|

Gear Pump Animation

A gear or gearwheel is a rotating machine element, machine part typically used to transmit rotation, rotational motion and/or torque by means of a series of teeth that engage with compatible teeth of another gear or other part. The teeth can be integral saliences or cavities machining, machined on the part, or separate pegs inserted into it. In the latter case, the gear is usually called a cogwheel. A cog may be one of those pegsDefinition of "cog" in the ''Oxford Learner's Dictionary'' online. Accessed on 2024-07-29.Definition of "cog" in the ''Merriam-Webster Dictionary'' online. Accessed on 2024-07-29. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Animated Two Spur Gears 1 2

Animation is a filmmaking technique whereby image, still images are manipulated to create Motion picture, moving images. In traditional animation, images are drawn or painted by hand on cel, transparent celluloid sheets to be photographed and exhibited on film. Animation has been recognised as an artistic medium, specifically within the Entertainment#Industry, entertainment industry. Many animations are either traditional animations or computer animations made with computer-generated imagery (CGI). Stop motion animation, in particular claymation, has continued to exist alongside these other forms. Animation is contrasted with live action, although the two do not exist in isolation. Many moviemakers have produced Live-action animation, films that are a hybrid of the two. As CGI increasingly Photorealism, approximates photographic imagery, filmmakers can easily Compositing, composite 3D animations into their film rather than using practical effects for showy visual effects (VFX). ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

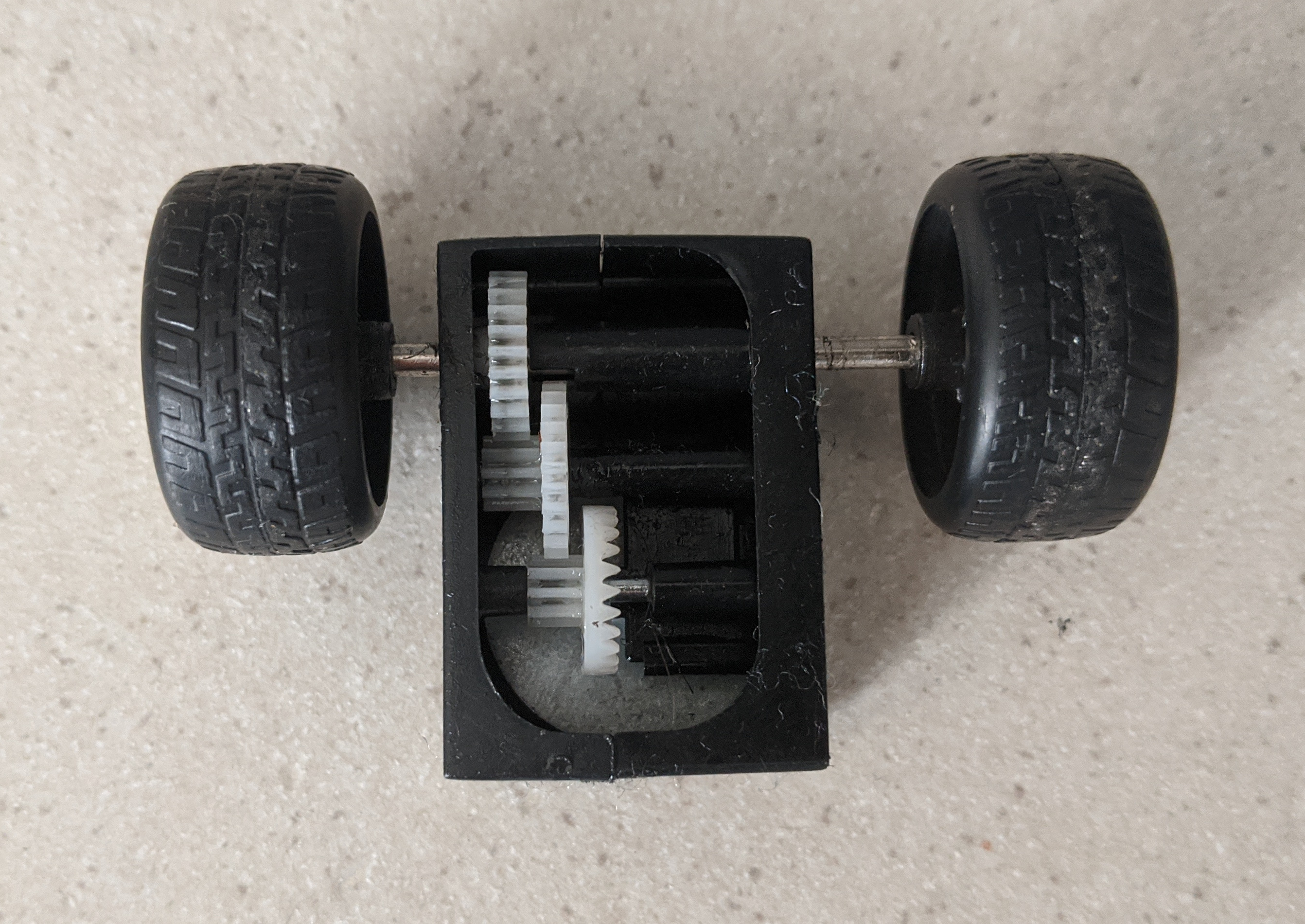

Friction Motor

A friction motor is a simple mechanism to propel toy cars, trucks, trains, action figures and similar toys. The motor consists of a large flywheel which is connected to the drive wheels of the toy via a gear, gear train with very low gear ratio, so that the flywheel revolves much faster than the wheels. The flywheel's axis is perpendicular to the direction in which the toy faces and in which it moves. When the toy is pushed forward, the drive wheels engage the flywheel. If higher energies are desired, pushing the vehicle forward repeatedly spins this flywheel up to greater speed. When let go, the flywheel drives the vehicle forward. Energy which is input by pushing the car is stored by the flywheel as rotational kinetic energy and can propel the toy after it is released. It is friction between the tyres and the surface on which the vehicle is operating which enables the energy input process, thus giving the name "friction motor" to the device. As the flywheel, unlike the spring of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Issus Coleoptratus

''Issus coleoptratus'' is a species of planthopper belonging to the family Issidae. Distribution and habitat This common species can be found in the western Palearctic realm, in the Near East, and in North Africa. These insects live on shrubbery and on foliage of various woody plants and common deciduous trees and in mixed forests (forest edges and parks).P.F. Whitehead & R.S. Ke/ref> Description ''Issus coleoptratus'' can reach a length of . The coloration of these planthoppers can vary from light brown and olive to nearly black. The head, including the eyes, is narrower than the pronotum. The forehead is usually dark brown to black in the upper third, with lighter spots. In the lower area it is greenish, yellowish or brownish. The leathery wings usually show a huge number of dark brown cross-veins with a dark brown discal spot and some evidence of banding. The forewing veins of males and females differs (sexual dimorphism), as they are effaced distally in the female, while in m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuously Variable Transmission

A continuously variable transmission (CVT) is an automated Transmission (mechanical device), transmission that can change through a continuous range of gear ratios, typically resulting in better fuel economy in gasoline applications. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds. Thus, CVT has a simpler structure, longer internal component lifespan, and greater durability. Compared to traditional automatic transmissions, it offers lower fuel consumption and is more environmentally friendly. CVTs are used in cars, tractors, Side-by-side (vehicle), side-by-sides, motor scooters, snowmobiles, bicycles, and Heavy equipment, earthmoving equipment. The most common type of CVT uses two pulleys connected by a Belt (mechanical), belt or Chain drive, chain; however, several other desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor Belt

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to a belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley, while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more. Overview Conveyors are durable and reliable components used in automated distribution and warehousing, as well as manufacturing and production facilities. In combination with computer-controlled pallet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

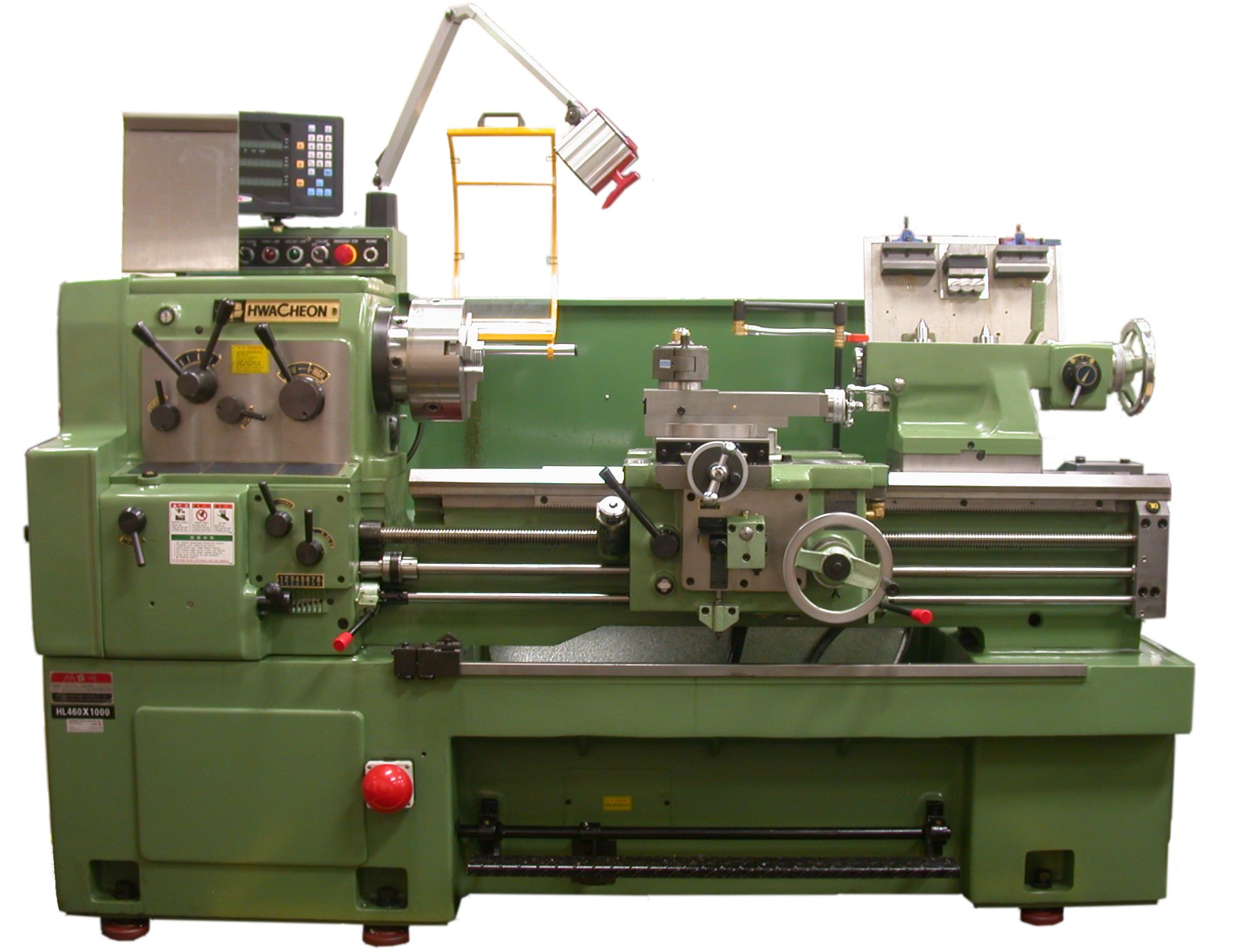

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission (mechanics)

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (industrialist), Louis Renault (who founded Renault, Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam engine, steam-powered devices. Applications of these devices included pumps, mill (grinding), mills and Hoist (device), hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and Horsepower, power output of an interna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

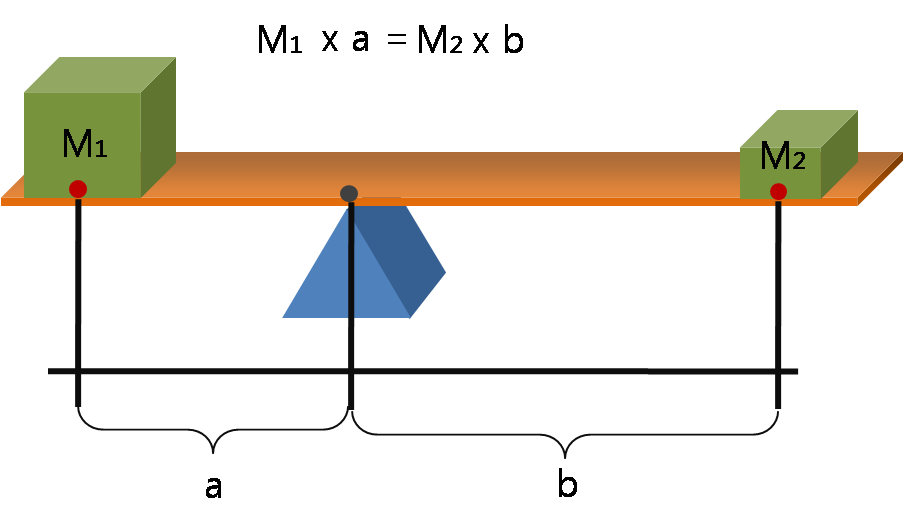

Mechanical Advantage

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for this is the ''law of the lever.'' Machine components designed to manage forces and movement in this way are called mechanisms. An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal machine does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal. Levers The lever is a movable bar that pivots on a fulcrum attached to or positioned on or across a fixed point. The lever operates by applying forces at different distances from the fulcrum, or pivot. The location of the fulcrum deter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lever

A lever is a simple machine consisting of a beam (structure), beam or rigid rod pivoted at a fixed hinge, or '':wikt:fulcrum, fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load, and effort, the lever is divided into Lever#Types of levers, three types. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage, which is mechanical advantage gained in the system, equal to the ratio of the output force to the input force. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English language, English around 1300 from . This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to , itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The word's primary origin is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geneva Drive

The Geneva drive or Geneva mechanism is a gear mechanism that translates a continuous rotation movement into intermittent rotary motion. The ''rotating drive'' wheel is usually equipped with a pin that reaches into a slot located in the other wheel (''driven wheel'' that advances it by one step at a time. The drive wheel also has an elevated circular blocking disc that "locks" the rotating driven wheel in position between steps. History The name, Geneva drive, is derived from the device's earliest application in Clock, mechanical watches, which were popularized in Geneva. The mechanism is frequently used in mechanical watches, since it can be made on a small scale and is able to withstand substantial mechanical stress. The ''Geneva drive'' is also called a "Maltese cross mechanism" due to the visual resemblance when the rotating wheel has four spokes. In the most common arrangement of the Geneva drive, the client wheel has four slots and thus advances the drive by one step ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-circular Gear

A non-circular gear (NCG) is a special gear design with special characteristics and purpose. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and with maximum Mechanical efficiency, efficiency, a non-circular gear's main objective might be ratio variations, axle displacement oscillations and more. Common applications include textile machines, potentiometers, CVTs (continuously variable transmissions), window shade panel drives, mechanical presses and high torque hydraulic engines. A regular gear pair can be represented as two circles rolling together without slip. In the case of non-circular gears, those circles are replaced with anything different from a circle. For this reason NCGs in most cases are not round, but round NCGs that look like regular gears are also possible (small ratio variations result from meshing area modifications). Generally, NCGs should meet all the requirements of regular gearing but in some cases, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Timing Belt

A toothed belt, timing belt, cogged belt, cog belt, or synchronous belt is a flexible belt with teeth moulded onto its inner surface. Toothed belts are usually designed to run over matching toothed pulleys or sprockets. Toothed belts are used in a wide array of mechanical devices where high power transmission is desired. Design and application ''Timing belts'', ''toothed belts'', ''cogged'' or ''cog belts'', and ''synchronous belts'' are non-slipping mechanical drive belts. They are made as flexible belts with teeth moulded onto their inner surface. The belts run over matching toothed pulleys or sprockets. When correctly tensioned, these types of belts have no slippage, and are often used to transfer motion for indexing or timing purposes (hence their name). They are often used in lieu of chains or gears, so there is less noise and a lubrication bath is not necessary. Toothed belts are used widely in mechanical devices, including sewing machines, photocopiers and many others. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |