|

Hoek–Brown Failure Criterion

The Hoek–Brown failure criterion is an empirical stress surface that is used in rock mechanics to predict the failure of rock. The original version of the Hoek–Brown criterion was developed by Evert Hoek and E. T. Brown in 1980 for the design of underground excavations. In 1988, the criterion was extended for applicability to slope stability and surface excavation problems. An update of the criterion was presented in 2002 that included improvements in the correlation between the model parameters and the geological strength index (GSI). The basic idea of the Hoek–Brown criterion was to start with the properties intact rock and to add factors to reduce those properties because of the existence of joints in the rock. Although a similar criterion for concrete had been developed in 1936, the significant tool that the Hoek–Brown criterion gave design engineers was a quantification of the relation between the stress state and Bieniawski's rock mass rating (RMR). The Hoek ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress (mechanics)

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like tension or compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Surface

A yield surface is a five-dimensional surface in the six-dimensional space of stresses. The yield surface is usually convex and the state of stress of ''inside'' the yield surface is elastic. When the stress state lies on the surface the material is said to have reached its yield point and the material is said to have become plastic. Further deformation of the material causes the stress state to remain on the yield surface, even though the shape and size of the surface may change as the plastic deformation evolves. This is because stress states that lie outside the yield surface are non-permissible in rate-independent plasticity, though not in some models of viscoplasticity.Simo, J. C. and Hughes, T,. J. R., (1998), Computational Inelasticity, Springer. The yield surface is usually expressed in terms of (and visualized in) a three-dimensional principal stress space ( \sigma_1, \sigma_2 , \sigma_3), a two- or three-dimensional space spanned by stress invariants ( I_1, J_2, J_3 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mohr–Coulomb Theory

Mohr–Coulomb theory is a mathematical model (see yield surface) describing the response of brittle materials such as concrete, or rubble piles, to shear stress as well as normal stress. Most of the classical engineering materials follow this rule in at least a portion of their shear failure envelope. Generally the theory applies to materials for which the compressive strength far exceeds the tensile strength. In geotechnical engineering it is used to define shear strength of soils and rocks at different effective stresses. In structural engineering it is used to determine failure load as well as the angle of fracture of a displacement fracture in concrete and similar materials. Coulomb's friction hypothesis is used to determine the combination of shear and normal stress that will cause a fracture of the material. Mohr's circle is used to determine which principal stresses will produce this combination of shear and normal stress, and the angle of the plane in which t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Theory (material)

Material failure theory is an interdisciplinary field of materials science and solid mechanics which attempts to predict the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure ( fracture) or ductile failure (yield). Depending on the conditions (such as temperature, state of stress, loading rate) most materials can fail in a brittle or ductile manner or both. However, for most practical situations, a material may be classified as either brittle or ductile. In mathematical terms, failure theory is expressed in the form of various failure criteria which are valid for specific materials. Failure criteria are functions in stress or strain space which separate "failed" states from "unfailed" states. A precise physical definition of a "failed" state is not easily quantified and several working definitions are in use in the engineering community. Quite often, phenomenological fail ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

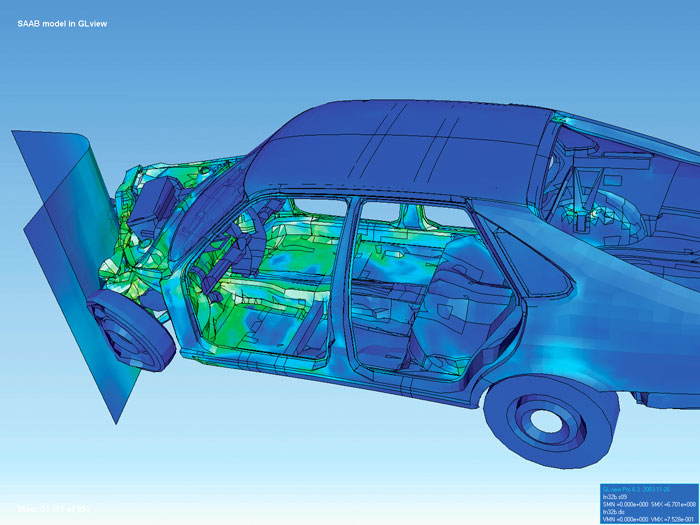

Finite Element Method

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |