|

Luggage Carrier

A luggage carrier, also commonly called a (bicycle) rack, is a device attached to a bicycle to which cargo or panniers can be attached. This is popular with utility bicycles and touring bicycles. Bicycle luggage carriers may be mounted on the front or rear of a bicycle. The rear mount is more common. Racks on the front are mostly reserved for utility and cargo bikes. A special type of front rack is a low rider which is mainly used for bicycle touring. The term luggage carrier can also refer to a device with two wheels used to wheel luggage or something of similar weight from one place to another, similar to a dolly (hand truck) but lighter and usually able to be folded up. Mounting Bicycles may have eyelets, tapped with a standard thread, at the dropouts on the rear chainstays, and on the front fork blades. Mounting a bike rack is possible without these eyelets, but requires additional hardware. A style of rack clamps only to the seatpost, does not require eyelets or add ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Rack , various devices to hold a bike still while working on it

{{disambig ...

The ambiguous term bicycle rack or bike rack may refer to: * Bicycle carrier, a device attached to a vehicle (e.g., to a car or bus) to which bicycles can be mounted for transport *Bicycle parking rack, a stationary fixture to which a bicycle can be securely attached (typically using a bicycle lock) to prevent theft *Luggage carrier, a device attached to a bicycle to facilitate carrying loads See also * Bicycle stand The term bicycle tools typically refers to specialty tools used on bicycles, as opposed to general purpose mechanical tools. such as spanners and hex wrenches. Various bicycle tools have evolved over the years into specialized tools for working on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Road Bicycle

The term road bicycle is used to describe bicycles built for traveling at speed on paved roads. Some sources use the term to mean racing bicycle. Other sources specifically exclude racing bicycles from the definition, using the term to mean a bicycle of a similar style but built more for endurance and less the fast bursts of speed desired in a racing bicycle; as such, they usually have more gear combinations and fewer hi-tech racing features. Certain of these bicycles have been referred to as 'sportive' bicycles to distinguish them from racing bicycles. Compared to other styles of bicycle, road bicycles share common features: * The tires are narrow, high-pressure, and smooth to decrease rolling resistance * The handlebars are bent ("dropped") to allow the rider position to be leaned forward and downward, which reduces the forward vertical cross-sectional area and thus highly reduces the air resistance * They usually use derailleur gears; however, single-speed and fixed-gea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Lighting

Bicycle lighting is illumination attached to bicycles whose purpose above all is, along with reflectors, to improve the visibility of the bicycle and its rider to other road users under circumstances of poor ambient illumination. A secondary purpose is to illuminate reflective materials such as cat's eyes and traffic signs. A third purpose may be to illuminate the roadway so that the rider can see the way ahead. Serving the latter purposes require much more luminous flux and thus more power. Many jurisdictions require one or more bicycle lights to be fitted to bicycles ridden at night — generally a white light in the front and a red light at the back, like with other vehicles. History Fire The earliest bicycle lamps were oil-fueled and started to be manufactured in 1876 for the Ordinary (High-Bicycle) and solid-tired tricycles. From 1896, acetylene gas lighting for bicycles started to be introduced and later in 1899, acetylene gas lamps for the motor-car became popula ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

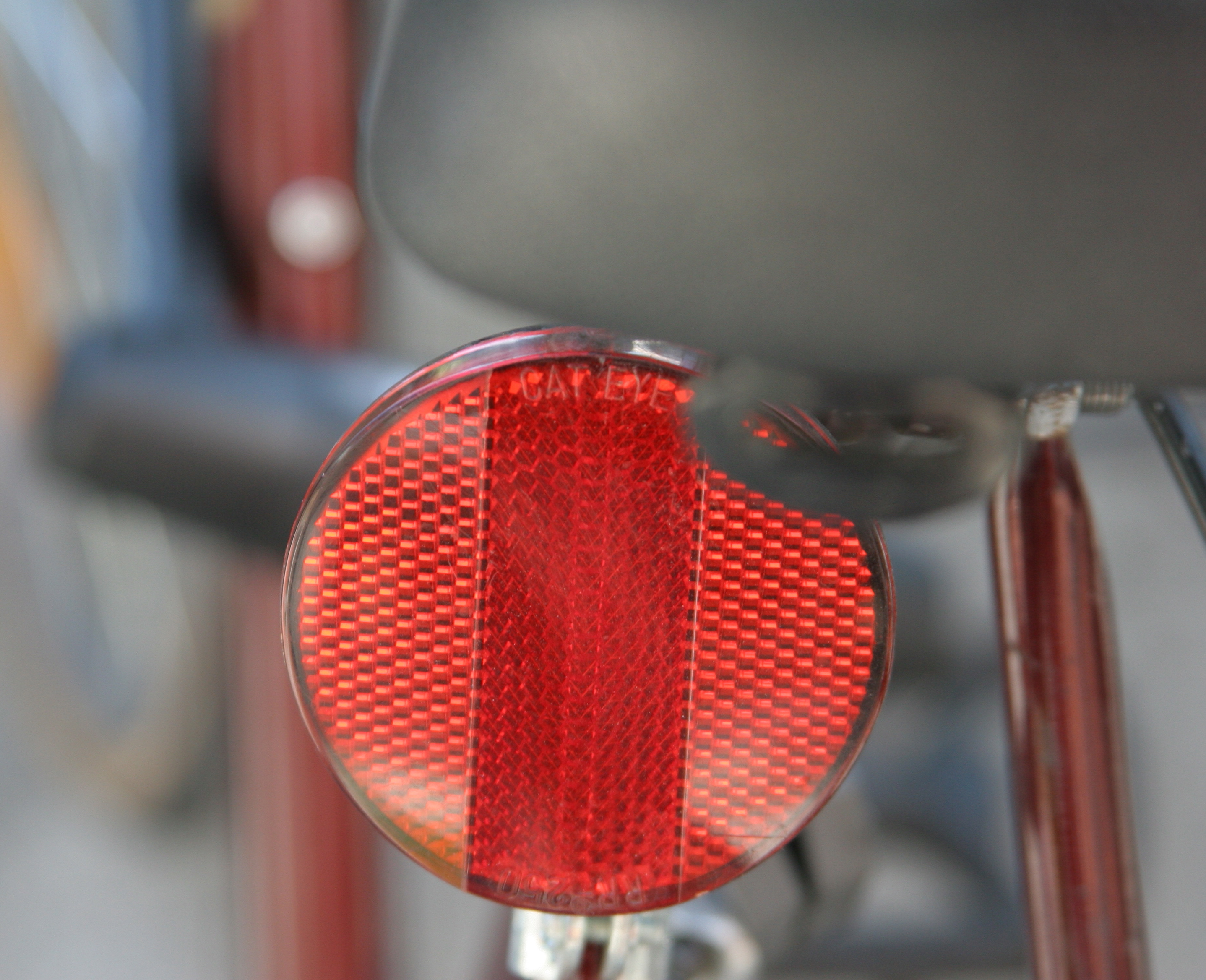

Safety Reflector

A safety reflector is a retroreflector intended for pedestrians, running, runners, motorized and non-motorized vehicles. A safety reflector is similar to reflective stripes that can be found on safety vests and clothing worn by road workers and rescue workers. They are sometimes erroneously called luminous badges or luminous tags, but this is incorrect as they do not themselves produce light, but only reflect it. Functioning A safety reflector aids visibility of a person or vehicle visible to on the road, as it reflects light from headlights of vehicles. Safety reflectors are especially useful where there are no streetlights. Unlike reflective stripes that are permanently fixed to clothing, the safety reflector is a stand-alone device that can be attached to any article of clothing as needed, often using a safety pin and some string. For vehicles, the reflector is usually a fixed part. In bicycles, reflectors are usually on wheels, pedals, under the seat, on the back of the l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Porteur Bicycle

There have been many human powered vehicles designed and constructed specifically for transporting loads since their earliest appearance in the 20th century. They are referred to variously depending on the number of wheels — typically two, three, or four — and by their specific use. Adjectives used to describe the tasks to which the bicycles, dicycles, tricycles, or quadracycles are put include cargo cycles (bi- / tri- / etc.), freight cycles, box cycles (due to the luggage carrier's shape), carrier cycles, and so on. Sometimes they are also called cycletrucks, which uses a sense of the word 'truck' predating the automobile. Cargo bike designs include a cargo area consisting of an open or enclosed box, a flat platform, or a wire basket, usually mounted over one or both wheels, low behind the front wheel, or between parallel wheels at either the front or rear of the vehicle. The frame, drivetrain and wheels must be constructed to handle loads larger than those on an ordinar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pannier

A pannier is a basket, bag, box, or similar container, carried in pairs either slung over the back of a beast of burden, or attached to the sides of a bicycle or motorcycle. The term derives from a Middle English borrowing of the Old French ''panier'', meaning 'bread basket'. Animal panniers Traditional panniers for Pack animal">animal transport are typically made of canvas, leather">canvas.html" ;"title="Pack animal">animal transport are typically made of canvas">Pack animal">animal transport are typically made of canvas, leather, or wicker. Modern panniers may be rectangular boxes of hard-sided plastic. Panniers are loaded in such a manner as to distribute weight evenly on either side of the animal. For Packhorse, horse packing, and when carrying particularly heavy loads on other animals they are supported by a pack saddle to distribute weight more evenly across the back of the animal. In some cases, additional items are placed on the back of the animal, between the pannier ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bolted Joint

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener (e. g., a Bolt (fastener), bolt) that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: Tension (physics), tension joints and Shear stress, shear joints. The selection of the components in a threaded joint is a complex process. Careful consideration is given to many factors such as temperature, corrosion, vibration, fatigue, and initial preload.Barrett, R. T. (1990). Fastener design manual' (No. NAS 1.61: 1228). Joint types Tension joint There are two types of tension joint: non-preloaded and preloaded. Non-preloaded tension joint These joints are not tightened to a precise preload, and the tension is mainly used to keep parts together without generating a high clamping force. An applied tensile load may cause separation of the joint. This type of joint should not be used w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rivet

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylinder (geometry), cylindrical shaft with a head on one end. The end opposite the head is called the ''tail''. On installation, the deformed end is called the ''shop head'' or buck-tail. Because there is effectively a head on each end of an installed rivet, it can support Tension (physics), tension loads. However, it is much more capable of supporting Shear force, shear loads (loads perpendicular to the axis of the shaft). Fastenings used in traditional wooden boat building, such as copper nails and clinch bolts, work on the same principle as the rivet but were in use long before the term ''rivet'' was introduced and, where they are remembered, are usually classified among nails and bolts respectively. History Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archeology, archaeological findings dating back to the Bronze Age. Rivet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and develo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |