|

Masking Tape

Masking tape, also known as painter's tape, is a type of pressure-sensitive tape made of a thin and easy-to-tear paper, and an easily released pressure-sensitive adhesive. It is available in a variety of widths. It is used mainly in painting, to Masking (in art), mask off areas that should not be painted. Some inexpensive masking tapes are suited for general use in homes and offices. Others are designed for professional house painters. Masking tapes for automotive or aircraft use have special characteristics for these demanding applications. History Masking tape was created in 1925 by 3M employee Richard Gurley Drew. Drew observed automobile, autobody workers growing frustrated when they removed butcher paper they had taped to cars they were painting. The strong adhesive on the tape peeled off some of the paint they had just applied. Touching up the damaged areas increased their costs. Drew realized the need for tape with a gentler adhesive. Constructions Several const ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then Powder coating#Curing, cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermosetting polymer. It is usually used to create a thick, tough finish that is more durable than conventional paint. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, Carbon-fiber reinforced polymer, carbon fiber, and medium-density fibreboard (MDF) to be powder coated, as little heat or oven dwell time is required to process them. History, properties, and uses of powder coating The powder coating process was invented around 1945 by Daniel Gustin and received US Patent 2 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

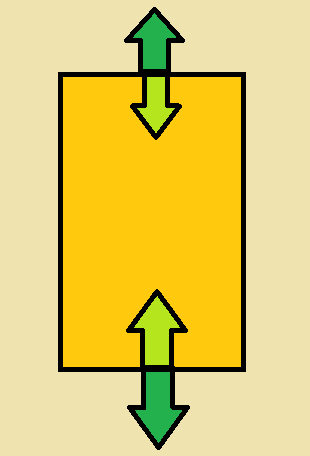

Chemistry Of Adhesive Tapes

The chemistry of pressure-sensitive adhesives describes the chemical science associated with pressure-sensitive adhesives (PSA). PSA tapes and labels have become an important part of everyday life. These rely on adhesive material affixed to a backing such as paper or plastic film. Because of the inherent tackiness of the adhesive material and low surface energy, these tapes can be placed onto a variety of substrates when light pressure is applied, including paper, wood, metals, and ceramics. The design of tapes requires a balance of the need for long service life and adaptation to a variety of environmental and human effects, including temperature, UV exposure, mechanical wear, contamination of the substrate surface, and adhesive degradation.Werner Karmann and Andreas B. Kummer "Tapes, Adhesive" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2000. Composition A typical PSA tape consists of a pressure-sensitive adhesive (the sticky part of the tape ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adhesive Tape

Adhesive tape is one of many varieties of backing materials coated with an adhesive. Several types of adhesives can be used. Types Pressure-sensitive tape Pressure-sensitive tape, PSA tape, self-stick tape or sticky tape consists of a pressure sensitive adhesive coated onto a backing material such as paper, plastic film, cloth, or metal foil. It is sticky (tacky) without any heat or solvent for activation and adheres to surfaces with light pressure. Typical adhesives are polymers such as acrylates, natural rubber, natural, and synthetic rubber. These tapes usually require a release agent on their backing or a release liner to cover the adhesive. Sometimes, the term "adhesive tape" is used for these tapes. Water-activated tape Water-activated tape, gummed paper tape or gummed tape is starch- or sometimes animal glue-based adhesive on a paper backing which becomes sticky when moistened. A specific type of gummed tape is called reinforced gummed tape (RGT). The backing o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicone

In Organosilicon chemistry, organosilicon and polymer chemistry, a silicone or polysiloxane is a polymer composed of repeating units of siloxane (, where R = Organyl group, organic group). They are typically colorless oils or elastomer, rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, grease, silicone rubber, rubber, silicone resin, resin, and Caulking, caulk. Silicone is often confused with one of its constituent elements, silicon, but they are distinct substances. Silicon is a chemical element, a hard dark-grey semiconductor, semiconducting metalloid, which in its crystalline form is used to make integrated circuits ("electronic chips") and solar cells. Silicones are compounds that contain silicon, carbon, hydrogen, oxygen, and perhaps other kinds of atoms as well, and have many very different physical and chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HVOF

Thermal spraying techniques are coating A coating is a covering that is applied to the surface of an object, or substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. powder coatings. Paints ... processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame). Thermal spraying can provide thick coatings (approx. thickness range is 20 microns to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical vapor deposition, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites. They are fed in powder or wire form, heated to a molten or semimolten state and accelerated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Spray

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame). Thermal spraying can provide thick coatings (approx. thickness range is 20 microns to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites. They are fed in powder or wire form, heated to a molten or semimolten state and accelerated towards substrates in the form of micrometer-size particles. Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminate

Simulated flight (using image stack created by μCT scanning) through the length of a knitting needle that consists of laminated wooden layers: the layers can be differentiated by the change of direction of the wood's vessels Shattered windshield lamination keeps shards in place Laminate flooring A flexible thin-film solar cell for aerospace use (2007) Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Lamination may be applied to textiles, glass, wood, or other materials. Laminating paper in plastic makes it sturdy, waterproof, and erasable. Laminating metals and electronic components ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

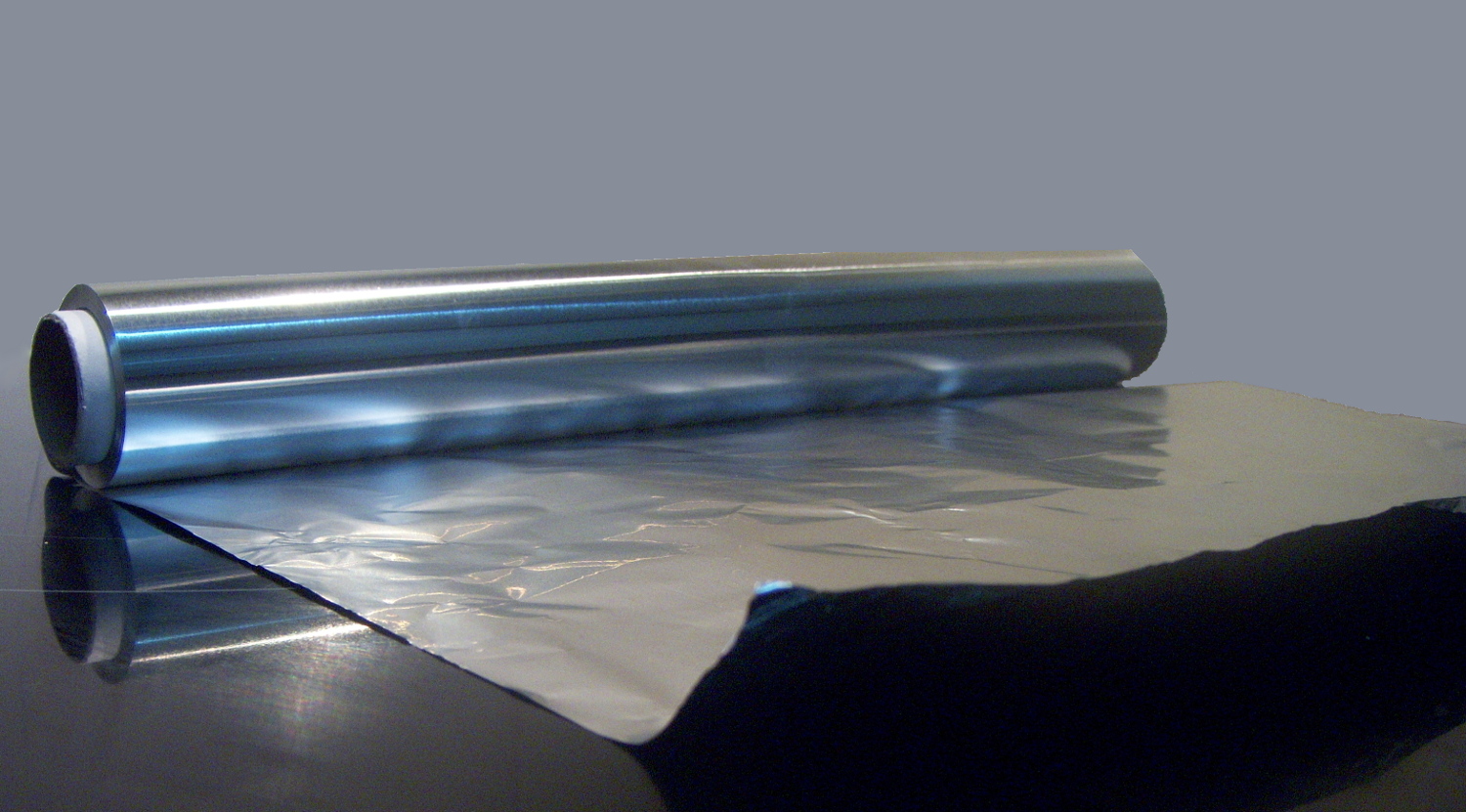

Foil (chemistry)

A foil is a very thin sheet of metal, typically made by hammering or rolling. Foils are most easily made with malleable metal, such as aluminium, copper, tin, and gold. Foils usually bend under their own weight and can be torn easily. For example, aluminium foil is usually about , whereas gold (more malleable than aluminium) can be made into foil only a few atoms thick, called gold leaf. Extremely thin foil is called metal leaf. Leaf tears very easily and must be picked up with special brushes. See also * Aluminium foil * Copper foil * Tin foil * Gold leaf * Metal leaf A metal leaf, also called composition leaf or schlagmetal, is a thin foil used for gilding and other forms of decoration. Metal leaves can come in many different shades, due to the composition of the metal within the metal leaf. Examples of this ... References Metalworking {{Metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sandblasting

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material (often called the ''media''). The first abrasive blasting process was patented by Benjamin Chew Tilghman on 18 October 1870. There are several variants of the process, using various media; some are highly abrasive, whereas others are milder. The most abrasive are shot blasting (with metal shot) and sandblasting (with sand). Moderately abrasive variants include glass bead blasting (with glass beads) and plastic media blasting (PMB) with ground-up plastic stock or walnut shells and corncobs. Some of these substances can cause anaphylactic shock to individuals allergic to the media. A mild version is sodablas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |