|

Leather-hard

In pottery, leather-hard is the condition of a clay or clay body when it has been partially dried to the point where all shrinkage has been completed, and it has a consistency similar to leather of the same thickness as the clay. At this stage, the clay object has approximately 15% moisture content. The clay is still visibly damp (normally a darkish grey, if it began whiteish) but has dried enough to be able to be handled without deformation. The body is able to be gouged or incised without breaking. The leather-hard stage is the easiest place to add on extension material that cannot be dried with the rest of the pot without causing some issues to occur. For instance, in some cases when handles are added before the base and sides have been dried, the handle can dry before the sides do and cause cracking, as the weight of the dried portion is no longer at the same equivalence with the wet side. The same goes for other additions to the pot that will not dry at the same rate as the r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pottery

Pottery is the process and the products of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard and durable form. Major types include earthenware, stoneware and porcelain. The place where such wares are made by a ''potter'' is also called a ''pottery'' (plural "potteries"). The definition of ''pottery'', used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". In art history and archaeology, especially of ancient and prehistoric periods, "pottery" often means vessels only, and sculpted figurines of the same material are called " terracottas". Pottery is one of the oldest human inventions, originating before the Neolithic period, with ceramic objects like the Gravettian culture Venus of Dolní Věstonice figurine discovered in the Czech Republic dating back to 29,000–25,000 BC, and pottery vessels tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clay Body

Pottery is the process and the products of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard and durable form. Major types include earthenware, stoneware and porcelain. The place where such wares are made by a ''potter'' is also called a ''pottery'' (plural "potteries"). The definition of ''pottery'', used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". In art history and archaeology, especially of ancient and prehistoric periods, "pottery" often means vessels only, and sculpted figurines of the same material are called " terracottas". Pottery is one of the oldest human inventions, originating before the Neolithic period, with ceramic objects like the Gravettian culture Venus of Dolní Věstonice figurine discovered in the Czech Republic dating back to 29,000–25,000 BC, and pottery vessels ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4). Clays develop plasticity when wet, due to a molecular film of water surrounding the clay particles, but become hard, brittle and non–plastic upon drying or firing. Most pure clay minerals are white or light-coloured, but natural clays show a variety of colours from impurities, such as a reddish or brownish colour from small amounts of iron oxide. Clay is the oldest known ceramic material. Prehistoric humans discovered the useful properties of clay and used it for making pottery. Some of the earliest pottery shards have been dated to around 14,000 BC, and clay tablets were the first known writing medium. Clay is used in many modern industrial processes, such as paper making, cement production, and chemical filtering. Between one-half and two-thirds of the world's population live or work in buildings made with clay, ofte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leather

Leather is a strong, flexible and durable material obtained from the tanning, or chemical treatment, of animal skins and hides to prevent decay. The most common leathers come from cattle, sheep, goats, equine animals, buffalo, pigs and hogs, and aquatic animals such as seals and alligators. Leather can be used to make a variety of items, including clothing, footwear, handbags, furniture, tools and sports equipment, and lasts for decades. Leather making has been practiced for more than 7,000 years and the leading producers of leather today are China and India. Animal rights groups claim that modern commercial leather making and the consumption of its products is unethically killing animals. According to the life-cycle assessment (LCA) report for the United Nations Industrial Development Organization, 99% of the raw hides and skins used in the production of leather derive from animals raised for meat and/or dairy production. Critics of tanneries claim that they engage in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "'' ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest k ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Glaze

Ceramic glaze is an impervious layer or coating of a vitreous substance which has been fused to a pottery body through firing. Glaze can serve to color, decorate or waterproof an item. Glazing renders earthenware vessels suitable for holding liquids, sealing the inherent porosity of unglazed biscuit earthenware. It also gives a tougher surface. Glaze is also used on stoneware and porcelain. In addition to their functionality, glazes can form a variety of surface finishes, including degrees of glossy or matte finish and color. Glazes may also enhance the underlying design or texture either unmodified or inscribed, carved or painted. Most pottery produced in recent centuries has been glazed, other than pieces in unglazed biscuit porcelain, terracotta, or some other types. Tiles are almost always glazed on the surface face, and modern architectural terracotta is very often glazed. Glazed brick is also common. Domestic sanitary ware is invariably glazed, as are many ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip (ceramics)

A slip is a clay slurry used to produce pottery and other ceramic wares. Liquified clay, in which there is no fixed ratio of water and clay, is called slip or clay slurry which is used either for joining leather-hard (semi-hardened) clay body (pieces of pottery) together by slipcasting with mould, glazing or decorating the pottery by painting or dipping the pottery with slip.What is slip in pottery thepotterywheel.com, accessed 10 July 2021. Pottery on which slip has been applied either for glazing or decoration is called the slipware. Engobe, from the French word for slip, is an term for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

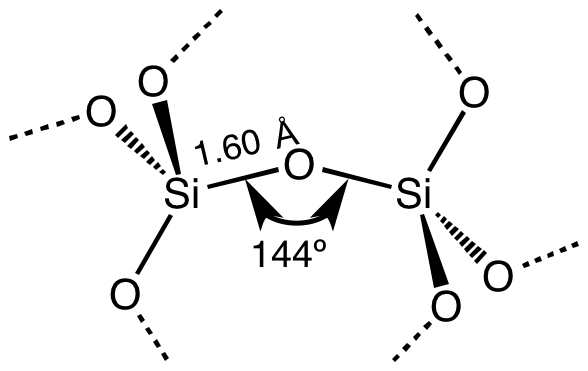

Silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and most abundant families of materials, existing as a compound of several minerals and as a synthetic product. Notable examples include fused quartz, fumed silica, silica gel, opal and aerogels. It is used in structural materials, microelectronics (as an electrical insulator), and as components in the food and pharmaceutical industries. Structure In the majority of silicates, the silicon atom shows tetrahedral coordination, with four oxygen atoms surrounding a central Si atomsee 3-D Unit Cell. Thus, SiO2 forms 3-dimensional network solids in which each silicon atom is covalently bonded in a tetrahedral manner to 4 oxygen atoms. In contrast, CO2 is a linear molecule. The starkly different structures of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biscuit (pottery)

Biscuit (also known as bisque) refers to any pottery that has been fired in a kiln without a ceramic glaze. This can be a final product such as biscuit porcelain or unglazed earthenware (such as terracotta) or, most commonly, an intermediate stage in a glazed final product. Confusingly, "biscuit" may also be used as a term for pottery at a stage in its manufacture where it has not yet been fired or glazed, but has been dried so that it is no longer plastic (easily deformed). The porous nature of (fired) biscuit earthenware means that it readily absorbs water, while vitreous wares such as porcelain, bone china and most stoneware Stoneware is a rather broad term for pottery or other ceramics fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non- refractory fire clay. Whether ... are non-porous even without glazing. The temperature of biscuit firing is today usually at least 1000°C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burnishing (pottery)

Burnishing is a form of pottery treatment in which the surface of the pot is polished, using a hard smooth surface such as a wooden or bone spatula, smooth stones, plastic, or even glass bulbs, while it still is in a leathery 'green' state, i.e., before firing. After firing, the surface is extremely shiny. This technique can be applied to concrete masonry, creating a polished finish. Burnishing can also be applied to wood, by rubbing two pieces together along the grain. Hard woods take the treatment best. Burnishing does not protect the wood like a varnish does, but does impart a glossy sheen. See also * Black-burnished ware, a type of Romano-British ceramic * Black-on-black ware, a pottery tradition developed by Puebloan Native American ceramic artists *Northern Black Polished Ware The Northern Black Polished Ware culture (abbreviated NBPW or NBP) is an urban Iron Age Indian culture of the Indian Subcontinent, lasting c. 700–200 BCE (proto NBPW between 1200 and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |