|

Materials For Use In Vacuum

Materials for use in vacuum are materials that show very low rates of outgassing in vacuum and, where applicable, are tolerant to bake-out temperatures. The requirements grow increasingly stringent with the desired degree of vacuum to be achieved in the vacuum chamber. The materials can produce gas by several mechanisms. Molecules of gases and water can be adsorbed on the material surface (therefore materials with low affinity to water have to be chosen, which eliminates many plastics). Materials may sublimate in vacuum (this includes some metals and their alloys, most notably cadmium and zinc). Or the gases can be released from porous materials or from cracks and crevices. Traces of lubricants, residues from machining, can be present on the surfaces. A specific risk is outgassing of solvents absorbed in plastics after cleaning. The gases liberated from the materials not only lower the vacuum quality, but also can be reabsorbed on other surfaces, creating deposits and contamin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Desorption

Desorption is the physical process where Adsorption, adsorbed atoms or molecules are released from a surface into the surrounding vacuum or fluid. This occurs when a molecule gains enough energy to overcome the activation barrier and the binding energy that keep it attached to the surface. Desorption is the reverse of the process of adsorption, which differs from absorption in that adsorption refers to substances bound to the surface, rather than being absorption (chemistry), absorbed into the bulk. Desorption can occur from any of several processes, or a combination of them: it may result from heat (thermal energy); incident light such as infrared, visible, or ultraviolet photons; or an incident beam of energetic particles such as electrons. It may also occur following chemical reactions such as oxidation or reduction in an electrochemical cell or after a chemical reaction of a adsorbed compounds in which the surface may act as a catalyst. Mechanisms Depending on the nature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Antimony

Antimony is a chemical element; it has chemical symbol, symbol Sb () and atomic number 51. A lustrous grey metal or metalloid, it is found in nature mainly as the sulfide mineral stibnite (). Antimony compounds have been known since ancient times and were powdered for use as medicine and cosmetics, often known by the Arabic name Kohl (cosmetics), kohl. The earliest known description of this metalloid in the West was written in 1540 by Vannoccio Biringuccio. China is the largest producer of antimony and its compounds, with most production coming from the Xikuangshan Mine in Hunan. The industrial methods for refining antimony from stibnite are Roasting (metallurgy), roasting followed by carbothermic reaction, reduction with carbon, or direct reduction of stibnite with iron. The most common applications for metallic antimony are in alloys with lead and tin, which have improved properties for solders, Bullet, bullets, and plain bearings. It improves the rigidity of lead-alloy pla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny gray with a hint of blue. It tarnishes to a dull gray color when exposed to air. Lead has the highest atomic number of any stable nuclide, stable element and three of its isotopes are endpoints of major nuclear decay chains of heavier elements. Lead is a relatively unreactive post-transition metal. Its weak metallic character is illustrated by its Amphoterism, amphoteric nature; lead and lead oxides react with acids and base (chemistry), bases, and it tends to form covalent bonds. Lead compounds, Compounds of lead are usually found in the +2 oxidation state rather than the +4 state common with lighter members of the carbon group. Exceptions are mostly limited ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paint

Paint is a material or mixture that, when applied to a solid material and allowed to dry, adds a film-like layer. As art, this is used to create an image or images known as a painting. Paint can be made in many colors and types. Most paints are either oil-based or water-based, and each has distinct characteristics. Primitive forms of paint were used tens of thousands of years ago in cave paintings. Clean-up solvents are also different for water-based paint than oil-based paint. Water-based paints and oil-based paints will cure differently based on the outside ambient temperature of the object being painted (such as a house). History Paint was used in some of the earliest known human artworks. Some cave paintings drawn with red or yellow ochre, hematite, manganese oxide, and charcoal may have been made by early ''Homo sapiens'' as long as 40,000 years ago. Paint may be even older. In 2003 and 2004, South African archeologists reported finds in Blombos Cave of a 100,000-y ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnesium

Magnesium is a chemical element; it has Symbol (chemistry), symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 of the periodic table), it occurs naturally only in combination with other elements and almost always has an oxidation state of +2. It reacts readily with air to form a thin Passivation (chemistry), passivation coating of magnesium oxide that inhibits further corrosion of the metal. The free metal burns with a brilliant-white light. The metal is obtained mainly by electrolysis of magnesium Salt (chemistry), salts obtained from brine. It is less dense than aluminium and is used primarily as a component in strong and lightweight magnesium alloy, alloys that contain aluminium. In the cosmos, magnesium is produced in large, aging stars by the sequential addition of three Helium nucleus, helium nuclei to a carbon nucleus. When such stars explo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanization

Galvanization ( also spelled galvanisation) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are coated by submerging them in a bath of hot, molten zinc. Protective action The zinc coating, when intact, prevents corrosive substances from reaching the underlying iron. It's main function is to act as a sacrificial anode to prevent the iron from rusting by cathodic protection. Zinc is more reactive than iron, so the zinc coating preferentially oxidizes to zinc carbonate, preventing the iron from corroding, even if there are gaps in the zinc coating. Additional electroplating such as a chromate conversion coating may be applied to provide further surface passivation to the substrate material. History and etymology The process is named after the Italian physician, physicist, biologist and philosopher Luigi Galvani (9 September 1737 – 4 December 1798). The earliest kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Cathode

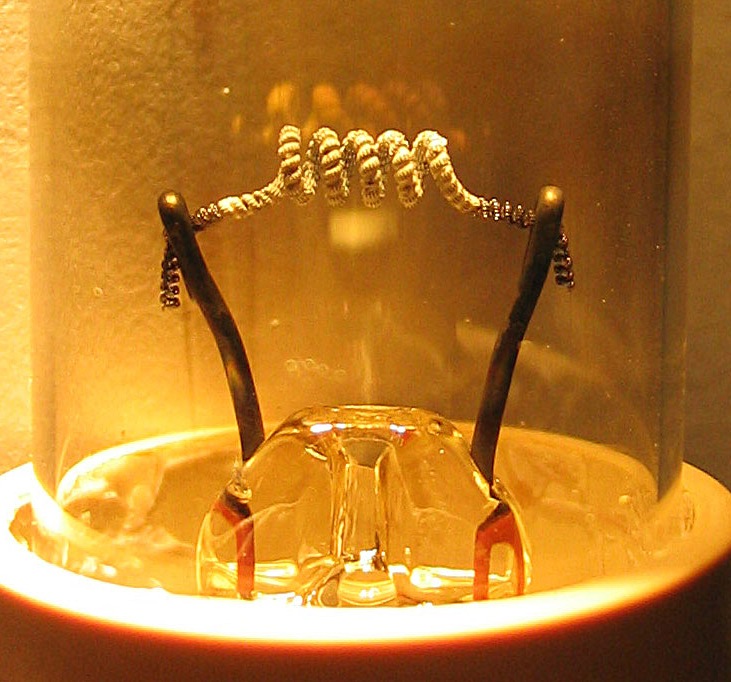

In vacuum tubes and gas-filled tubes, a hot cathode or thermionic cathode is a cathode electrode which is heated to make it emit electrons due to thermionic emission. This is in contrast to a cold cathode, which does not have a heating element. The heating element is usually an electrical filament heated by a separate electric current passing through it. Hot cathodes typically achieve much higher power density than cold cathodes, emitting significantly more electrons from the same surface area. Cold cathodes rely on field electron emission or secondary electron emission from positive ion bombardment, and do not require heating. There are two types of hot cathode. In a ''directly heated cathode'', the filament is the cathode and emits the electrons. In an ''indirectly heated cathode'', the filament or ''heater'' heats a separate metal cathode electrode which emits the electrons. From the 1920s to the 1960s, a wide variety of electronic devices used hot-cathode vacuum tubes. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. In use since prehistoric times, it is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass is similar to bronze, a copper alloy that contains tin instead of zinc. Both bronze and brass may include small proportions of a range of other Chemical element, elements including arsenic, lead, phosphorus, aluminium, manganese and silicon. Historically, the distinction between the two alloys has been less consistent and clear, and increasingly museums use the more general term "list of copper alloys, copper alloy". Brass has long been a popular material for its bright gold-like appearance and is still used for drawer pulls and door handle, doorknobs. It has also been widely used to ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic table. In some respects, zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size. Zinc is the 24th most abundant element in Earth's crust and has five stable isotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest workable lodes are in Australia, Asia, and the United States. Zinc is refined by froth flotation of the ore, roasting, and final extraction using electricity ( electrowinning). Zinc is an essential trace element for humans, animals, plants and for microorganisms and is necessary for prenatal and postnatal development. It is the second most abundant trace metal in humans after iron, an import ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. Brazing joins the same or different metals with considerable strength. Process Brazing has many advantages over other metal-joining techniques, such as welding. Since brazing does not melt the base metal of the joi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint. Soldering is commonly used in the electronics industry for the manufacture and repair of Printed circuit board, printed circuit boards (PCBs) and other electronic components. It is also used in plumbing and Metalworking, metalwork, as well as in the manufacture of jewelry and other decorative items. The solder used in the process can vary in composition, with different alloys used for different applications. Common solder alloys include tin-lead, tin-silver, and tin-copper, among others. Lead-free solder has also become more widely used in recent years due to health and environmental concerns associated with the use of lead. In addition to the type of solder used, the temperature and method of heating also p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |