joint solidifies. Advantages of this process are fast cycle times (on the order of a few seconds), automation, repeatability, and good weld appearance. Only plastics which have dipoles can be heated using radio waves and therefore not all plastics are able to be welded using this process. Also, this process is not well suited for thick or overly complex joints. The most common use of this process is lap joints or seals on thin plastic sheets or parts. Heating mechanism Four types of polarization can occur in materials subjected to high-frequency alternating electric fields: * Electronic or electric polarizatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |