|

Mercedes-Benz OM 138

The Mercedes-Benz OM 138 is a diesel engine manufactured by Daimler-Benz. In total, 5,719 units were produced between 1935 and 1940.According to Oswald, 1,082 engines were made for the L 1100 and 2,670 were made for the L 1500. Daimler says that 1,967 diesel-powered W 138s were produced. It was the first diesel engine especially developed and made for a passenger car. The first vehicle powered by the OM 138 was the Mercedes-Benz 260 D, Mercedes-Benz W 138. The light Mercedes-Benz trucks L 1100 and L 1500 as well as the bus O 1500The O 1500 is a variant of the L 1500, however, it has its own model number. were also offered with the OM 138 as an alternative to the standard Otto cycle, Otto engine. Impact Daimler-Benz started mass production of the six-cylinder inline truck diesel engine OM 5 in 1928. Technical improvements allowed an increase in rated rotational speed, thus allowing more power with lower displac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Daimler Benz AG

Mercedes-Benz Group AG (formerly Daimler-Benz, DaimlerChrysler, and Daimler) is a German multinational automotive company headquartered in Stuttgart, Baden-Württemberg, Germany. It is one of the world's leading car manufacturers. Daimler-Benz was formed with the merger of Benz & Cie., the world's oldest car company, and Daimler Motoren Gesellschaft in 1926. The company was renamed DaimlerChrysler upon the acquisition of the American automobile manufacturer, Chrysler Corporation in 1998, it was renamed to Daimler upon the divestment of Chrysler in 2007. In 2021, Daimler was the second-largest German automaker and the sixth-largest worldwide by production. In February 2022, Daimler was renamed Mercedes-Benz Group as part of a transaction that spun-off its commercial vehicle segment as an independent company, Daimler Truck. The Mercedes-Benz Group's marques are Mercedes-Benz for cars and vans (including Mercedes-AMG and Mercedes-Maybach). It has shares in other vehicle manufa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

MHV MB L1500 Wood Gasifier 1937

MHV may refer to: * MHV Amplitudes (particle physics) - maximally helicity violating amplitudes * MHV connector The MHV (miniature high voltage) connector is a type of RF connector used for terminating coaxial cable. Description The connector looks almost identical to a typical BNC connector, but is designed to not mate with BNC jacks. It features two bay ... (electronics) - miniature high voltage RF connector * Mojave Air & Space Port, FAA and IATA code * Mouse hepatitis virus {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

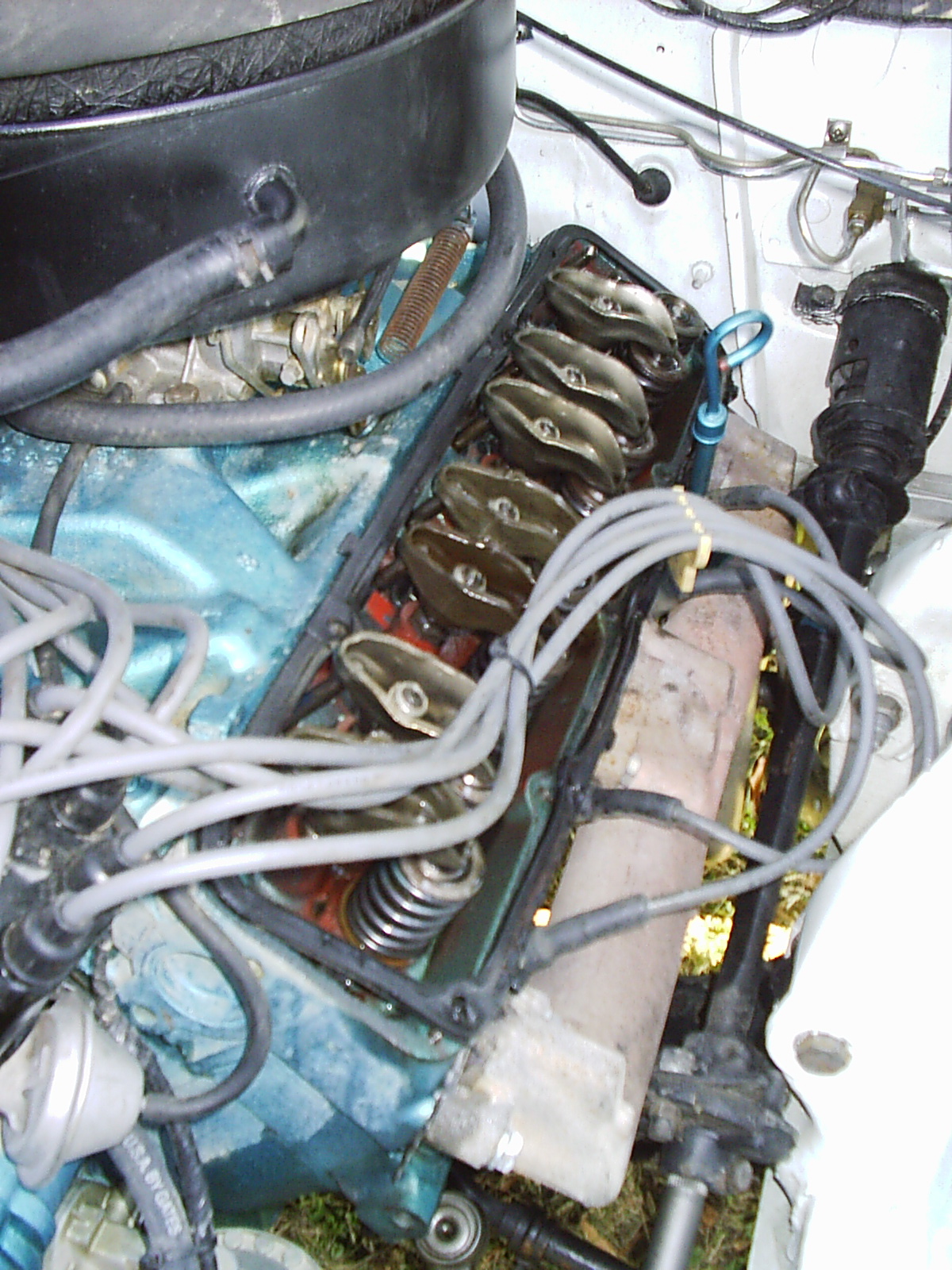

Pushrod

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder banks. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical Inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical veloc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In a piston engine, the cylinder head sits above the cylinders, forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern overhead valve and overhead camshaft engines, the head is a more complicated metal block that also contains the inlet and exhaust passages, and often coolant passages, valvetrain components, and fuel injectors. Number of cylinder heads A piston engine typically has one cylinder head per bank of cylinders. Most modern engines with a "straight" (inline) layout today use a single cylinder head that serves all the cylinders. Engines with a "V" layout or "flat" layout typically use two cylinder heads (one for each cylinder bank), however a small number of 'narrow-angle' V engines (such as the Volkswagen VR5 and VR6 engines) use a single cylinder head spanning the two banks. Most radial engines have one head for each cylind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grey Cast Iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely used cast material based on weight.. It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey cast iron's high thermal conductivity and specific heat capacity are often exploited to make cast iron cookware and disc brake rotors. on brakes in freight trains has been greatly reduced in the European Union over concerns regarding noise pollution. Deutsche Bahn for example had replaced grey iron brakes on 53,000 of its freight cars (85% of their fleet) with newer, quieter models by 2019—in part to comply with a law that came into force in December 2020. Structure A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gearbox

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (who founded Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam-powered devices. Applications of these devices included pumps, mills and hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and power output of an internal combustion engine (ICE) varies with its rpm, automobiles powered by ICEs require multiple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting (metalworking), casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankcase

A crankcase is the housing in a reciprocating engine, piston engine that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the Cylinder (engine), cylinder(s). This design of the engine does not include an oil sump in the crankcase. Four-stroke engines typically have an oil sump at the bottom of the crankcase and the majority of the engine's oil is held within the crankcase. The fuel/air mixture does not pass through the crankcase, though a small amount of exhaust gasses often enter as "blow-by" from the combustion chamber, particularly in engines with worn rings. The crankcase often forms the upper half of the main bearing journals (with the bearing caps forming the other half), although in some engines the crankcase completely surrounds the main bearing journals. An ''open-crank'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valvetrain

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Sump

Within piston engines, a wet sump is part of a lubrication system whereby the crankcase sump is used as an integral oil reservoir. An alternative system is the dry sump, whereby oil is pumped from a shallow sump into an external reservoir.Wet sump and dry sump compared - https://www.knowyourparts.com/technical-resources/engine/oil-system-differences/#:~:text=Dry%20Oil%20Systems%20Wet%20sump%20systems%20store%20the,is%20used%20to%20pump%20oil%20from%20the%20motor. Piston engines are lubricated by oil which is pumped into various bearings, and thereafter allowed to drain to the base of the engine under gravity. In most production automobiles and motorcycles, which use a wet sump system, the oil is collected in a capacity pan at the base of the engine, known as the sump or oil pan, where it is pumped back up to the bearings by the internal oil pump. A wet sump offers the advantage of a simple design, using a single pump and no external reservoir. Since the sump is internal, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |